Building assembly type ceramic tile and building technology using ceramic tile

A prefabricated, ceramic tile technology, applied in the direction of architecture, building components, building structures, etc., can solve the problems of not being able to use immediately, the overall main body is rough, and the inconvenience of work and life, so as to expand the space, facilitate construction, and increase the overall earthquake resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

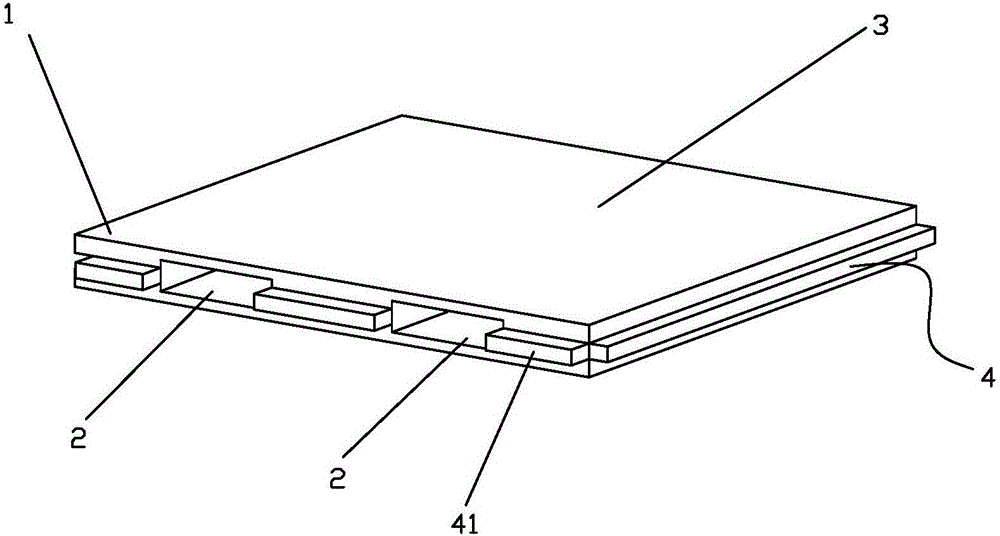

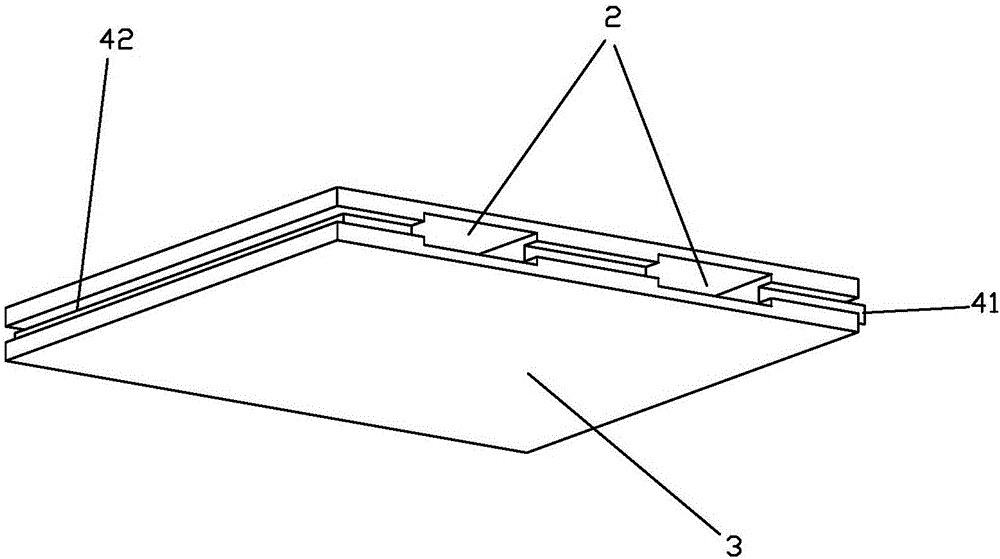

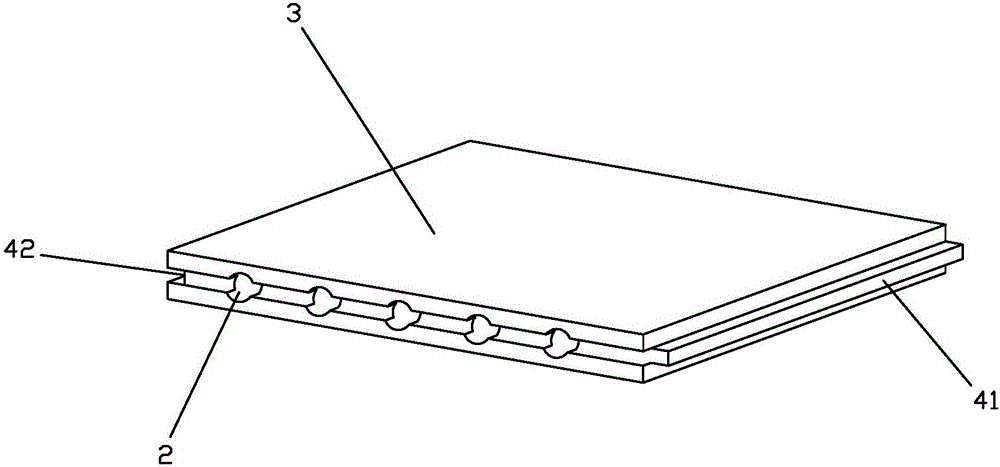

[0063] Such as Figure 1-10 An assembled porcelain ceramic brick for construction is shown, which includes a brick body 1, the inside of which is provided with functional grooves 2 running through its opposite sides, and the outer side of said brick body 1 is provided with ceramic tiles integrally sintered and formed. Decorative layer 3 , the porcelain decorative layer 3 is integrally formed on the outer surface of the main body 1 , and the outer side of the brick main body 1 is also provided with a connecting mechanism 4 for connecting and fixing the adjacent brick main body 1 . In the assembled ceramic tile of the present invention, the porcelain decorative layer on the brick body is fired together with the brick body, so that in the construction process, the brick body can be used in floor construction, wall construction, or house construction. Column construction does not require external decoration. After the brick body is installed in place, the porcelain decorative laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Destruction strength | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com