Splitblip molecular weight distribution high-cis-polydiene and preparation method thereof

A molecular weight distribution, polydiene technology, applied in the field of bimodal molecular weight distribution high cis polydiene and its preparation, can solve the problems of difficulty in preparing polybutadiene or polyisoprene products, high price and the like , to achieve the effect of stable and easy control of the polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] at 50°C and N 2 Under protection, add neodymium octanoate (0.088mmol) and 2-ethylhexanoic acid (0.088mmol) into a dry catalyst preparation bottle at 50°C and mix the solution for 2 hours before adding chloroform (1.2mmol), trichloro Ethyl acetate (0.13mmol) and triisobutylaluminum (Al(i-Bu) 3 ) (1.41mmol) in the mixed solution reacted at 50°C for 1 hour, after the two solutions were fully mixed, they were aged at 50°C for 1 hour to prepare a light gray blue transparent homogeneous catalyst system.

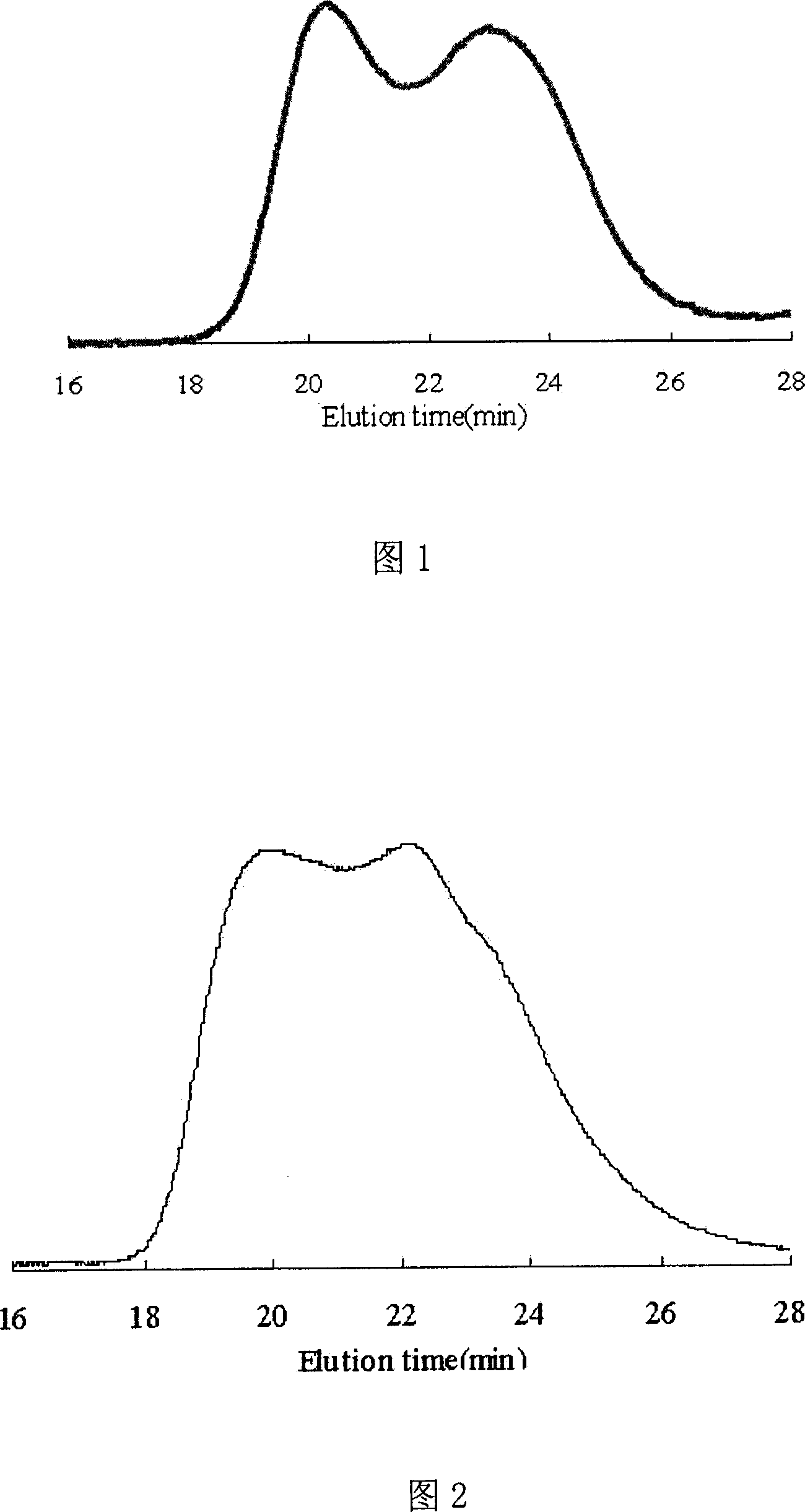

[0034] in N 2 Under protection, add 40ml of butadiene and raffinate (i.e. C 6 ~C 8 alkane mixed solution) mixed solution (wherein monomer mass concentration is 20%) and above-mentioned catalyst solution (catalyst / monomer=0.9mmol / mol) start polymerization, after reacting for 3 hours, add 2,6 containing 0.1% by mass - Ethanol solution of di-tert-butyl-p-cresol and hydrochloric acid to terminate the polymerization. After removing the solvent and unreacted monomers, the pol...

Embodiment 2

[0036] at 50°C and N 2 Under protection, neodymium octanoate (0.088mmol) and 2-ethylhexanoic acid (0.04mmol) were pre-mixed in a dry catalyst preparation bottle at 0°C for 160 hours, then added to chloroform (0.99mmol), dichloromethane ( 0.08mmol), ethyl trichloroacetate (0.11mmol) and triisobutylaluminum (Al(i-Bu) 3 )(1.41mmol) and diisobutylaluminum hydride Al(i-Bu) 2 H) (0.12 mmol) in the solution after reacting at 50° C. for 1 hour, after the two solutions were fully mixed, aged at 50° C. for 1 hour to prepare a light gray blue transparent homogeneous catalyst system.

[0037] in N 2 Under protection, add 40ml of butadiene and raffinate (i.e. C 6 ~C 8 alkane mixed solution) mixed solution (wherein monomer mass concentration is 20%) and above-mentioned catalyst solution (catalyst / monomer=0.7mmol / mol) start polymerization, after reacting for 2.2 hours, add 2,6 containing 0.1% by mass - Ethanol solution of di-tert-butyl-p-cresol and hydrochloric acid to terminate the pol...

Embodiment 3

[0039] at 40°C and N 2 Under protection, in a dry catalyst preparation bottle, mix solution of neodymium octanoate (0.088mmol) and 2-ethylhexanoic acid (0.02mmol) in advance, then add trichloroethane (0.088mmol), 2-phenyl-2- Chloropropane (0.01mmol) and triisobutylaluminum (Al(i-Bu) 3 ) (1.41mmol), mixed uniformly and then aged for 2 hours to prepare a light gray blue transparent homogeneous catalyst system A.

[0040] at 50°C and N 2 Under protection, ethyl trichloroacetate (0.13mmol) was reacted with triisobutylaluminum (Al(i-Bu)3) (1.41mmol) in a dry catalyst preparation bottle for 1 hour, and then neodymium octanoate (0.088 mmol) and 2-ethylhexanoic acid (0.36mmol), mix uniformly and continue to age at 50°C for 1 hour to prepare a light gray blue transparent homogeneous catalyst system B.

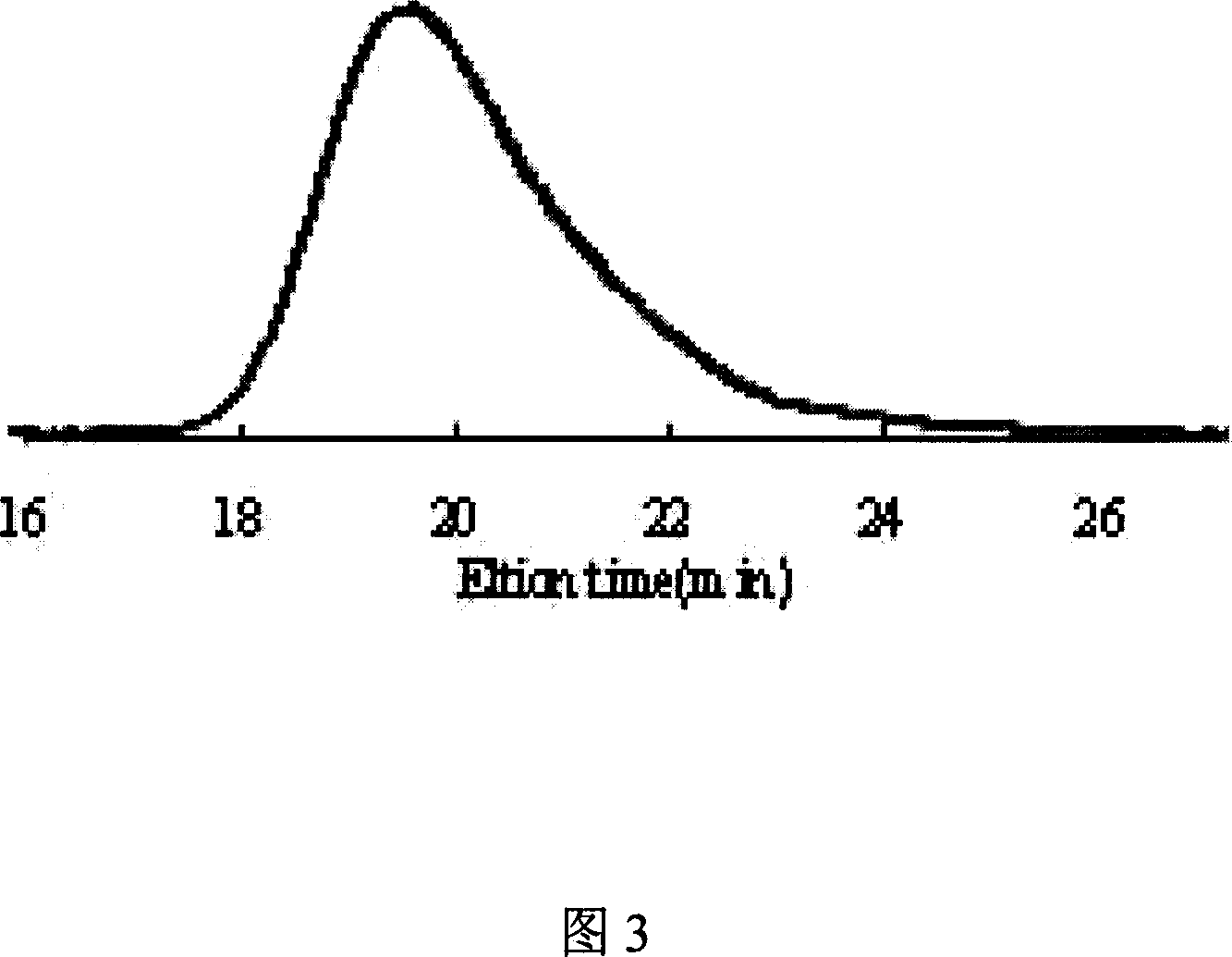

[0041] in N 2 Under protection, add 40ml of butadiene and raffinate (i.e. C 6 ~C 8 alkane mixed solution) mixed solution (wherein monomer mass concentration is 20%) and above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com