Low-solid high-viscosity polyvinyl acetate emulsion and preparation method thereof

A polyvinyl acetate emulsion and high-viscosity technology, applied in the direction of non-polymer adhesive additives, adhesive types, monocarboxylate copolymer adhesives, etc., can solve the problem of low viscosity of emulsion, increased environmental hazards, Affect the appearance of the product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

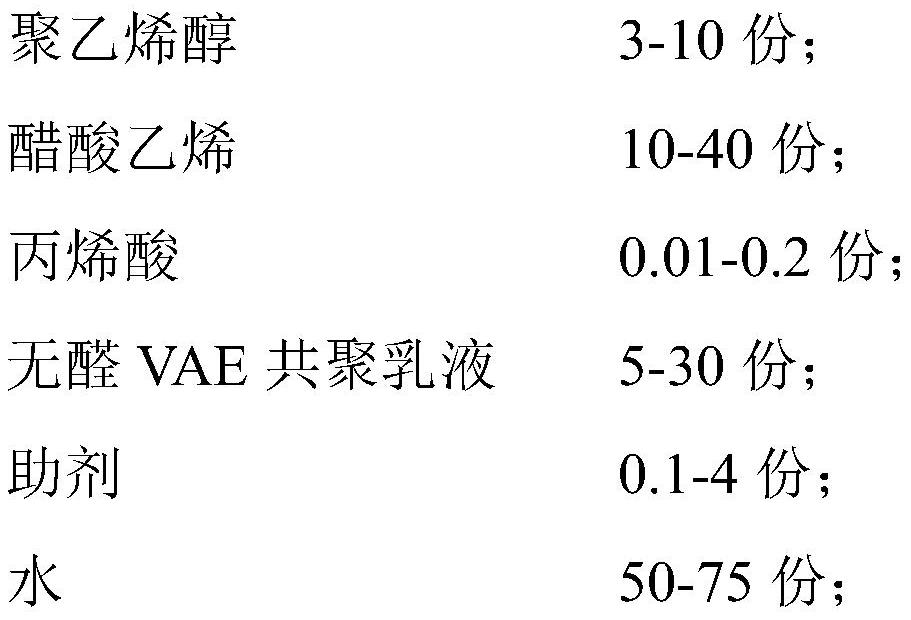

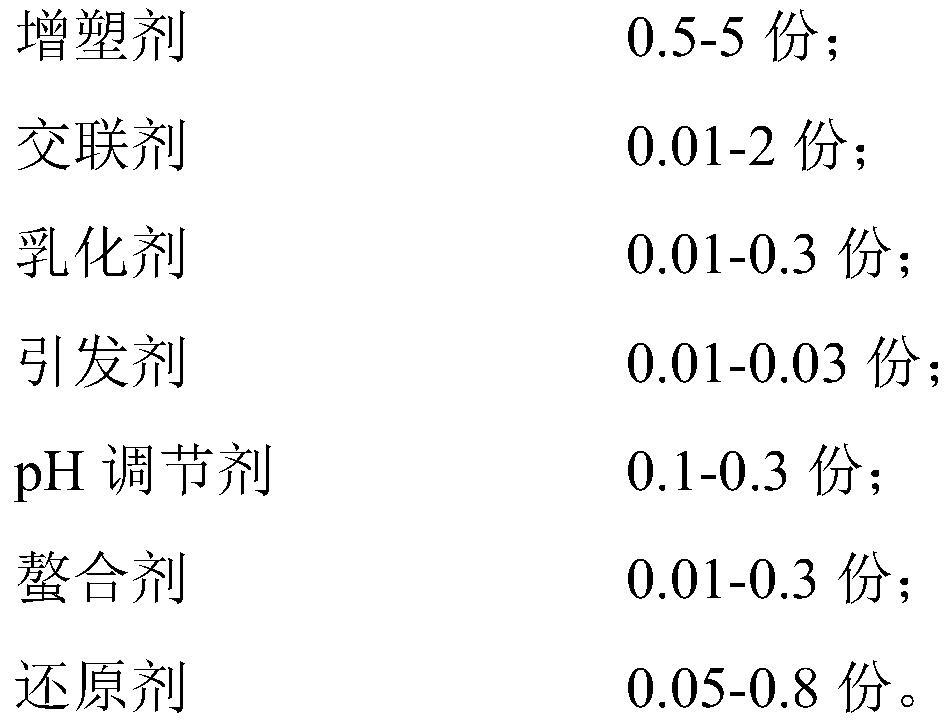

[0035] This example provides the low-solid and high-viscosity polyvinyl acetate emulsion, prepared from the following raw materials in parts by weight, as shown in Table 1.

[0036] Table 1

[0037]

[0038]

[0039] Among them, the degree of polymerization of polyvinyl alcohol in the above table is 88%, the degree of alkali hydrolysis, the molecular weight is 24000, and the viscosity is about 50 mPa.s, among which BP24 from Changchun, Taiwan, China is preferred.

[0040] The initiator is a peroxide initiator. Ammonium persulfate, industrial grade, is purchased from Shanghai Sanaisi Reagent Co., Ltd. in this embodiment; the crosslinking agent is acrylic acid hydroxy ester crosslinking agent, and methyl Hydroxypropyl acrylate, industrial grade; defoamer selects water-based defoamer in this embodiment, Hemings, W-082 type; Disodium acetate; pH regulator is bicarbonate, sodium bicarbonate is selected in the present embodiment; Emulsifier is selected K12 in the present embo...

Embodiment 1

[0068] The viscosity of the emulsion prepared in Example 1-3 reaches more than 2 times of the industry standard, wherein, the effect of Example 1-2 is remarkable, reaching more than 4 times of the industry standard, and Example 3 is due to the dropwise addition of the monomer mixture in the preparation method The stirring speed and the length of time used are not in the preferred range, which affects the viscosity and compressive shear strength of the emulsion, and its viscosity / mechanical properties are slightly worse than those of Examples 1-2, but still better than those of Comparative Examples. Compared with Example 1, Comparative Example 1 did not add the monomer mixture step by step, which affected the latex particle number and particle size of the emulsion, so the viscosity was low and the mechanical properties were poor; Comparative Example 2 was compared with Example 1, and the monomer mixture was added. When the mixing speed is too fast, the particle size of the emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com