Acrylic emulsion for carpet gum, carpet gum and preparation method thereof

An acrylic emulsion, carpet back glue technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of volatilization of organic solvents, unstable viscosity, etc., and achieve simple and good construction equipment. The effect of repeated peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

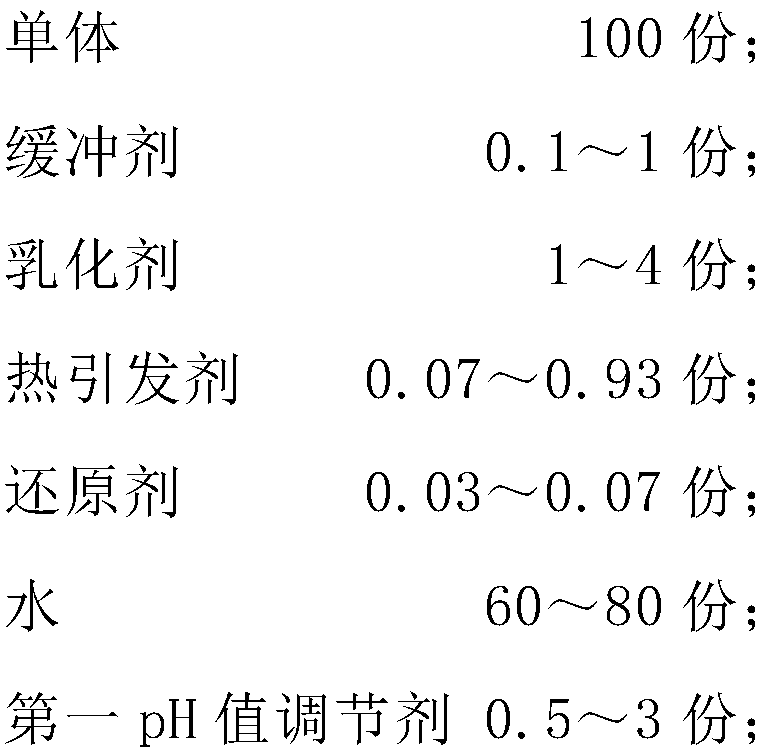

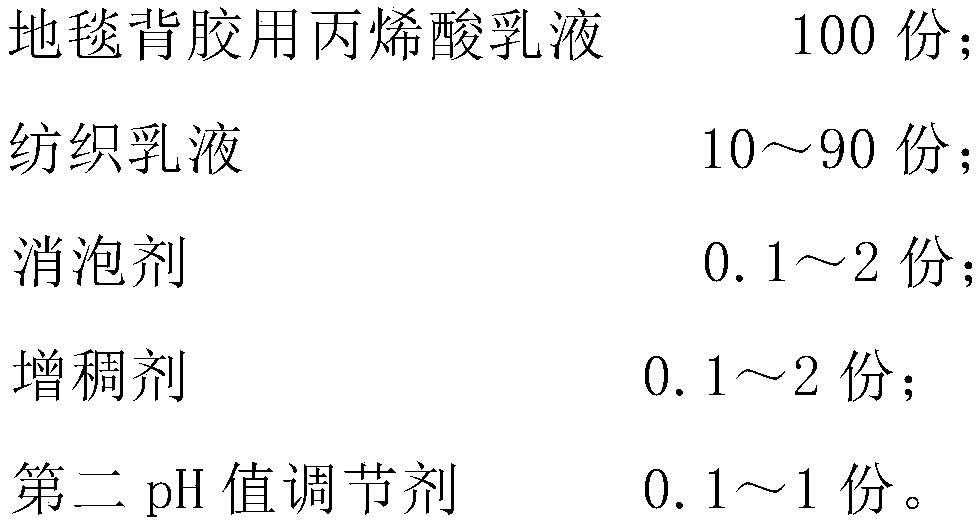

Method used

Image

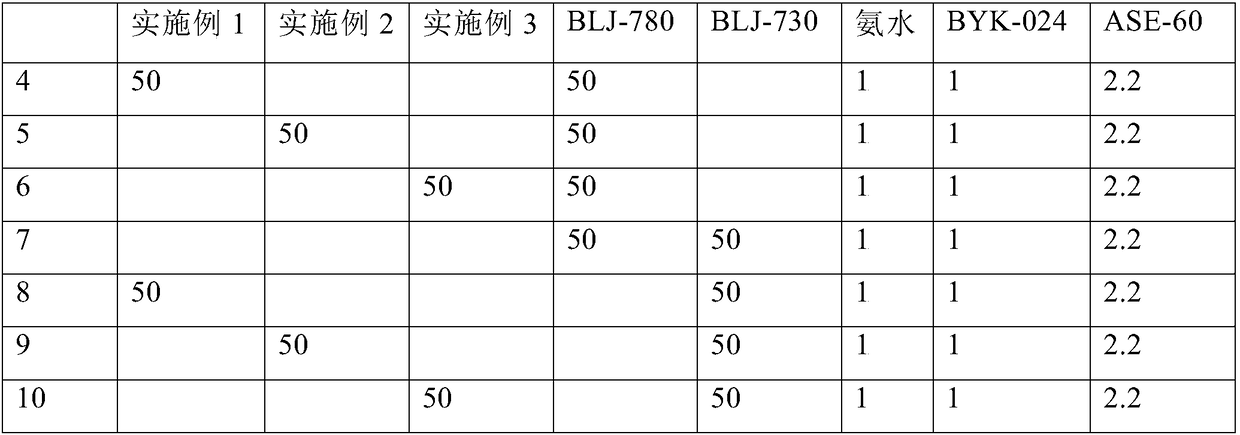

Examples

Embodiment 1

[0046] (1) Pre-emulsification of monomers: Mix 15 parts by mass of SVS-86 and 25 parts by mass of FES77 with 2 parts by mass of DP100 emulsifier and 230 parts of deionized water in a beaker, add 172 parts by mass of EHA, 634 parts by mass of BA, 72 parts by mass of methyl methacrylate, 2.85 parts by mass of HDDA, 6.2 parts by mass of AA, after the addition of monomers, slowly increase the stirring speed to 200rpm, and then stir at a constant speed for half an hour to prepare a pre-emulsion;

[0047] (2) Preparation of seed emulsion: put 1.4 parts by mass of sodium bicarbonate in 140 parts by mass of still bottom water, heat to 85°C, dissolve 2.3 parts by mass of sodium persulfate in 27 parts of deionized water, add it to the reactor, and after five minutes Add 5% pre-emulsion and react for 15 minutes.

[0048] (3) Emulsion preparation: 1.1 parts of sodium persulfate was dissolved in 50 g of deionized water, and added dropwise synchronously with the remaining pre-emulsion for 3...

Embodiment 2

[0052] (1) Pre-emulsification of monomers: Mix 15 parts by mass of SVS-86 and 25 parts by mass of FES77 with 2 parts by mass of DP100 emulsifier and 230 parts of deionized water in a beaker, add 172 parts by mass of BA, 634 parts by mass of EHA, 72 parts by mass of methyl methacrylate, 2.85 parts by mass of HDDA, 6.2 parts by mass of AA, after the addition of monomers, slowly increase the stirring speed to 200rpm, and then stir at a constant speed for half an hour to prepare a pre-emulsion;

[0053] Other steps are identical with embodiment 1

Embodiment 3

[0055](1) Pre-emulsification of monomers: mix 10 parts by mass of SVS-86 and 30 parts by mass of FES-32 with 2 parts by mass of Mix ON-870 emulsifier and 230 parts of deionized water in a beaker, add 172 parts by mass of BA, 634 parts by mass of EHA, 72 parts by mass of methyl methacrylate, 2.85 parts by mass of HDDA, 6.2 parts by mass of AA, and add the monomer After completion, slowly increase the stirring speed to 200rpm, and then stir at a constant speed for half an hour to obtain a pre-emulsion;

[0056] Other steps are identical with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com