Cigarette filter tip rod capable of sustained releasing mint and production technique thereof

A production process and filter tip technology are applied in the field of cigarette tip sticks for slow-release menthol by applying membrane technology and the field of production technology thereof, which can solve the problems of uneven cooling of menthol, short product preservation period and the like, and achieve long storage time, The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1kg of gelatin, 9kg of water and 5kg of 95% alcohol are heated and dissolved, and sealed and placed after cooling to form a film-forming material solution.

[0044] 3kg of peppermint is dissolved in 7kg of 95% alcohol to obtain a peppermint essence solution.

[0045] Slowly add 1 kg of mint into 9 kg of film-forming material solution under stirring condition to obtain a film-forming material solution added with mint.

[0046] The cotton thread is soaked in the mint essence solution first, and then absorbs the film-forming material solution added with the mint, and then the wet or dry cotton thread is passed through the pulling force of the forming machine, and is formed together with the tow to obtain a slow-release mint cigarette filter rod.

Embodiment 2

[0048] Heat and dissolve 1kg of gum arabic, 9kg of water and 5kg of 95% alcohol, and seal it after cooling to form a film-forming material solution.

[0049] 5kg of peppermint is dissolved in 5kg of 95% alcohol to obtain a peppermint essence solution.

[0050] Slowly add 1.5 kg of mint into 8.5 kg of film-forming material solution under stirring condition to obtain a film-forming material solution with mint added.

[0051] The cotton thread is soaked in the mint essence solution first, and then absorbs the film-forming material solution added with the mint, and then the wet or dry cotton thread passes through the pulling force of the forming machine, and is formed together with the tow to obtain a slow-release mint cigarette filter rod.

Embodiment 3

[0053]1 kg of carboxymethyl cellulose, 9 kg of water and 5 kg of 95% alcohol are dissolved by heating, sealed and placed after cooling to form a film-forming material solution.

[0054] 7kg of peppermint was dissolved in 3kg of 95% alcohol to obtain a peppermint essence solution.

[0055] Slowly add 2 kg of mint to 8 kg of polymer solution under stirring condition to obtain a film-forming material solution added with mint.

[0056] The cotton thread is soaked in the mint essence solution first, and then absorbs the film-forming material solution added with the mint, and then the wet or dry cotton thread passes through the pulling force of the forming machine, and is formed together with the tow to obtain a slow-release mint cigarette filter rod.

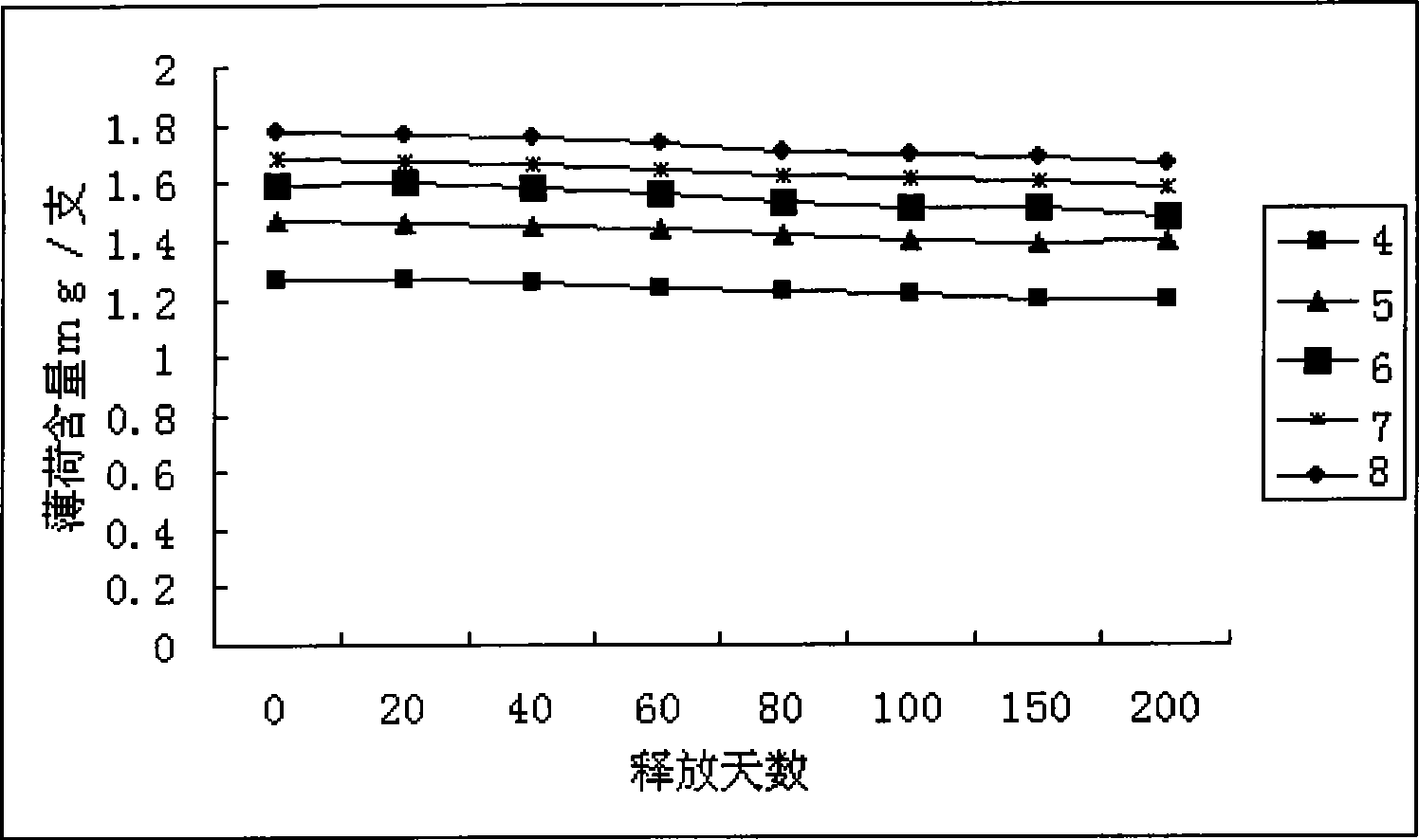

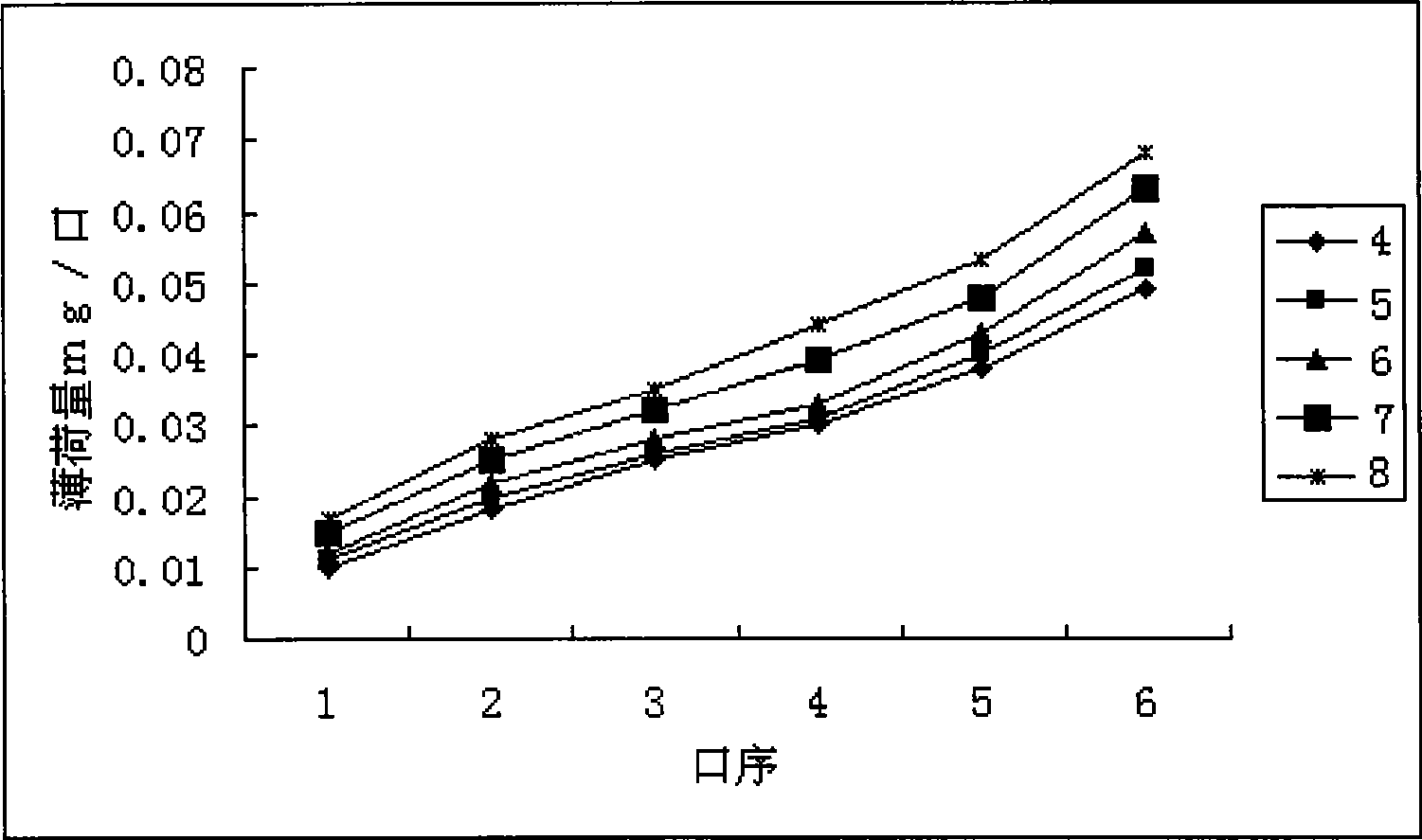

[0057] The film-forming material of the present invention is water-soluble, and mint is almost insoluble in water. Therefore, the present invention adds an appropriate proportion of ethanol in the film-forming material, so that both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com