Silicone acrylic emulsion and application of silicone acrylic emulsion as textile finishing agent

A silicone-acrylic emulsion and fabric technology, which is applied in animal fibers, fiber processing, textiles and papermaking, etc., can solve the problems of complicated product production process, increased product production cost, low product solid content, etc., and achieves low cost and easy operation. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

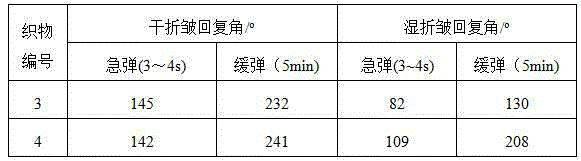

Examples

Embodiment 1

[0042] Embodiment one: the preparation of emulsion

[0043] Mix 27 parts of butyl acrylate and 10 parts of methyl methacrylate, and dissolve 0.8% ammonium persulfate in water. Add deionized water, 0.8 parts of SDS, 0.4 parts of NP-10, and 0.4 parts of NaHCO into a 250ml four-neck flask equipped with an electric mixer, a thermometer and a condenser. 3 , blow nitrogen, raise the temperature to 60°C, stir for 20min, add one-third of the mixture of the two monomers into the flask, stir for 30min, raise the temperature to 70°C, add a quarter of the initiator aqueous solution, and react for 30min. Add 2 parts of vinyltriethoxysilane to the remaining monomer mixture and mix well. Add the mixture of the three monomers and the aqueous solution of the initiator dropwise at a certain rate, raise the temperature to 80°C after the dropwise addition, keep the temperature for 2.5 hours, stop heating, and cool to room temperature; neutralize with ammonia water to pH=7~8, stir evenly , filte...

Embodiment 2

[0044] Embodiment two: the preparation of emulsion

[0045] Mix 27 parts of butyl acrylate and 10 parts of methyl methacrylate, and dissolve 0.8% ammonium persulfate in water. Add deionized water, 0.8 parts of SDS, 0.4 parts of NP-10, and 0.4 parts of NaHCO into a 250ml four-neck flask equipped with an electric mixer, a thermometer and a condenser. 3 , blow nitrogen, raise the temperature to 60°C, stir for 20min, add one-third of the mixture of the two monomers into the flask, stir for 30min, raise the temperature to 70°C, add a quarter of the initiator aqueous solution, and react for 30min. Add 3 parts of vinyltriethoxysilane to the remaining monomer mixture and mix well. Add the mixture of the three monomers and the aqueous solution of the initiator dropwise at a certain rate, raise the temperature to 80°C after the dropwise addition, keep the temperature for 2.5 hours, stop heating, and cool to room temperature; neutralize with ammonia water to pH=7~8, stir evenly , filte...

Embodiment 3

[0046] Embodiment three: the preparation of emulsion

[0047] Mix 29 parts of butyl acrylate and 8 parts of methyl methacrylate, and dissolve 1% ammonium persulfate in water. Add deionized water, 1 part of SDS, 0.5 part of NP-10, 0.4 part of NaHCO into a 250ml four-necked flask equipped with an electric mixer, a thermometer and a condenser 3 , blow nitrogen, raise the temperature to 60°C, stir for 20min, add one-third of the mixture of the two monomers into the flask, stir for 30min, raise the temperature to 70°C, add a quarter of the initiator aqueous solution, and react for 30min. Add 2 parts of vinyltriethoxysilane to the remaining monomer mixture and mix well. Add the mixture of the three monomers and the aqueous solution of the initiator dropwise at a certain rate, raise the temperature to 80°C after the dropwise addition, keep the temperature for 3 hours, stop heating, and cool to room temperature; neutralize with ammonia water to pH=7~8, stir evenly, Filtration, disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com