Initiator composition used for synthesizing polyacrylamide capable of displacing oil

A polyacrylamide and initiator technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult to meet the requirements of polymers for tertiary oil recovery, low molecular weight of polyacrylamide, and poor temperature and salt resistance. , to achieve the effect of uniform chain growth, reduced polymerization reaction speed, and good temperature resistance and salt resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

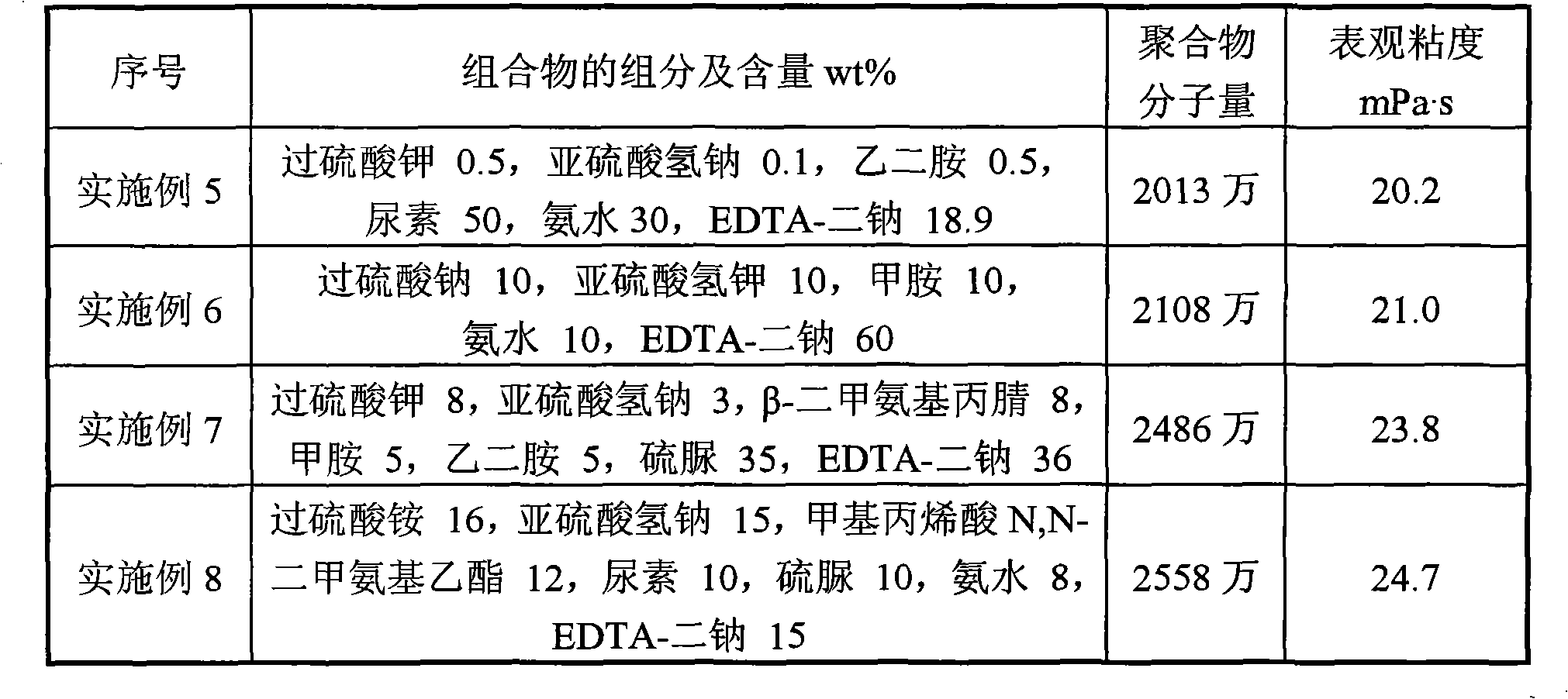

Examples

Embodiment 1

[0011] First add 125g of acrylamide (AM) into 352g of deionized water, stir and dissolve evenly, adjust the pH value to 8 with 5% NaOH solution, and cool the water bath to 15°C, then start to pass high-purity nitrogen gas into it. After nitrogen for 30 min, 10 g of 1.25% aqueous urea solution, 10 g of 0.9% disodium ethylenediaminetetraacetic acid (EDTA-disodium) aqueous solution, 1 g of 1.25% N,N-dimethylaminoethyl methacrylate (DMAEMA) aqueous solution were added successively, 1.25% potassium persulfate aqueous solution 1g, 1% sodium bisulfite aqueous solution 1g, after 1 hour, the reaction temperature was gradually raised to 40 ° C, after 4 hours of reaction, a gel-like polymer product was obtained, after cutting the gel, add 10% NaOH aqueous solution 140g, hydrolyzed at 90°C for 2 hours, then vacuum-dried at 75°C for 6h, crushed and sieved with a pulverizer, then sampled for analysis.

[0012] According to GB / T12005.2-89 polyacrylamide solid content determination method, th...

Embodiment 2

[0014] First add 125g of acrylamide (AM) into 370g of deionized water, stir and dissolve evenly, adjust the pH value to 8 with 5% NaOH solution, and cool the water bath to 15°C, then start to pass high-purity nitrogen gas into it. After nitrogen for 30 min, add 1.25% thiourea aqueous solution 1g, 0.81% ethylenediaminetetraacetic acid disodium (EDTA-disodium) aqueous solution 1g, 1.25% β-dimethylaminopropionitrile aqueous solution 1g, 1.25% sodium persulfate aqueous solution 1g, 1g of 1.69% potassium sulfite aqueous solution, after 1 hour, the reaction temperature was gradually raised to 40°C, and after 4 hours of reaction, a gel-like polymer product was obtained. After the gel was cut, 140g of 10% NaOH aqueous solution was added, and the reaction was hydrolyzed at 90°C for 2 hours, then vacuum-dried at 75°C for 6 hours, crushed and sieved with a pulverizer, and then sampled for analysis.

[0015] According to GB / T12005.2-89 polyacrylamide solid content determination method, th...

Embodiment 3

[0017]First add 125g of acrylamide (AM) into 370g of deionized water, stir and dissolve evenly, adjust the pH value to 8 with 5% NaOH solution, and cool the water bath to 15°C, then start to pass high-purity nitrogen gas into it. After nitrogen for 30min, add 1.38% urea aqueous solution 1g, 0.33% ethylenediaminetetraacetic acid disodium (EDTA-disodium) aqueous solution 1g, 0.99% N, N-dimethyl diallyl ammonium chloride aqueous solution 1g, 1.25 % ammonium persulfate aqueous solution 1g, 2.63% potassium sulfite aqueous solution 1g, after 1 hour, the reaction temperature was gradually raised to 40°C, and after 4 hours of reaction, a gel-like polymer product was obtained, and 140g of 10% NaOH aqueous solution was added after cutting the glue, It was hydrolyzed at 90°C for 2 hours, then vacuum-dried at 75°C for 6 hours, crushed and sieved with a pulverizer, and then sampled for analysis.

[0018] According to GB / T12005.2-89 polyacrylamide solid content determination method, the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com