Green, safe and environmentally friendly process for industrialized continuous large-scale production of aldehyde-free water-based adhesives

A water-based adhesive, production process technology, applied in the direction of adhesive type, vinyl aromatic copolymer adhesive, spray evaporation, etc., can solve the problem of green chemical production goals that do not conform to the reaction principle of atom economy, and do not Suitable for continuous large-scale production, high pressure of separation and recovery, etc., to achieve the effect of saving solvent recovery energy consumption, reducing evaporation heat consumption, and reducing vaporization partial pressure

Active Publication Date: 2022-06-10

新元化学(山东)股份有限公司 +1

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, during the polymer preparation process, a combination of solvent precipitation and centrifugation or filtration separation is used to produce a large amount of solid-liquid mixed solvent, and the separation and recovery pressure is relatively high. At the same time, the mother liquor after centrifugation or filtration contains a considerable proportion of low molecular weight polymers. It cannot be reused, resulting in a large amount of hazardous waste, which does not conform to the reaction principle of atomic economy and the production goal of green chemistry, and is not suitable for industrial continuous large-scale production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0078] The polymerization reaction solution is at 180 ° C N

Embodiment 2

[0086] The polymerization reaction solution is at 150 ° C N

Embodiment 3

[0094] The polymerization reaction solution is at 200 ° C N

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

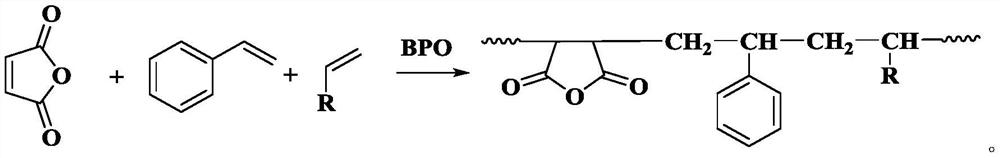

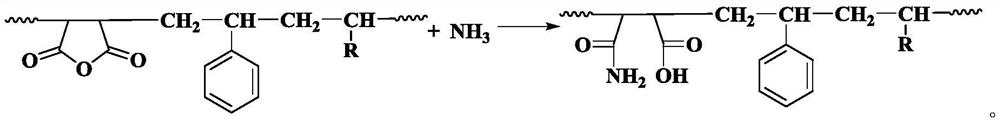

The invention relates to a green, safe and environment-friendly process for industrialized continuous large-scale production of aldehyde-free water-based adhesives, comprising: monomers with carbon-carbon unsaturated double bonds and acid anhydride groups, at least one other carbon-carbon unsaturated double The monomer of the bond is used as the raw material, and the polymerization reaction is carried out with the participation of the solvent and the initiator; the polymerization reaction liquid is subjected to solid-liquid separation under the action of high-temperature inert carrier gas, the solvent is vaporized, and returned to the polymerization reaction after condensation; the solid material is used as the polymer The intermediate is subjected to a gas-solid reaction with the mixed gas of ammonia and air to obtain a solid formaldehyde-free water-based adhesive product. The green, safe and environment-friendly production process of the aldehyde-free water-based adhesive provided by the present invention has the advantages of green, safe, environmental protection, simple process, mild reaction conditions, good atom economy, etc., and can realize the automatic control of the whole process, save labor, and is suitable for non-toxic Continuous industrial production of aldehyde water-based adhesives.

Description

Green, safe and environmentally friendly process for industrialized continuous large-scale production of aldehyde-free water-based adhesives technical field The present invention relates to the technical field of adhesive for wood-based panels, specifically, relate to a kind of aldehyde-free water-based adhesive green Color safety and environmental protection production process Background technique In current wood-based panel production, "trialdehyde glue" (urea-formaldehyde resin, phenolic resin and trialdehyde resin) prepared with formaldehyde as raw material Polycyanamide formaldehyde resin) occupies a large proportion, more than 80%. The board using "trialdehyde glue" will release free formaldehyde for a long time, Pollute the indoor environment and seriously threaten the health of residents. With the improvement of people's living standards, the consumption rationale for green ecology More and more people agree and pay more and more attention to the environmen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J135/06C08F222/08C08F212/08C08F212/36C08F232/08C08F8/30B01D1/18

CPCC09J135/06C08F222/08C08F212/08C08F212/36C08F8/30B01D1/18C08F232/08

Inventor 解乐福邵军强苗晓亮刘晓敏丛飞周建民赵伟洁

Owner 新元化学(山东)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com