Mortar for quickly repairing filling layer of slab ballastless track, and preparation method and use method of mortar

A ballastless track and filling layer technology, applied in the field of building materials, can solve the problems of no emergency repair materials and high material prices, achieve excellent durability and vibration fatigue resistance, increase compatibility, excellent temperature adaptability and constructability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

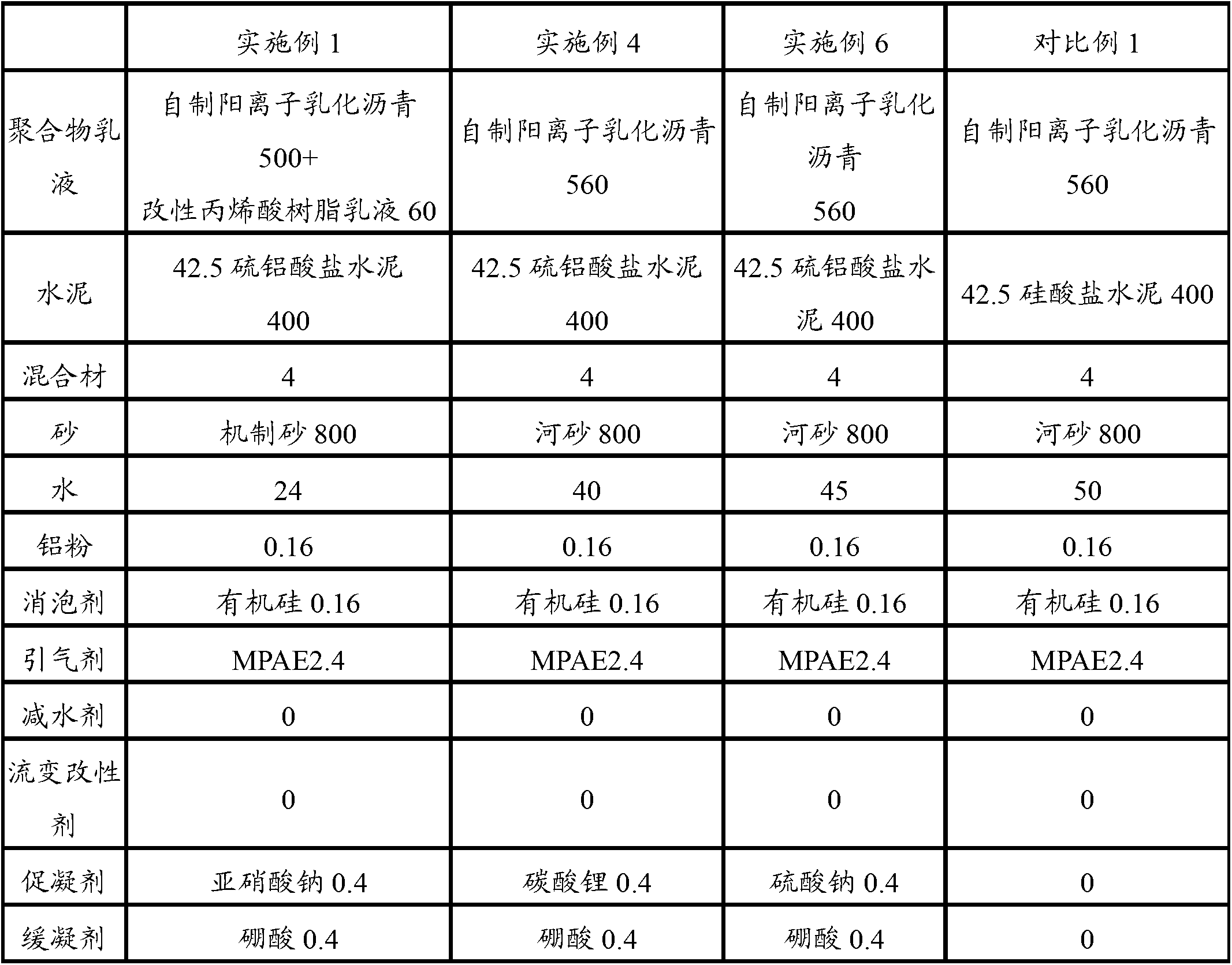

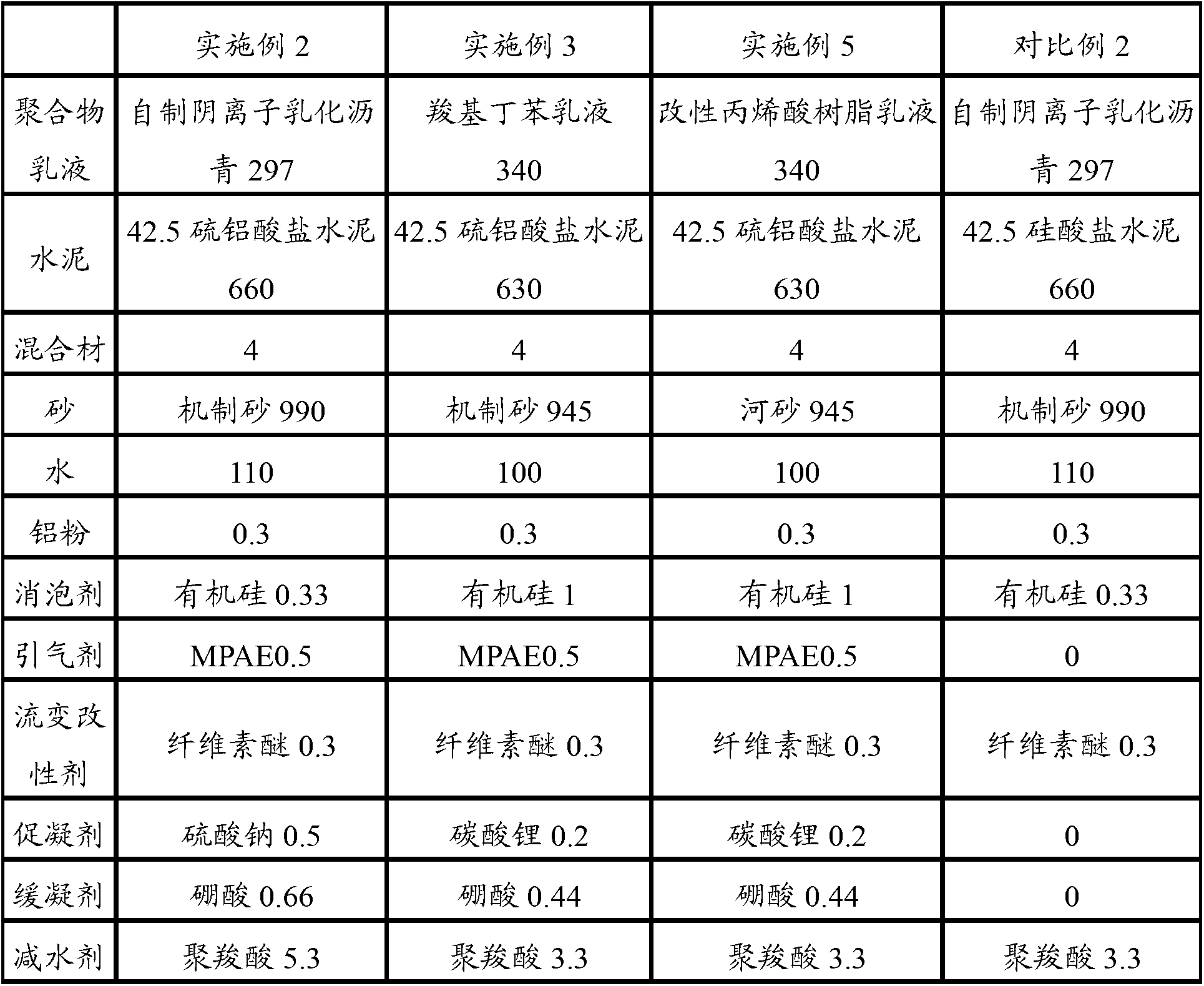

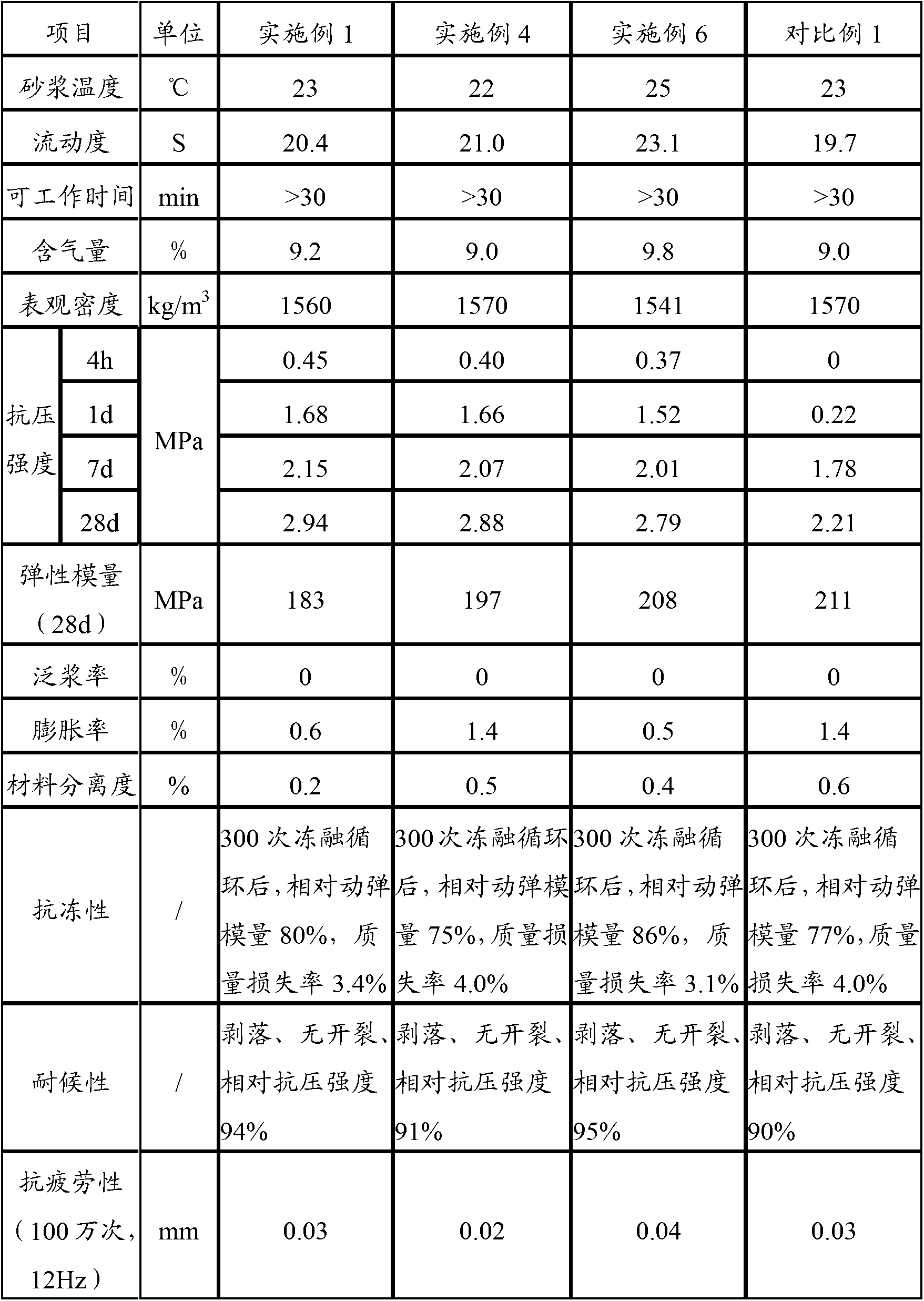

Examples

Embodiment Construction

[0047] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

[0048] The experimental methods in the following examples are conventional methods unless otherwise specified. The reagent materials used in the following examples are all commercially available products unless otherwise specified.

[0049] The preparation process of the quick repair mortar for ballastless track filling layer according to the present invention is as follows:

[0050] ① Add polymer emulsion, water, defoamer, and water reducer to the mortar mixer in sequence, and stir at a slow speed. The stirring speed is 20-40rpm;

[0051] ② Add sand and stir at a medium speed, the stirring speed is 60-80rpm;

[0052] ③ Add cement, admixture, coagulation regulator, rheology modifier, and air-entraining agent in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com