Elastic waterproof emulsion

A waterproof emulsion and elastic technology, applied in the field of preparation of elastic waterproof emulsion, can solve the problems of loss of waterproof function, emulsion does not have calcium ion stability, demulsification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

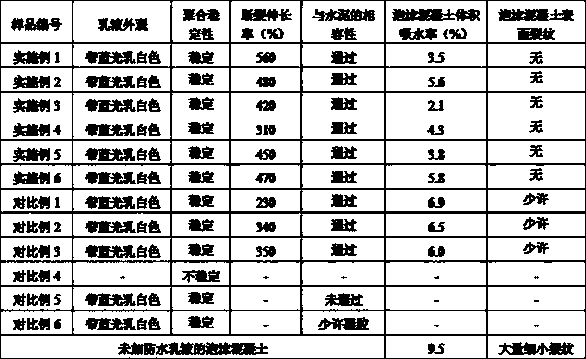

Examples

Embodiment 1

[0048] In a 2000ml three-necked reaction kettle equipped with a mechanical stirrer, a condenser and a constant pressure funnel, add 1g of buffering agent sodium bicarbonate and 250ml of water, stir to dissolve and heat to 80°C; mix 196g of styrene, 140g of butyl acrylate, and 145g of isooctyl ester, 7.5g of hydroxyethyl acrylate, 7.5g of acrylic acid, 4g of the composition of hexanediol diacrylate and trimethylolpropane triacrylate, and 4g of diacetone acrylamide were stirred and dissolved completely to obtain mixed monomers, which were Pour it into 250ml of water dissolved with 1.8g of reactive emulsifier, 1.8g of anionic emulsifier, and 3.6g of nonionic emulsifier under high-speed stirring, emulsify for 15min to obtain pre-emulsified monomer, add 10% of pre-emulsified monomer to the reaction In the kettle, add 1.5g of ammonium persulfate initiator to initiate the polymerization reaction. After the system turns blue and the reflux of the monomer disappears, add the remaining p...

Embodiment 2

[0050] In a 2000ml three-necked reactor equipped with a mechanical stirrer, a condenser and a constant pressure funnel, add 1g of buffering agent sodium bicarbonate and 250ml of water, stir to dissolve and heat to 75°C; mix 290g of vinyl acetate, 198g of butyl acrylate, and Acrylic acid 5g, composition 7.5g of octapentyl glycol diacrylate and pentaerythritol triacrylate, 7.5g of acetoacetoxyethyl acrylate were stirred and dissolved to obtain mixed monomers, which were poured into the dissolved reaction type under high-speed stirring. Put 2g of emulsifier, 2g of anionic emulsifier, and 4g of nonionic emulsifier in 250ml of water, emulsify for 15min to obtain pre-emulsified monomer, add 10% of the pre-emulsified monomer to the reaction kettle, add 1.5g of ammonium persulfate initiator to initiate polymerization Reaction, after the system turns blue and the reflux of the monomer disappears, add the remaining pre-emulsified monomer dropwise, and the addition is completed in about 3...

Embodiment 3

[0052] In a 2000ml three-necked reaction kettle equipped with a mechanical stirrer, a condenser and a constant pressure funnel, add 1g of buffering agent sodium bicarbonate and 250ml of water, stir to dissolve and heat to 50°C; add 25g of glycidyl methacrylate, vinyl chloride 100g, 70g of butyl acrylate, 300g of vinylidene chloride, 5g of tetrahydrophthalic anhydride, 7.5g of diethylene glycol acrylate and butanediol diacrylate, 5g of acetoacetamidoethyl methacrylate, stirred and dissolved completely Obtain the mixed monomer, pour it into 250ml water dissolved with 2g of reactive emulsifier, 2g of anionic emulsifier, and 4g of nonionic emulsifier under high-speed stirring, emulsify for 15min to obtain pre-emulsified monomer, and mix 10% of the pre-emulsified monomer Add it into the reaction kettle, and add 1.5g of redox initiator tert-butyl hydroperoxide and 1.5g of sodium formaldehyde sulfoxylate dropwise at the same time. Add the pre-emulsified monomer and redox initiator in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com