Environment-friendly latex paint and preparation method thereof

A kind of latex paint, environment-friendly technology, applied in the direction of biocide-containing paint, coating, powder coating, etc., can solve the problems of no indoor air purification and sterilization, insufficient elongation and toughness, unreasonable preparation process, etc., to achieve low Effect of VOC, excellent durability, good purification and sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

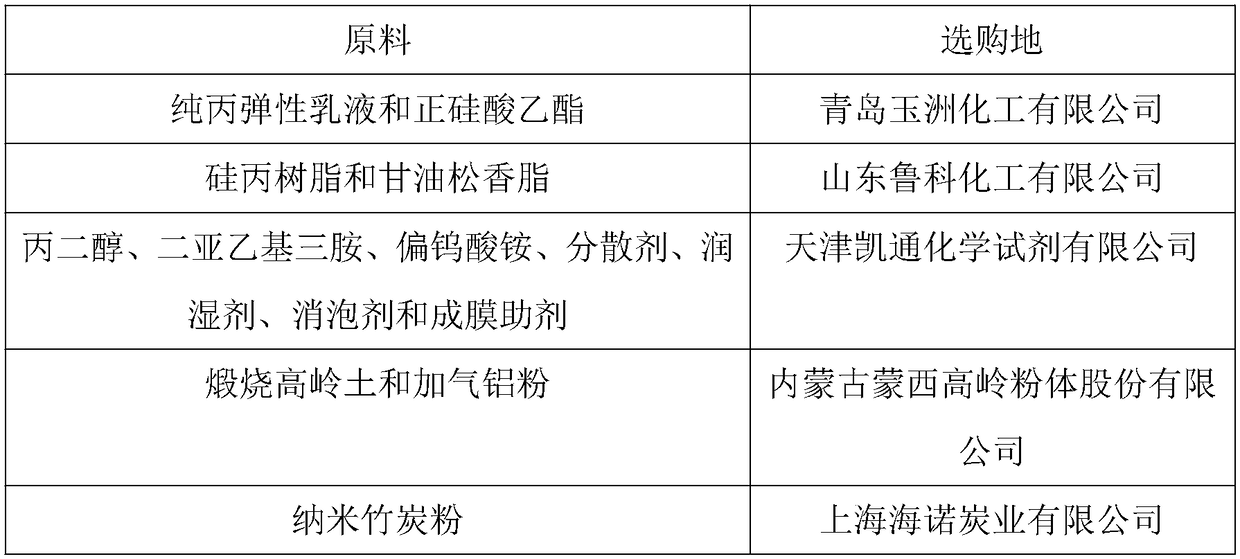

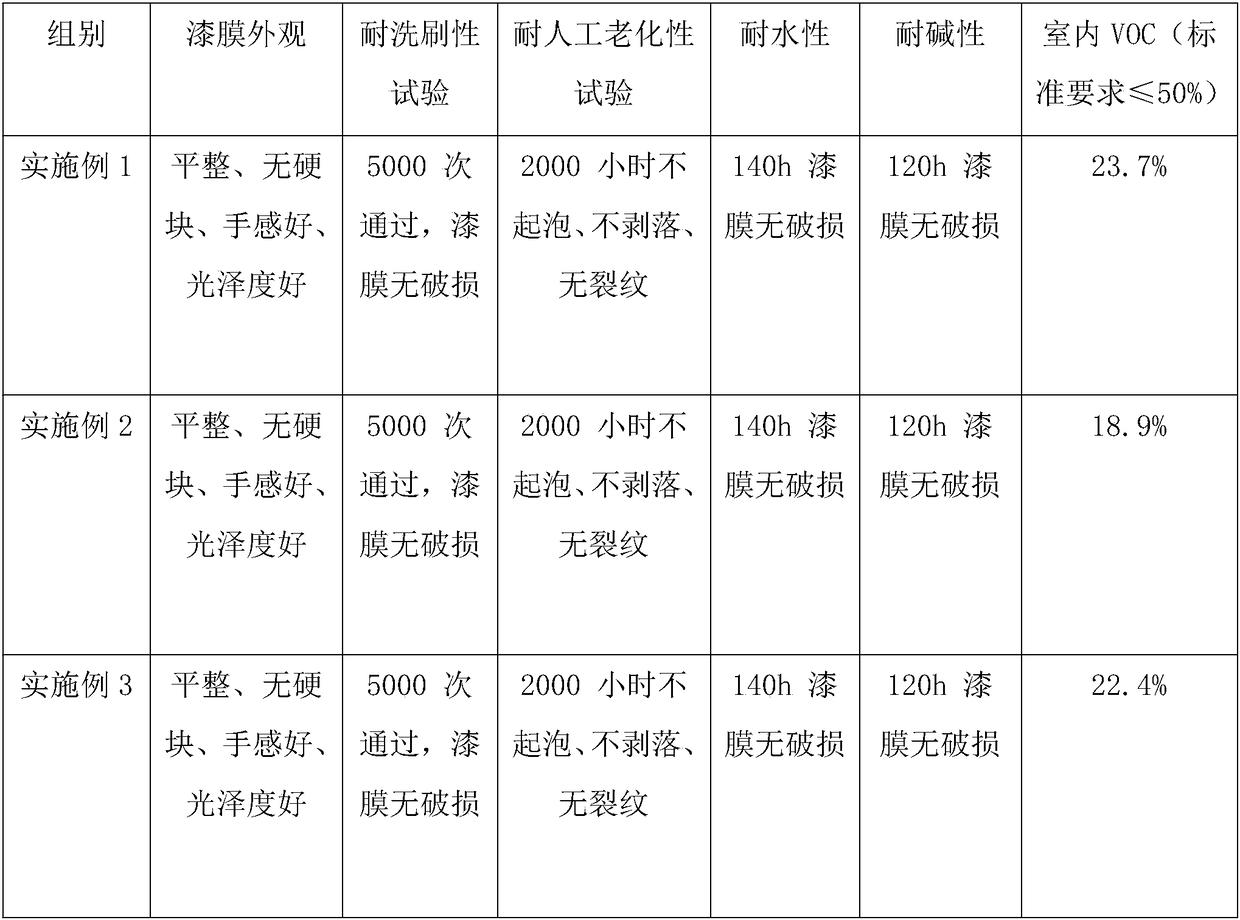

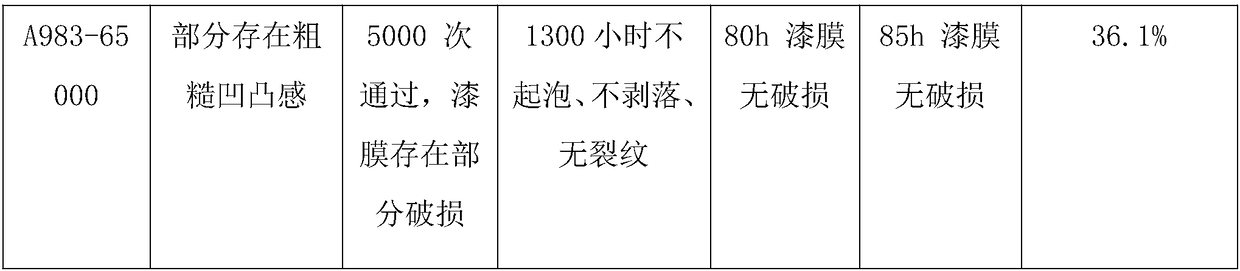

Embodiment 1

[0024] An environmentally friendly latex paint, the following raw materials are weighed for use: 40kg of pure acrylic elastic emulsion, 10kg of silicone acrylic resin, 5kg of glycerin rosin resin, 5kg of tetraethyl orthosilicate, 20kg of calcined kaolin, 5kg of aerated aluminum powder, modified nano Bamboo charcoal powder 5kg, propylene glycol 10kg, diethylenetriamine 1kg, ammonium metatungstate 4kg, dispersant 2kg, wetting agent 1kg, defoamer 1kg, film-forming aid 1kg and deionized water 20kg;

[0025] The above-mentioned calcined kaolin is obtained through the following steps: first remove impurities from the raw material kaolin, then pre-dry it at 105°C for 40 minutes, then transport it to a calciner for calcination at a temperature of 580°C, hold it for 2 hours, and output it for cooling to 55°C, add 1% lauryl oleate equivalent to the weight of kaolin, 1% dimethylacetamide and 3% polyethylene micropowder wax, stir and mix, and then transport it to the impact mill for grindi...

Embodiment 2

[0035] An environmentally friendly latex paint, the following raw materials are weighed for use: 50kg of pure acrylic elastic emulsion, 15kg of silicone acrylic resin, 10kg of glycerin rosin resin, 10kg of tetraethyl orthosilicate, 25kg of calcined kaolin, 10kg of aerated aluminum powder, modified nano Bamboo charcoal powder 10kg, propylene glycol 15kg, diethylenetriamine 2kg, ammonium metatungstate 6kg, dispersant 3kg, wetting agent 2kg, defoamer 2kg, film-forming aid 2kg and deionized water 25kg;

[0036] The above-mentioned calcined kaolin is prepared by the following steps: first remove impurities from the raw material kaolin, then pre-dry at 115°C for 50 minutes, and then transport it to a calciner for calcination at a temperature of 600°C, hold it for 2.5 hours, and output Cool to 60°C, add 2% lauryl oleate equivalent to the weight of kaolin, 2% dimethylacetamide and 4% polyethylene micropowder wax, stir and mix, and then transport to the impact mill Grinding into powder...

Embodiment 3

[0046] An environmentally friendly latex paint, the following raw materials are weighed for use: 60kg of pure acrylic elastic emulsion, 20kg of silicone acrylic resin, 15kg of glycerin rosin resin, 15kg of tetraethyl orthosilicate, 30kg of calcined kaolin, 15kg of aerated aluminum powder, modified nano Bamboo charcoal powder 15kg, propylene glycol 20kg, diethylenetriamine 3kg, ammonium metatungstate 8kg, dispersant 4kg, wetting agent 3kg, defoamer 3kg, film-forming aid 3kg and deionized water 30kg;

[0047] The above-mentioned calcined kaolin is prepared through the following steps: first remove impurities from the raw material kaolin, then pre-dry it at 125°C for 60 minutes, then transport it to a calciner for calcination treatment at a temperature of 620°C, hold it for 3 hours, and output it for cooling to 65°C, add 3% lauryl oleate equivalent to the weight of kaolin, 3% dimethylacetamide and 5% polyethylene micropowder wax, stir and mix, and then transport it to the impact m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com