Flexible vinyl dedicated to wire and cable

A soft polyvinyl chloride, wire and cable technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of partial waste of antioxidants, influence on mechanical and physical properties, influence of tensile strength retention rate on thermal stability time, etc. Achieve the effects of easy processing, excellent heat resistance and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

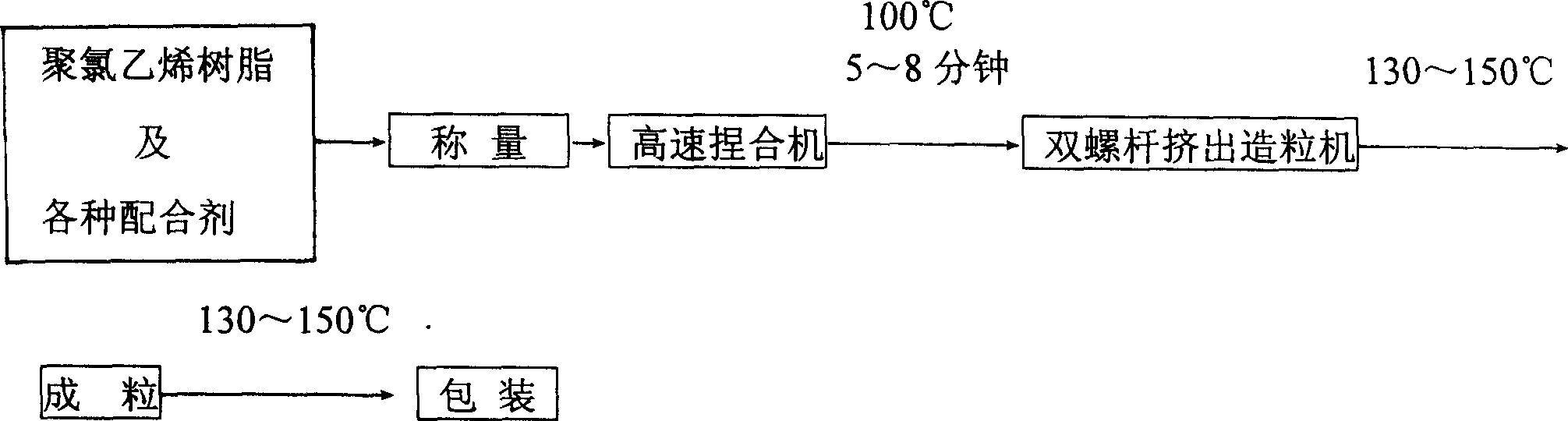

Method used

Image

Examples

Embodiment 1

[0040] The degree of polymerization is 1300 PVC resin 100 parts;

[0041] 50 parts of tetraoctyl pyromellitic acid (TOPM);

[0042] 10 parts of lead cyanurate;

[0043] Antioxidant B225 0.8 parts;

[0044] Antioxidant DLTP 0.2 part;

Embodiment 2

[0048] 30 parts of PVC resin with a degree of polymerization of 1300;

[0049] 70 parts of PVC resin with a degree of polymerization of 2500;

[0050] 90 parts of tetraoctyl pyromellitic acid (TOPM);

[0051] 10 parts of lead cyanurate;

[0052] Antioxidant B225 0.8 parts;

[0053] Antioxidant DLTP 0.2 parts;

Embodiment 3

[0057] Antioxidant B225 0.5 parts;

[0058] Antioxidant DLTP 0.1 part;

[0059] All the other quantities are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polymerization | aaaaa | aaaaa |

| Polymerization | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com