Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

181results about How to "The polymerization reaction is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

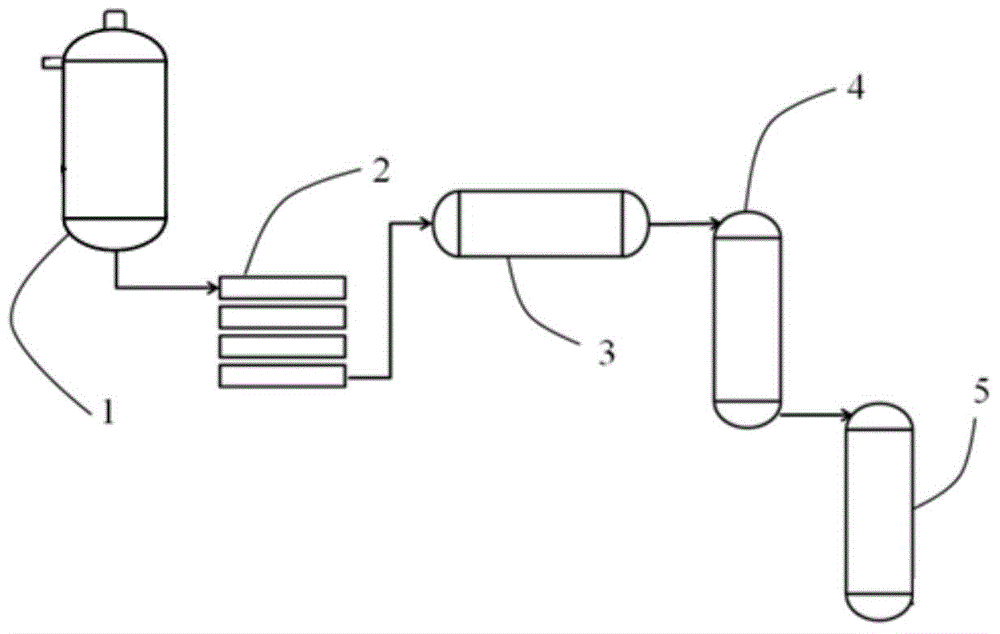

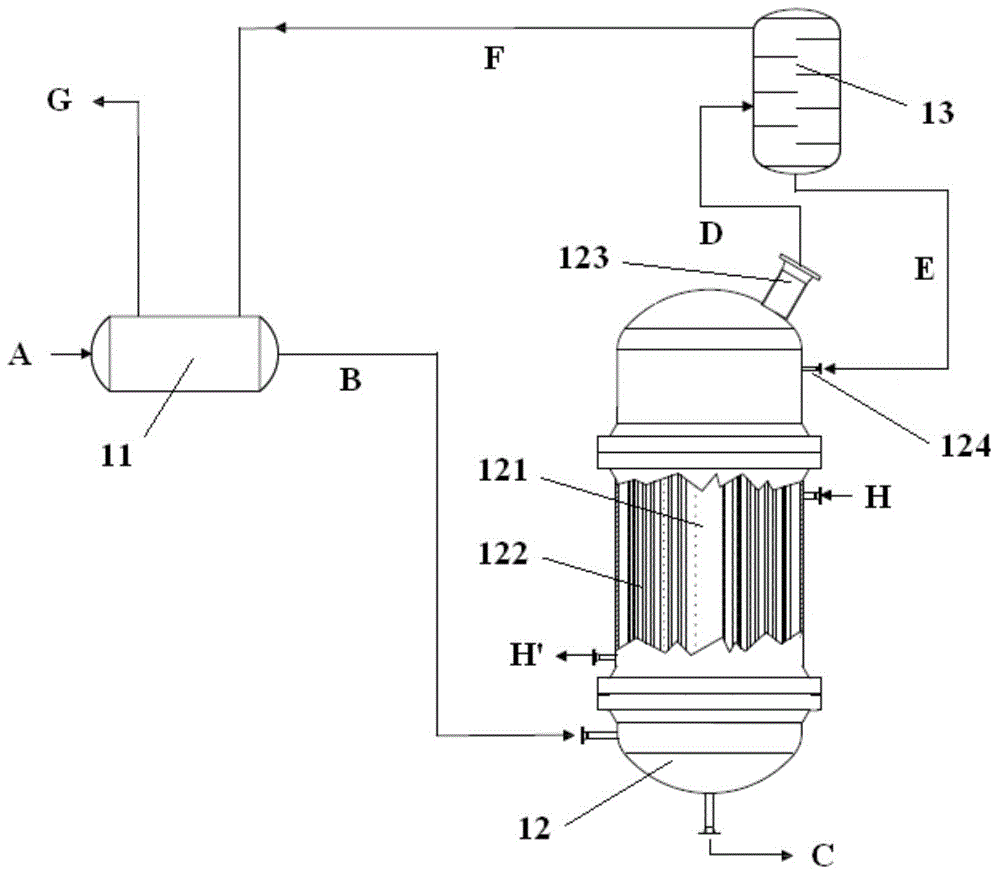

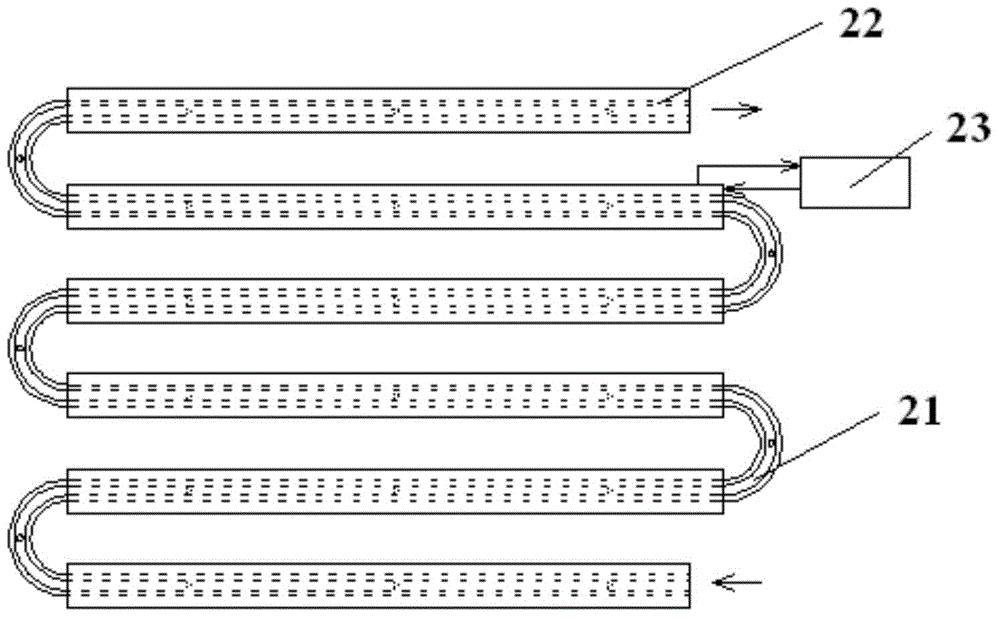

Production equipment and method of polyamide 5X

ActiveCN105885037ASuitable for continuous polymerization processGuaranteed uptimeEvaporator accessoriesChemical/physical/physico-chemical stationary reactorsPolyamideProcess engineering

The invention provides production equipment and method of polyamide 5X. The production equipment comprises a concentration device, a prepolymerization device, a pressure reducing device, a separating device and a final polymerization device which are connected in sequence. The concentration device, the prepolymerization device, the pressure reducing device, the separating device and the final polymerization device are adopted in the production equipment of polyamide 5X, operation of all production links is guaranteed, and the production equipment and method are especially suitable for producing polyamide 5X.

Owner:CATHAY R&D CENT CO LTD +2

UV-curable elastic polyurethane acrylate emulsion and synthesis method thereof

InactiveCN104558499ASelf-emulsifyingGood flexibilityInksPolyurea/polyurethane coatingsPolyesterEndcapping

The invention discloses UV-curable elastic polyurethane acrylate emulsion and a synthesis method thereof. The synthesis method of the UV-curable elastic polyurethane acrylate emulsion comprises the following steps: carrying out reaction on polyester glycol or polyether glycol, carboxylic acid-containing glycol and diisocyanate to generate a prepolymer, adding an optimized micromolecular chain extender for carrying out chain extension, then adding hydroxy-containing acrylate for carrying out blocking reaction, diluting by virtue of an organic solvent, neutralizing and salifying by adopting organic amine, finally adding deionized water for carrying out hydration, and adding a photoinitiator to obtain the UV-curable elastic polyurethane acrylate emulsion. The UV-curable elastic polyurethane acrylate emulsion is polyurethane blocked by acrylate, and a molecular chain of the UV-curable elastic polyurethane acrylate emulsion is provided with hydrophilic negative ions and double bonds, so that the UV-curable elastic polyurethane acrylate emulsion has self-emulsifying property and photocuring activity; and a cured film formed by carrying out photocuring on the synthesized elastic polyurethane acrylate emulsion has excellent mechanical properties, tensile strength is 21MPa, and elongation is 350%, so that the elastic polyurethane acrylate emulsion can serve as matrix resin of water-based ink and waterborne UV-curable elastic paint.

Owner:HUNAN SUIFENG NEW MATERIAL & TECH DEV

Preparation method and product of modified polyurethane flexible high-molecular emulsion containing side long chain alkyl

ActiveCN104774307AGood flexibilityImprove low temperature resistancePolyurea/polyurethane coatingsPolyolefinTriol

The invention relates to a preparation method and product of a modified polyurethane flexible high-molecular emulsion containing side long chain alkyl. The preparation method comprises the following steps: preparing raw materials including a polymeric monomer, a modifying agent, an auxiliary agent and water; performing dehydration pretreatment on polyether triol and polyether glycol; performing prepolymerization; performing chain extension; sealing ends; and emulsifying to prepare a modified polyurethane flexible high-molecular emulsion product containing side long chain alkyl. According to the modified polyurethane flexible high-molecular emulsion disclosed by the invention, polysiloxane chain links and polyolefin chain links are embedded into a skeleton structure of the modified polyurethane flexible high-molecular emulsion, and polyurethane high molecules are modified by using long chain alkyl. The obtained modified polyurethane flexible high-molecular emulsion containing side long chain alkyl has a certain density of long chain crosslinking and side long chain alkyl, has excellent stability, can be applied to dry coating processing of various substrate coatings and artificial leathers, and ensures that significant water-repellent and anti-fouling abilities, extremely excellent extension performance, excellent low-temperature high flexibility and anti-bending performance of product coating films can be achieved; and the product is safe and environment-friendly, and is convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

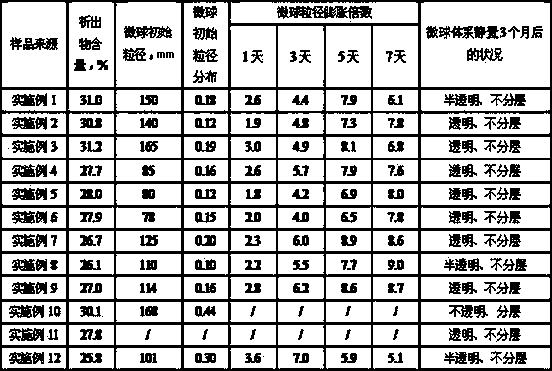

Polyacrylamide reversed-phase microemulsion profile control system

ActiveCN104277175AThe polymerization reaction is stableEasy to controlDrilling compositionCross-linkMicrosphere

The invention relates to a polyacrylamide reversed-phase microemulsion profile control system, and mainly solves the problems in the prior art that a polymer microballon subjected to profile control is easily broken through by water flooding and is bad in expansion property at a high temperature and a high salinity. The polyacrylamide reversed-phase microemulsion profile control system is prepared from a reversed-phase microemulsion under the effect of an oxidation reduction composite initiator through a polymerization reaction. The reversed-phase microemulsion comprises, in parts by weight, 1) 10-70 parts of an oily solvent, 2) 1-25 parts of an emulsifier, 3) 0.01-15 parts of a hydrophobic monomer, 4) 5-60 parts of acrylamide, 5) 1-40 parts of a water-soluble temperature-resistant salt-resistant monomer, 6) 0.001-5 parts of a cross-linking agent, and 7) 10-60 parts of water. The technical scheme relatively well solves the problems and applicable to tertiary oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

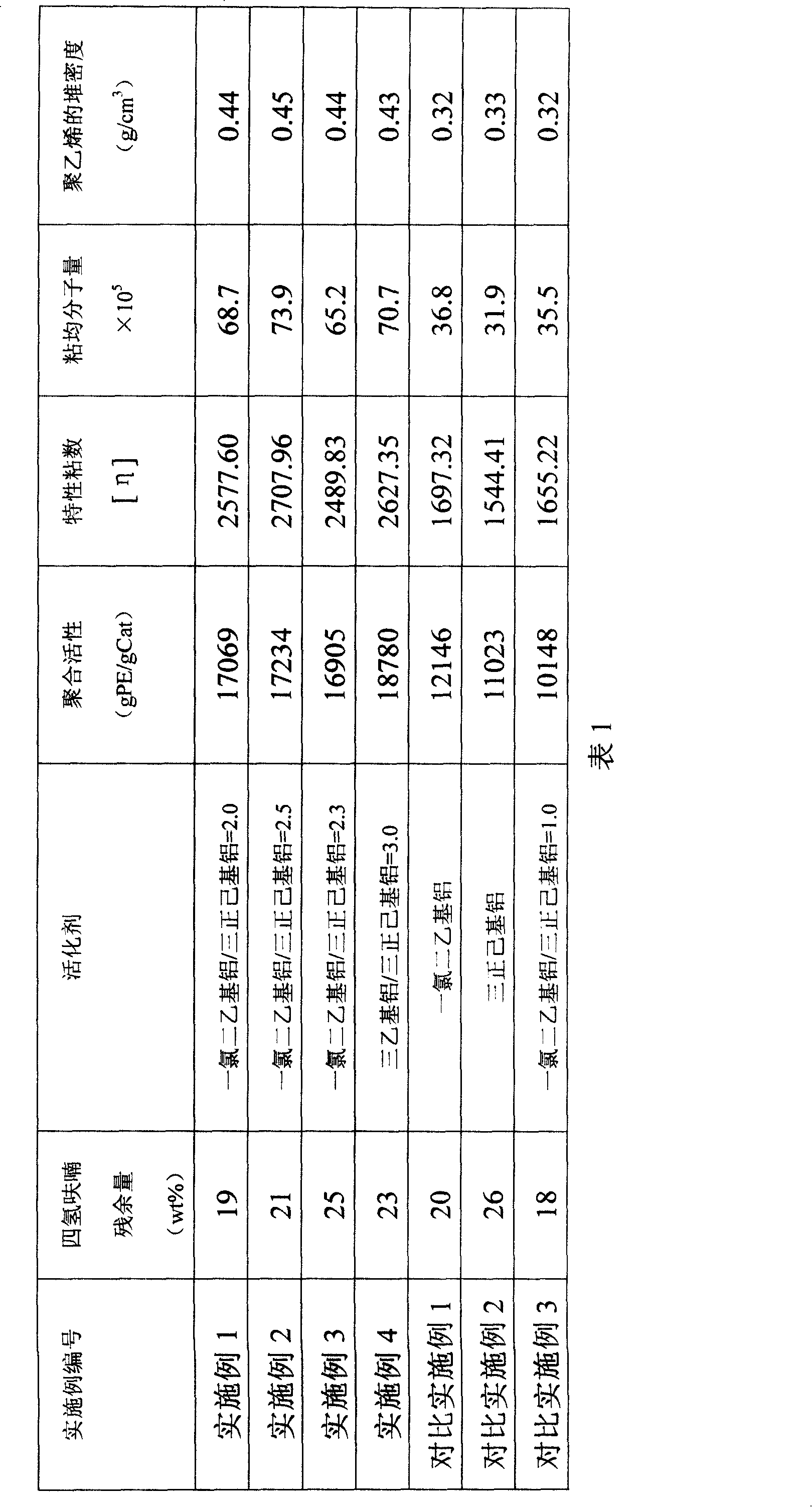

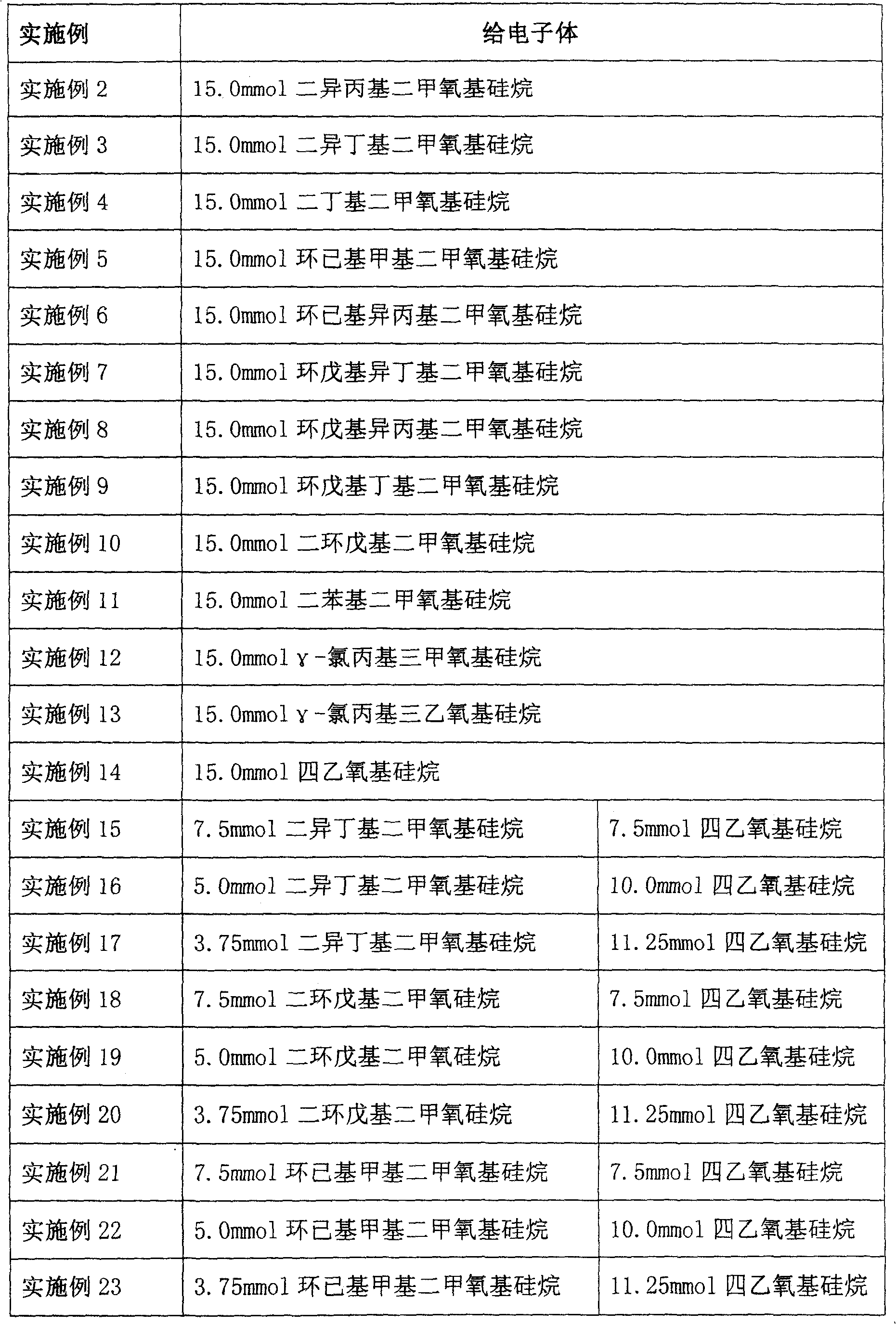

Method for preparing superhigh molecular weight polythene catalyst and application thereof

InactiveCN101235109ASimple manufacturing methodHigh polymerization activityBulk chemical productionPolymer scienceHigh activity

The invention relates to a preparation method of super high molecular weight polyethylene catalyst, which is characterized by comprising: (1) preparing the main components of ti-containing catalyst; (2) pre-activating the main components of a ti-containing catalyst; (3) using a catalyst promoter to completely activate the pre-activated main components of ti-containing catalyst. Compared with the prior art, the invention provides a preparation method of super high molecular weight polyethylene catalyst with high stack density and high activity, while the catalyst can be used for ethane polymerization directly, without pre-polymerization, thereby simplifying polymerization.

Owner:SHANGHAI RES INST OF CHEM IND

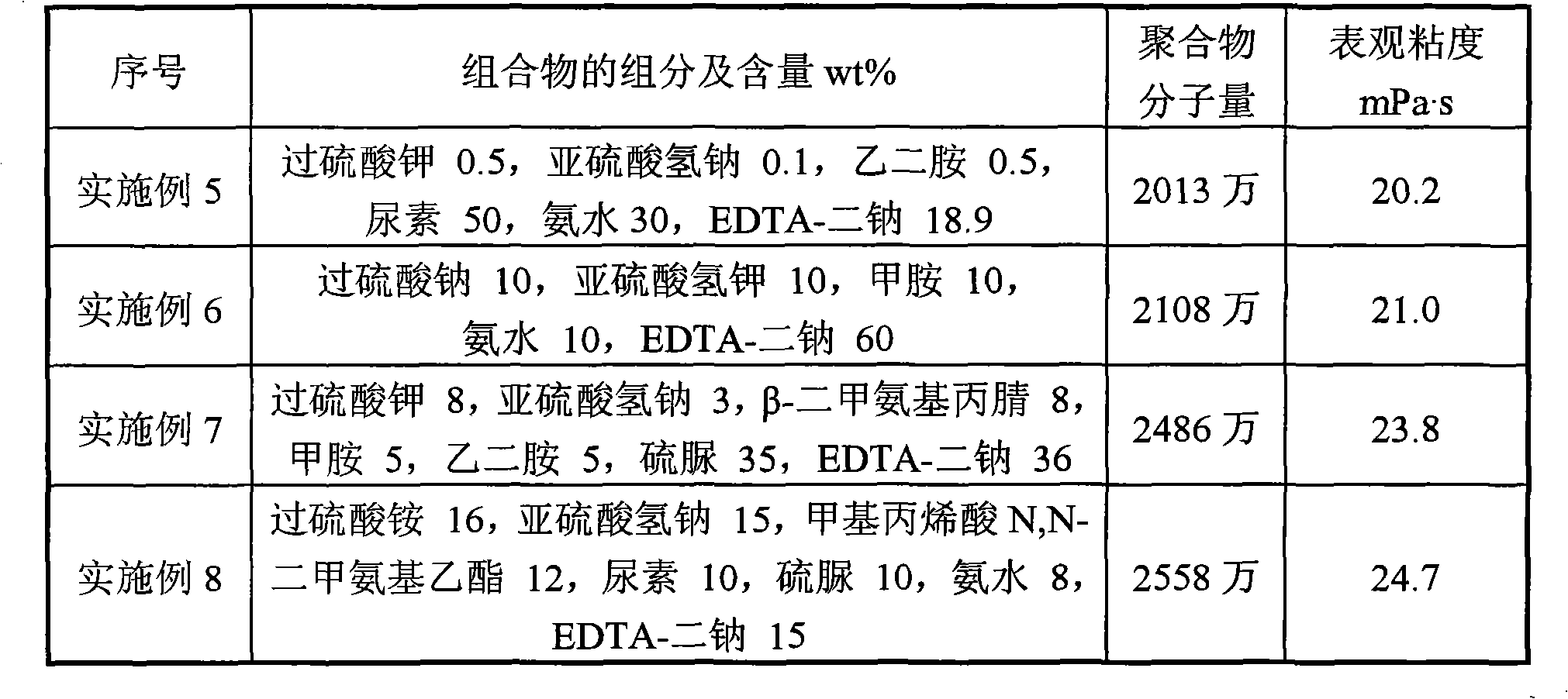

Initiator composition used for synthesizing polyacrylamide capable of displacing oil

ActiveCN102372806AImprove solubilityEven growthDrilling compositionEthylenediamineAmmonium compounds

The invention relates to an initiator composition used for synthesizing polyacrylamide capable of displacing oil, which mainly solves the problems of low polyacrylamide molecular weight, poor heat resistance and salt resistance performances and difficult satisfaction for technical requirement of tertiary oil extraction. The initiator composition used for synthesizing polyacrylamide capable of displacing oil comprises the following ingredients by weight percentage: (a) 0.5-20% of persulfate; (b) 0.1-40% of sulfite or acid sulfite; (c) 0.5-20% of NR1R2R3-represented trialkylamine compounds or N<+>R4R5R6R7-represented quaternary ammonium compounds or NH2R8-represented aliphatic amine compounds, wherein R1-R7 in the formula are selected from C1-C14 straight chain or branched chain alkyl or alkyl derivatives, R8 is selected from straight chain or branched chain alkyl or alkyl derivatives; (d) 10-80% of urea, thiourea or ammonia liquor; (e) 5-60% of ethylenediaminetetraacetic acid. The technical scheme of the invention better solves the problems and can be used in industrial production of oil displacement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-strength high-temperature-resistance polymer nanospheres

InactiveCN103992433AThe polymerization reaction is stableIncrease reaction rateDrilling compositionMicrosphereActive agent

The invention relates to a preparing method of high-intensity high-temperature-resistance polymer nanometer microspheres. The preparing method comprises the following characteristic process steps that itaconic acid is neutralized by a sodium hydroxide solution; acrylamide, cross-linking agents and a hectorite aqueous dispersion are added; the mixture is uniformly stirred, and a monomer and hectorite mixed solution is obtained; then, the monomer and hectorite mixed solution is added into a three-necked flask containing oil-soluble solvents and Span80 / Tween80 composite surfactants; uniform stirring is carried out, and a transparent reversed-phase microemulsion is formed; the reversed-phase microemulsion is heated, then, a certain amount of oxidizing agents and reducing agents are added for initiating reversed-phase microemulsion polymerization; and demulsification, precipitation, washing, drying and fine grinding are carried out, and white polymer nanometer microsphere powder is obtained. The polymer nanometer microspheres prepared by the preparing method provided by the invention have the proper water absorption and salt absorption properties, better water absorption swelling property, higher jelly strength and higher temperature resistance, and meet the ultra-low permeability reservoir profile control and water shutoff requirements that the water absorption speed of polymer deep profile control agents is not suitable to be too high or too low, the water absorption rate is not suitable to be too high or too low, the permeability is smaller than 1*10<-3>[mu]m<2>, and the pore throat radius is smaller than 8[mu]m.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Oil-displacing agent composition used for improving recovery ratio of high-temperature reservoir and preparation method of composition

ActiveCN103666433AHigh molecular weightIncrease the relative molecular massDrilling compositionActive agentCarboxylic acid

The invention relates to an oil-displacing agent composition for improving a recovery ratio of a high-temperature reservoir and a preparation method of the composition, mainly solving the problems that a polymer-containing oil-displacing agent in the prior art is poor in temperature resistance, salt resistance and thermal stability resistance, and low in displacement efficiency. In order to solve the problems better, a following technical scheme is adopted as follows: the oil-displacing agent composition comprises the following components in percentage by weight: 0.005%-8.0% of high-temperature-resistant and oil-displacing acrylamide polymers, 0.005%-5.0% of a fatty alcohol polyoxyethylene ether carboxylate surfactant and 87.0%-99.99% of injected water. The preparation method of the oil-displacing agent composition comprises the following steps: regulating a pH value; ventilating a nitrogen gas and removing an oxygen gas; carrying out hydrolysis reaction; drying, crushing and sieving to obtain acrylamide polymers; stirring the acrylamide polymers, the fatty alcohol polyoxyethylene ether carboxylate and the injected water for 0.5 hour-5 hours at 5 DEG C-45 DEG C, and uniformly mixing to obtain the oil-displacing agent composition. And therefore, the oil-displacing agent composition can be used for tertiary oil recovery production of the high-temperature reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing high water absorbing resin by process of reversed phase suspension polymerizing polypropylene

This invention relates to a method to prepare superabsorbent polycrylic acid (or its salt) resin by verse-suspension polymerization, with cyclohexane adopted as solvent, crylic acid as monomers, K2S208 as initiators and N, N'-methylenebisacrylamide as cross-linking reagent. It has the characteristics that the dispersants for verse-suspension in the reaction system can be monoglyceryl ester or octadecyl phosphatide / span-60 complex or octadecyl phosphatide / monogylceryl ester complex and the dispersants weigh 2~20% of crylic acid monomers. The superabsorbent polycrylic acid resin prepared in this invention is white or light yellow visible impurity-free gel solid or solid particles, with sufficient gel strength, a water absorption of over 600ml / g and a salt solution absorption of over 70ml / g.

Owner:ZHEJIANG UNIV

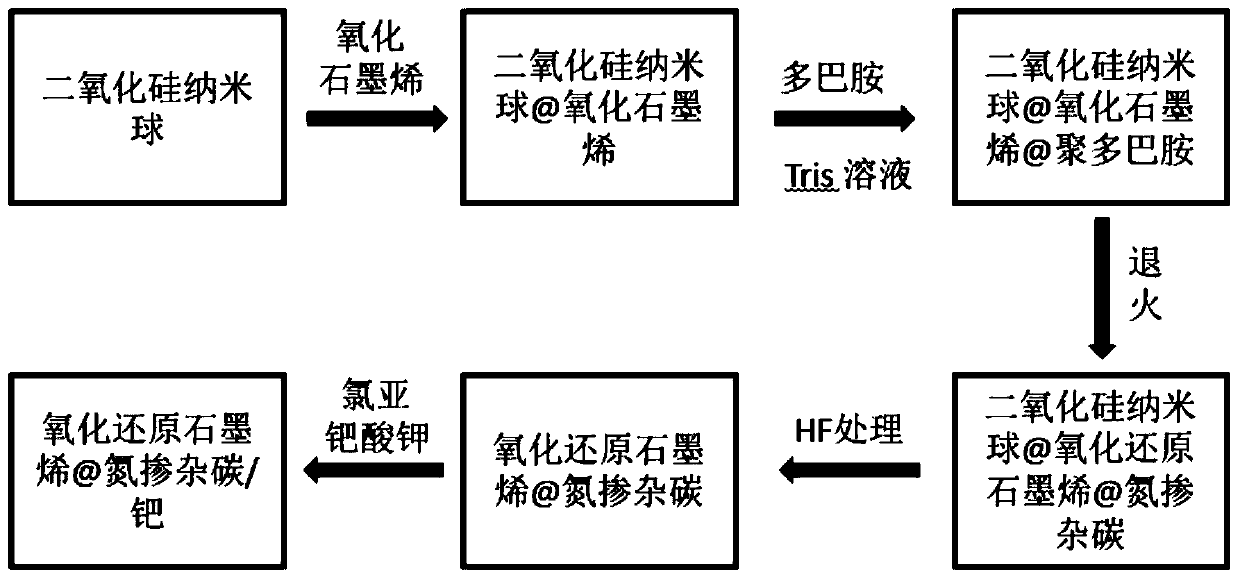

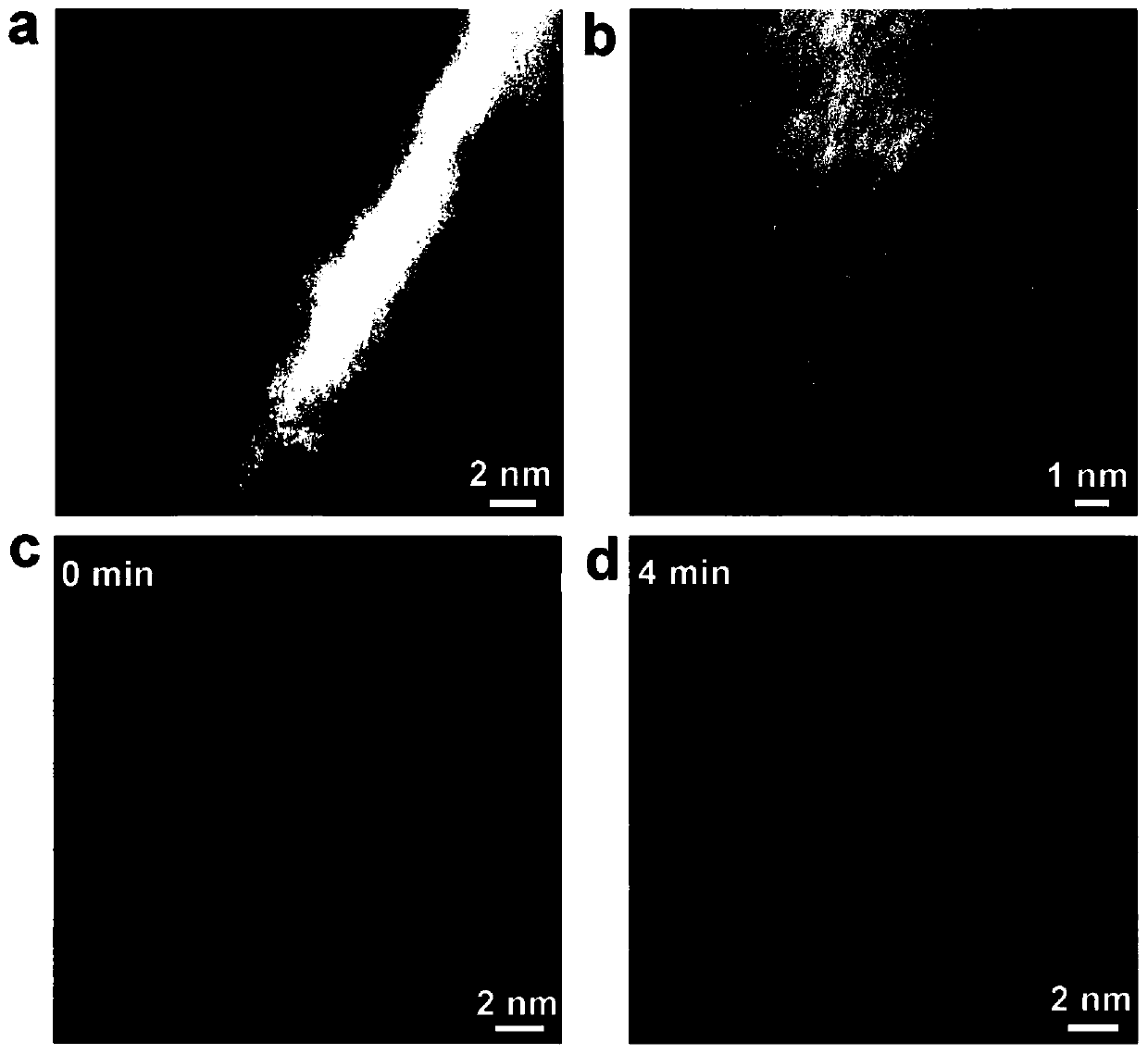

Monatomic catalyst, and preparation method and application thereof

InactiveCN110787827AImprove stabilityEnhanced interactionPhysical/chemical process catalystsOrganic compound preparationPtru catalystOrganic chemistry

The invention belongs to the field of catalysts, and discloses a monatomic catalyst, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) synthesizing a SiO2-coated GO composite material by coating SiO2 nanospheres with graphene oxide; (2) synthesizing a SiO2-coated GO-coated PDA composite material by coating the SiO2-coated GO composite material with polydopamine; (3) synthesizing an RGO-coated NC composite material by coating reduced graphene oxide with nitrogen-doped carbon; and (4) synthesizing an RGO-coated NC / Pd monatomic catalystby loading the RGO-coated NC composite material with Pd monatoms. According to the preparation method disclosed by the invention, the overall process flow of the preparation method is set, and the reaction conditions and parameters of each key process step are improved, so that the dispersity, the catalyst activity and the cycling stability of metallic single atom can be effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

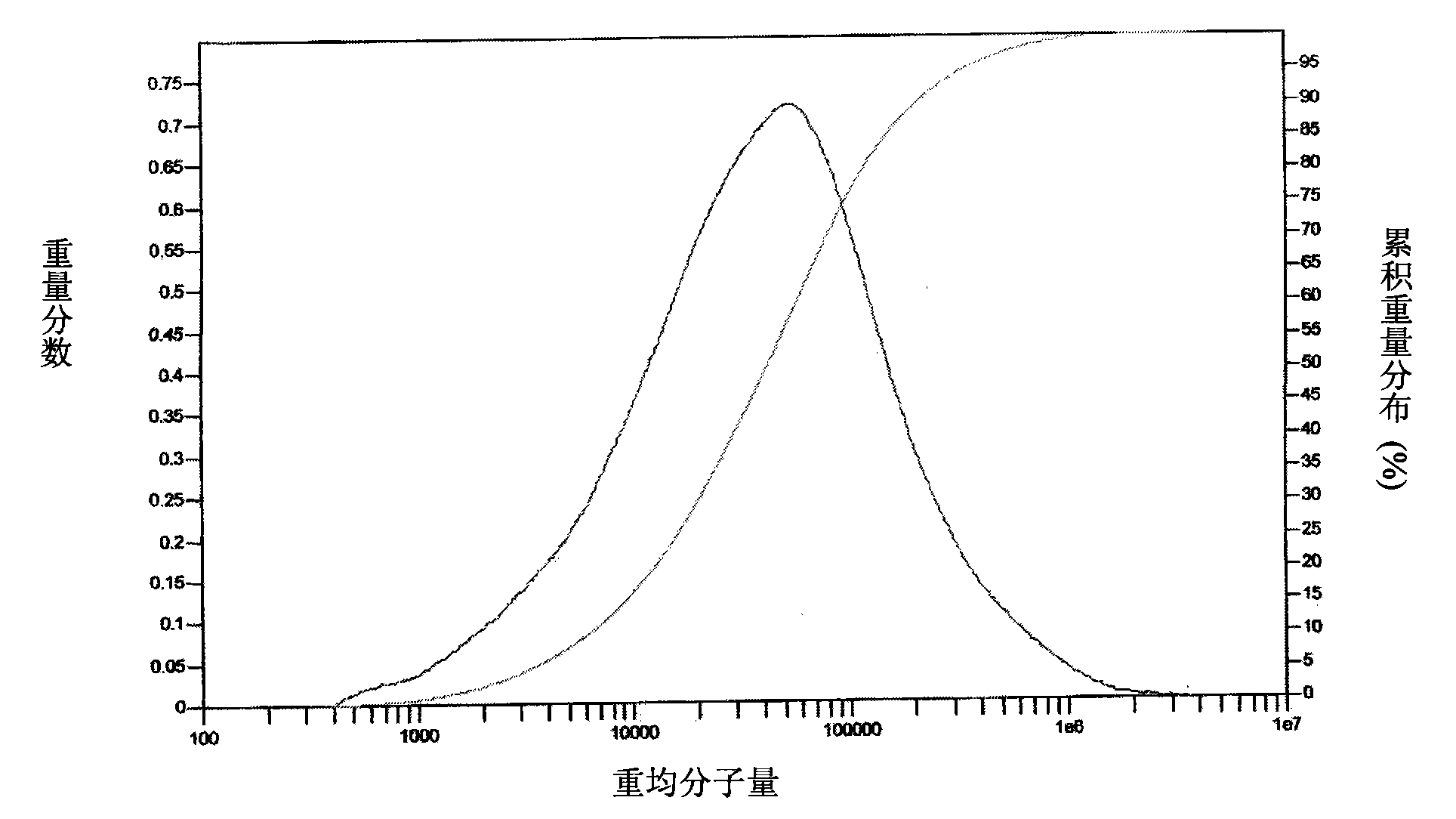

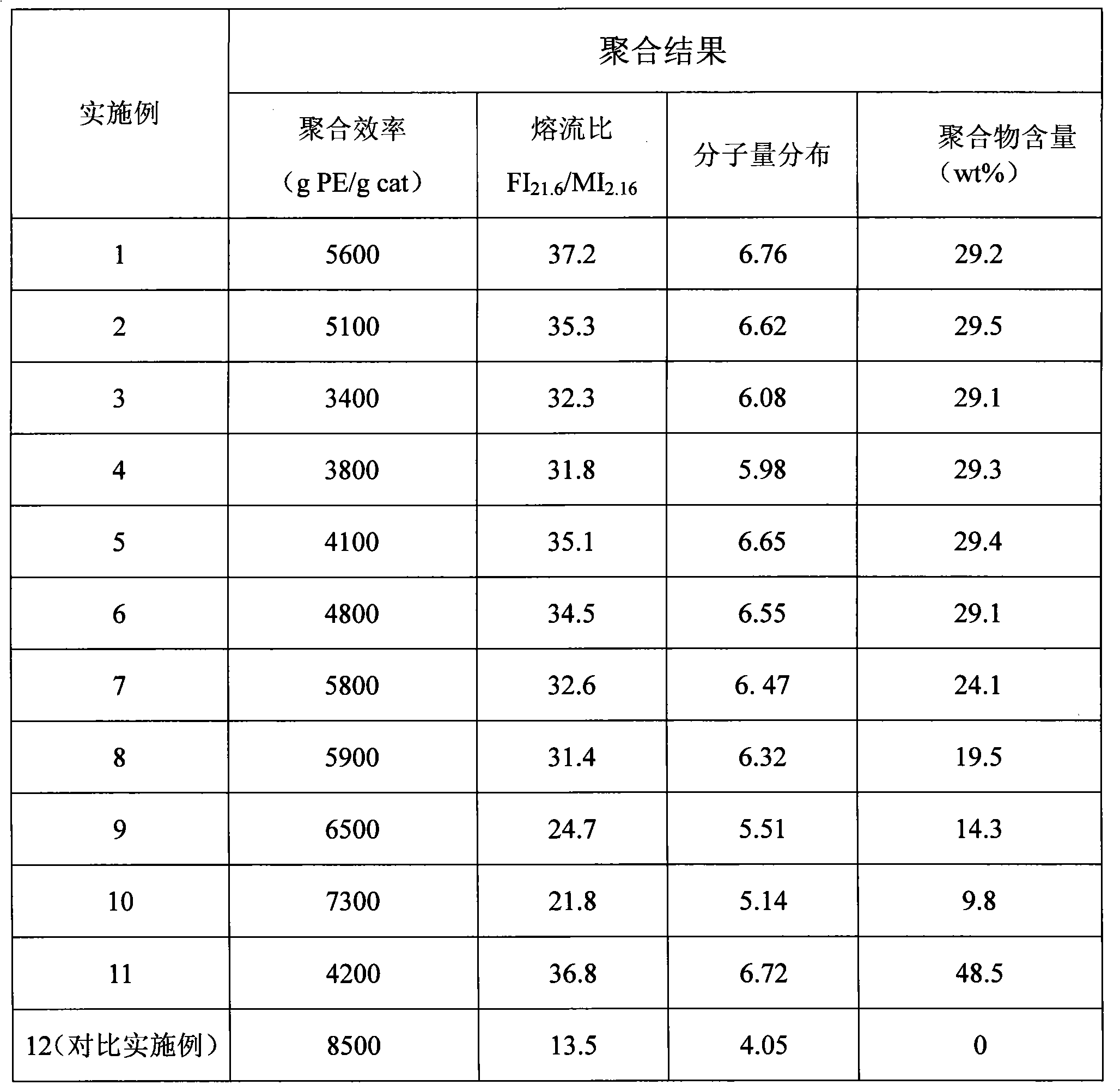

Ziegler-Natta polyethylene catalyst with wide molecular weight distribution, and preparation method thereof

InactiveCN101880339AThe polymerization reaction is stableThe reaction process is simpleBulk chemical productionAluminiumPolymerization catalysts

The invention relates to a Ziegler-Natta polyethylene catalyst used for vinyl polymerization, a preparation method and an application thereof. The main catalyst component of vinyl polymerization catalyst is prepared by the reaction with the following method: using magnesium powder as raw material for reaction to generate new ecological halide; leading the new ecological halide to have complexation reaction with titanium compound and treated silicon dioxide under the condition that electron donor exists; leading complexation product to have contact reaction with alkyl aluminium compound in alkane solvent system; and after heating and drying, having complexation reaction on the product of the contact reaction and polymer containing polar functional group in the alkane solvent system. The polyethylene catalyst is formed by the main catalyst component and cocatalyst metal organic compound, is higher in polymerization activity, and has the advantage that the produced polymer has wider molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for improving ageing whiteness of vinyl chloride resin

The invention provides a method for improving ageing whiteness of vinyl chloride resin. The method comprises the following steps: adding water, dispersing agent, vinyl chloride monomer, initiator, fisheye resisting agent and pH regulator in a reaction kettle for polymerization, and adding terminator and antioxidant in the reaction system simultaneously to obtain vinyl chloride resin, wherein the pH regulator is ammonium hydrogen carbonate, the antioxidant is imperfectly hindered phenol chain terminator antioxidant, the weight ratio of pH regulator to antioxidant is 1:1.76-2. In the inventive method, the resin particle size distribution width is lowered, resin particle shape is more regular, the heat resistance of the produced vinyl chloride resin is enhanced, the ageing whiteness index is obviously improved, and inherent quality of resin is enhanced. The polymerization in the production process is stable, quality repeatability of resin of each batch is good, and the new aid adopting composite preparation method can be applied in cauldron industrialized production.

Owner:SHANGHAI CHLOR ALKALI CHEM

Method for producing high absorptive resin

A process for preparing high-hydroscopicitiy resin includes prepolymerization between monomers to be polymerized, trigger, system and cross-linking agent, and polymerizing to obtain gel-state solid product. Its advantages are high hydroscopicity (500-2000 g / g for deionized water), high water absorbing speed (less than 10 S) and high gel strength after the water is absorbed by it.

Owner:KEYUAN PRODIVE POWER PROMOTION CENT OF PETROCHEM IND SHANDONG

Method for producing high-degree of polymerization polyvinyl chloride resin by using suspension method

The invention discloses a method for producing high-degree of polymerization polyvinyl chloride resin by using a suspension method, which comprises the following steps of: step 1, charging by adopting a constant-temperate water feeding technology, a whole-process airtight feeding technology and a DCS (Distributed Control System) automatic control technology; step 2, producing the high-degree of polymerization polyvinyl chloride resin by adopting a low-temperature method; and step 3, obtaining the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000. With the adoption of the method for producing the high-degree of polymerization polyvinyl chloride resin by using the suspension method, the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000 can be produced in a 70 m<3> polymerization kettle system, has the advantages of low energy consumption, large batch production and stable quality and can be produced in the whole year.

Owner:HANGZHOU ELECTROCHEM GROUP

Preparation die for polymer optical fiber prefabricated bar and preparation method for the prefabricated bar

InactiveCN101564877AEasy to separateThe material has good chemical stability and heat resistanceCladded optical fibreOptical articlesEngineeringFiber

The invention provides a reaction die for a polymer optical fiber prefabricated bar, which includes a non-rigid polymerization container with closed lower end, a removable top cover and a tense polytetrafluoroethylene rope or metal wire, wherein the top cover is provided with a hole which makes an inner cavity of the polymerization container communicated with outside, circumference of the top cover is closely combined with the polymerization container, the polytetrafluoroethylene rope or metal wire is arranged at axle center of the polymerization container and penetrates overall length of the polymerization container. The reaction die has simple structure, and is suitable for industrial popularization. The invention also provides a method for preparing the polymer optical fiber prefabricated bar by using the reaction die. The method has simple operation, and is easy for industrial use, the prefabricated bar prepared by the method has flattening surface, less bubble, obvious fiber core cladding boundary and controllable diameter, is easy to be drawn to form fiber and realize doping to prepare various functional optical fiber prefabricated bar.

Owner:UNIV OF SCI & TECH OF CHINA

Efficient clay inhibitor for shale gas fracturing and preparation method of efficient clay inhibitor

InactiveCN104312575AGood compatibilityIncrease productivityDrilling compositionAcetic acidSwelling ratio

The invention discloses an efficient clay inhibitor for shale gas fracturing and a preparation method of efficient clay inhibitor. The efficient clay inhibitor for shale gas fracturing comprises the following raw materials in parts by weight: 650-850 parts of water, 190-230 parts of cationic monomer, 100-140 parts of acrylamide, 0.5 part of EDTA, 0.5-3 parts of an initiator A and 0.5-3 parts of an initiator B. According to the invention, the solid content of the synthesized efficient clay inhibitor is about 35%, and an anti-swelling ratio is 80.3% when the dosage is 0.5%; the efficient clay inhibitor is an excellent clay inhibitor with less dosage, quick action and low price. In addition, the efficient clay inhibitor has high temperature resistance, more durable shale stability and excellent compatibility. According to the efficient clay inhibitor for shale gas fracturing, the production synthesis temperature is 40 DEG C, the polymerization reaction is stable, the production efficiency is high, and the product performance is very stable.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +2

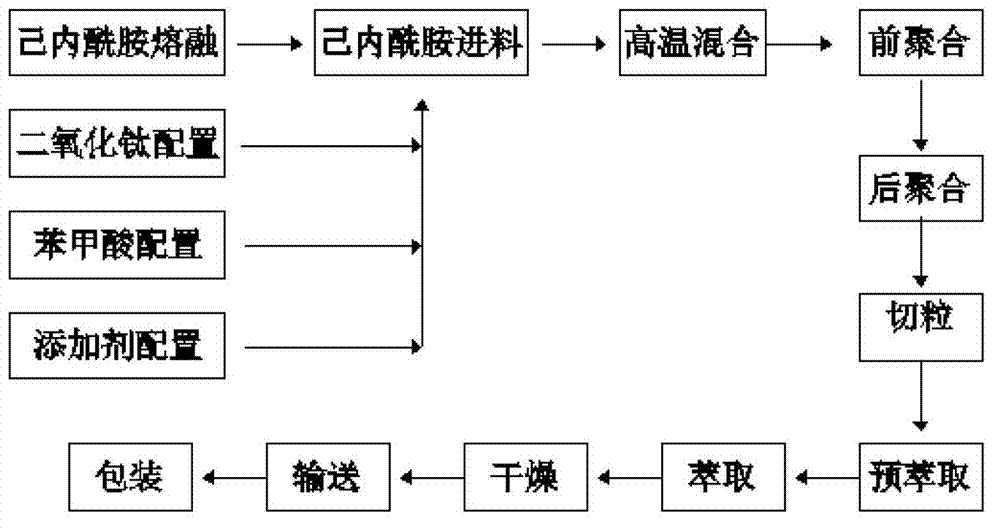

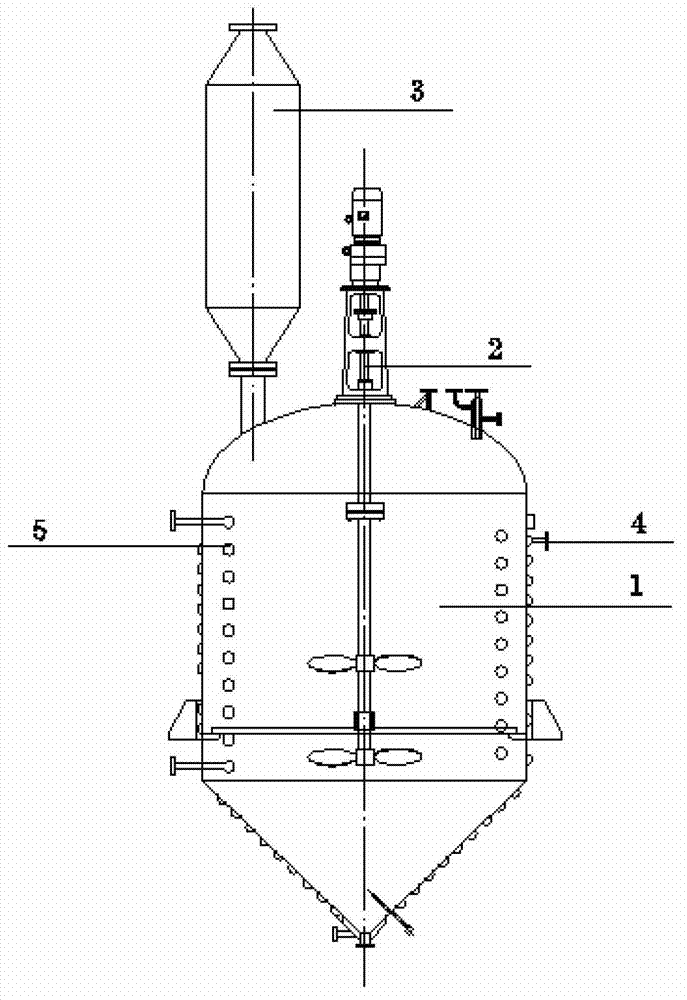

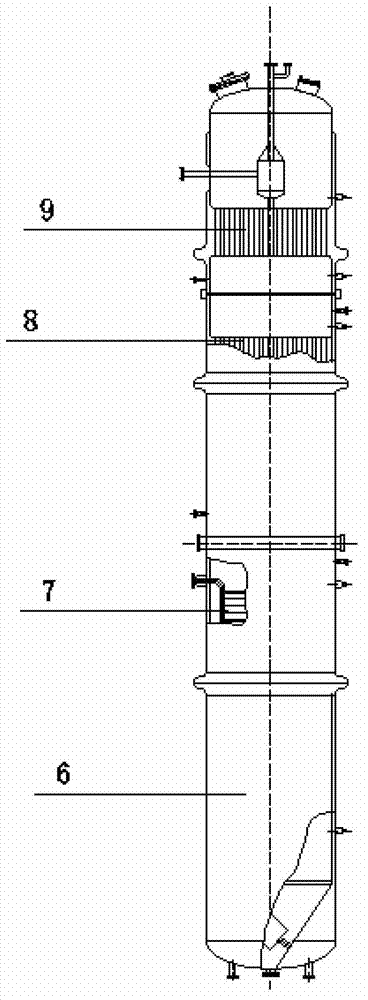

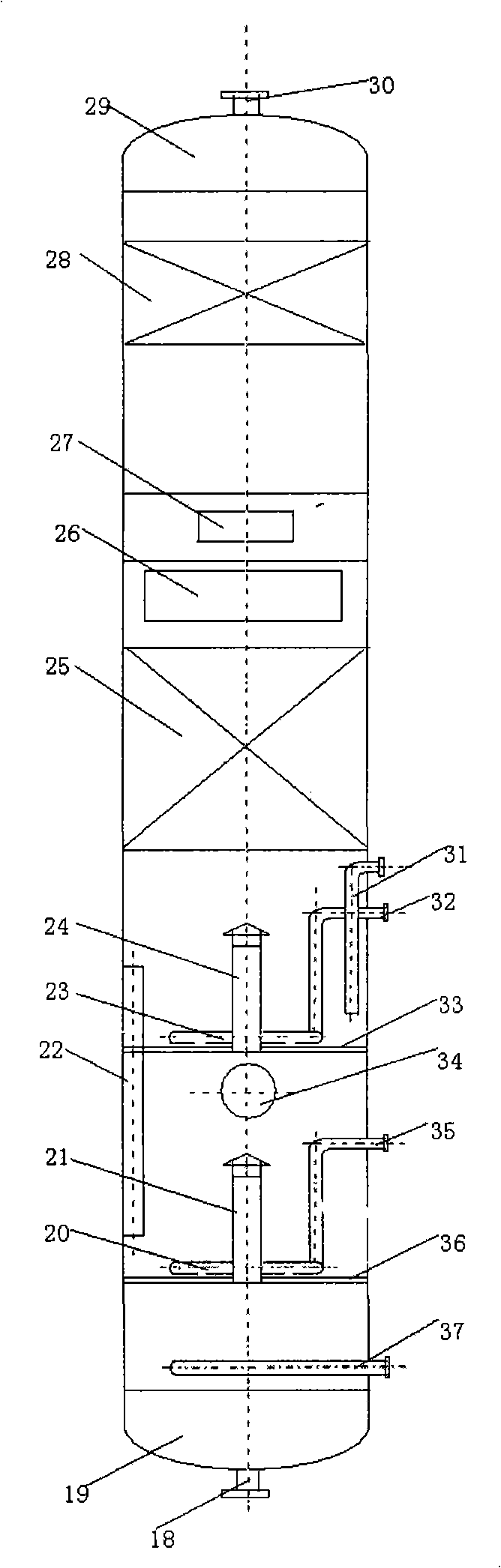

Polymerization manufacturing technique and device for polyamide

The invention relates to a polymerization manufacturing technique and device for polyamide. The manufacturing technique comprises the steps of feeding molten caprolactam, titanium dioxide, benzoic acid and an additive, dynamically mixing at a high temperature for prepolymerization and postpolymerization, granulating, pre-extracting, extracting and drying to obtain the final product. The device comprises a melting system, a feed system, a high-temperature dynamic mixing system, prepolymerization and postpolymerization towers, a pre-extraction column, an extraction column, a recycling system and a drying tower. According to the invention, a high-temperature dynamic mixing tank is set additionally. The mixing of the raw materials and hydrolysis for ring opening and dehydration of polyamide are performed at a state of dynamically mixing to achieve a more sufficient and stable pre-addition polymerization and a more uniform and stable molecular distribution of post-polycondensation. A slice and a water separator of the extraction column are used for mainly extracting oligomers through the pre-extraction column and extracting a caprolactam monomer through the extraction column with a stable concentration. A slice cooler of the drying tower is used for cooling the slices rapidly. An extraction water recycling system is used for recycling the oligomers in the pre-extraction water and the caprolactam monomer in the extraction water.

Owner:武汉森大科技研究发展中心

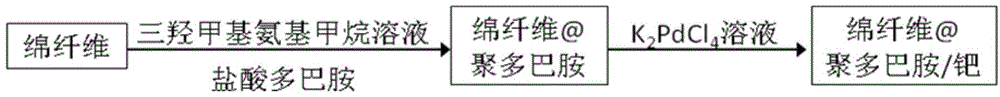

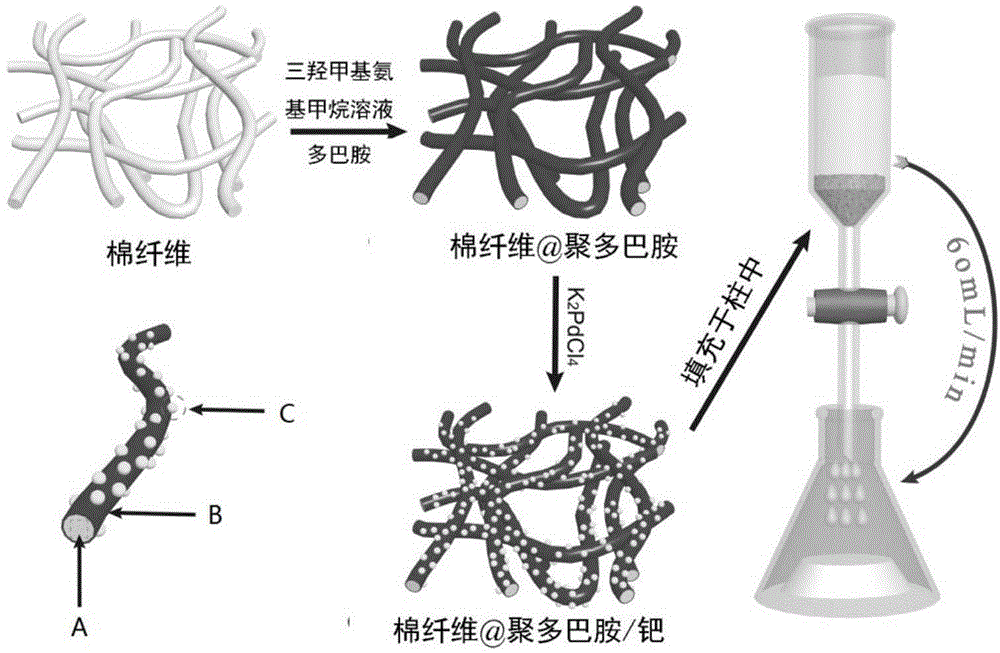

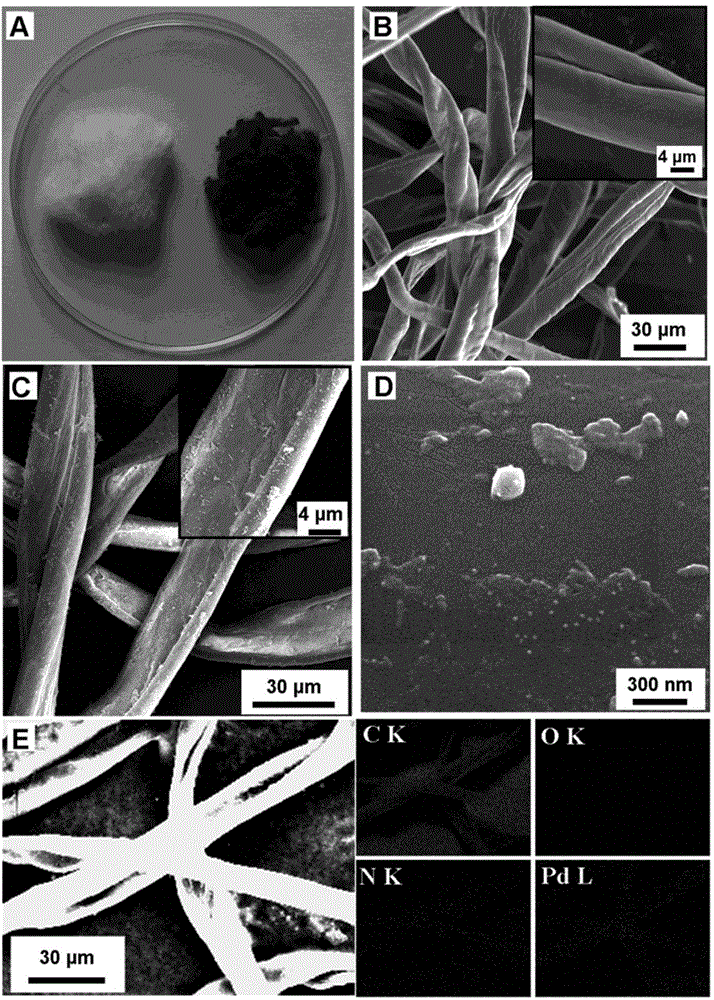

Preparation method and application of fibrous catalyst

InactiveCN104549499ACatalytic activity is not affectedEasy to separate and recycleOrganic-compounds/hydrides/coordination-complexes catalystsFiberPolymer science

The invention discloses a preparation method and application of a fibrous catalyst. The preparation method comprises the following steps: (1) synthesizing a fiber @ polydopamine composite material; (2) preparing a fiber@ polydopamine-precious metal composite material; (3) finally obtaining the fibrous catalyst. The fibrous catalyst is applied to fixed beds. By using reaction materials which are low in cost and easy to get, the prepared fibrous catalyst is easy to separate and recover, can be applied to fixed beds, can be used for realizing continuous catalystic reaction, has positive effect for reducing the application cost of the catalyst and has the advantage of improving the production efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

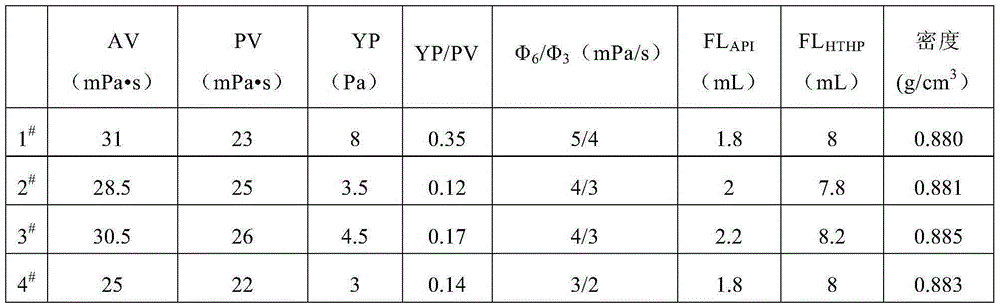

Whole oil-based drilling fluid viscosifier and preparation method thereof

InactiveCN106753289AThe polymerization reaction is stableFully polymerizedDrilling compositionPolyesterPolyol

The invention provides a whole oil-based drilling fluid viscosifier and a preparation method thereof. The preparation method for the whole oil-based drilling fluid viscosifier comprises the steps: 1) uniformly mixing 15-50 parts by weight of polyester polyol, 5-15 parts by weight of a polymerization promoter and 50-150 parts by weight of a solvent at room temperature so as to obtain a mixture; 2) heating the mixture to 40-60 DEG C, adding 15-80 parts by weight of isocyanate and 0.3-1.0 part of a polymerization catalyst under a stirring condition, and continuing to heat the mixture to 70-90 DEG C and enabling the mixture to react for 3-5 h so as to obtain an intermediate product; and 3) cooling the intermediate product to 40-50 DEG C, adding 5-15 parts by weight of a polymerization promoter, heating to 60-80 DEG C and continuing a reaction for 2-3 h so as to obtain the whole oil-based drilling fluid viscosifier. The whole oil-based drilling fluid viscosifier prepared by the preparation method can effectively improve suspension stability of a drilling fluid and improve the rheological property of the drilling fluid without changing the density of the drilling fluid; and therefore, the whole oil-based drilling fluid viscosifier is suitable for exploration and development of low pressure reservoirs.

Owner:PETROCHINA CO LTD

Preparation method of ultra-high molecular weight cationic polyacrylamide

The invention relates to a preparation method of ultra-high molecular weight cationic polyacrylamide, which belongs to the acrylamide aqueous solution polymerization technical process. The method is characterized in that a cation monomer is acryloyloxyethyl trimethyl ammonium chloride or methacryloyloxyethyl trimethyl ammonium chloride, the amount of the cation monomer accounts for 5-60% of mass of the mixed monomer; an single azoamidine compound initiator is used, the amount of the azoamidine compound initiator accounts for 0.005-0.035% of the monomer mass; initiation is carried out at low temperature, thermal insulating polymerization is carried out, and the initiation temperature is 5-30 DEG C; a cosolvent, a chain transferring agent and addition of the cosolvent account for 2-5% of monomer mass, the addition of the chain transferring agent accounts for 0.01-0.07% of monomer mass, the pH value is adjusted to 6-7, and nitrogen is introduced for removing oxygen for polymerization. The preparation method of ultra-high molecular weight cationic polyacrylamide can prepare the product with relative molecular weight greater than or equal to 25,000,000. The dissolvability is good, the ultra-high molecular weight cationic polyacrylamide accords with the industrial standard, and is easy for large-scale industrial production, and the method can be widely used for the industries of tertiary oil extraction, sewage processing, papermaking, weaving, printing and dyeing and the like.

Owner:CHINA PETROLEUM & CHEM CORP

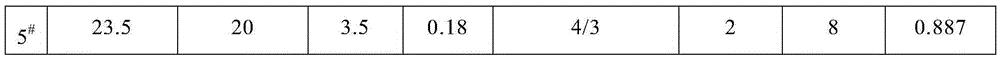

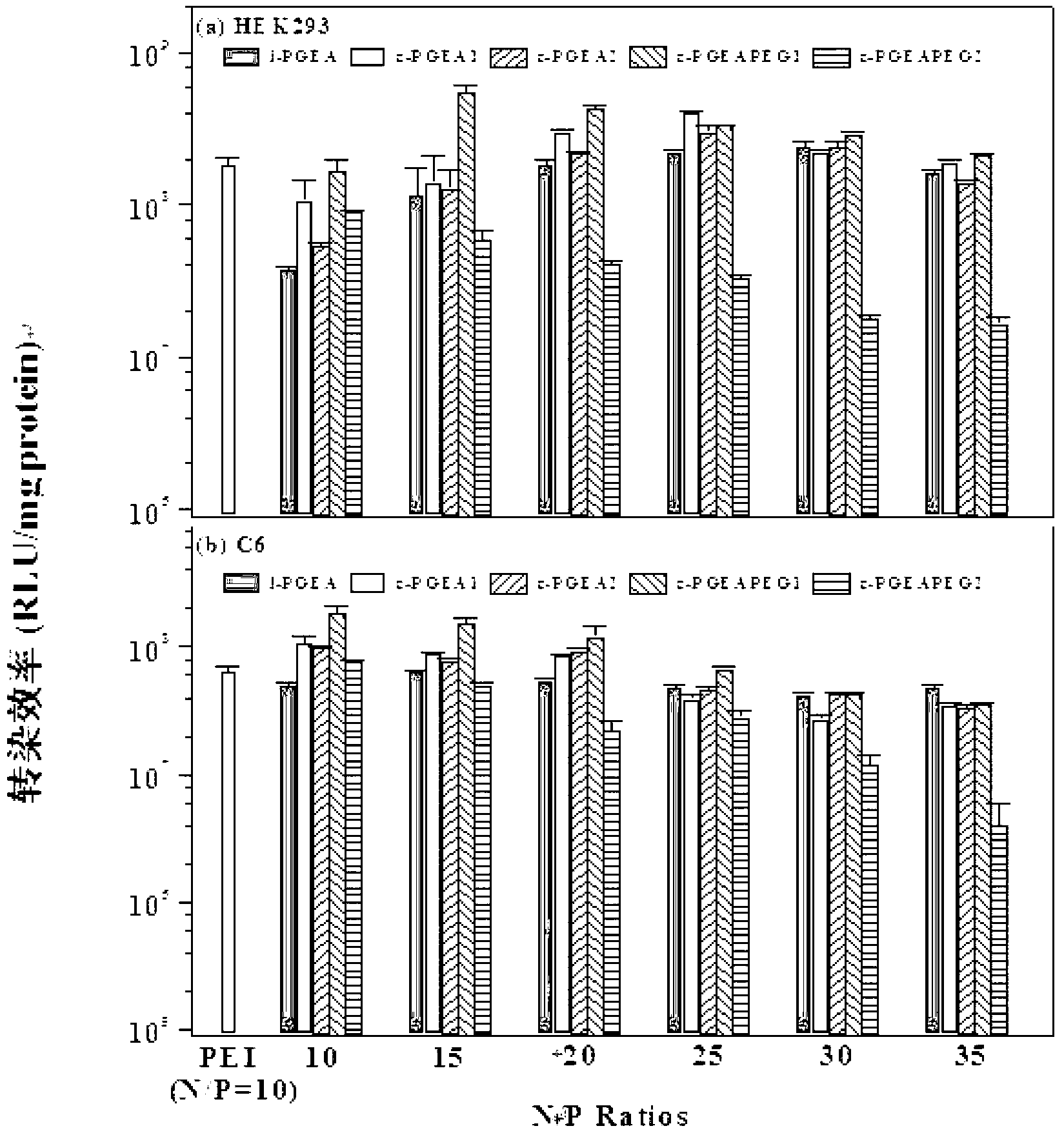

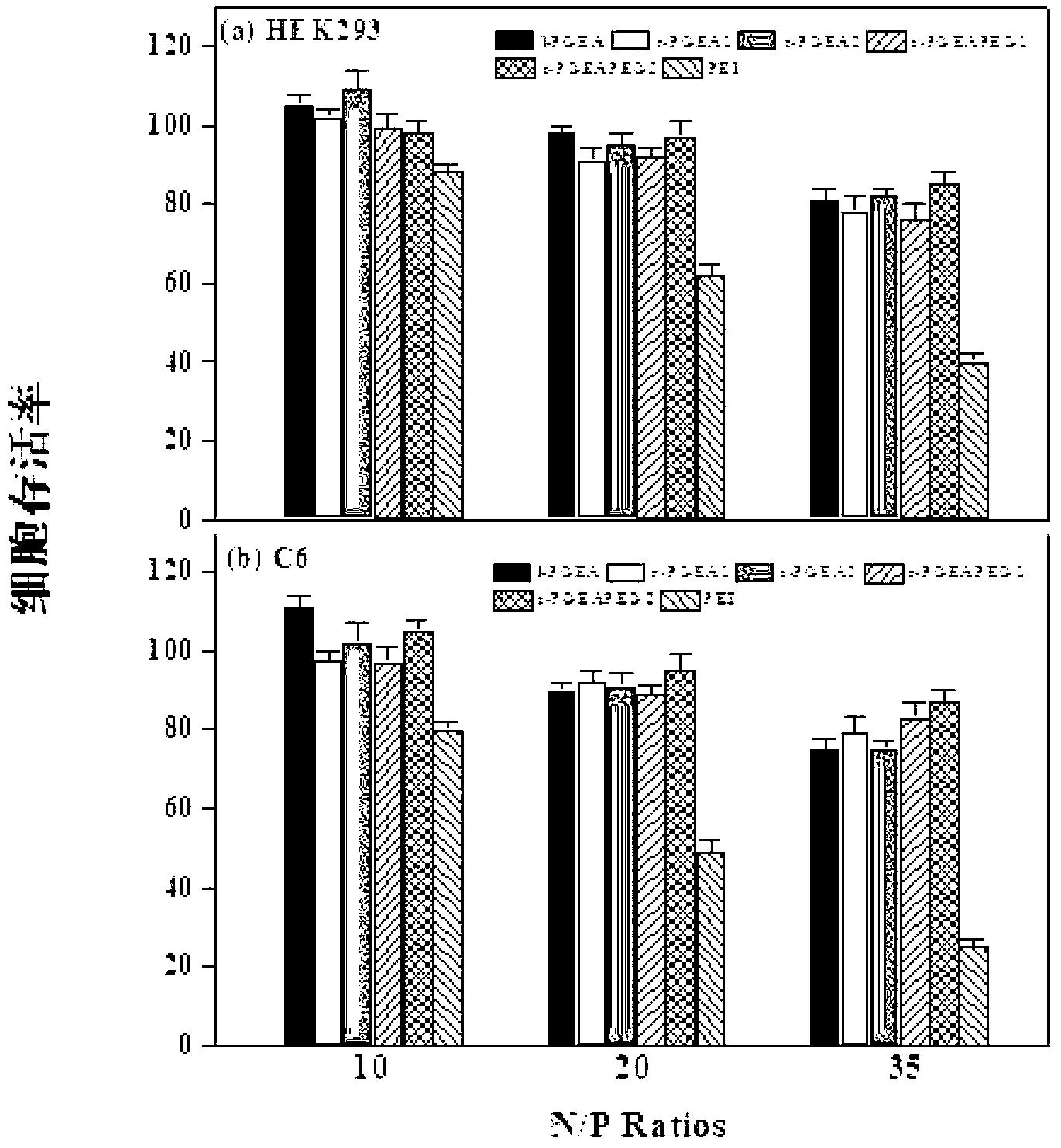

ATRP method for constructing cationic gene vector with PGMA as skeleton

InactiveCN102702407AHigh transfection efficiencyGood storage stabilityOther foreign material introduction processesMethacrylateViral Genes

The invention discloses an ATRP method for constructing a series of low-toxicity and high-efficiency cationic gene vectors with PGMA (polyglyceryl methacrylate) as a skeleton in the technical field of the non-viral gene vectors. The ATRP method is smooth in polymerization reaction and easy to control; according to the ATRP method, a variety of high-performance cationic gene vectors with different molecular weights and narrow molecular weight distribution can be prepared as required; and the prepared cationic gene vectors are good in storage stability, have a transfection efficiency higher than the gold standard PEI in Hepg2, C6, Cos7, HEK293 and other cells, are easy to use and have a commercial potential.

Owner:萨恩化学技术(上海)有限公司

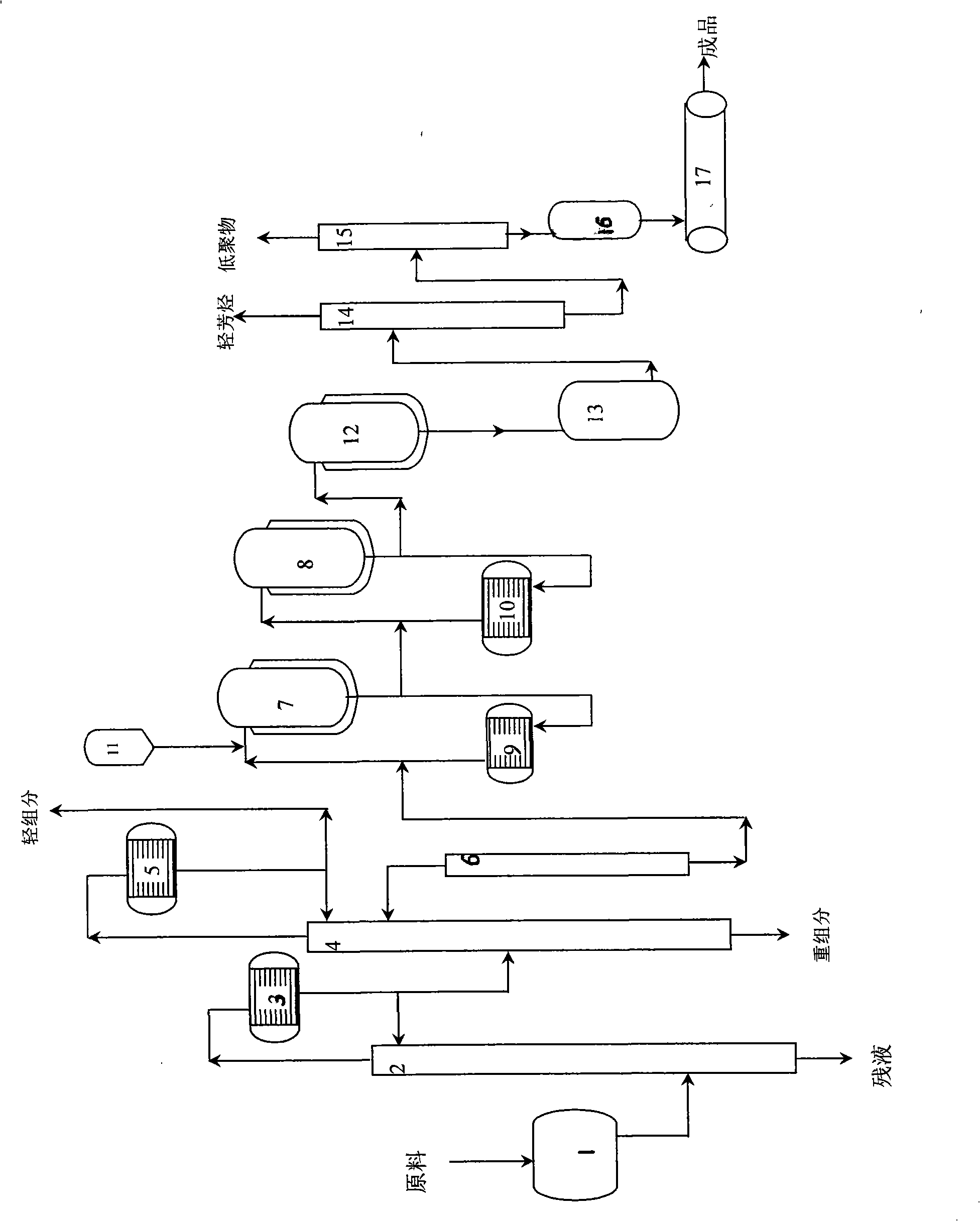

Process and equipment for continuous catalytic polymerization aggregation of C9 petroleum resin

The invention relates to a process and equipment for the continuous catalytic polymerization aggregation of C9 petroleum resin. The process adopts multi-tower refining for separating and refining C9 raw materials, and adopts a continuous catalytic polymerization technique and a solvent and low polymer stripping technique for realizing automatic continuous large-scale production, wherein a stripping tower used in the stripping technique comprises two major parts, namely a distilling section and a stripping section; the distilling section is provided with a plurality of layers of fillers for better separating gas and liquid components; and the stripping section adopts a multi-stage stripping device for stripping. The process and the equipment can overcome the drawbacks in the production process of the conventional process such as uneasy stable control, high energy consumption and unstable product quality. The C9 petroleum resin produced by the process and the equipment is improved in color phase and resin softening point.

Owner:DAQING HUAKE

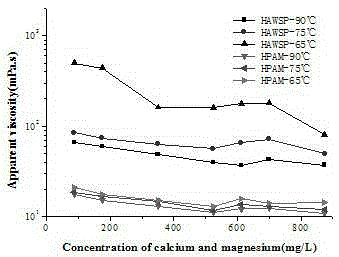

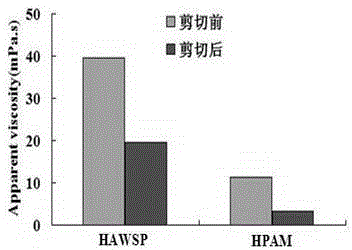

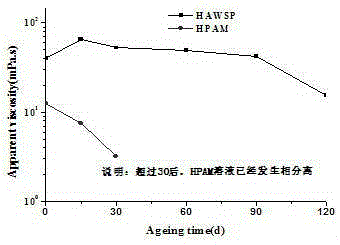

Temperature-resistant and salt-resistant hydrophobic association polymer preparation method

InactiveCN106749887AGood viscosity increasing effectTemperature resistanceDrilling compositionPolymer scienceNitrogen gas

The present invention provides a temperature-resistant and salt-resistant hydrophobic association polymer preparation method, which comprises: (1) sequentially adding deionized water, disodium ethylenediaminetetraacetate, an acrylamide monomer, N,N-dioctylacrylamide, 2-acrylamido-2-methylpropanesulfonic acid, a surfactant, a co-solvent, a chain transfer agent and an inorganic salt to a polymerization kettle, uniformly stirring, and cooling to a temperature of 5-10 DEG C under the action of frozen salt water; (2) introducing high purity nitrogen for 1-2 h, adding a multi-stage composite initiator, carrying out an adiabatic polymerization reaction for 5-7 h, taking out a colloid, and granulating; and (3) adding a hydrolysis agent, carrying out hydrolysis for 2-4 h at a temperature of 90-110 DEG C, and drying for 2-3 h at a temperature of 90-110 DEG C to obtain the temperature-resistant and salt-resistant hydrophobic association polymer. According to the present invention, the prepared temperature-resistant and salt-resistant hydrophobic association polymer has advantages of good tackifying property, good temperature resistance, good salt resistance, good shearing resistance, good long-term stability, and high oil displacement efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

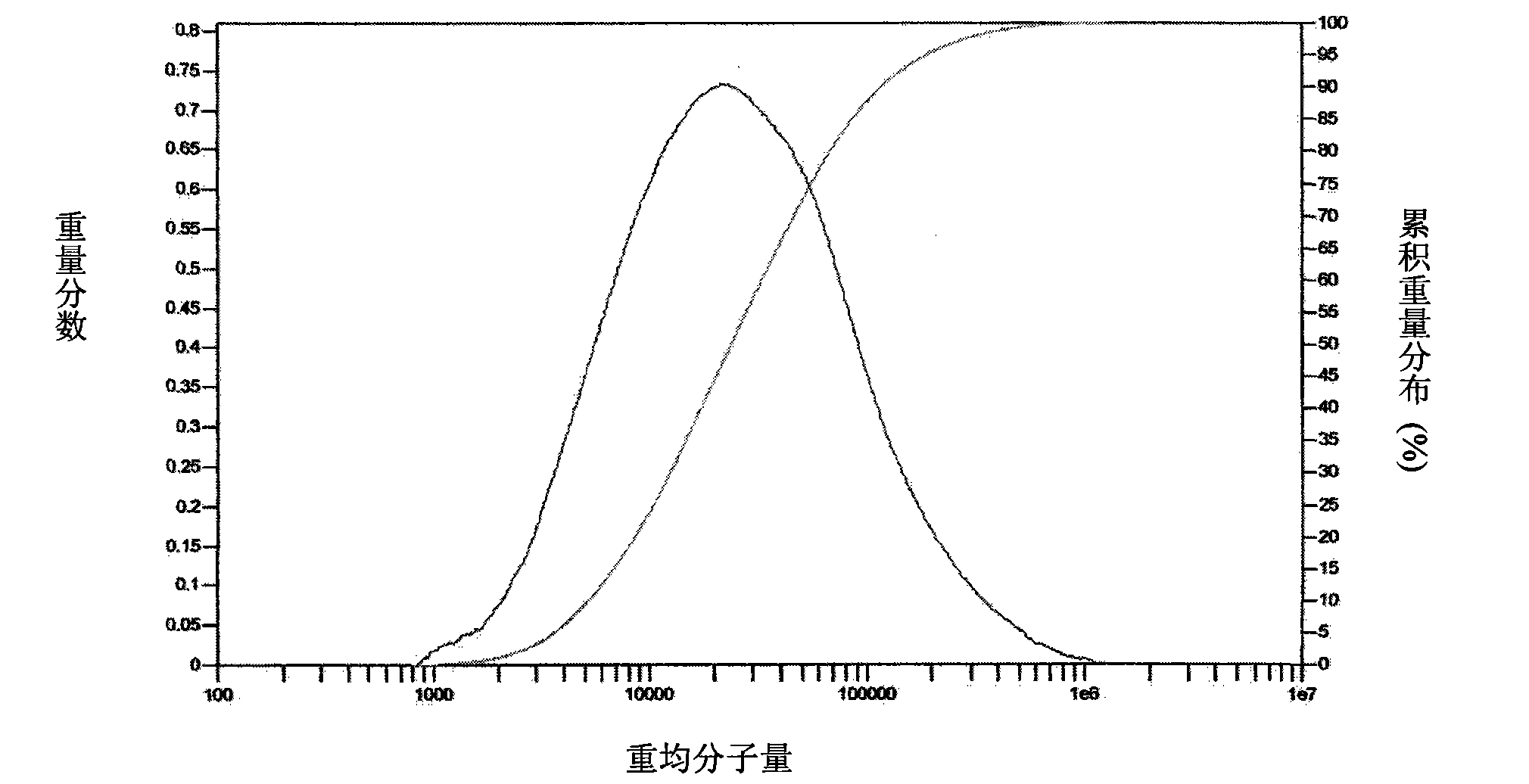

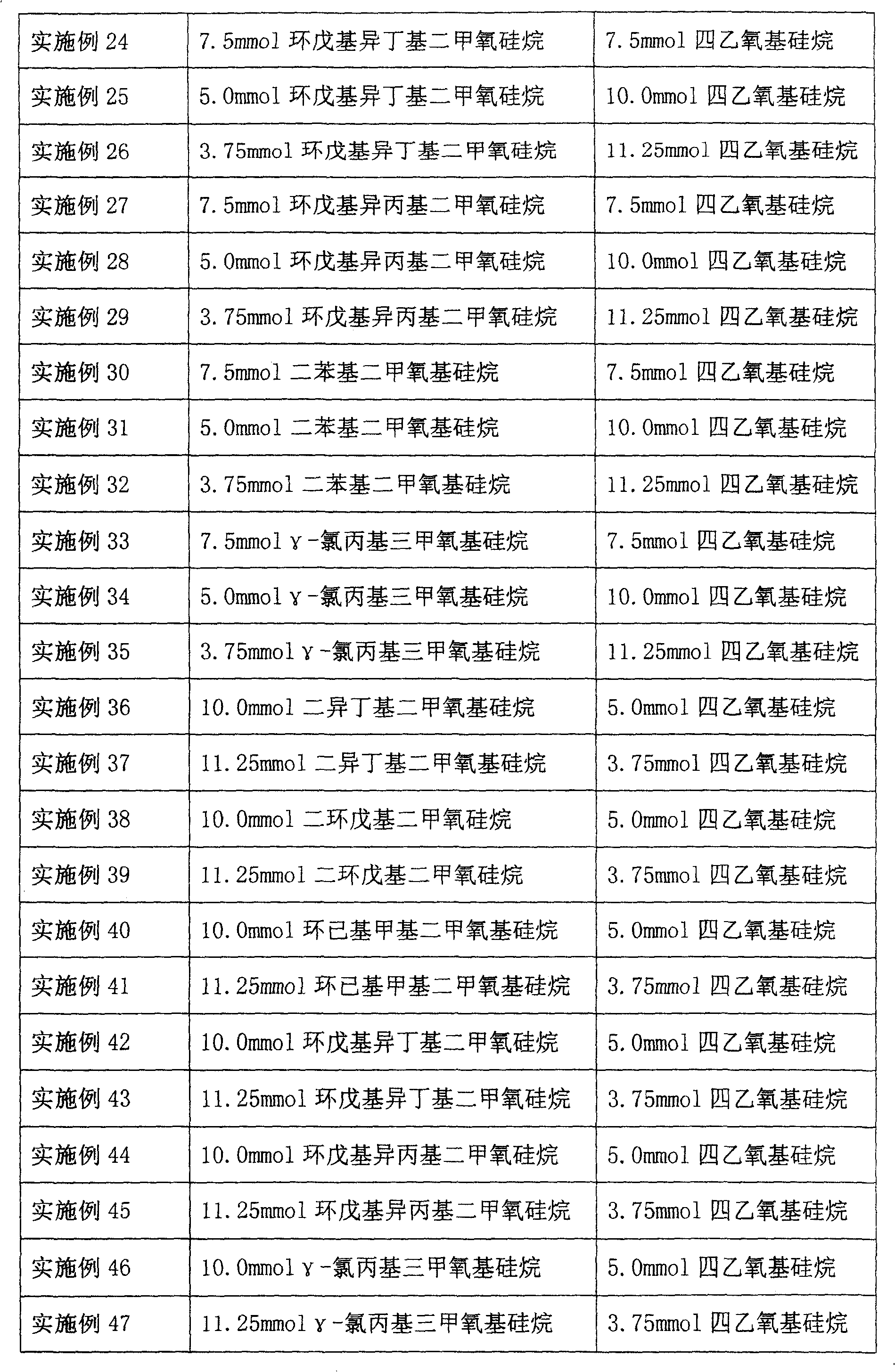

Catalytic system for producing ultrahigh molecular weight polyethylene

The invention provides a catalyst system used for preparing ultra-high molecular weight polyethylene. According to the invention, the catalyst system comprises active ingredients, outer electron donors and catalyst promoters; wherein, the total weight of active ingredients of the catalyst based on 100 parts by weight comprises 12.0 to 18.0 parts by weight of magnesium, 4.0 to 8.0 parts by weight of titanium, 1.1 to 11.0 parts by weight of alkoxy group and 55.0 to 75.0 parts by weight of halogens by weight. The method for preparing the active ingredients comprises the steps that: serous fluid of magnesium-alcohol complex is prepared, the serous fluid reacts with the electron donor of (R)nSi, pre-loading titanium reacts with loading titanium. The ultra-high molecular weight polyethylene is prepared by adopting the synergistic effect of the active ingredients, R <1> R <11> Si (OR <111>) <2> and the organoaluminium compound R 3-n ALX n of the invention. The catalyst system of the invention has the advantages of high bulk density, excellent dynamic stability, and the ultra-high molecular weight polyethylene prepared has the advantages of good product form, mean particle distribution and high bulk density; the molecular weight can be adjusted between 2 million and 7 million.

Owner:BEIJING JINDINGKE CHEM TECH

Preparation method of ultra-high molecular weight anionic polyacrylamide

ActiveCN103509146AThe polymerization reaction is stableInitiation efficiency is highPolymer scienceDecomposition

The invention relates to a preparation method of ultra-high molecular weight anionic polyacrylamide, belonging to the technical field of compound preparation. The preparation method comprises the following steps of preparing deionized water, an acrylamide water solution, a hydrolyzing agent, a cosolvent and a chain transfer agent into a polymerization system; besides, compounding two azo initiators with different decomposition temperatures, and decomposing the two azo initiators at the lower temperature. According to a triggered polymerization process, the polymerization reaction is stable, the initiation efficiency is high, the defects that the consumption speed is too high caused by the single azo initiator, and the reaction is incomplete caused when the free radicals of the initiator are consumed off in a later period of the reaction, so that the polymer molecular weight is lowered are effectively overcome, and the ultra-high molecular weight anionic polyacrylamide having the molecular weight more than or equal to 350 million is prepared. The product is suitable for polymer flooding of tertiary oil recovery of an oil field, sewage treatment flocculants and papermaking, spinning and printing-dyeing industries.

Owner:CHINA PETROLEUM & CHEM CORP

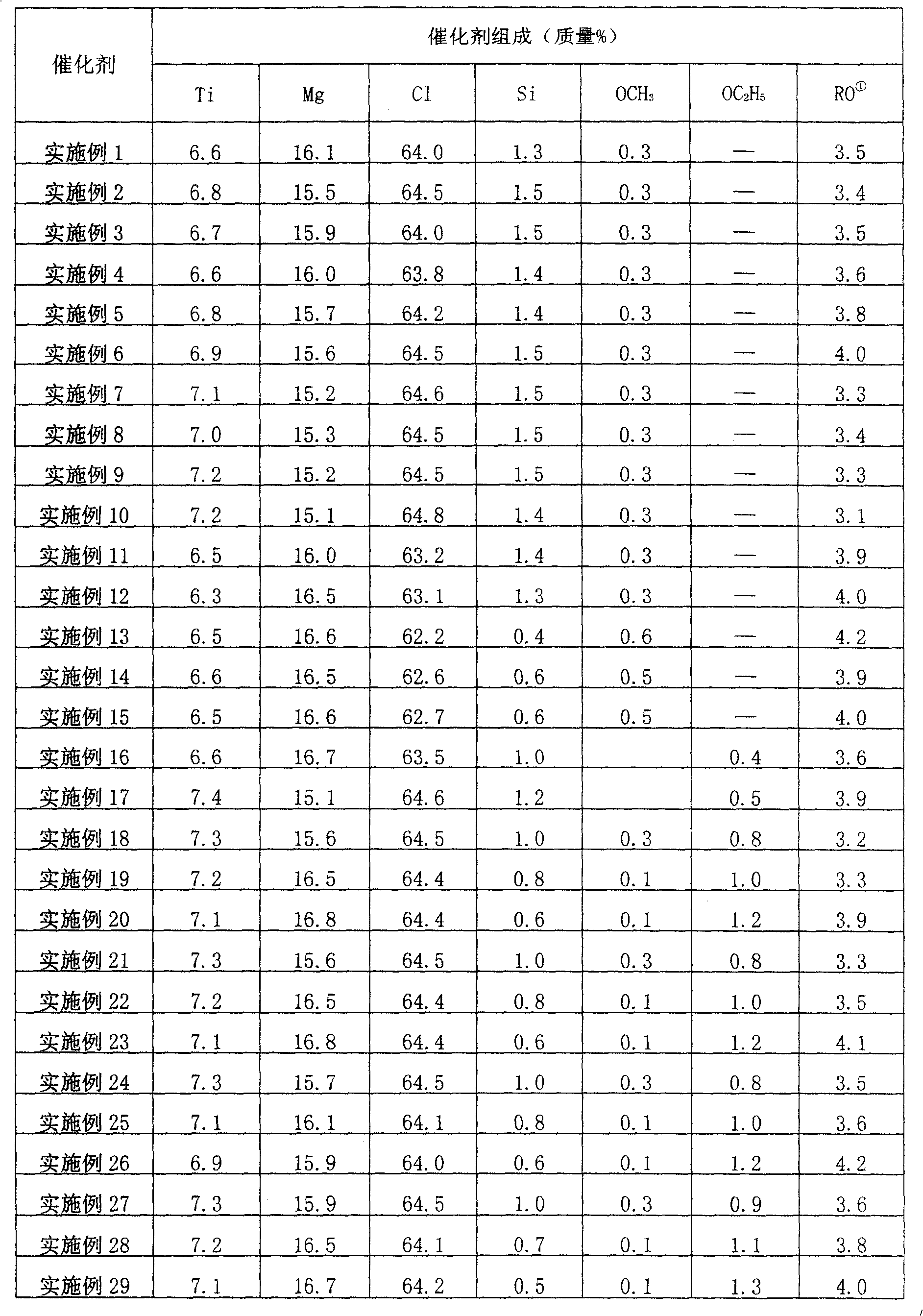

Preparation of fibrous catalyst loaded with metal nanoparticles and application

ActiveCN108212193AImprove catalytic performanceLow application costPhysical/chemical process catalystsFiberMetal catalyst

The invention discloses preparation of a fibrous catalyst loaded with metal nanoparticles and application. The preparation method comprises the following steps: adding metal salt into a solution system containing trihydroxy methyl aminomethane, fiber and dopamine hydrochloride to obtain mixed solution, then stirring, polymerizing dopamine to obtain polydopamine, wrapping fiber with the polydopamine, and simultaneously loading the metal nanoparticles; then, carrying out heat annealing treatment under the atmosphere of inertial gas to prepare a fiber@nitrogen-doped carbon metal compound material, namely the fibrous catalyst loaded with metal nanoparticles. The preparation and the application disclosed by the invention have the beneficial effects that by setting of a whole process flow of thepreparation method and improvement on reaction conditions and parameters of all key process steps, the activity and the cycling stability of the loaded nano-metal catalyst can be effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

PH and temperature double-sensitive intelligent nanogel and preparation method thereof

The invention provides a pH and temperature double-sensitive intelligent nanogel and a preparation method thereof. The method comprises the following steps: adding ltaconic acid into sodium hydroxide solution to obtain partially neutralized ltaconic acid water solution; adding acrylamide, N-isopropyl acrylamide and a crosslinking agent into the partially neutralized ltaconic acid water solution, and stirring to obtain a transparent single mixture solution; adding the transparent single mixture solution into a mixed solvent containing oil-soluble solvent and Span80 / Tween 80 composite surfactant, stirring, heating to 40-60DEG C, and adding an oxidant and a reducing agent, to obtain intelligent transparent or semitransparent nanogel reversed-phase microemulsion; demulsifying and precipitating the intelligent transparent or semitransparent nanogel reversed-phase microemulsion with ethanol, washing, drying and grinding to the pH and temperature double-sensitive intelligent nanogel. The invention further provides the pH and temperature double-sensitive intelligent nanogel prepared by adopting the preparation method. The pH and temperature double-sensitive intelligent nanogel has good pH and temperature double sensitivity.

Owner:PETROCHINA CO LTD

Catalyst composition for gaseous polymerization or copolymerization of ethene and preparaing method thereof

A composition of ethylene gas polymerization and polymerized catalysts and its preparation method. It is composed by catalyst carrier, main catalyst, and co-catalyst, which is characterized in, active silicon dioxide as the carrier, the main catalyst containing at least a titanium compound, a slurry catalyst with dehydrated mineral oil as the disperser, aluminum alkyl as the co-catalyst. The method comprises: supporting mixed solution of TiCl3,MgCl2 and THF on the active silicon dioxide carrier, after prereducing, the mixed solution mixing with dehydrated mineral oil and forming slurry catalyst main body, which consists of the catalyst system with aluminum alkyl. The catalyst system is suitable for ethylene gas polymerization and co polymerization, especially for high-performance catalystfor producing low-density polyethylene by gas polymerization.

Owner:ZIBO XINSU CHEM

Method for preparing chloroethylene-n-butyl acrylate copolymer resin with suspension process

InactiveCN106279490AImprove product qualityCopolymerization effect is obviousApparent densityCopolymer

The invention provides a preparation method of chloroethylene-n-butyl acrylate copolymer resin with a suspension process and belongs to the technical field of chemical polymer synthesis. The suspension polymerization process is adopted, and a polymerization formula is adjusted and optimized, and the n-butyl acrylate copolymer adding technology is controlled, therefore, the prepared chloroethylene-n-butyl acrylate copolymer resin product has the advantages of regular shape, concentrated size distribution, higher apparent density and lower oil absorption rate, is transparent and presents remarkable internal plasticity and impact resistance.

Owner:YIBIN HAIFENG HERUI

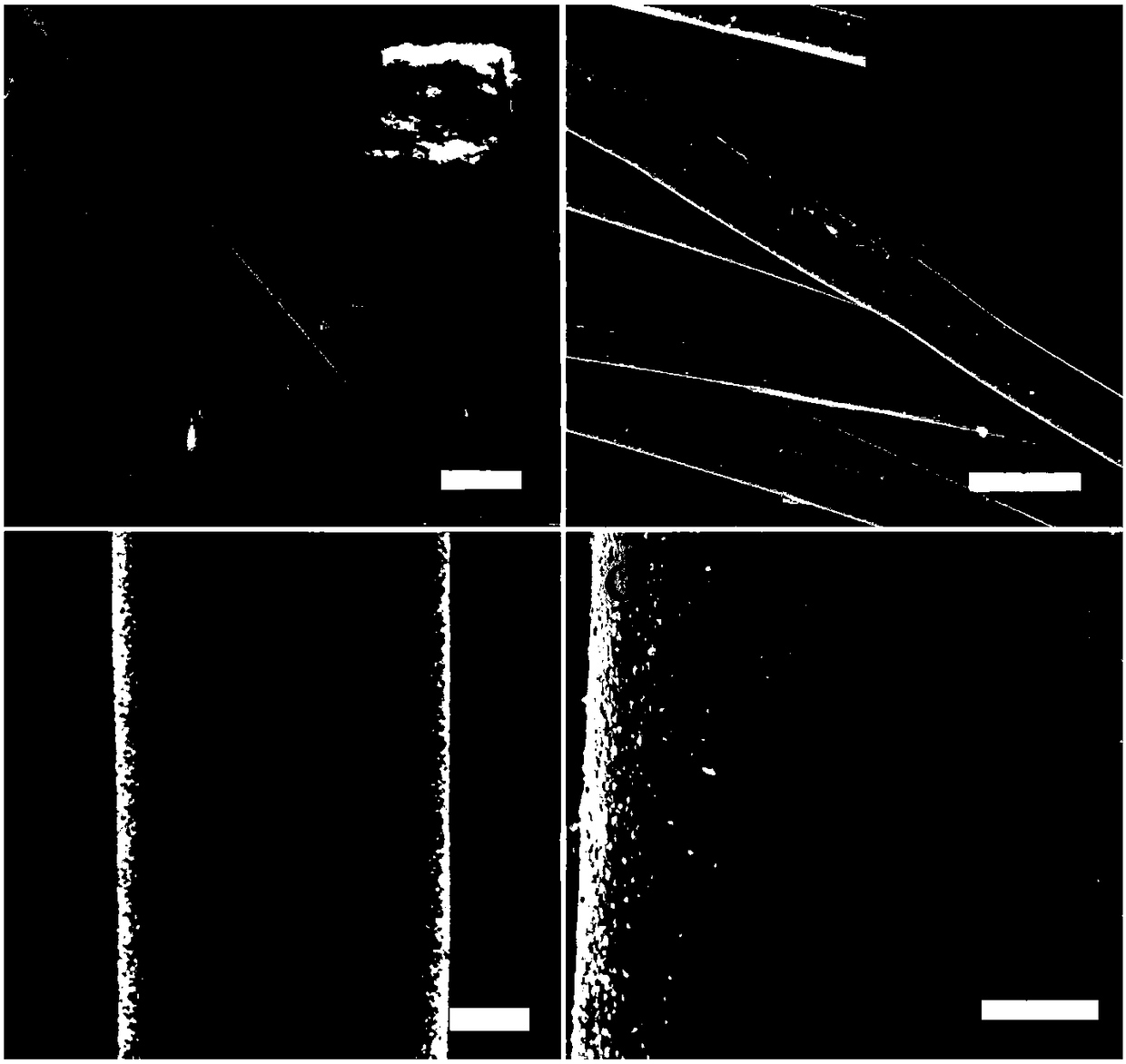

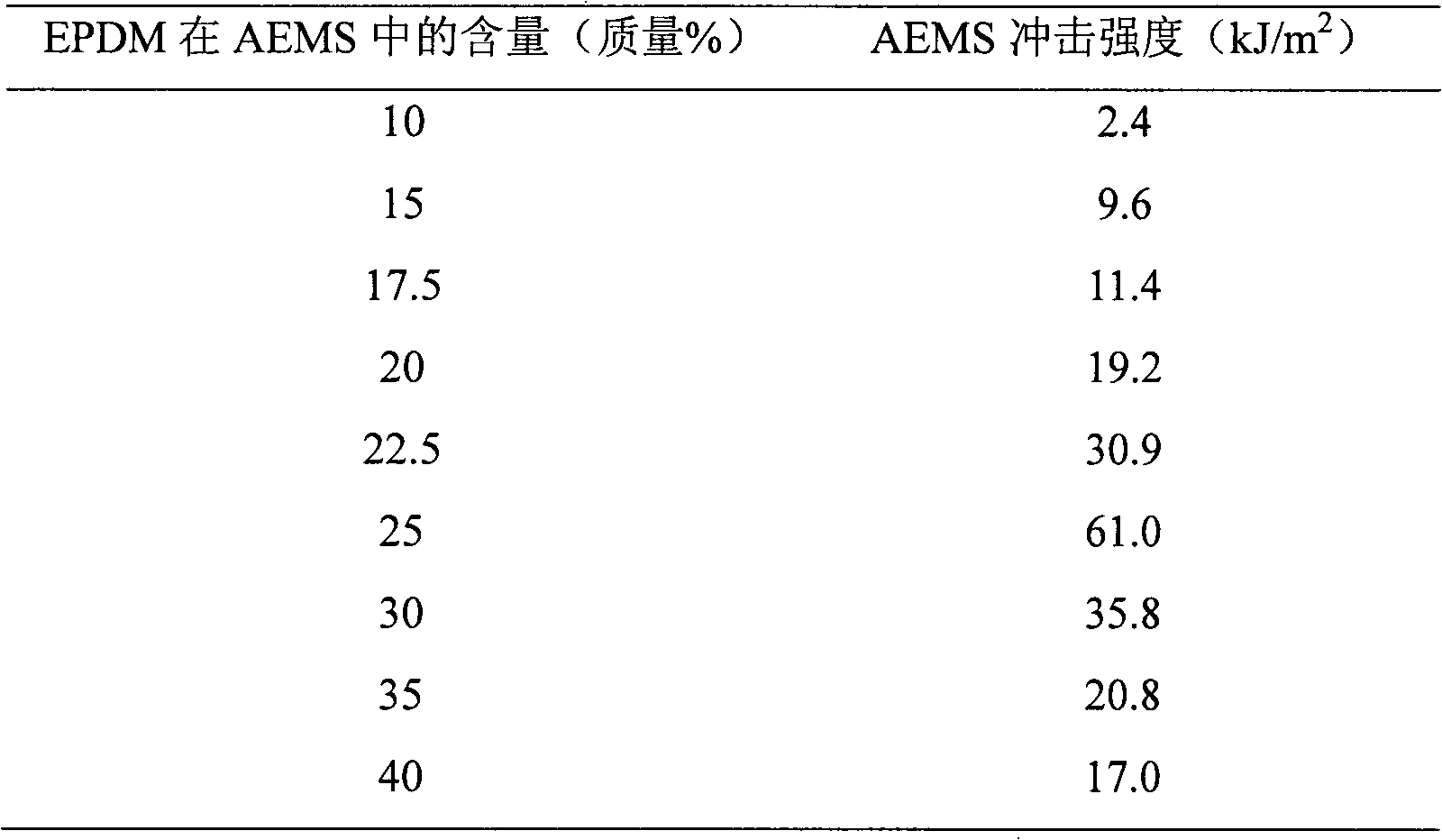

Method of preparing ethylene propylene diene monomer graft polymer through solution grafting copolymerization and application thereof

The invention discloses a method of preparing ethylene propylene diene monomer (EPDM) graft polymer through solution grafting copolymerization and an application thereof in the preparation of engineering plastics. The method optimizes and improves the preparation method on the basis of the solution grafting copolymerization preparation of EPDM-g-SAN, introduces polar monomer MMA, synthesizes EPDM-g-MAN or EPDM-g-MAS which has less content of AN unit of the graft chain, on the condition of low AN dosage; in addition, the highest monomer conversion rate of the method can reach 70-95% by adjusting the monomer proportioning so as to increase the grafting rate and grafting efficiency of the grafting copolymerization system and significantly improve the compatibility between EPDM graft polymer and SAN resin and the toughening efficiency of EPDM graft polymer to SAN resin. By mixing the EPDM graft polymer prepared in the invention and SAN resin, impact resistance engineering plastics with excellent weather resistance, aging resistance and yellowing resistance and high glossiness can be prepared.

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com