Environmentally friendly nano graphene conductive ink and preparation method and application thereof

A technology of nano-graphene and conductive ink, which is applied in applications, inks, household appliances, etc., can solve the problem of silver being easily oxidized, and achieve the effects of meeting the requirements of printing suitability, improving stability, and widening the source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

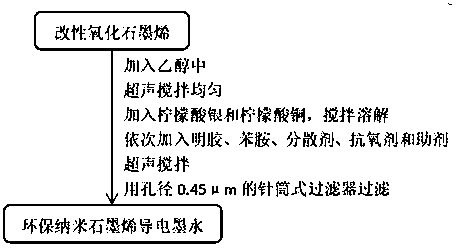

Method used

Image

Examples

Embodiment 1

[0028] Composition of raw materials (parts by weight): 20 parts of modified graphene oxide, 15 parts of silver citrate, 15 parts of copper citrate, 3 parts of aniline, 2 parts of gelatin, 1 part of magnesium stearate, tetrakis [β-(3,5 - 2 parts of tertiary butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester, 1 part of auxiliary agent, 50 parts of ethanol and 30 parts of water;

[0029] The auxiliary agent is composed of the following raw materials in parts by weight: 10 parts of polyethylene glycol 400, 2 parts of sorbitol, 1 part of simethicone, and 2 parts of Tween.

[0030] The modified graphene oxide is prepared by the following method:

[0031] S1. Graphene oxide is prepared by liquid phase exfoliation;

[0032] S2. Add the graphene oxide prepared in step S1 into deionized water, stir evenly with ultrasonic waves, add a silane coupling agent, stir and react at 60°C for 1h, cool to room temperature, centrifuge, discard the supernatant, and dry the solid to obtain ...

Embodiment 2

[0036] Raw material composition (parts by weight): 35 parts of modified graphene oxide, 25 parts of silver citrate, 20 parts of copper citrate, 10 parts of aniline, 5 parts of gelatin, 3 parts of zinc stearate, 5 parts of diphenylamine, 5 parts of additives 70 parts, 70 parts of ethanol and 50 parts of water;

[0037] The auxiliary agent is composed of the following raw materials in parts by weight: 15 parts of polyethylene glycol 400, 5 parts of sorbitol, 2 parts of simethicone, and 5 parts of Tween.

[0038] The modified graphene oxide is prepared by the following method:

[0039]S1. Graphene oxide is prepared by liquid phase exfoliation;

[0040] S2. Add the graphene oxide prepared in step S1 into deionized water, stir ultrasonically, add a silane coupling agent, stir and react at 60°C for 3h, cool to room temperature, centrifuge, discard the supernatant, and dry the solid to obtain Graphene oxide modified by silane coupling agent;

[0041] A preparation method of enviro...

Embodiment 3

[0044] Raw material composition (parts by weight): 22 parts of modified graphene oxide, 17 parts of silver citrate, 16 parts of copper citrate, 4 parts of aniline, 3 parts of gelatin, 2 parts of ethylene bisstearamide, 2,6-tri 3 parts of grade butyl-4-methylphenol, 2 parts of additives, 55 parts of ethanol and 25 parts of water;

[0045] The auxiliary agent is composed of the following raw materials in parts by weight: 12 parts of polyethylene glycol 400, 3 parts of sorbitol, 1.2 parts of simethicone, and 3 parts of Tween.

[0046] The modified graphene oxide is prepared by the following method:

[0047] S1. Graphene oxide is prepared by liquid phase exfoliation;

[0048] S2. Add the graphene oxide prepared in step S1 into deionized water, stir evenly with ultrasonic waves, add a silane coupling agent, stir and react at 60°C for 2h, cool to room temperature, centrifuge, discard the supernatant, and dry the solid to obtain Graphene oxide modified by silane coupling agent;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com