Water-based composite resin composition, water-based plastic paint and preparation method of water-based plastic paint

A composite resin and composition technology, used in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor scratch resistance, too slippery, and poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

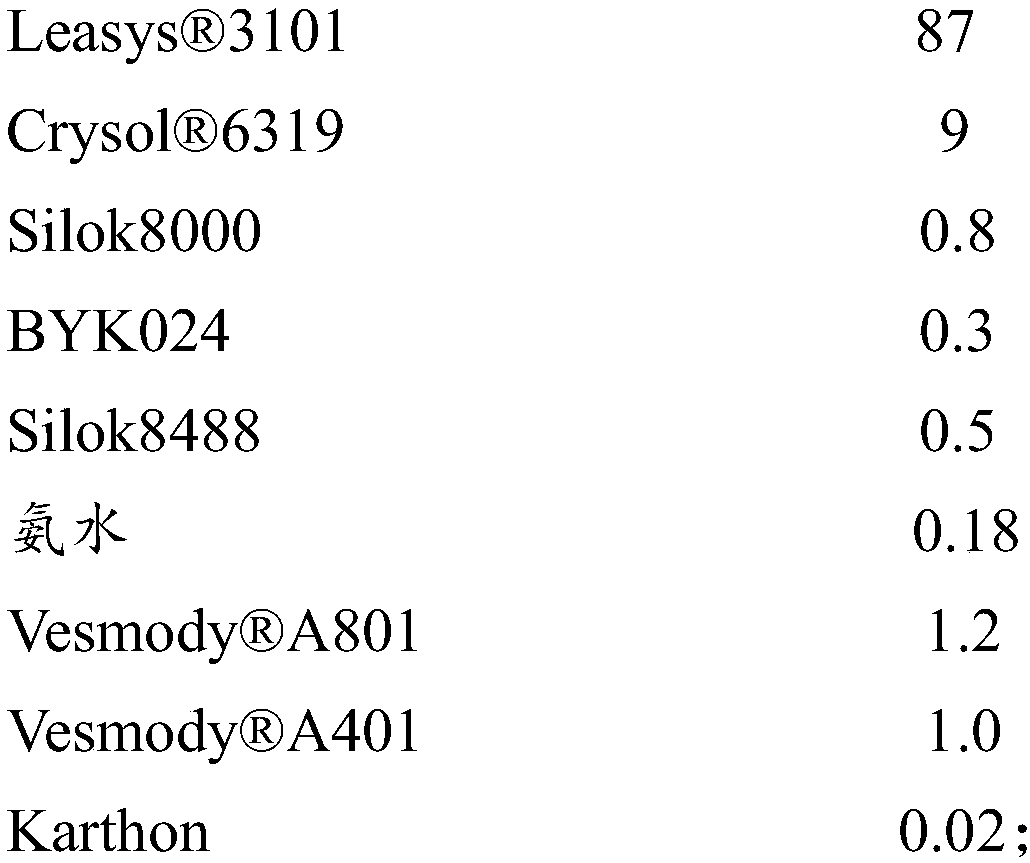

[0090]Water-based plastic paint consists of component A and component B. Wherein, the formulation weight parts of component A and component B are composed as follows:

[0091] Component A

[0092]

[0093] Component B

[0094] 5;

[0095] in, It is a water-based large particle size polyurethane resin, and its main raw materials include hexamethylene diisocyanate, 4,4'-dicyclohexylmethane diisocyanate, polytetrahydrofuran ether diol, polycaprolactone diol, MPEG1200, N-( 2-Aminoethyl)-2-aminoethanesulfonate, N-(2-hydroxyethyl)ethylenediamine and isophoronediamine.

[0096] It is a water-based acrylic resin, and its main raw materials include styrene, methyl methacrylate, and tetrahydrofuran acrylate.

[0097] The manufacturing method of water-based plastic paint is:

[0098] The preparation method of component A: In the dispersing barrel, start the dispersing machine, adjust the speed at 300-500 rpm, and add it according to the formula Water-based wetting agent,...

Embodiment 2

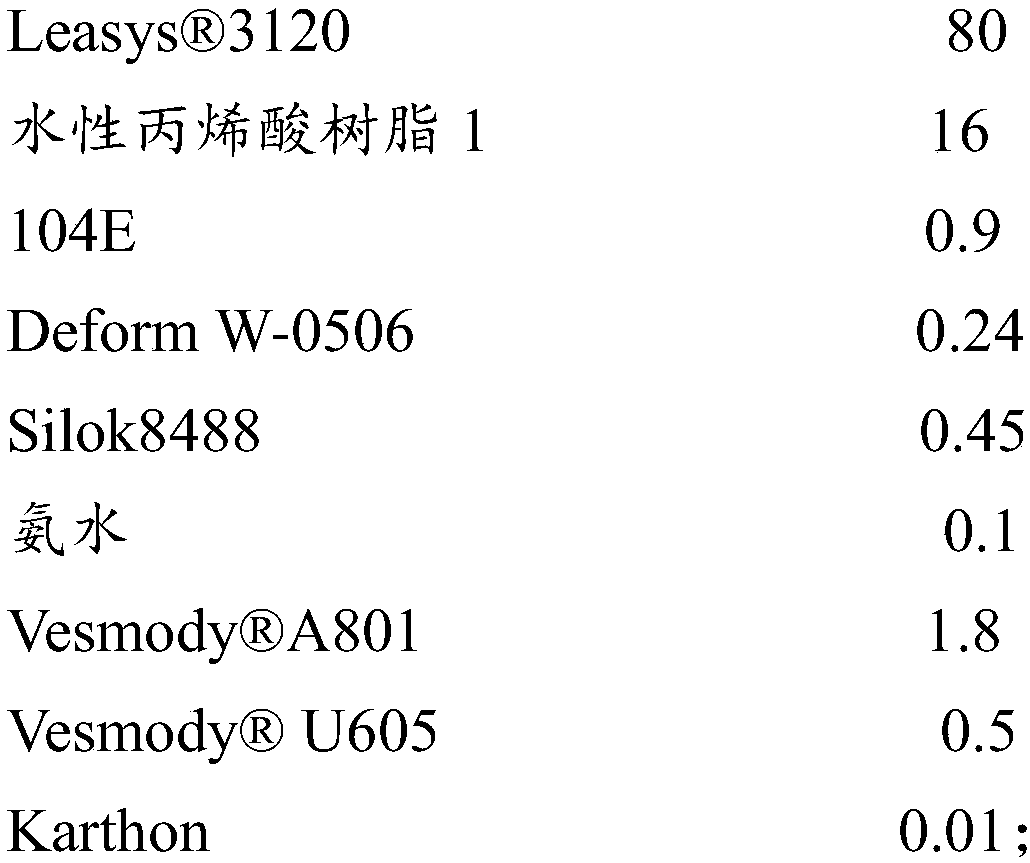

[0101] Water-based plastic paint consists of component A and component B. Wherein, the formulation weight parts of component A and component B are composed as follows:

[0102] Component A

[0103]

[0104] Component B

[0105] 6;

[0106] in, It is a water-based large particle size self-dulling polyurethane resin, and its main raw materials include hexamethylene diisocyanate, isophorone diisocyanate, polytetrahydrofuran ether diol, polycarbonate diol, N120, N-(2-aminoethyl base)-2-aminoethanesulfonate, N-(2-hydroxyethyl)ethylenediamine and isophoronediamine.

[0107] Among them, the main raw materials of the water-based acrylic resin 1 include styrene, methyl methacrylate, tetrahydrofuran acrylate, and tetrahydrofuryl acrylate. The preparation method is as follows:

[0108] Under the protection of nitrogen, mix 2 parts of sodium dodecylsulfonate, 2 parts of nonylphenyl polyoxyethyl ether, 0.5 parts of ammonium persulfate and 60 parts of water, stir to make it full...

Embodiment 3

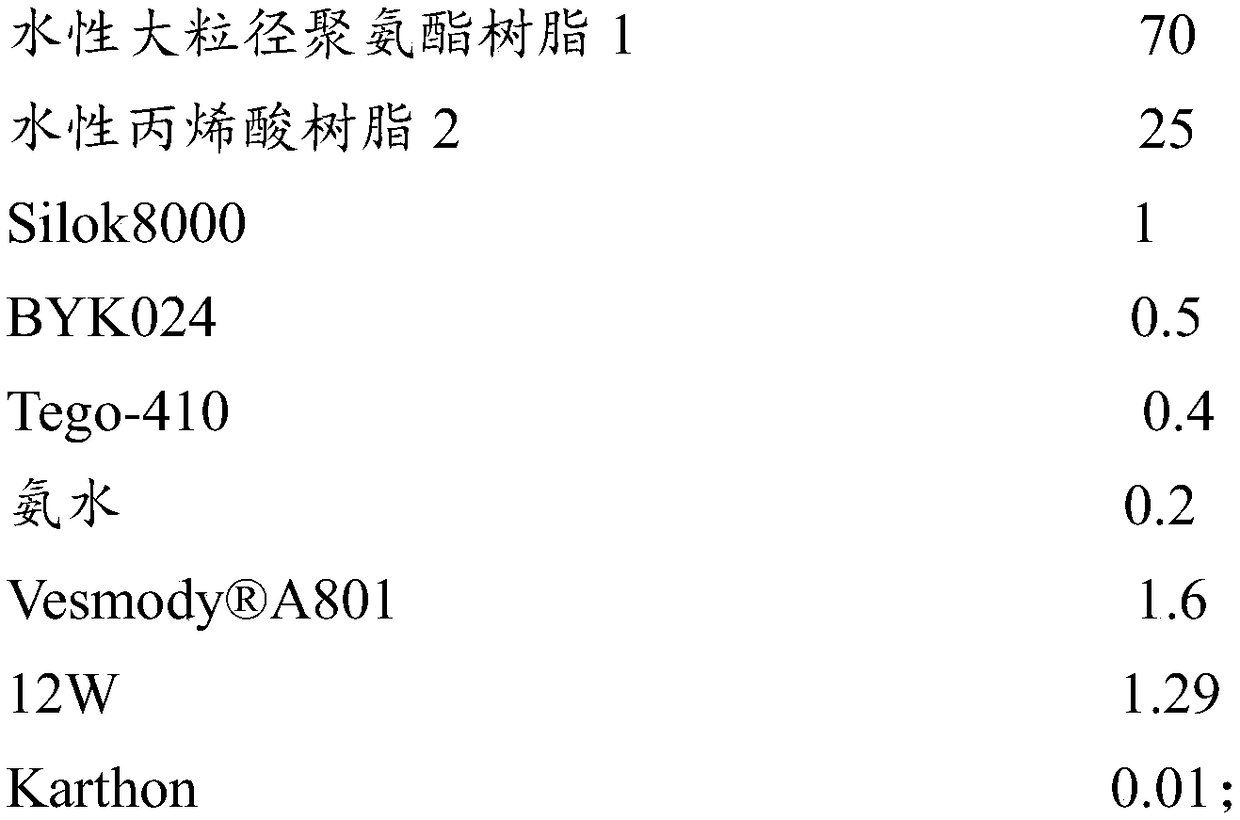

[0112] Water-based plastic paint consists of component A and component B. Wherein, the formulation weight parts of component A and component B are composed as follows:

[0113] Component A

[0114]

[0115] Component B

[0116] 4;

[0117] Among them, the main raw materials of water-based large particle size polyurethane resin 1 include hexamethylene diisocyanate, isophorone diisocyanate, polytetrahydrofuran ether diol, polycarbonate diol, polycaprolactone diol, MPEG1200, diol Methylolpropionic acid, sodium N-(2-aminoethyl)-2-aminoethanesulfonate, N-(2-hydroxyethyl)ethylenediamine, and ethylenediamine. Add the dehydrated polyol, aliphatic diisocyanate, hydrophilic compound and acetone into a reaction vessel filled with nitrogen for contact, and stir the mixture at 80°C for reaction; until the NCO value in the system reaches 1.8wt%, The obtained prepolymer was dissolved in acetone and cooled, and the aqueous solution in which the chain extender was dissolved was broug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com