Vertical laminated busbar-based converter module

A technology of laminated busbars and converters, which is applied in the direction of output power conversion devices, electrical components, cooling/ventilation/heating transformation, etc., can solve the problem of reducing the inductance value of IGBT power devices to peak absorption capacitors, and shortening peak absorption capacitors The distance from the IGBT power device and other issues can be avoided to avoid excessive stray inductance, compact structure, and reduce the inductance value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

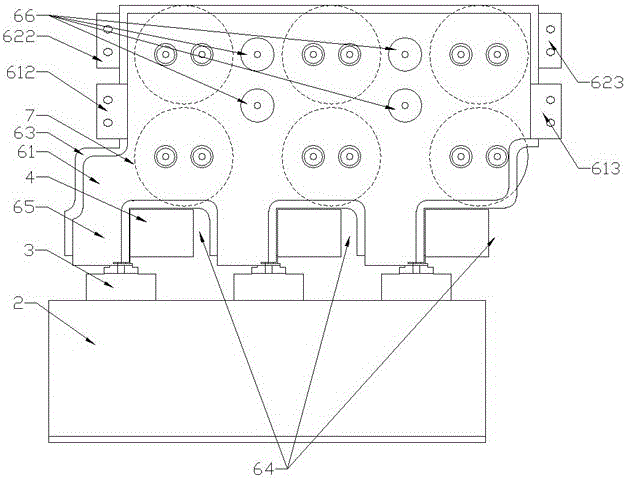

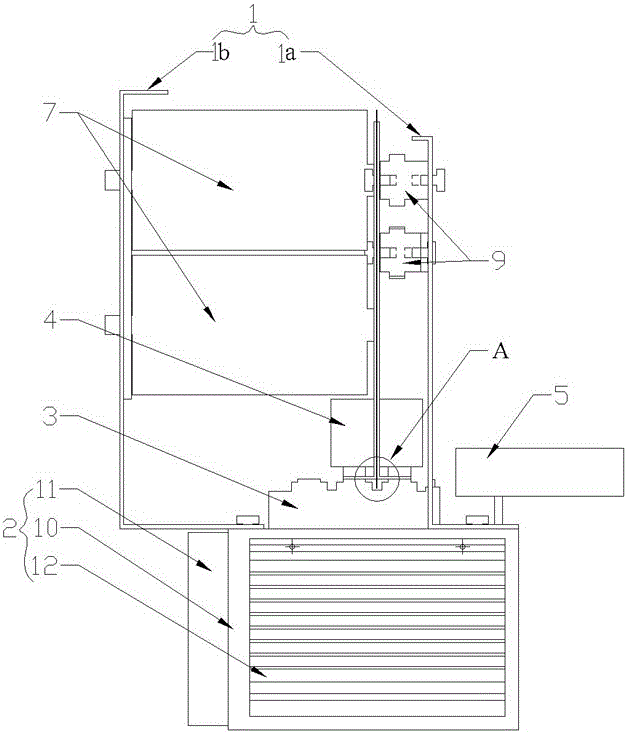

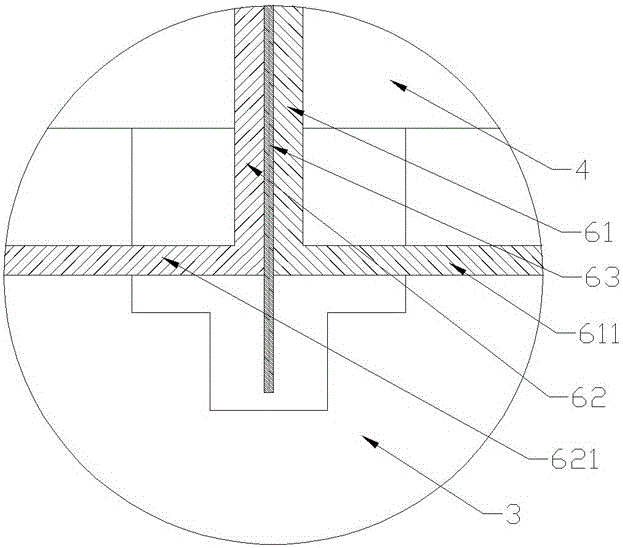

[0030] Such as Figure 1 to Figure 7As shown, in this embodiment, the module includes a support frame 1, a heat dissipation system 2, three IGBT power devices 3, three peak absorbing capacitors 4, a drive unit 5, a three-phase half-bridge DC busbar 6 and six DC Supporting capacitors 7 , the six DC supporting capacitors 7 are film capacitors and evenly distributed on the three-phase half-bridge DC busbar 6 . The support frame 1 includes a front support 1a and a rear support 1b, the front support 1a and the rear support 1b are vertically arranged on the heat dissipation system 2 and are located on both sides of the three-phase half-bridge DC busbar 6, in The three-phase half-bridge DC busbar 6 is also provided with four mechanical holes 66, one end of the DC support capacitor 7 is connected to the three-phase half-bridge DC busbar 6, and the other end is fixed to the rear bracket 1b Four insulating columns 9 are arranged between the three-phase half-bridge DC busbar 6 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com