Quick-hardened early-strengthened non-cracking surface layer self-leveling mortar and preparing method thereof

A technology of self-leveling mortar and surface layer, applied in the field of self-leveling mortar, can solve the problems of needing maintenance, insufficient compressive strength, cracking, etc., and achieve the effect of solving the cracking of ground leveling hollow drum, improving construction efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]A preparation method of rapid-hardening, early-strength and non-cracking surface layer self-leveling mortar, comprising the following steps:

[0036] 1) Add water and stir evenly so that the initial fluidity of the mortar is 150±5mm. The fluidity of the self-leveling mortar is measured by the degree of expansion of the mortar. According to the test standard, pour the mortar into a sleeve with a diameter of 3cm and a height of 5cm. Then lift it up, the mortar flows freely and spreads out into a circle, and the diameter of the circle is the degree of fluidity;

[0037] 2) Evenly spread the stirred self-leveling mortar on the base surface coated with the interface agent, use the rake to assist the leveling, and then roll it back and forth several times with the defoaming roller;

[0038] 3) After the mortar is hardened and dried, polish the surface of the mortar and evenly apply a layer of polyurethane finishing agent.

[0039] Preferably, in step 1), the mass ratio of wat...

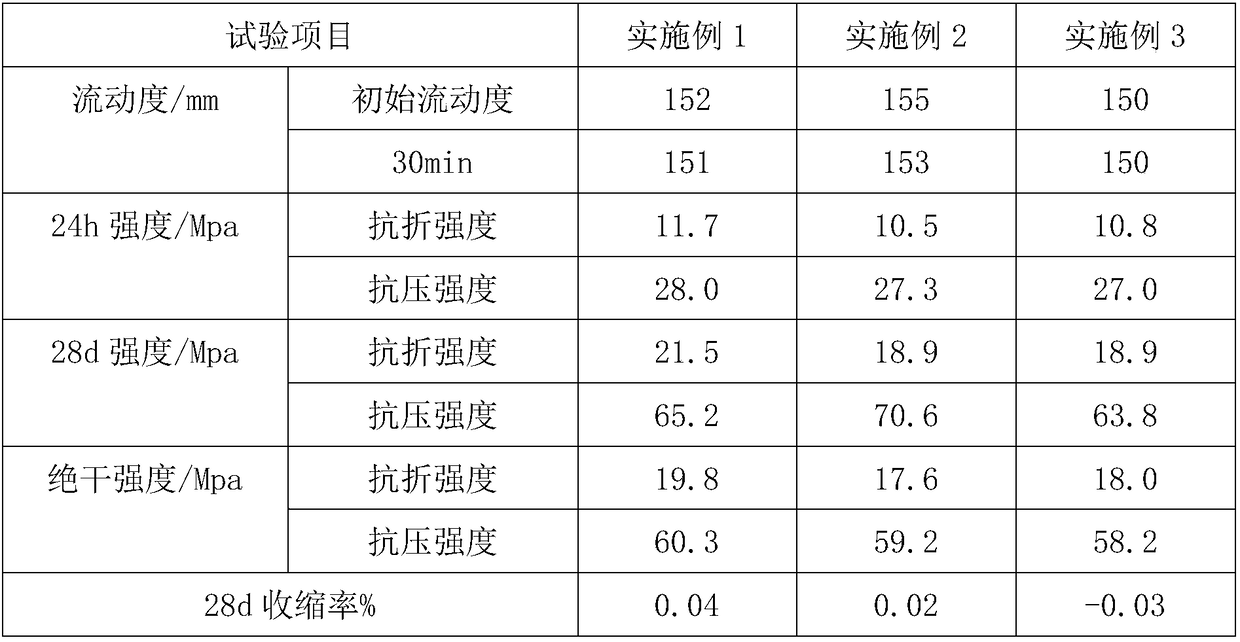

Embodiment 1

[0043] A fast-hardening, early-strength, non-cracking surface layer self-leveling mortar is composed of the following raw materials by mass percentage: α-hemihydrate gypsum 50%, 52.5 white cement 10%, heavy calcium 5%, quartz sand 12.78%, quartz powder 20% , retarder 0.1%, water reducing agent 0.3%, redispersible latex powder 0.5%, thickening stabilizer 0.03%, defoamer 0.17%, pigment 0.28%, silica fiber 0.4%, waterproofing agent 0.2%, Coalescing aid 0.3%.

[0044] The preparation method of the fast-hardening and early-strength non-cracking surface layer self-leveling mortar comprises the following steps:

[0045] 1) According to the water-to-powder ratio of 0.20:1, add water and stir evenly, and the initial fluidity of the mortar is 152mm after testing;

[0046] 2) Evenly spread the stirred self-leveling mortar on the base surface coated with the interface agent, use the rake to assist the leveling, and then roll it back and forth several times with the defoaming roller;

[...

Embodiment 2

[0049] A fast-hardening, early-strength, non-cracking surface layer self-leveling mortar is composed of the following raw materials by mass percentage: α-hemihydrate gypsum 40%, 52.5 white cement 15%, heavy calcium 11.4%, quartz sand 14%, quartz powder 15% , retarder 0.15%, water reducing agent 0.35%, redispersible latex powder 0.8%, thickening stabilizer 0.05%, defoamer 0.3%, pigment 0.5%, silica fiber 1.0%, waterproofing agent 0.5%, Coalescing aid 0.32%.

[0050] The preparation method of the fast-hardening and early-strength non-cracking surface layer self-leveling mortar comprises the following steps:

[0051] 1) According to the water and powder ratio of 0.21:1, add water and stir evenly, and the initial fluidity of the mortar is 155mm after testing;

[0052] 2) Evenly spread the stirred self-leveling mortar on the base surface coated with the interface agent, use the rake to assist the leveling, and then roll it back and forth several times with the defoaming roller;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com