Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Fully polymerized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant fiber reinforced geopolymer for 3D printing of Zhaozhou Bridge, and preparation method thereof

InactiveCN109400031ALow water absorptionAvoid crackingAdditive manufacturing apparatusCement productionFiberCalcium hydroxide

The invention relates to a plant fiber reinforced geopolymer for 3D printing of the Zhaozhou Bridge, and a preparation method thereof. The plant fiber reinforced geopolymer comprises, by weight, 0.95-1.35 parts of fly ash, 0.025-0.055 part of calcium hydroxide powder, 0.015-0.035 part of plant fiber, 0.03-0.09 part of slag, 0.08-0.13 part of silica fume, 0.05-0.08 part of clay, 1.2-1.4 parts of quartz sand, 0.65-1.2 parts of composite alkali activators, 0.005-0.012 part of sodium bentonite, 0.005-0.009 part of viscosity modifier, 0.02-0.05 part of polyvinyl alcohol treatment solution, 0.0035-0.0065 part of coupling agent and 0.05-0.15 part of water. The plant fiber reinforced geopolymer with the plant fibers as toughening materials has the advantages of low cost, low density, regenerability and environmental protection, and is beneficial to promotion of the practical engineering application of 3D printing geopolymer materials.

Owner:HEBEI UNIV OF TECH

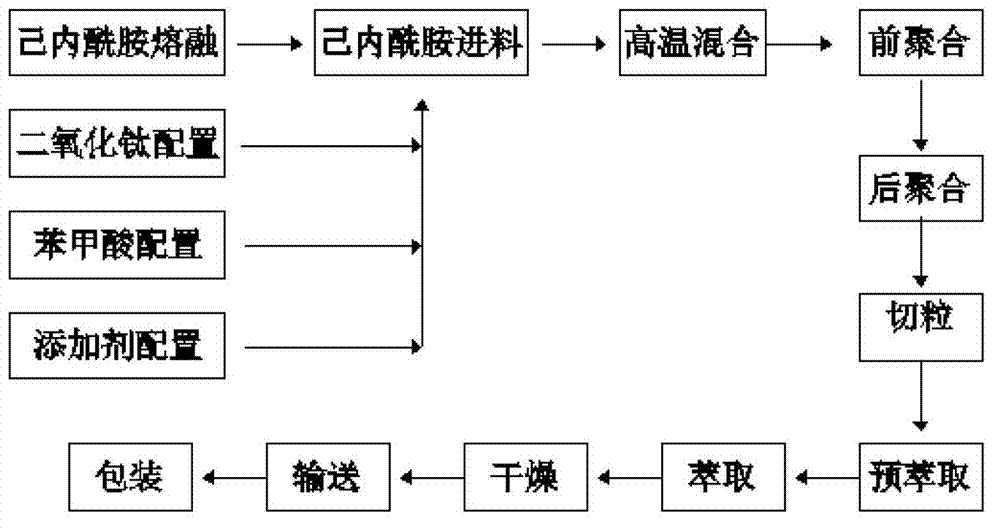

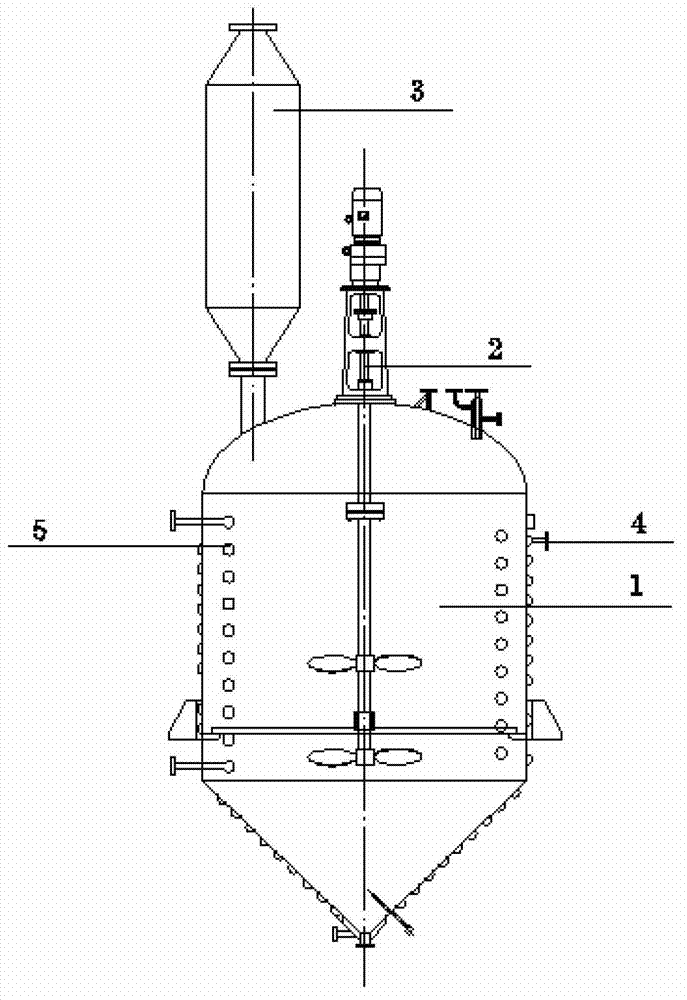

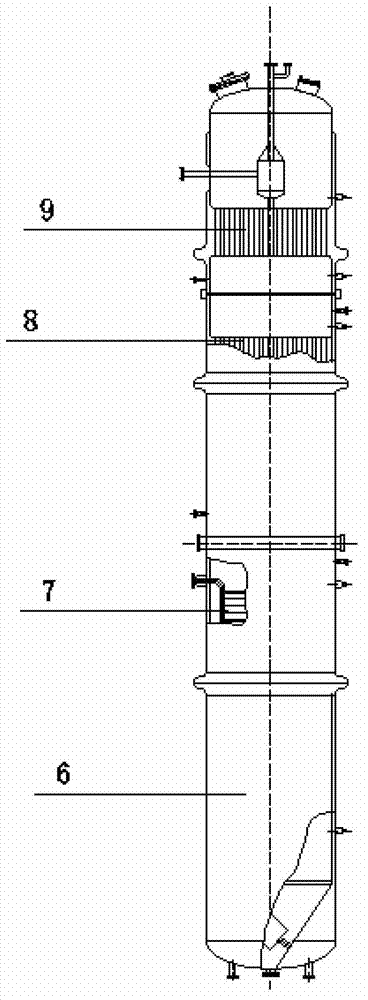

Polymerization manufacturing technique and device for polyamide

The invention relates to a polymerization manufacturing technique and device for polyamide. The manufacturing technique comprises the steps of feeding molten caprolactam, titanium dioxide, benzoic acid and an additive, dynamically mixing at a high temperature for prepolymerization and postpolymerization, granulating, pre-extracting, extracting and drying to obtain the final product. The device comprises a melting system, a feed system, a high-temperature dynamic mixing system, prepolymerization and postpolymerization towers, a pre-extraction column, an extraction column, a recycling system and a drying tower. According to the invention, a high-temperature dynamic mixing tank is set additionally. The mixing of the raw materials and hydrolysis for ring opening and dehydration of polyamide are performed at a state of dynamically mixing to achieve a more sufficient and stable pre-addition polymerization and a more uniform and stable molecular distribution of post-polycondensation. A slice and a water separator of the extraction column are used for mainly extracting oligomers through the pre-extraction column and extracting a caprolactam monomer through the extraction column with a stable concentration. A slice cooler of the drying tower is used for cooling the slices rapidly. An extraction water recycling system is used for recycling the oligomers in the pre-extraction water and the caprolactam monomer in the extraction water.

Owner:武汉森大科技研究发展中心

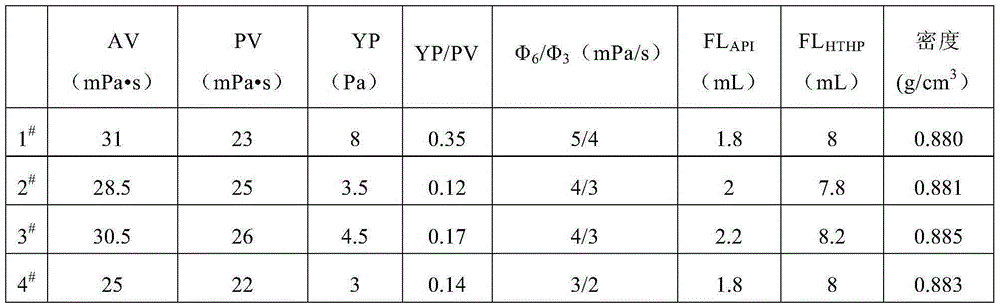

Whole oil-based drilling fluid viscosifier and preparation method thereof

InactiveCN106753289AThe polymerization reaction is stableFully polymerizedDrilling compositionPolyesterPolyol

The invention provides a whole oil-based drilling fluid viscosifier and a preparation method thereof. The preparation method for the whole oil-based drilling fluid viscosifier comprises the steps: 1) uniformly mixing 15-50 parts by weight of polyester polyol, 5-15 parts by weight of a polymerization promoter and 50-150 parts by weight of a solvent at room temperature so as to obtain a mixture; 2) heating the mixture to 40-60 DEG C, adding 15-80 parts by weight of isocyanate and 0.3-1.0 part of a polymerization catalyst under a stirring condition, and continuing to heat the mixture to 70-90 DEG C and enabling the mixture to react for 3-5 h so as to obtain an intermediate product; and 3) cooling the intermediate product to 40-50 DEG C, adding 5-15 parts by weight of a polymerization promoter, heating to 60-80 DEG C and continuing a reaction for 2-3 h so as to obtain the whole oil-based drilling fluid viscosifier. The whole oil-based drilling fluid viscosifier prepared by the preparation method can effectively improve suspension stability of a drilling fluid and improve the rheological property of the drilling fluid without changing the density of the drilling fluid; and therefore, the whole oil-based drilling fluid viscosifier is suitable for exploration and development of low pressure reservoirs.

Owner:PETROCHINA CO LTD

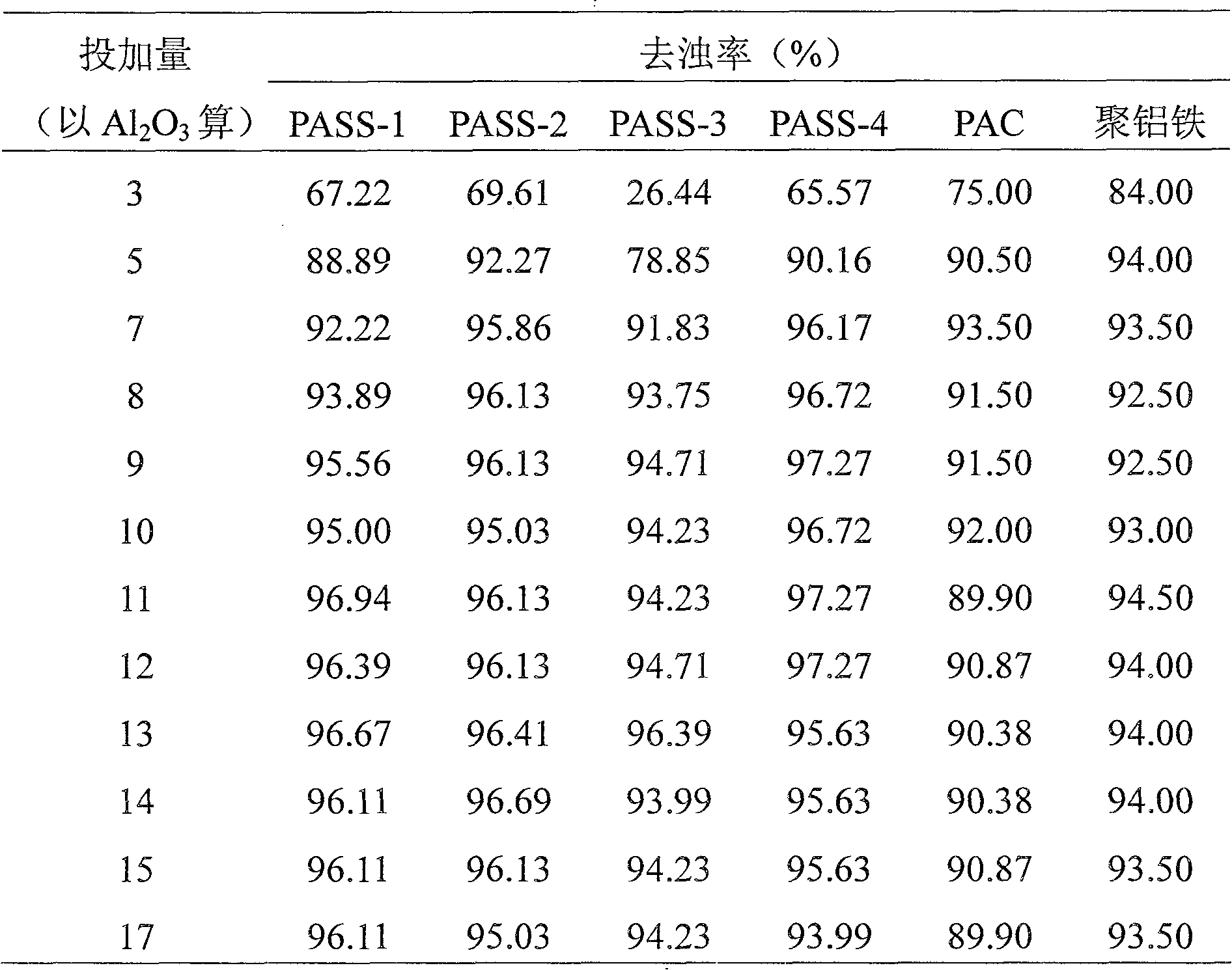

Prepn process of high concentration polymerized aluminium sulfate flocculant

InactiveCN1974426AHigh degree of polymerizationIncrease concentrationAluminium compoundsWater/sewage treatment by flocculation/precipitationWater bathsHigh concentration

The present invention discloses preparation process of high concentration polymerized aluminum sulfate flocculant. The preparation process includes two steps of preparing high concentration stable sodium metaaluminate solution and polymerization reaction. During the preparation of high concentration stable sodium metaaluminate solution, sodium gluconate is added into sodium hydroxide solution at 100-120 deg.c, aluminum hydroxide, stabilizer and initiator ammonium persulfate are also added. The polymerization reaction includes dissolving sodium carbonate in small amount of water, adding sodium silicate solution and sodium metaaluminate solution to obtain alkali intermediate product, high speed dispersing aluminum sulfate solution in a water bath and adding the alkali intermediate product slowly, mixing, stirring at 55-60 deg.c to mature and obtain high concentration polymerized aluminum sulfate flocculant. The flocculant has high stability, alumina content of 8.21-10.84 % and basicity of 65.90-72.93 %.

Owner:SOUTH CHINA UNIV OF TECH

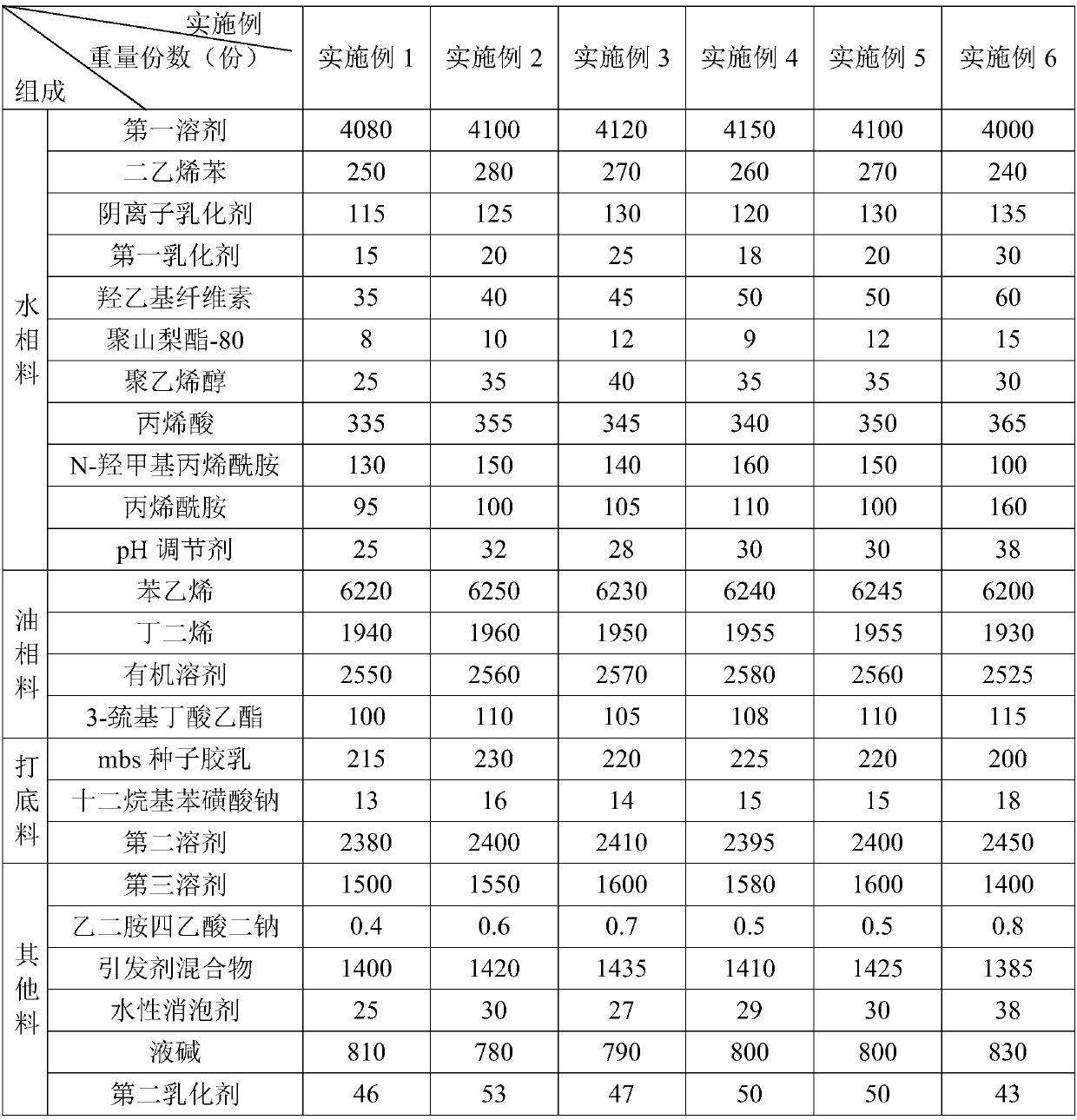

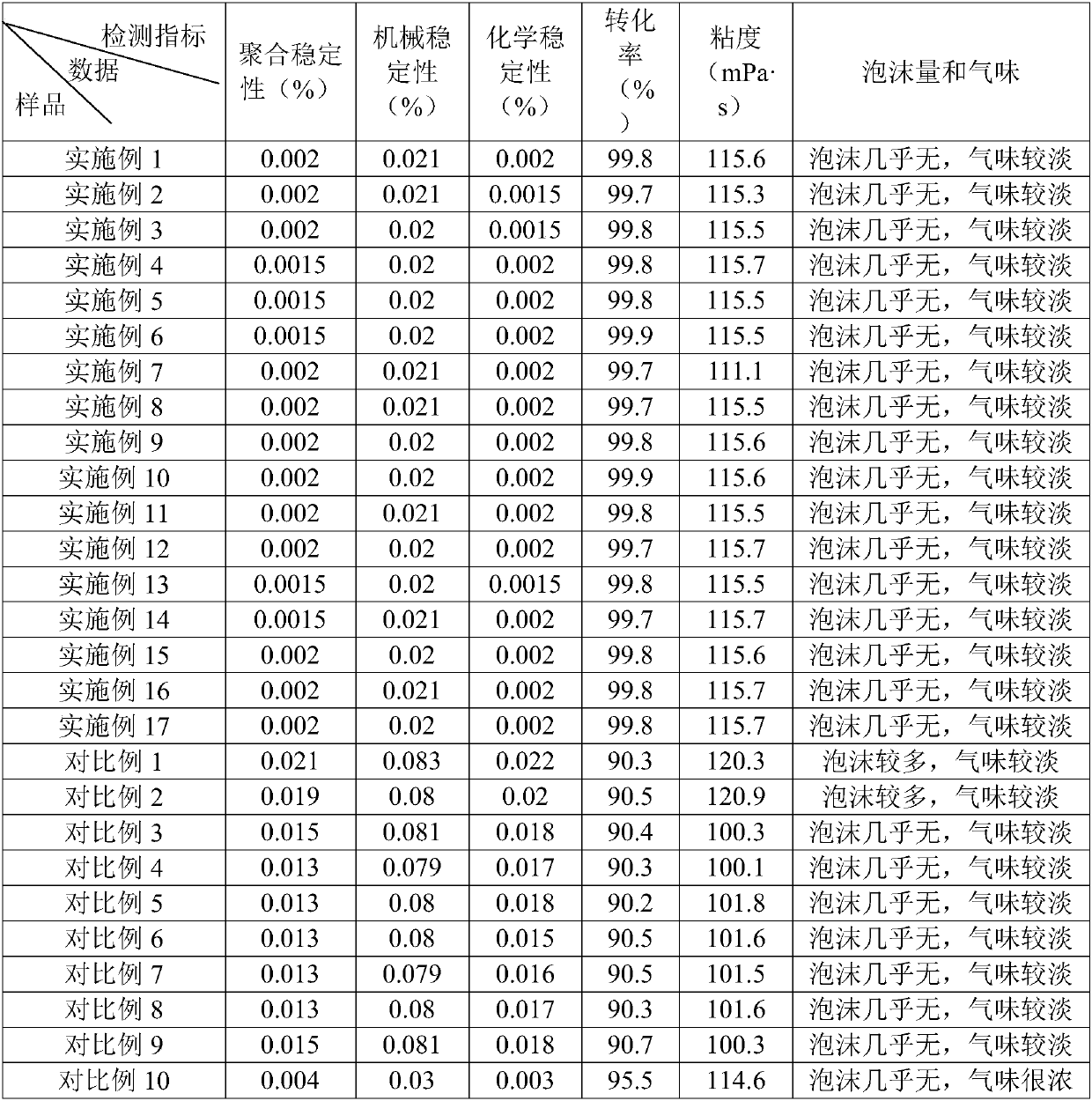

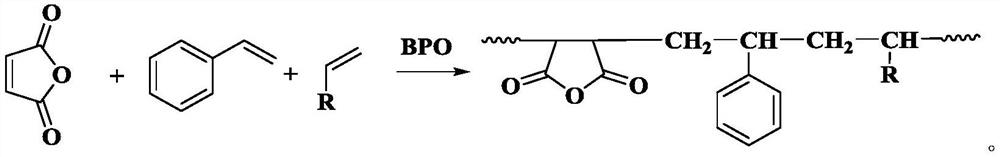

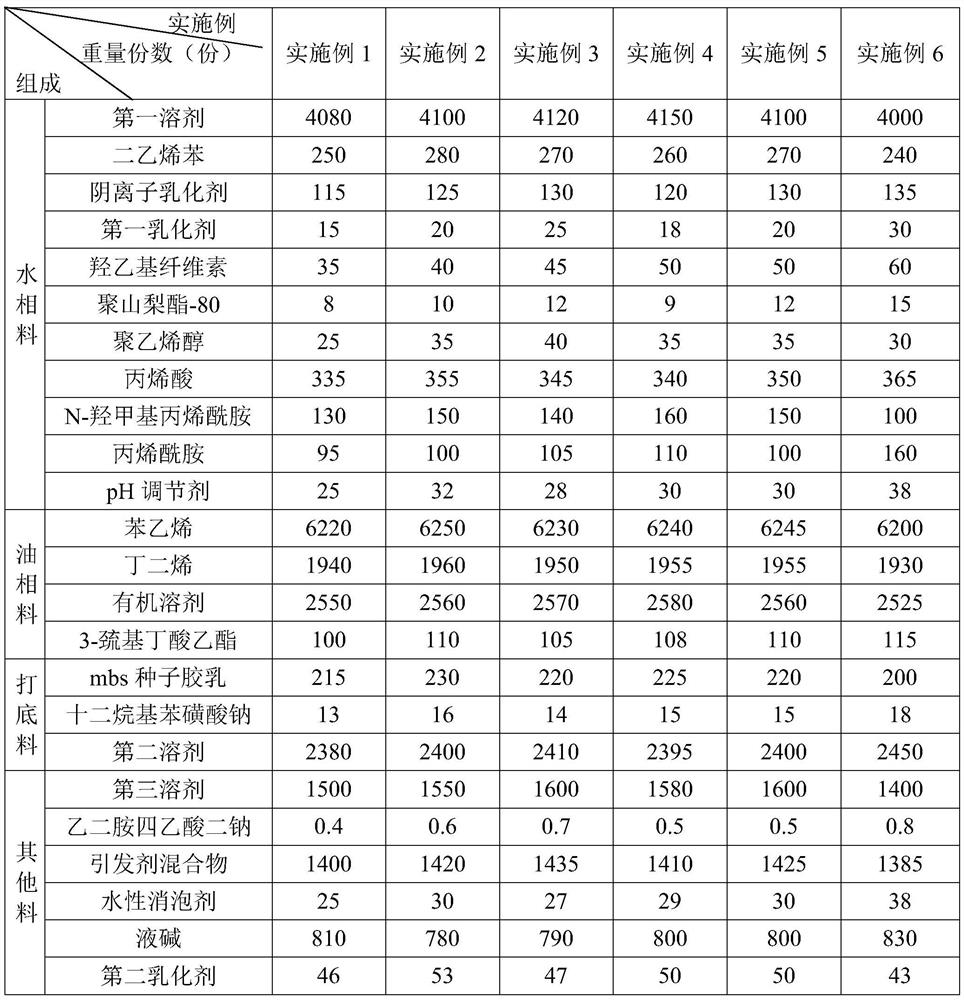

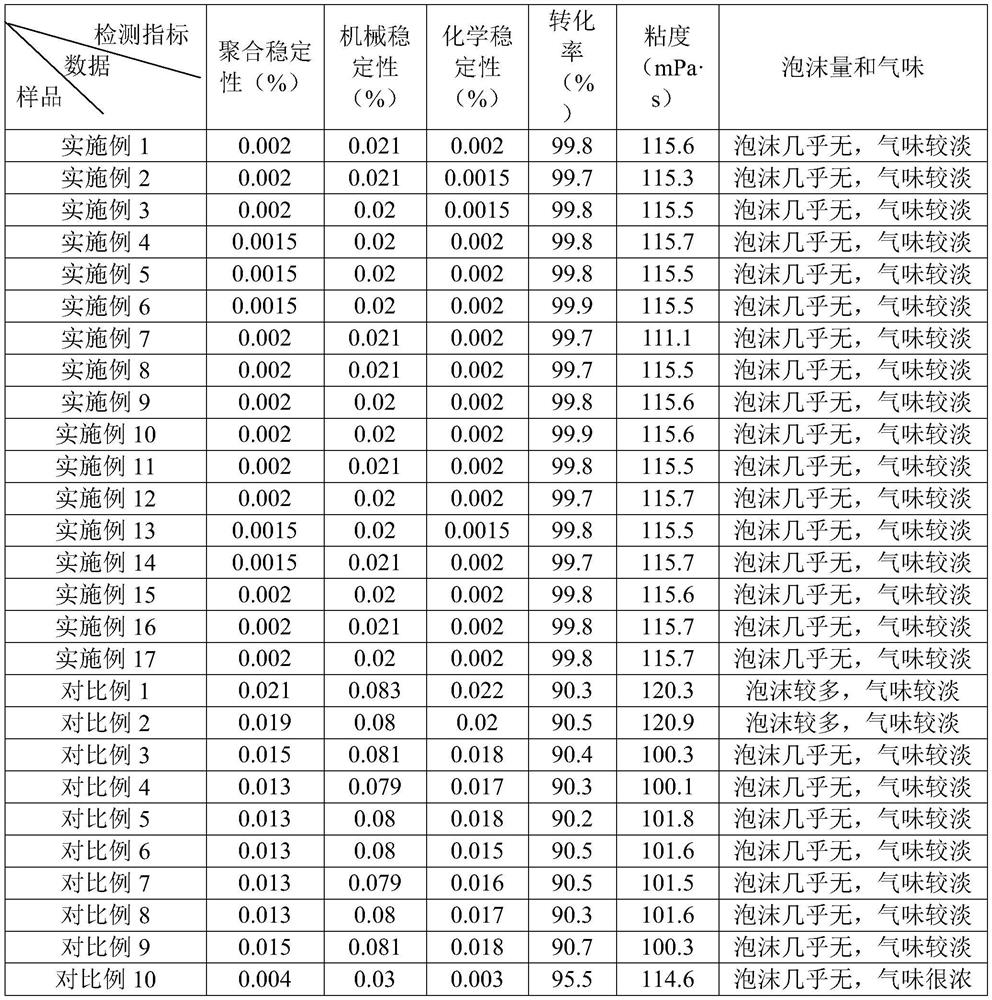

Carboxylic butadiene-styrene latex and preparation technology thereof

InactiveCN107936165AImprove polymerization stabilityImprove mechanical stabilityPolymer scienceMeth-

The invention discloses carboxylic butadiene-styrene latex and a preparation technology thereof. The carboxylic butadiene-styrene latex is prepared from water phase materials, oil phase materials, priming materials, and other materials, wherein the water phase materials comprise a first solvent, a first emulsifier, acrylic acid, N-hydroxymethyl acrylamide, acrylamide and a pH (potential of hydrogen) regulator; the oil phase materials comprise styrene, butadiene and ethyl 3-mercaptobutyrate; the priming materials comprise mbs seed latex, sodium dodecyl benzene sulfonate, and a liquid alkaline mixture; the other materials comprise a fourth solvent, ethylenediaminetetraacetic acid disodium salt, an initiator mixture, a water-based defoamer, liquid alkaline, and a second emulsifier; the firstemulsifier selects an anion emulsifier; the second emulsifier selects a non-ionic emulsifier; the first solvent and the fourth solvent are respectively soft water. The prepared carboxylic butadiene-styrene latex has the advantages that the conversion rate is high, and the polymerizing stability, mechanical stability and chemical stability are good.

Owner:杭州龙驹合成材料有限公司

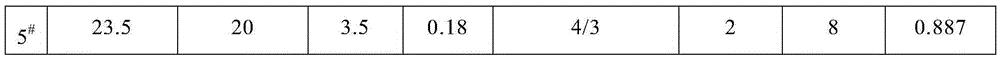

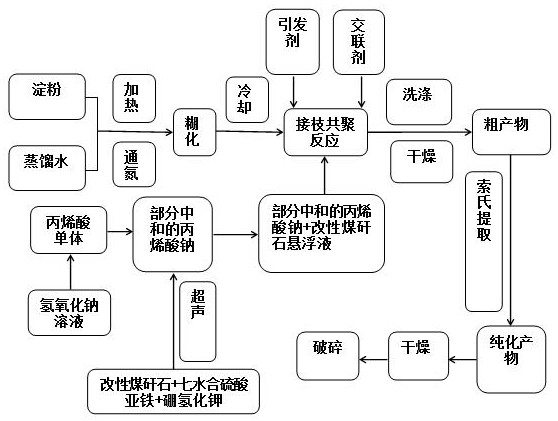

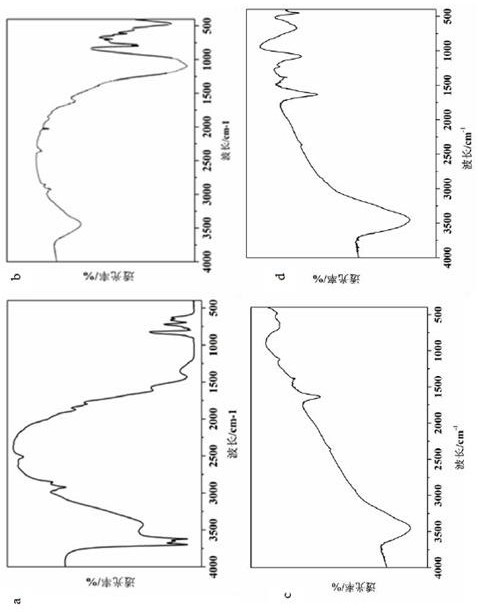

Starch grafted coal gangue coated nano zero-valent iron composite material and preparation method thereof

PendingCN112263996AIncrease valueIncrease added valueOther chemical processesWater contaminantsPotassium borohydrideActive agent

The invention relates to the field of composite material preparation, in particular to a starch grafted coal gangue coated nano zero-valent iron composite material and a preparation method thereof. Inthe reversed-phase suspension polymerization, a reversed-phase suspension polymerization system consists of a water phase and an oil phase; the water phase is composed of water, starch, an initiator,a cross-linking agent, a polymeric monomer, ferrous sulfate heptahydrate, potassium borohydride and a surfactant, and the oil phase is composed of a dispersing agent; the volume ratio of the water phase to the oil phase is 1-5. The composite material obtained by the invention not only has good adsorption capacity of coal gangue, but also fully utilizes a complex three-dimensional network structure and various active functional groups of starch to stabilize and disperse nano zero-valent iron, can effectively prevent the oxidation of the nano zero-valent iron, and has a good treatment effect onCr (VI) containing water.

Owner:YULIN UNIV

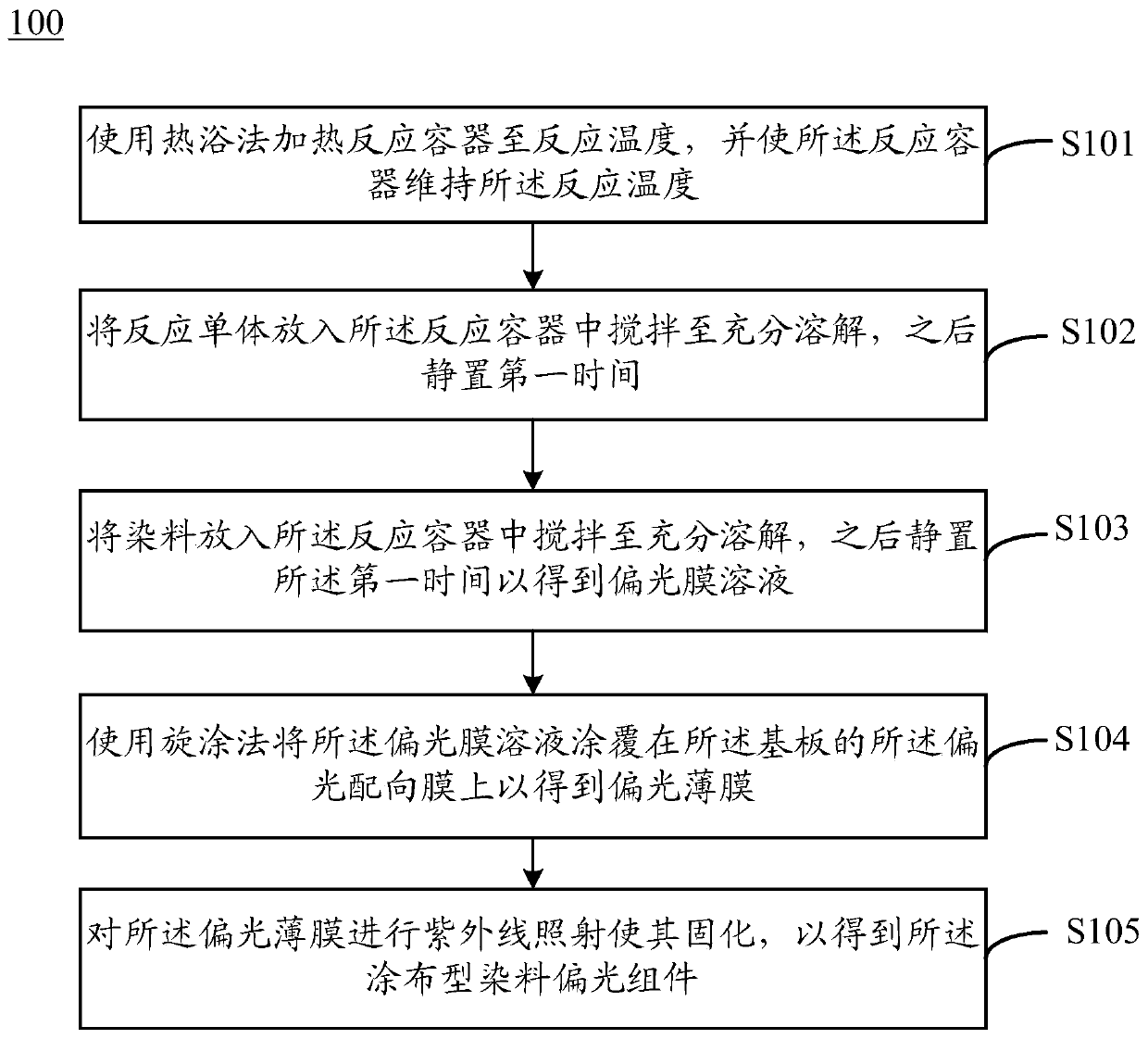

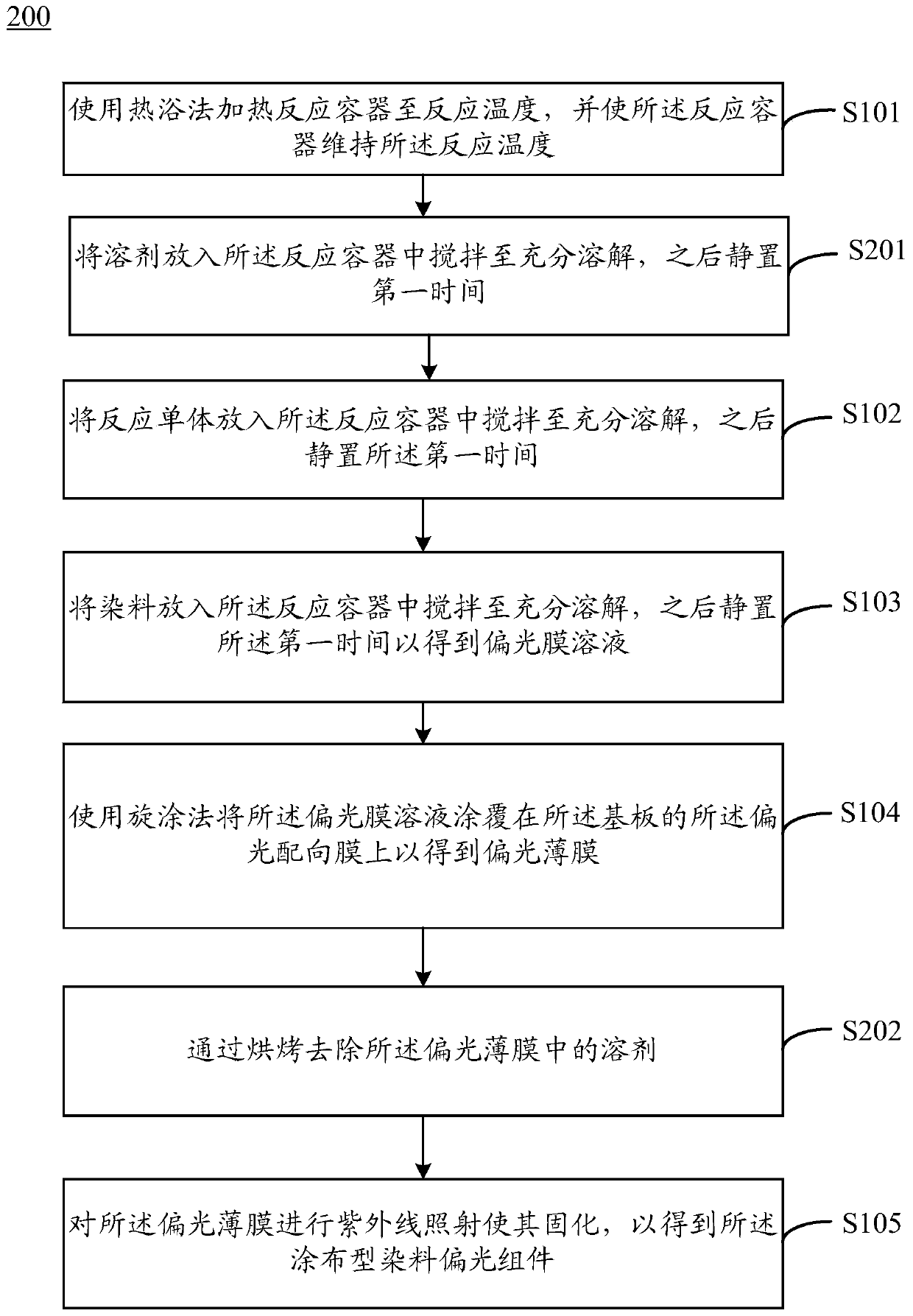

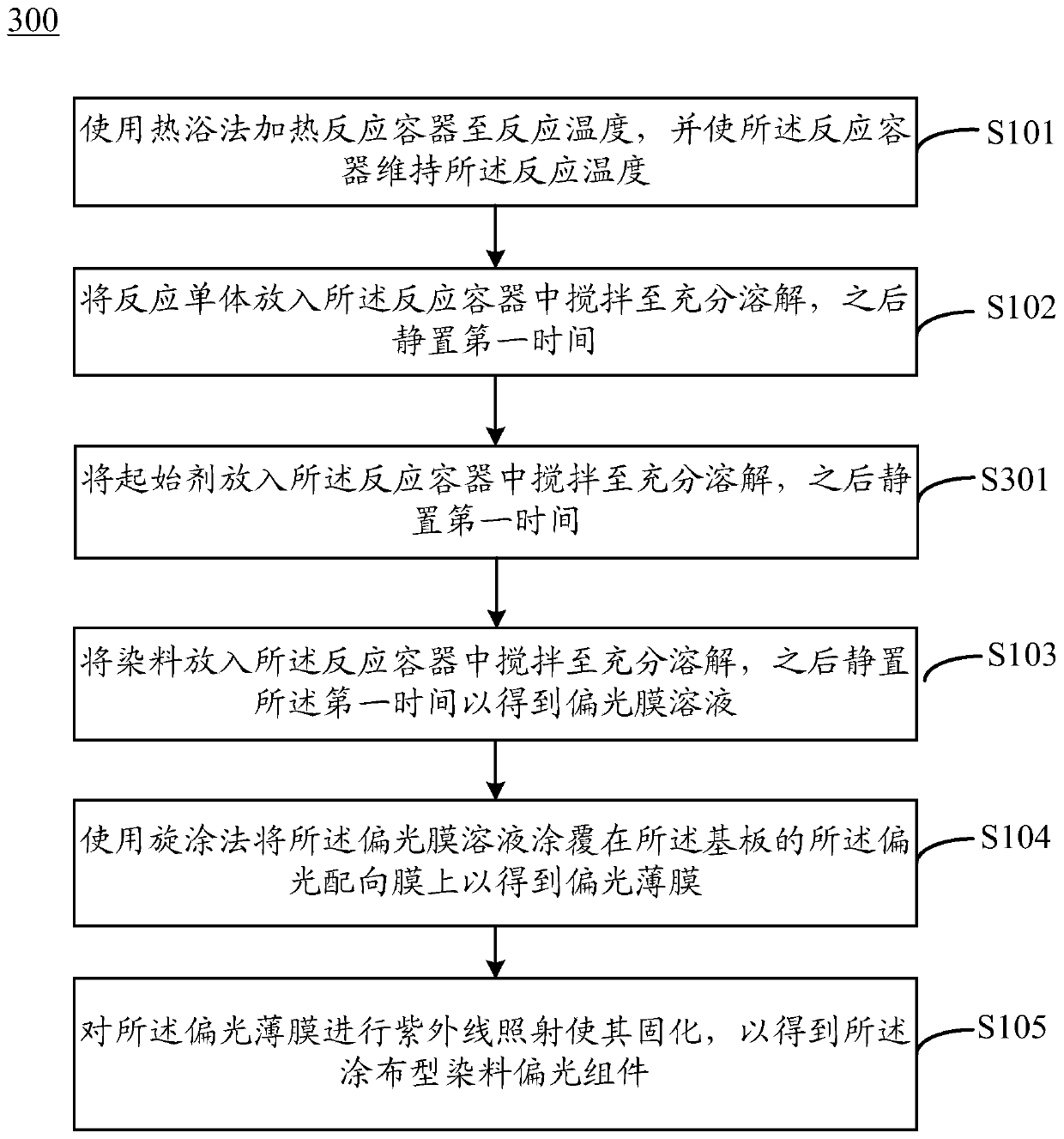

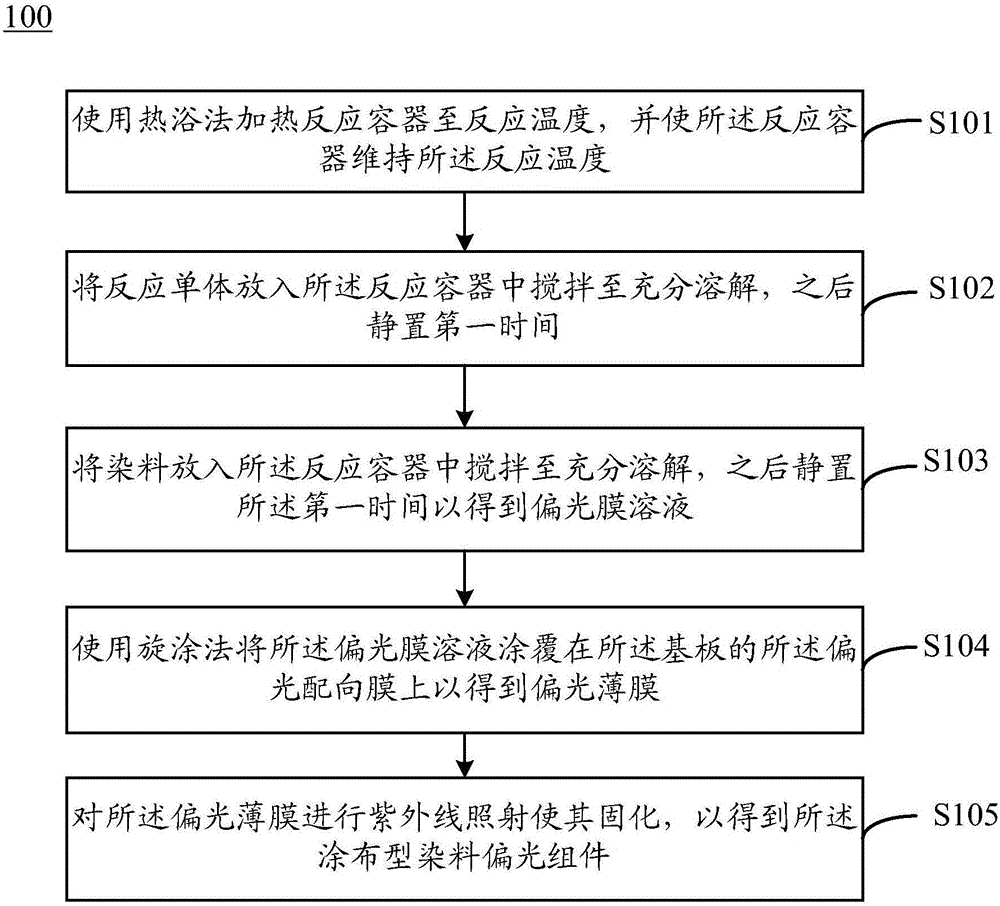

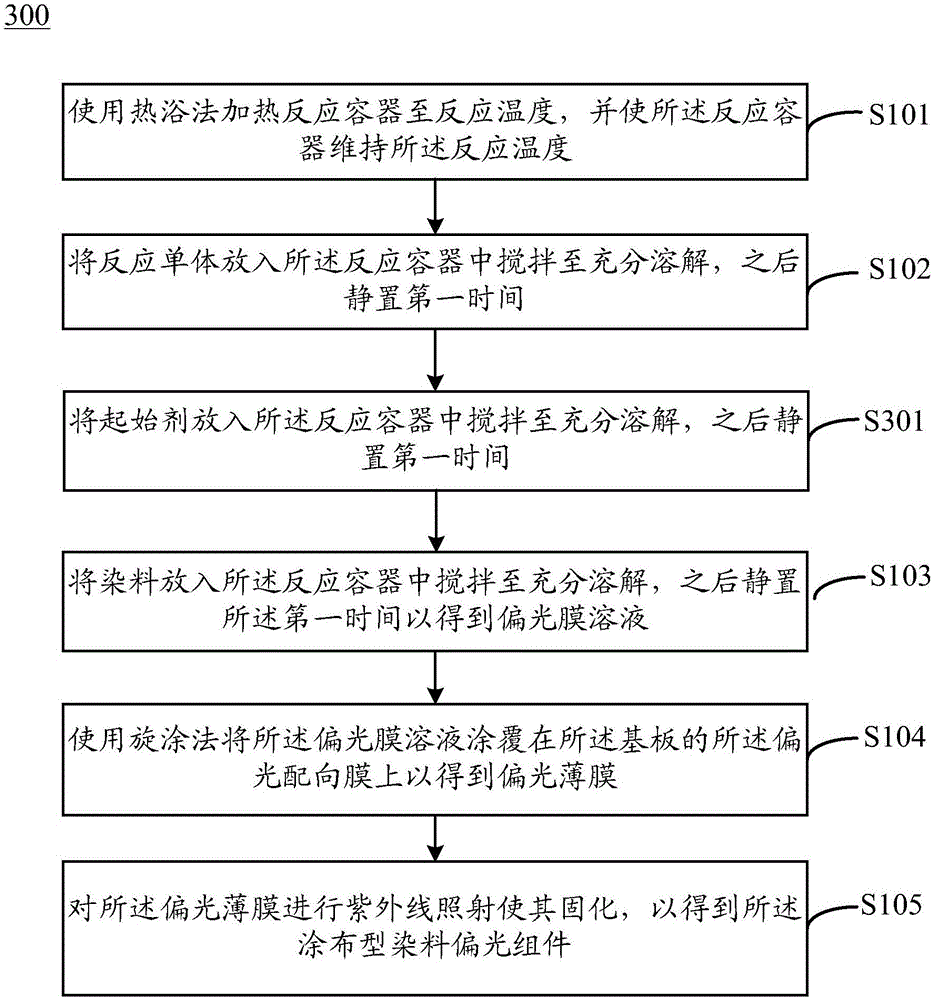

Preparation method of coating type dye polarization component and liquid crystal panel

ActiveCN106154390AAvoid reunionReunion is not easy to happenPolarising elementsNon-linear opticsLiquid-crystal displayUltraviolet

The invention provides a preparation method of a coating type dye polarization component, wherein the coating type dye polarization component comprises a substrate; a polarization alignment film is arranged on the substrate; the preparation method comprises the following steps: heating a reaction vessel to a reaction temperature according to a hot bath method, maintaining the reaction temperature in the reaction vessel; placing a reaction monomer in the reaction vessel, stirring and fully dissolving, then standing for a first time interval; placing a dye in the reaction vessel, stirring and fully dissolving, then standing for the first time interval to obtain a polarization film solution; coating the polarization film solution on the polarization alignment film of the substrate by using a spin-coating method to obtain a polarization film; curing the polarization film through ultraviolet irradiation to obtain the coating type dye polarization component. The invention further provides a liquid crystal panel. The solution of the invention can improve a polarization degree of a polarizer and improve a contrast ratio of the liquid crystal panel.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer

ActiveCN103601886ASolve the problem of low molecular weightHigh molecular weightMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention relates to a preparation method of a poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer. The preparation method comprises two steps of prepolymerization reaction and post-polycondensation reaction. The reaction time of a prepolymer in a double-screw extruder is 10-60 minutes, and the double-screw extruder is provided with three temperature zones according to a sequence from a feeding port to a discharging port, wherein the temperatures of the tree temperature zones are respectively 160-180 DEG C, 180-190 DEG C and 190-200 DEG C. According to the preparation method, the double-screw extruder is used for carrying out the post-polycondensation reaction, and specific temperature and time are used for controlling parameters, so that the intrinsic viscosity [eta] of the PIPD polymer obtained in the end is 28-30dL / g, the molecular weight of the polymer is greatly increased, meanwhile, the stirring is facilitated, and the PIPD polymer can be easily conveyed and transferred to a spinning working section, thus the production efficiency is improved, and the production cost is reduced.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Polyimide precursor, polyimide film and preparation method thereof, and display device

ActiveCN112574411AGood dispersionIncrease temperatureBulk chemical productionIdentification meansPolymer scienceDisplay device

The invention provides a polyimide precursor, a polyimide film, a preparation method of the polyimide film and a display device; the polyimide precursor is synthesized in ionic liquid by using sulfonated diamine, dianhydride and hydrophilic nano silicon dioxide, and the polyimide film containing nano silicon dioxide is prepared by using the polyimide precursor. The polyimide film has good mechanical properties and heat resistance, the 1% thermal weight loss temperature is 430-540 DEG C, the glass transition temperature is 330-480 DEG C, the tensile strength is 220-450 MPa, the transmittance at400 nm is 60-86%, and an effective solution is provided for the defects of polyimide as a transparent substrate or a transparent cover plate at the present stage.

Owner:武汉柔显科技股份有限公司 +1

Modified thermoplastic phenolic resin adhesive used in automobile brake pad and preparation method thereof

The invention provides a modified thermoplastic phenolic resin adhesive used in automobile brake pads and a preparation method thereof. The adhesive is prepared from following components, by weight: 100 parts of phenols, 73-80 parts of aldehydes, 0.05-0.08 parts of acids, 1-7 parts of nano organic modified montmorillonite, 2-4 parts of D-glucose and 1-7 parts of dialdehydes. The preparation method comprises following steps: (A) adding the nano organic modified montmorillonite and the acid into a reaction container according to ratio and stirring the mixture for 30 min at 50-60 DEG C; (B) increasing the temperature to 90-100 DEG C, adding 73-80 parts of aldehydes to the reaction liquid within 60-90 min, and continuously performing the reaction with temperature maintained for 30-60 min; (C) adding 2-4 parts of D-glucose to the reaction liquid, and performing a reaction for 10-20 min at 90-100 DEG C; (D) adding 1-7 parts of dialdehydes to the reaction liquid,, and performing a reaction at 90-100 DEG C for 25-40 min; and (E) starting a vacuum pump to control the pressure in the reaction container to be -0.08 MPa, and performing dehydration for 5 h to prepare the modified thermoplastic phenolic resin adhesive. The method increases the heat resistance and toughness of phenolic resin and reduces the contents of free phenols and volatiles in the resin.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

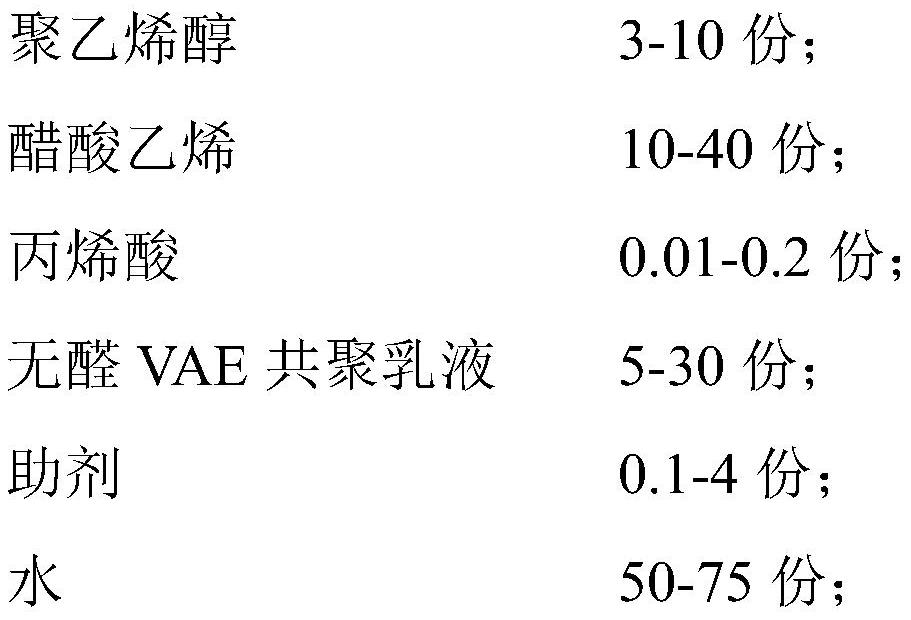

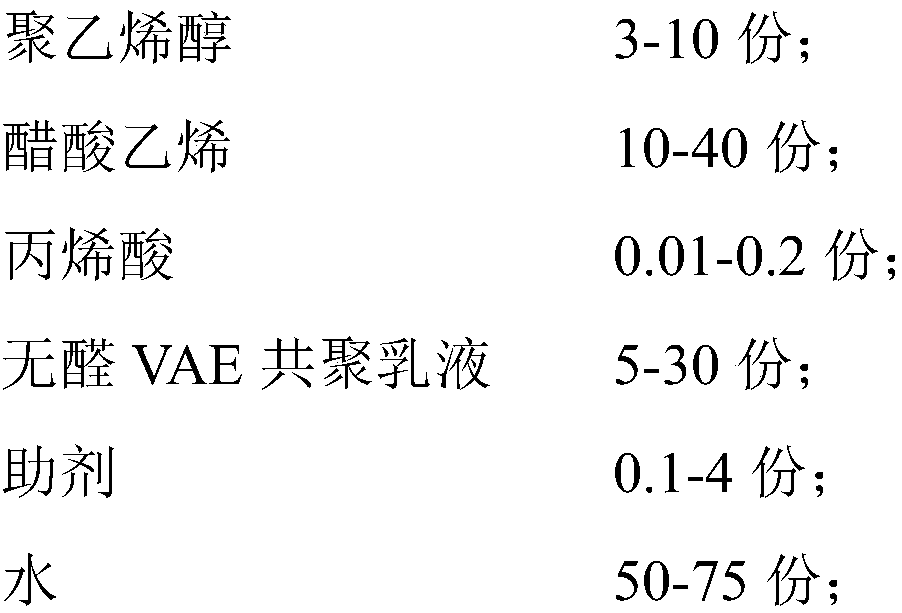

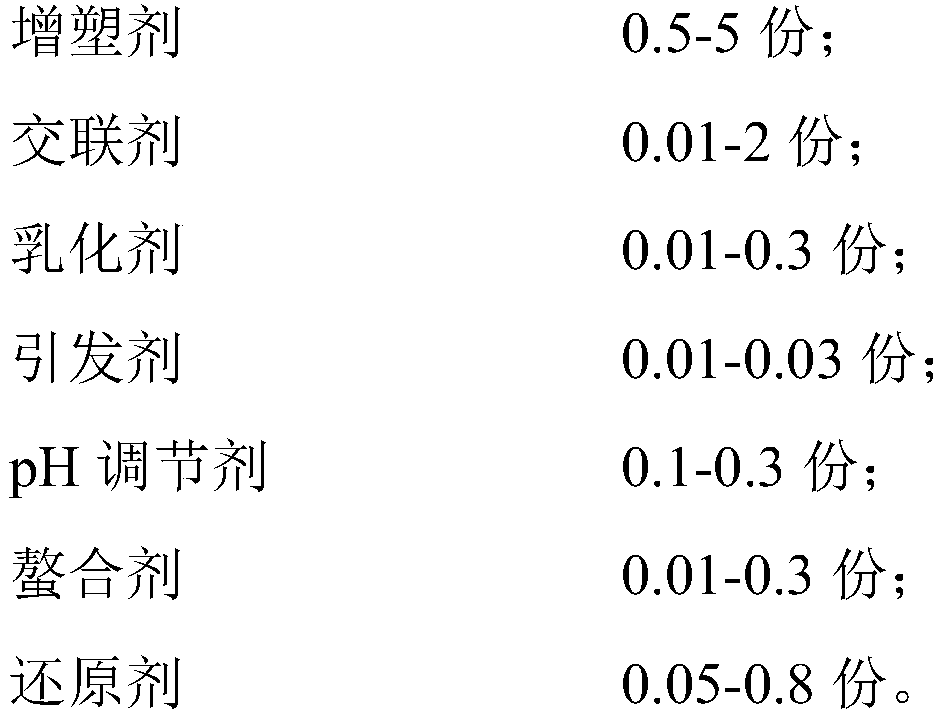

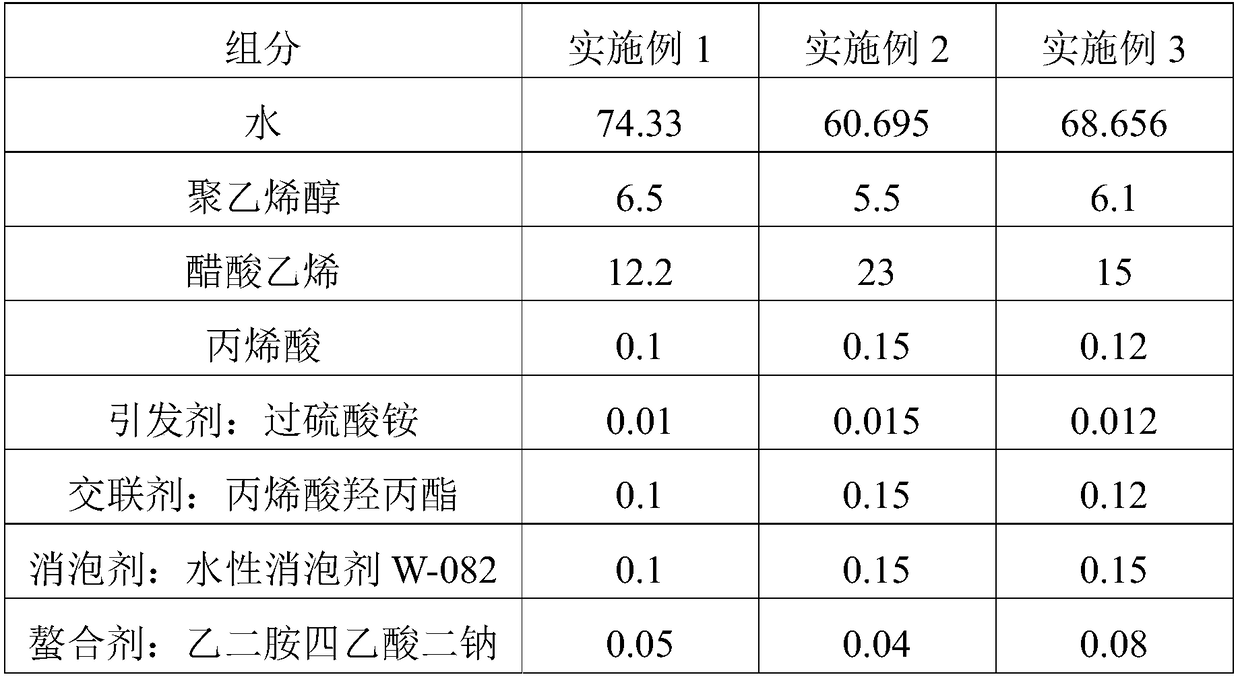

Low-solid high-viscosity polyvinyl acetate emulsion and preparation method thereof

ActiveCN108822766AHigh viscosityFully polymerizedMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer sciencePolyvinyl acetate

The invention provides a low-solid high-viscosity polyvinyl acetate emulsion which comprises raw materials, namely vinyl acetate and acrylic acid as monomer mixtures, on the basis of formula optimization, a preparation that the monomer mixtures are added at different steps is implemented, and in addition, the monomer mixtures are stirred and dropped at the same time when the monomer mixtures are added at a second step, so that due to reasonable cooperation of the formula components and the preparation method, a sufficient polymerization reaction can be achieved, the viscosity of the polyvinylacetate emulsion can be greatly increased without starch for thickening, and meanwhile high adhesion strength can be achieved.

Owner:广东嘉宝莉科技材料有限公司

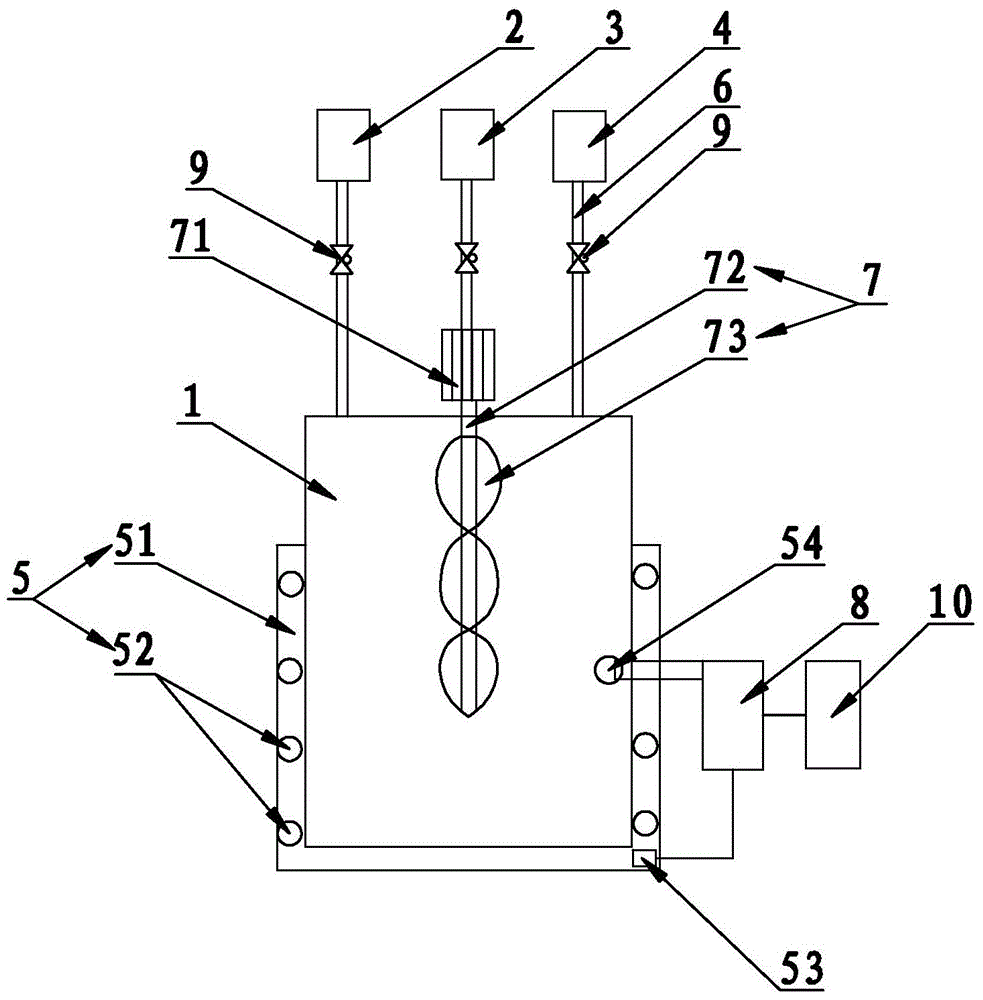

Production equipment for naphthalene water reducer

The invention discloses production equipment for a naphthalene water reducer. The production equipment comprises a reaction kettle, a first raw material tank, a second raw material tank, a third raw material tank, a thermal insulating device, material delivery pipes, a stirring device, a control system and a displayer; the outer side of the lower portion of the reaction kettle is provided with the thermal insulating device, the thermal insulating device comprises a thermal insulating interlayer, steam pipes, a temperature sensor and a temperature regulator, and the steam pipes for heating are arranged in the thermal insulating interlayer and spirally wound on the outer side of the reaction kettle; the temperature sensor is arranged at the bottom inside the thermal insulating interlayer and connected with the temperature regulator arranged on the outer side of the reaction kettle; each material delivery pipe is provided with a flow control valve; the stirring device comprises a motor, a stirring shaft and a stirring blade; the motor, the flow control valves and the temperature regulator are all connected with the control system, and the output end of the control system is connected with the displayer. The production equipment for the water reducer achieves the advantages that the automation degree and the production efficiency are high, raw materials fully react, and the product quality is improved.

Owner:ANHUI FUNAN LVYUAN CHEM

Preparation method of long-carbon-chain polyamide based on pentanediamine

The invention discloses a preparation method of long carbon chain polyamide based on pentamethylene diamine. Comprising the following steps: (1) reacting pentamethylene diamine, long carbon chain dibasic acid and water at 50-70 DEG C to obtain a polyamide salt solution; and (2) carrying out polymerization reaction on raw materials including the polyamide salt solution, a catalyst, an antioxidant and a molecular weight regulator under the condition of temperature programming to obtain the pentanediamine-based long-carbon-chain polyamide. The pentamethylene diamine-based long carbon chain polyamide which is good in mechanical property, high in transparency and easy to process can be obtained.

Owner:BEIJING UNIV OF CHEM TECH

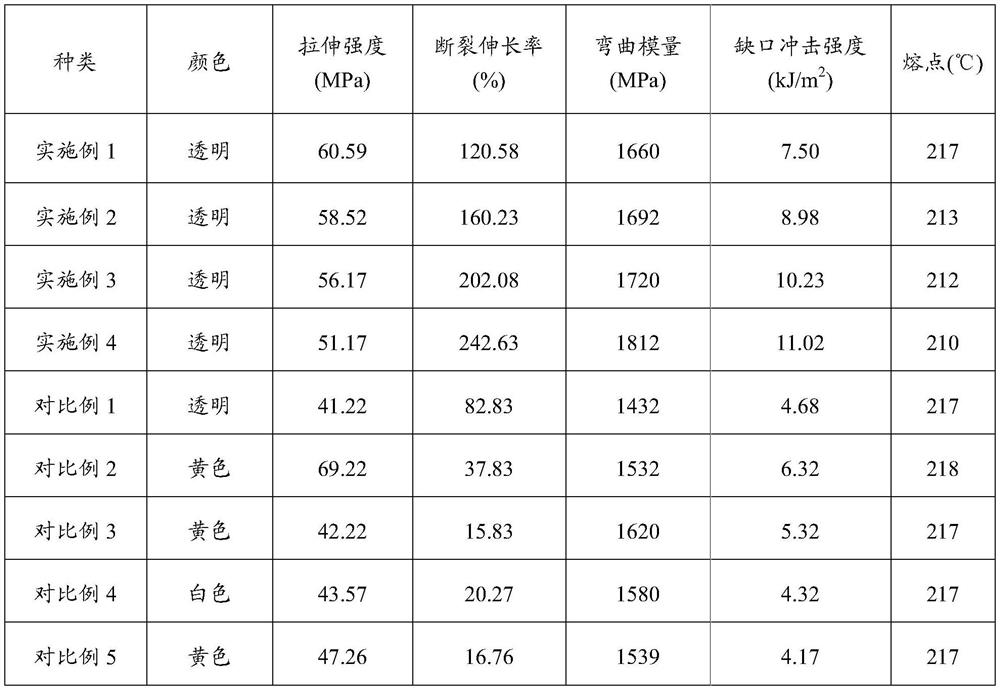

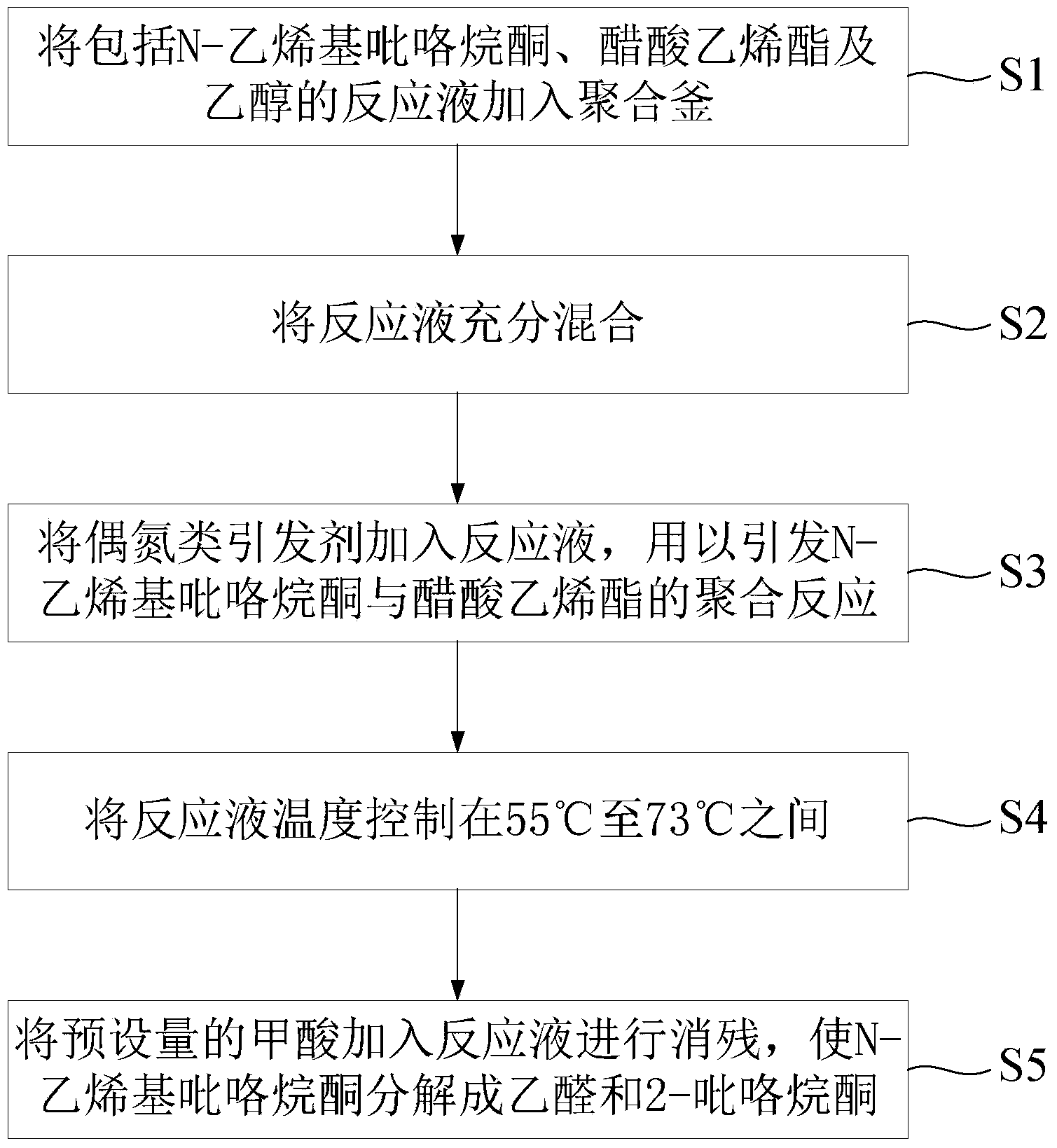

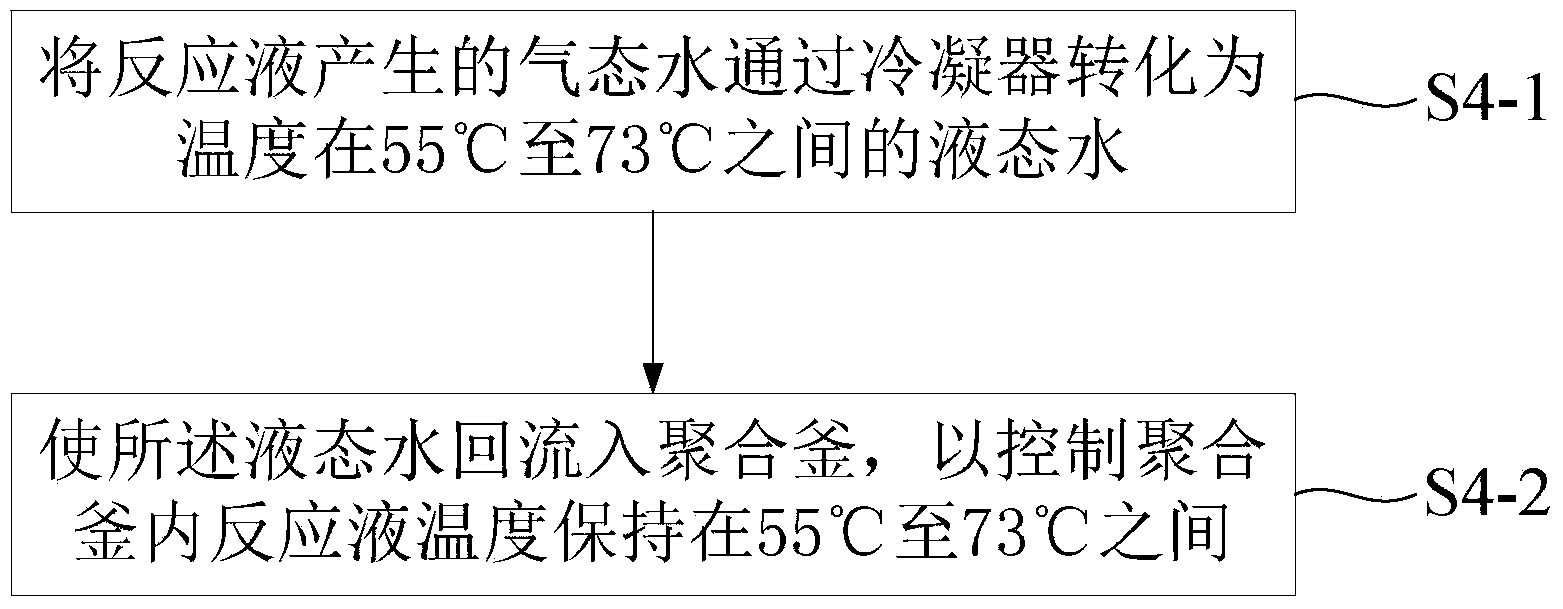

Preparation method of vinyl pyrrolidone-vinyl acetate copolymer

The invention discloses a preparation method of a vinyl pyrrolidone-vinyl acetate copolymer. The method at least comprises the following steps: adding a reaction solution containing N-vinyl-2-pyrrolidone, vinyl acetate and ethanol into a polymerization kettle; thoroughly mixing the reaction solution; adding an azo initiator into the reaction solution to initiate the polymerization reaction between the N-vinyl-2-pyrrolidone and vinyl acetate, wherein the temperature of the reaction solution is controlled at 55-73 DEG C, and the reaction time is 4-5 hours; adding a preset amount of formic acid into the reaction solution to eliminate residues, thereby decomposing the N-vinyl-2-pyrrolidone into acetaldehyde and 2-pyrrolidone. The method has the advantages of simple steps, low cost and high efficiency, and can ensure the quality requirements for the vinyl pyrrolidone-vinyl acetate copolymer.

Owner:重庆斯泰克瑞登梅尔材料技术有限公司

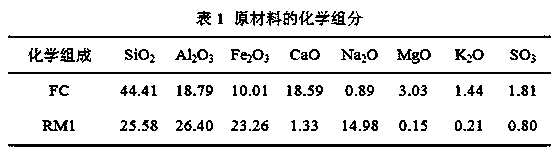

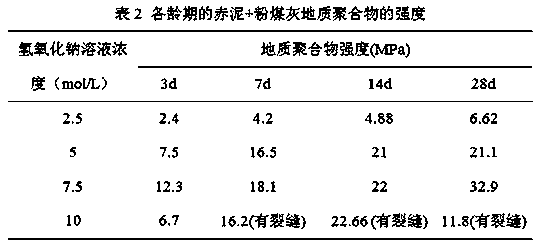

A kind of red mud and fly ash geopolymer material formula and preparation method thereof

ActiveCN105837067BIncrease consumptionSolve storage problemsCement productionRed mudMetallic materials

The invention discloses a red mud and coal ash geopolymer material formula, and belongs to the field of comprehensive utilization of waste and preparation of inorganic nonmetal materials. Red mud and coal ash are adopted as basic raw materials, a sodium hydroxide solution is adopted as an exciting agent, and a red mud and coal ash geopolymer material is prepared. The mass ratio of the red mud to the coal ash to the sodium hydroxide solution is 1:1:(0.8-1). The polymer materials of different strengths can be obtained by adding sodium hydroxide solutions of different concentrations. Maintenance is performed at the temperature of 50-80 DEG C for 24-36 h, the polymerization reaction is more sufficient, the geopolymer material of the high strength can be obtained, the highest strength can reach 32 MPa or more in 28 d, and the red mud and coal ash geopolymer material formula can be widely used for a constructional engineering material. According to the geopolymer material, the red mud and the coal ash are utilized, the preparation method is simple, no large number of resources need to be consumed, the consumption of the red mud is large, the purpose of recycling the red mud can be achieved, energy and land are saved, and environment pollution caused by the red mud is eliminated.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

Preparation process of high concentration polymerized aluminium sulfate flocculant

InactiveCN100546920CHigh degree of polymerizationIncrease concentrationSilicon compoundsWater/sewage treatment by flocculation/precipitationWater bathsHigh concentration

Owner:SOUTH CHINA UNIV OF TECH

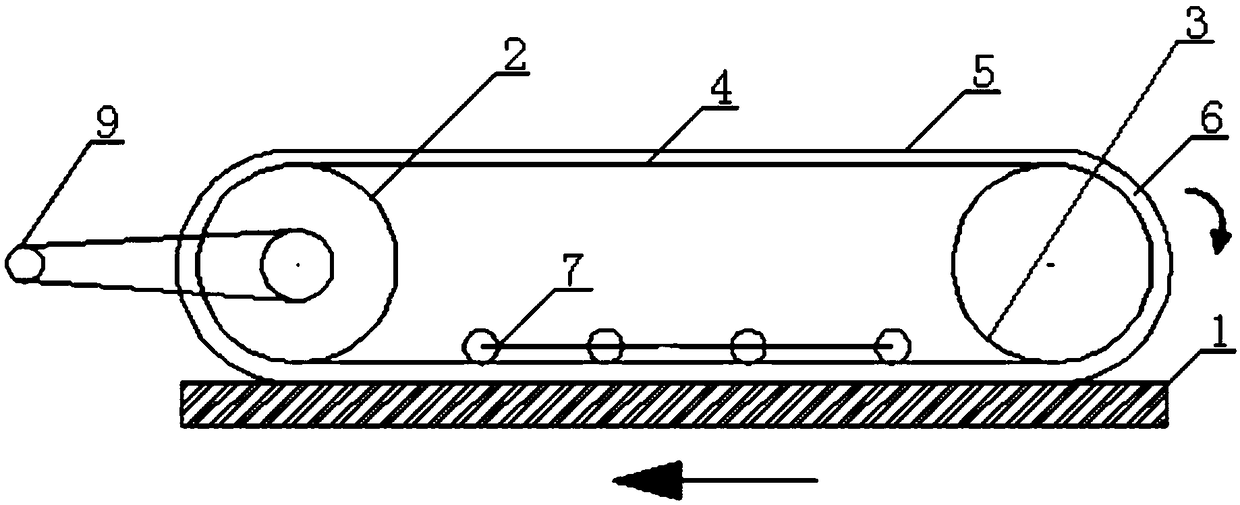

Thermal insulation device for belt type polymerization

The invention discloses a thermal insulation device for belt type polymerization. The thermal insulation device is arranged above a polymer, and comprises a drive wheel, a driven wheel, a conveyor belt arranged on the drive wheel and the driven wheel in a driving way, a pressing mechanism arranged in a liftable way between the drive wheel and the driven wheel and used for downward pressing the conveyor belt on the upper surface of the polymer, wherein the conveyor belt comprises an inner layer conveyor belt, an outer layer conveyor belt and a thermal insulation interlayer clamped between the inner layer conveyor belt and the outer layer conveyor belt. The thermal insulation device for belt type polymerization is suitable for continuously producing the polymer, the conveyor belt with the thermal insulation interlayer is pressed on the upper surface of the polymer, and can prevent the polymer from making contact with external gas in a thermal insulation process and can greatly reduce evaporative heat loss of the polymer, the thermal insulation effect is good, a high temperature can be kept in the polymer, polymerization reaction can be more sufficient, and the aim of reducing the content of residual monomers is achieved.

Owner:JIANGSU FEYMER TECH

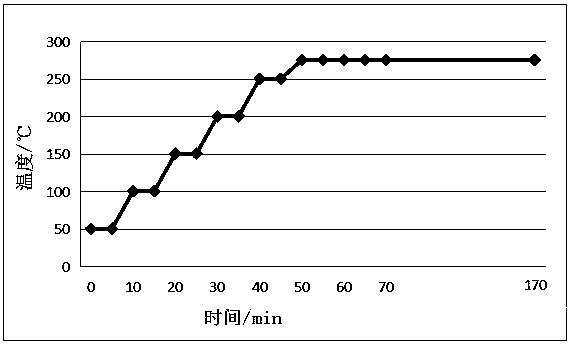

Curing method for photosensitive resin BCB

ActiveCN108717933AReduces the likelihood of oxidative agingImprove BCB qualitySemiconductor/solid-state device manufacturingEngineeringPlasma reaction

The invention belongs to the technical field of production of semiconductor chips, and in particular relates to a curing method for photosensitive resin BCB. The method comprises the following steps of coating photosensitive BCB glue on the surface of an epitaxial wafer, forming a photosensitive BCB glue pattern on the surface of the epitaxial wafer by using a photoetching method; 2, etching the photosensitive BCB glue on the surface of the epitaxial wafer via a plasma reaction; 3, placing the etched epitaxial wafer into an annealing furnace, inputting the mixed gas of H2 and Ar for protection, raising the temperature from 50 DEG C to 275 DEG C in a multistage warming and heat-retaining manner, and keeping warm for 2h at the temperature of 275 DEG C; and 4, then increasing the flow for inputting the mixed gas of H2 and Ar to quickly reduce the temperature of the annealing furnace to the room temperature, and stopping inputting the mixed gas of H2 and Ar, thus completing curing. According to the curing method for the photosensitive resin BCB provided by the invention, the multistage warming and heat-retaining manner is used, so that the BCB polymerization reaction is more sufficient; and when in annealing, the mixed gas of H2 and Ar is used for replacing traditional N2 to serve as a protection gas, so that the possibility of oxidation and aging is reduced, and the BCB quality isimproved.

Owner:湖北光安伦芯片有限公司

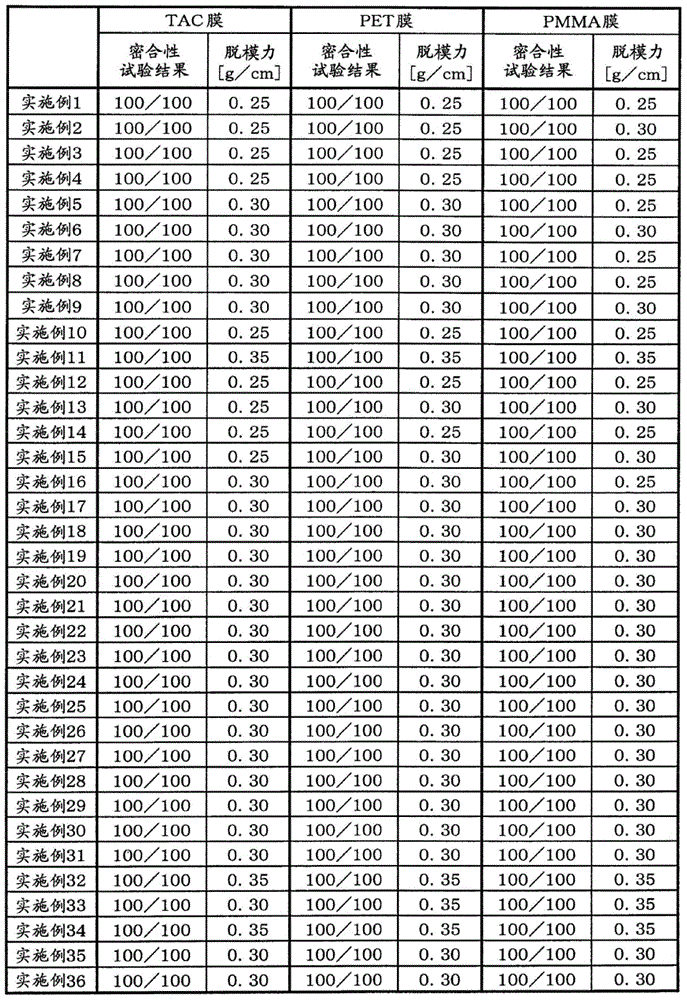

embossing material

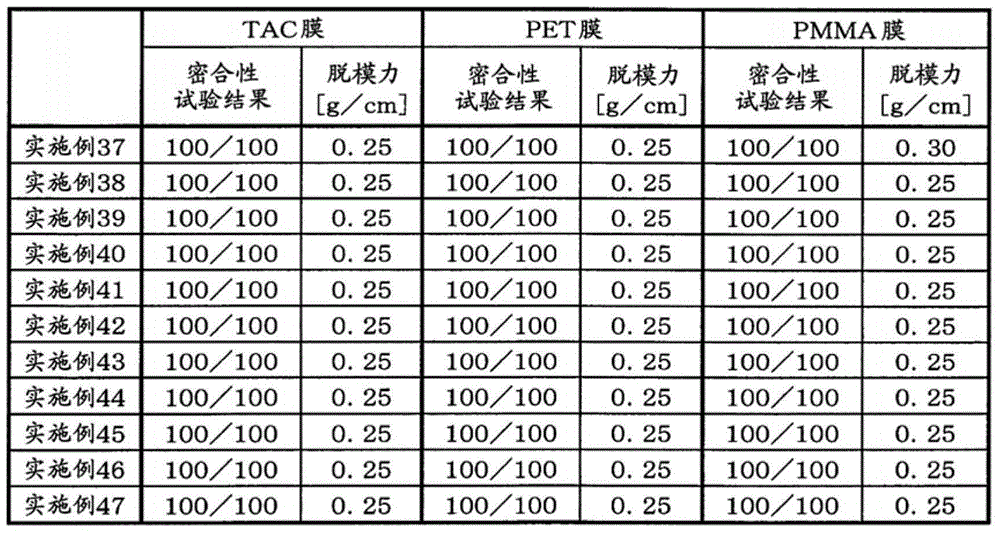

InactiveCN103503115BLow release forceFully polymerizedLayered productsNanoinformaticsAdditive ingredientSolvent

The subject of the present invention is to provide an imprint of a film that is in the form of a transparent and uniform varnish that does not peel off in a cross-cut test for evaluating the adhesion of a coating film, and that has a release force of 0.5 g / cm or less. Material. Means for solving the problem of the present invention relates to an imprint material comprising: (A) component: a compound having at least one oxyalkylene unit having 2, 3, or 4 carbon atoms and having at least 2 polymerizable groups , (B) component: photopolymerization initiator, (C) component: the solvent which swells or dissolves the surface part of a film base material, and (D) component: organosilicon compound.

Owner:NISSAN CHEM CORP

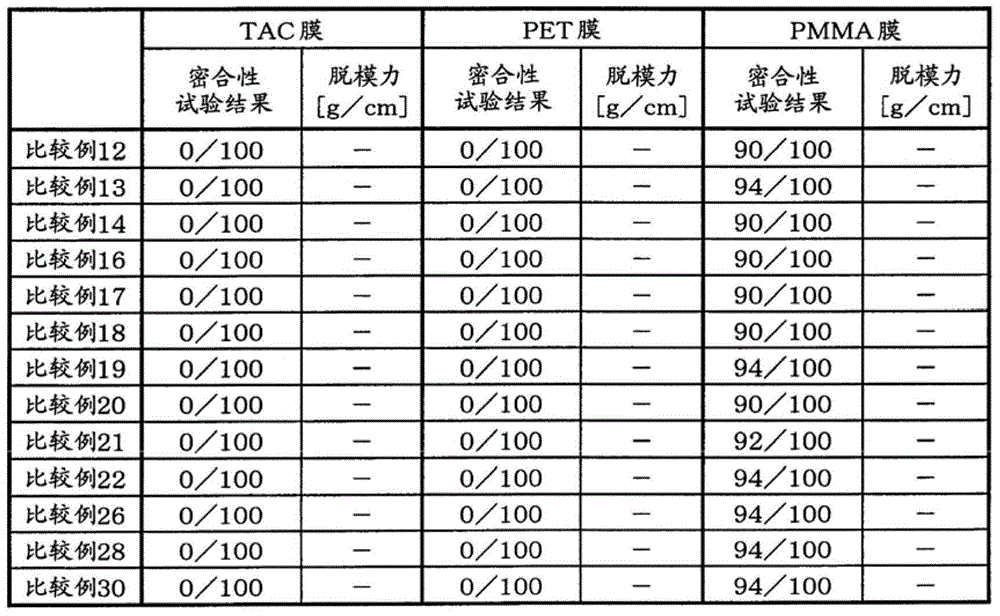

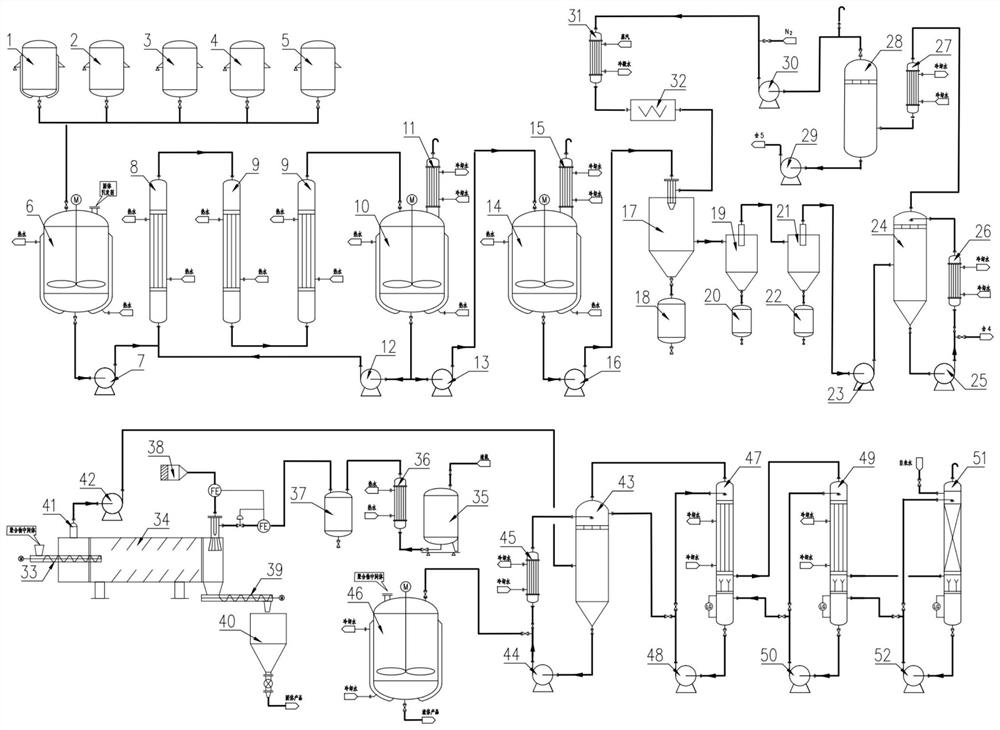

Green, safe and environmentally friendly process for industrialized continuous large-scale production of aldehyde-free water-based adhesives

ActiveCN113801611BHigh molecular weightImprove conversion rateVinyl aromatic copolymer adhesivesEvaporation by sprayingAdhesiveSolid reaction

The invention relates to a green, safe and environment-friendly process for industrialized continuous large-scale production of aldehyde-free water-based adhesives, comprising: monomers with carbon-carbon unsaturated double bonds and acid anhydride groups, at least one other carbon-carbon unsaturated double The monomer of the bond is used as the raw material, and the polymerization reaction is carried out with the participation of the solvent and the initiator; the polymerization reaction liquid is subjected to solid-liquid separation under the action of high-temperature inert carrier gas, the solvent is vaporized, and returned to the polymerization reaction after condensation; the solid material is used as the polymer The intermediate is subjected to a gas-solid reaction with the mixed gas of ammonia and air to obtain a solid formaldehyde-free water-based adhesive product. The green, safe and environment-friendly production process of the aldehyde-free water-based adhesive provided by the present invention has the advantages of green, safe, environmental protection, simple process, mild reaction conditions, good atom economy, etc., and can realize the automatic control of the whole process, save labor, and is suitable for non-toxic Continuous industrial production of aldehyde water-based adhesives.

Owner:新元化学(山东)股份有限公司 +1

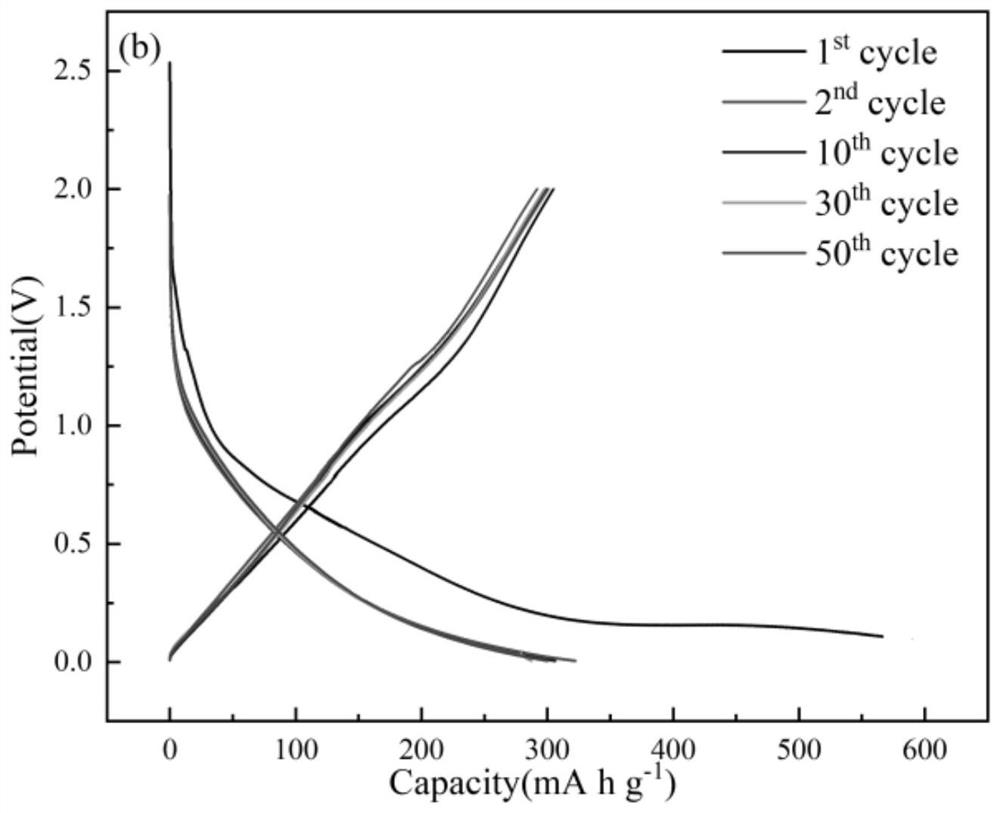

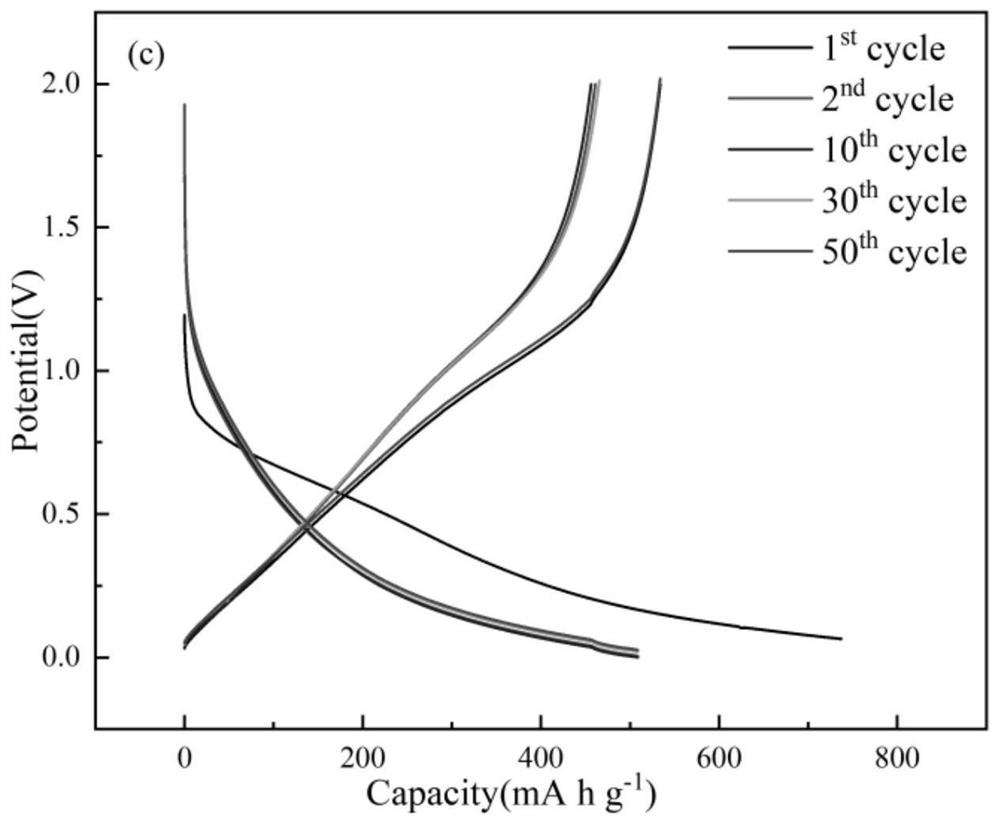

Nitrogen-doped carbon electrode material and preparation method thereof

PendingCN113415795ASmall particle sizeNarrow particle size distributionNegative electrodesSecondary cellsAcrylonitrileLithium-ion battery

The invention discloses a nitrogen-doped carbon electrode material, which is prepared by the following steps of removing electrolyte from polymer emulsion prepared from acrylonitrile and other monomers, adding electrolyte solution, standing to form polymer hydrogel, drying the polymer hydrogel, and carrying out two-step heat treatment of oxidation and carbonization to obtain the nitrogen-doped carbon electrode material. The invention also provides a preparation method of the nitrogen-doped carbon electrode material. The method has the following advantages that the nitrogen with electrochemical activity in the obtained material can change the conductivity and interface stability of the carbon material and improve the reaction kinetics of a carbon-based electrode, so that the structural stability and lithium storage performance of the carbon negative electrode material of the lithium ion battery are improved.

Owner:KUNMING UNIV OF SCI & TECH

High-efficiency organic coagulant

PendingCN112239260AImprove the coagulation effectEasy to handleWater/sewage treatment by flocculation/precipitationMeth-Polyacrylamide

The invention relates to the technical field of coagulants, and in particular, relates to a high-efficiency organic coagulant which is specifically prepared by the following preparation steps: (1) adding hydroxymethylated polyacrylamide and an ethanol solution with the mass concentration of 63% into a container, and stirring and mixing; (2) raising the temperature of the container to 70-85 DEG C,adjusting the pH value of the solution after 3 hours, and reacting for 6 hours under an acidic condition; and (4) adding a quaternary ammonium salt monomer into the container, uniformly stirring and mixing, dropwise adding polymethyldiallylammonium chloride (HCA) into a reaction kettle, and reacting for 9 hours to obtain the organic coagulant. The organic coagulant has the beneficial effects thatthe polymerization reaction is promoted to be more sufficient through the polymethyldiallyl ammonium chloride (HCA), the preparation method is simple, secondary pollution such as heavy metal is not generated, the prepared organic coagulant is good in coagulation effect, the putting amount of treated wastewater can be reduced, and the sludge dewatering treatment cost and the later treatment cost can also be reduced.

Owner:山东万和环保节能技术有限公司

Butadiene-styrene latex and preparation method thereof

The invention discloses butadiene-styrene latex and a preparation method thereof. The butadiene-styrene latex is prepared from water phase materials (a first solvent, divinylbenzene, an anionic emulsifier, a first emulsifier, hydroxyl ethyl cellulose, polysorbate-80, acrylic acid, N-methylol acrylamide, acrylic amide, and a pH regulator), oil phase materials (styrene, butadiene, an organic solvent, and 3-mercaptobutyrate), base materials (mbs seed latex, sodium dodecylbenzenesulfonate and a second solvent), and other materials (a third solvent, EDTA, initiator mixture, a water-based foam suppressor, liquid base, and a second emulsifier), wherein both the first emulsifier and the second emulsifier are non-ionic emulsifiers, the first solvent, the second solvent and the third solvent are allsoft water, and the organic solvent comprises one of butyl acetate, butyl acetate, and butyl acrylate. The butadiene-styrene latex has advantages of good water resistance, aggregate stability, mechanical stability, and chemical stability.

Owner:杭州龙驹合成材料有限公司

An organic concrete and its preparation method

ActiveCN107804905BImprove the coagulation effectNo secondary pollutionWater/sewage treatment by flocculation/precipitationEpoxyPolymer science

The invention discloses an organic coagulant and a preparation method thereof, and belongs to the technical field of wastewater treatment. The preparation method comprises the following steps: takingorganic amine and epoxy chloropropane as the primary raw materials to synthesize an intermediate namely epoxy chloropropane-organic amine; and then modifying the intermediate by a modifier to promotethe intermediate to carry out copolymerization reactions with quaternary ammonium salt monomers under the action of an initiator to obtain the organic coagulant. The prepared organic coagulant has a good coagulating effect, and the secondary pollution and post treatment load are both reduced.

Owner:广州安达净水材料有限公司

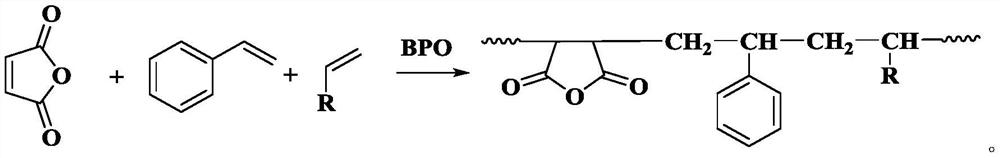

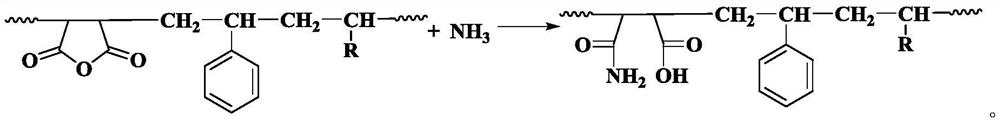

Green, safe and environment-friendly device and method for industrial continuous large-scale production of formaldehyde-free aqueous adhesive

ActiveCN113856605AHigh molecular weightImprove conversion rateCombination devicesGas treatmentAdhesiveProcess engineering

The invention relates to a green, safe and environment-friendly device and method for industrial continuous large-scale production of a formaldehyde-free aqueous adhesive. The device comprises a polymerization reaction system, a solvent recovery system and an ammonification reaction system. The method comprises three steps of polymerization reaction, solvent recovery and ammonification reaction. The polymerization reaction system adopts a circulation loop technology, and the reaction is controlled through a tubular reactor; the solvent recovery system adopts inert gas N2 or CO2 for circulating spray drying; and the ammoniation reaction system adopts a powdery material gas-solid continuous ammoniation process, and ammonia gas is diluted by air. The green, safe and environment-friendly production process of the formaldehyde-free water-based adhesive has the advantages of being green, safe, environment-friendly, simple in process, mild in reaction condition, good in atom economy and the like, full-process automatic control can be achieved, labor is saved, and the method is suitable for continuous industrial production of the formaldehyde-free water-based adhesive.

Owner:新元化学(山东)股份有限公司 +1

Styrene-butadiene latex and its preparation method

The invention discloses butadiene-styrene latex and a preparation method thereof. The butadiene-styrene latex is prepared from water phase materials (a first solvent, divinylbenzene, an anionic emulsifier, a first emulsifier, hydroxyl ethyl cellulose, polysorbate-80, acrylic acid, N-methylol acrylamide, acrylic amide, and a pH regulator), oil phase materials (styrene, butadiene, an organic solvent, and 3-mercaptobutyrate), base materials (mbs seed latex, sodium dodecylbenzenesulfonate and a second solvent), and other materials (a third solvent, EDTA, initiator mixture, a water-based foam suppressor, liquid base, and a second emulsifier), wherein both the first emulsifier and the second emulsifier are non-ionic emulsifiers, the first solvent, the second solvent and the third solvent are allsoft water, and the organic solvent comprises one of butyl acetate, butyl acetate, and butyl acrylate. The butadiene-styrene latex has advantages of good water resistance, aggregate stability, mechanical stability, and chemical stability.

Owner:杭州龙驹合成材料有限公司

A kind of preparation method of poly[2,5-dihydroxy-1,4-phenylenepyridodiimidazole] polymer

ActiveCN103601886BSolve the problem of low molecular weightHigh molecular weightMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention relates to a preparation method of poly[2,5-dihydroxy-1,4-phenylenepyridodiimidazole] polymer. The present invention includes two steps of pre-polymerization and post-condensation reaction. The reaction time of the pre-polymer in the twin-screw extruder is 10-60 minutes. Zones are 160-180°C, 180-190°C and 190-200°C respectively. The present invention adopts a twin-screw extruder to carry out post-condensation reaction, and adopts specific temperature and time control parameters, so that the intrinsic viscosity [η]=28-30dL / g of the PIPD polymer produced at the end greatly improves its molecular weight , and at the same time, it is convenient to stir and transfer the PIPD polymer to the spinning section more easily, which improves the production efficiency and reduces the production cost.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Preparation method of coating type dye polarizing component and liquid crystal panel

ActiveCN106154390BAvoid reunionReunion is not easy to happenPolarising elementsNon-linear opticsLiquid-crystal displayUltraviolet

The invention provides a preparation method of a coating type dye polarization component, wherein the coating type dye polarization component comprises a substrate; a polarization alignment film is arranged on the substrate; the preparation method comprises the following steps: heating a reaction vessel to a reaction temperature according to a hot bath method, maintaining the reaction temperature in the reaction vessel; placing a reaction monomer in the reaction vessel, stirring and fully dissolving, then standing for a first time interval; placing a dye in the reaction vessel, stirring and fully dissolving, then standing for the first time interval to obtain a polarization film solution; coating the polarization film solution on the polarization alignment film of the substrate by using a spin-coating method to obtain a polarization film; curing the polarization film through ultraviolet irradiation to obtain the coating type dye polarization component. The invention further provides a liquid crystal panel. The solution of the invention can improve a polarization degree of a polarizer and improve a contrast ratio of the liquid crystal panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Low-solid high-viscosity polyvinyl acetate emulsion and preparation method thereof

ActiveCN108822766BHigh viscosityFully polymerizedMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer sciencePolyvinyl acetate

The invention provides a low-solid high-viscosity polyvinyl acetate emulsion which comprises raw materials, namely vinyl acetate and acrylic acid as monomer mixtures, on the basis of formula optimization, a preparation that the monomer mixtures are added at different steps is implemented, and in addition, the monomer mixtures are stirred and dropped at the same time when the monomer mixtures are added at a second step, so that due to reasonable cooperation of the formula components and the preparation method, a sufficient polymerization reaction can be achieved, the viscosity of the polyvinylacetate emulsion can be greatly increased without starch for thickening, and meanwhile high adhesion strength can be achieved.

Owner:广东嘉宝莉科技材料有限公司

A kind of curing method of photosensitive resin bcb

ActiveCN108717933BFully polymerizedQuality improvementSemiconductor/solid-state device manufacturingEtchingSemiconductor chip

The invention belongs to the technical field of semiconductor chip manufacturing, and specifically relates to a method for curing photosensitive resin BCB, comprising the following steps: 1) coating a photosensitive BCB glue on the surface of an epitaxial wafer, and forming a photosensitive BCB glue on the surface of the epitaxial wafer by photolithography 2) Treat the photosensitive BCB adhesive on the surface of the epitaxial wafer by plasma reactive etching; 3) Put the etched epitaxial wafer into the annealing furnace, and pass H 2 and Ar mixed gas protection, using a multi-stage temperature rise and heat preservation method from 50°C to 275°C, and kept at 275°C for 2h; 4) Then increase the amount of H 2 and Ar mixed gas flow rate, quickly lower the temperature of the annealing furnace to room temperature, stop feeding H 2 and Ar mixed gas to complete the curing. The curing method of the photosensitive resin BCB provided by the invention adopts the mode of multi-stage temperature rise and heat preservation, so that the polymerization reaction of BCB is more sufficient; and when annealing, H 2 Mixed gas with Ar replaces traditional N 2 As a protective gas, it reduces the possibility of oxidative aging and improves the quality of BCB.

Owner:湖北光安伦芯片有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d0f58cdd-7ce6-4dd0-8c91-b0f4bbca9a4a/2013106175895100002DEST_PATH_IMAGE001.PNG)

![Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d0f58cdd-7ce6-4dd0-8c91-b0f4bbca9a4a/2013106175895100002DEST_PATH_IMAGE002.PNG)

![A kind of preparation method of poly[2,5-dihydroxy-1,4-phenylenepyridodiimidazole] polymer A kind of preparation method of poly[2,5-dihydroxy-1,4-phenylenepyridodiimidazole] polymer](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/bdb9785e-041f-4708-8347-645a2252b8b4/DEST_PATH_IMAGE001.PNG)

![A kind of preparation method of poly[2,5-dihydroxy-1,4-phenylenepyridodiimidazole] polymer A kind of preparation method of poly[2,5-dihydroxy-1,4-phenylenepyridodiimidazole] polymer](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/bdb9785e-041f-4708-8347-645a2252b8b4/DEST_PATH_IMAGE002.PNG)