A compound electrolyte material and its making method

A composite electrolyte and composition technology, applied in capacitor electrolytes/absorbents, chemical instruments and methods, circuits, etc., can solve problems such as poor long-term stability, easy leakage of liquid electrolytes, and shortened working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] According to the liquid mixture A is 94wt%, the solid inorganic layered compound powder B is 6wt%, wherein the solid inorganic layered compound powder is Na-montmorillonite, its particle size is 50-500nm, and the specific surface area is 100m 2 / g;

[0056] Described liquid mixture is:

[0057] A-1) Ethanol 80wt%

[0058] A-2) a kind of inorganic salt (lithium iodide) 10wt%

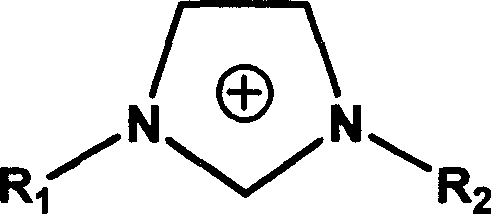

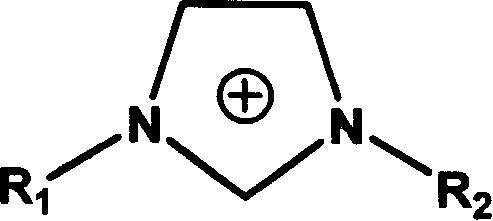

[0059] A-3) An ionic liquid (1-propyl-3-methylimidazolium iodide) 10wt%

[0060] A-4) The amount of iodine iodine and component A-2) and components

[0061] Iodine I contained in A-3) 2 / I - (Iodine) molar ratio is 1:10

[0062] The ionic liquid used in the present embodiment and the following examples, 1-propyl-3-methylimidazolium iodide salt, is the use of "Li Yongfang et al., "Chemical Bulletin", 2002 (4): 243-250) ion It is prepared by the one-step method introduced in "Progress in Liquid Research", that is, adding N-methylimidazole and n-propane iodide at a ratio of 5:4 to cyclohexane, ...

Embodiment 2

[0069] 1. Weigh according to the following components and formula:

[0070] composition

Dosage

A-1

ethanol (solvent)

20g

[0071] A-2

Lithium iodide (inorganic salt)

3g

A-3

1-Propyl-3-methylimidazolium iodide salt (ionic liquid)

3g

A-4

iodine

0.87g

A-5

4-tert-butylpyridine (additive)

3g

B

Na-montmorillonite (inorganic layered compound)

1.9g

[0072] 2. Preparation of electrolyte:

[0073] (a) Configure the liquid mixture: dissolve the weighed lithium iodide, 1-propyl 3-methylimidazolium iodide salt, iodine and additive 4-tert-butylpyridine in ethanol, and perform mechanical stirring to mix evenly to form a transparent The liquid mixture; Other steps are with embodiment 1

[0074] 3. The preparation and testing steps of the battery are the same as in Example 1. The photoelectrochemical performance test results of the battery are sho...

Embodiment 3

[0076] 1. Weigh according to the following components and formula:

[0077] composition

Dosage

A-1

ethanol (solvent)

20g

A-2

Lithium iodide (inorganic salt)

0g

A-3

1-Propyl-3-methylimidazolium iodide salt (ionic liquid)

2.5g

A-4

iodine

0.25g

A-5

4-tert-butylpyridine (additive)

2.5g

B

Na-montmorillonite (inorganic layered compound)

1.6g

[0078] 2. Preparation of electrolyte:

[0079] (a) Configure the liquid mixture: dissolve the weighed 1-propyl 3-methylimidazolium iodide salt, iodine and 4-tert-butylpyridine in ethanol, and perform mechanical stirring to mix uniformly to form a transparent liquid mixture; Step is with embodiment 1

[0080] 3. The preparation and testing steps of the battery are the same as in Example 1. The photoelectrochemical performance test results of the battery are shown in Table I.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com