Coating composition for manufacturing ceramic-like coating as well as preparation method and application of coating composition

A technology of ceramic coating and composition, which is applied in the field of making ceramic-like coating composition and its preparation, which can solve the problems of limited application, difficult local repair, brittle material, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

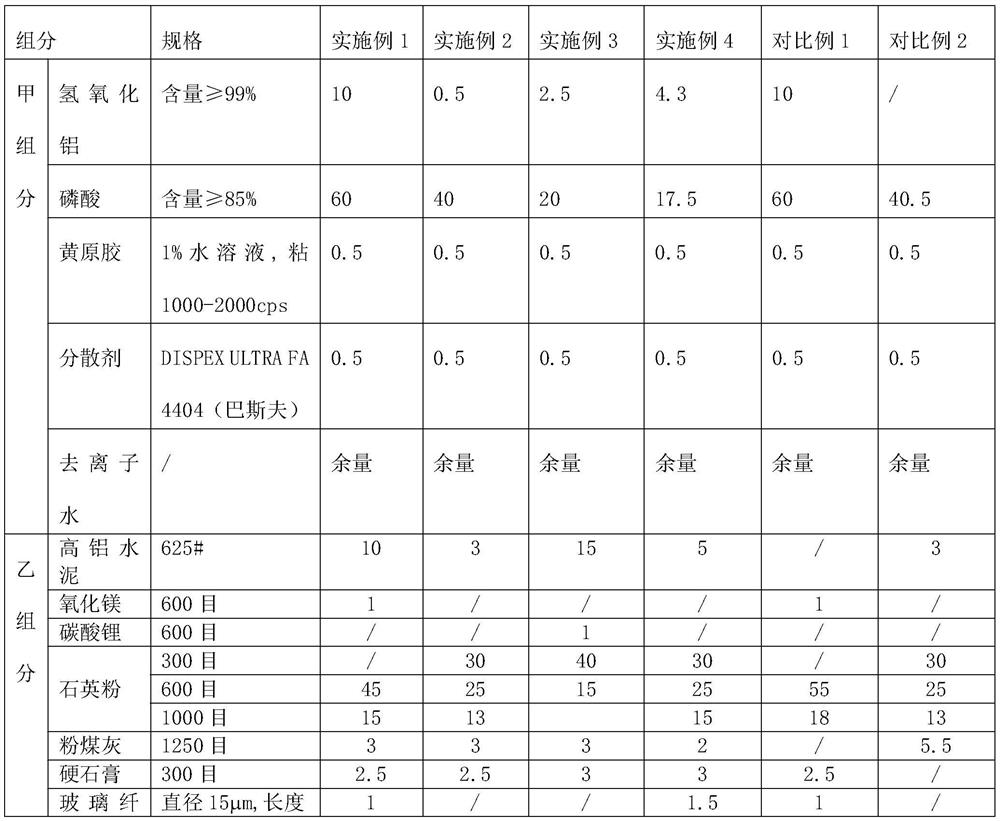

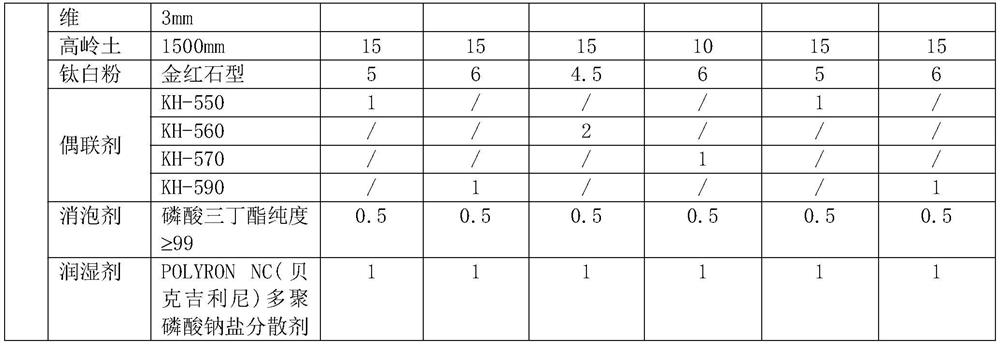

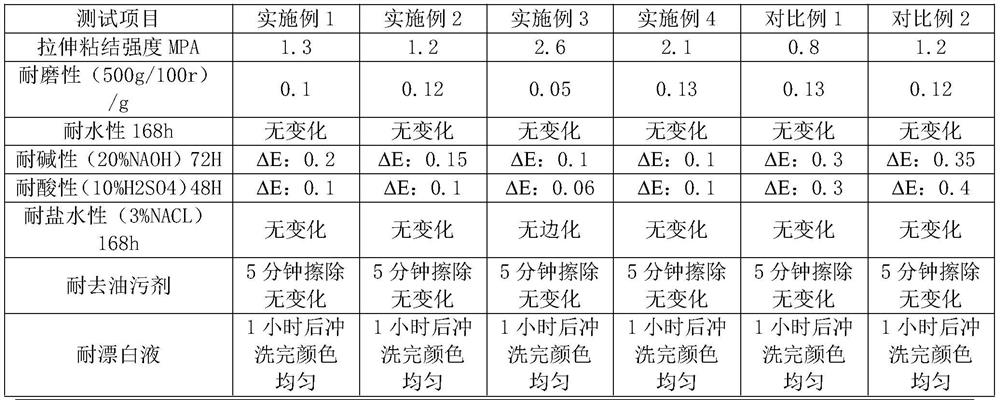

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of above-mentioned coating composition embodiment, comprises the following steps:

[0029] S1. Preparation of component A: Mix aluminum hydroxide and water evenly, stir and add phosphoric acid, heat the mixture to 90°C, stir until transparent, keep it warm for 6 hours, add the remaining materials after cooling to room temperature, and stir evenly to obtain component A;

[0030] S2. Preparation of component B: Add materials except glass fiber into a ball mill, mix for 2 hours, put the material after ball milling into a conical mixer, add glass fiber, stir and mix for 15 minutes to obtain component B.

[0031] For the application of the above coating composition example, the component A and component B were stirred and mixed for 15 minutes at a mass ratio of 40:100, uniformly coated on the substrate, and cured at room temperature to obtain a ceramic-like coating:

Embodiment 1

[0032] Embodiment 1 and comparative example 1 are used for metal surface decoration and anticorrosion;

Embodiment 2

[0033] Embodiment 2 and comparative example 2 are used for PVC plastic surface decoration;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com