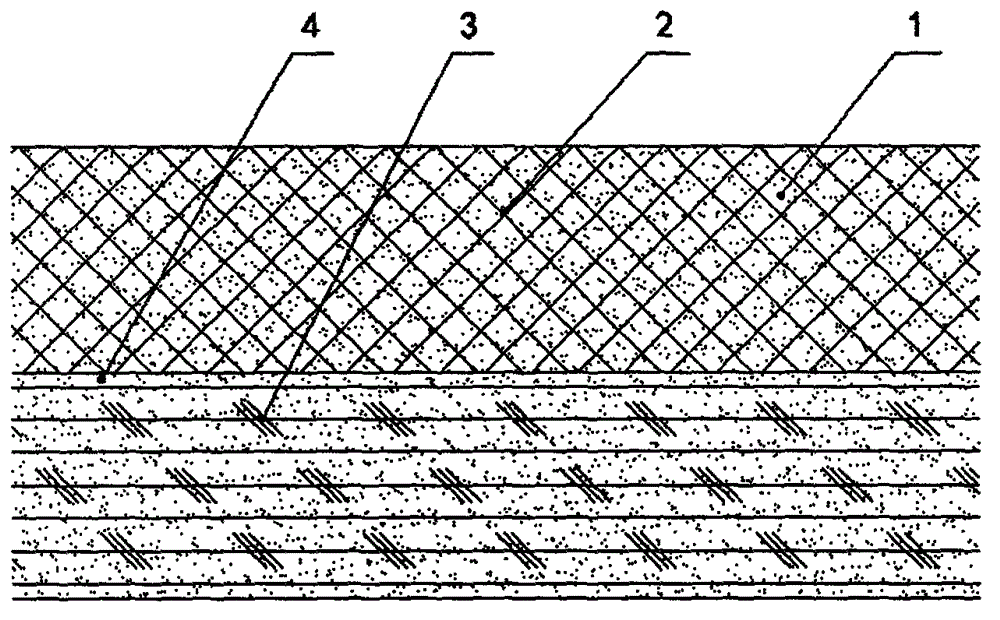

Plane single-sheet compound veneer with UV (Ultraviolet) primer

A technology of composite wood and primer, applied in the field of decorative materials, can solve the problems of insufficient paint filling effect and poor composite characteristics, and achieve the effect of excellent economic practicability and overcoming cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The surface layer is natural cherry veneer with a thickness of 0.2mm, with a thickness of 0.09mm and a surface density of 29g / m 2 The imported non-woven fabric is the bottom material, and the hot-melt adhesive film paper is laid flat between the bottom layer and the surface layer, which is put into a hot-pressing machine for hot pressing. The hot-pressing temperature is 140°C and the hot-pressing pressure is 1.3MPa. Cut the composite non-woven veneer to a regular size of 2500mm x 630mm in length, then flatten and fix the cut veneer on a flat and flexible board, and then put the board and the above-mentioned composite veneer into the UV primer roller Coating production line, after roller coating, sanding treatment. After natural aging. After detection, it is supplied to downstream customers in a single flat state.

Embodiment 2

[0027] Use natural red oak veneer with a thickness of 0.25mm as the surface layer, with a thickness of 0.1mm and a surface density of 30g / m 2 The kraft paper is the bottom material, and the hot-melt adhesive film paper is used between the layers. Put it into the hot-pressing machine for hot-pressing and compounding. The hot-pressing temperature is 145°C and the hot-pressing pressure is 1.35MPa. Cut the compounded kraft paper veneer to a size of 2600mm x 870mm in length, then flatten and fix the cut veneer on a flat and flexible board, and then put the board and the above-mentioned composite veneer into the production line with UV primer roller coating , After the roller is painted, it is then sanded. After natural aging. After detection, it is supplied to downstream customers in a single flat state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com