Preparation method of vinyl pyrrolidone-vinyl acetate copolymer

A technology for the copolymerization of vinylpyrrolidone and vinyl acetate, which is applied in the field of preparation of vinylpyrrolidone and vinyl acetate copolymers, can solve problems such as inaccessibility, and achieve the effects of low cost, high efficiency and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

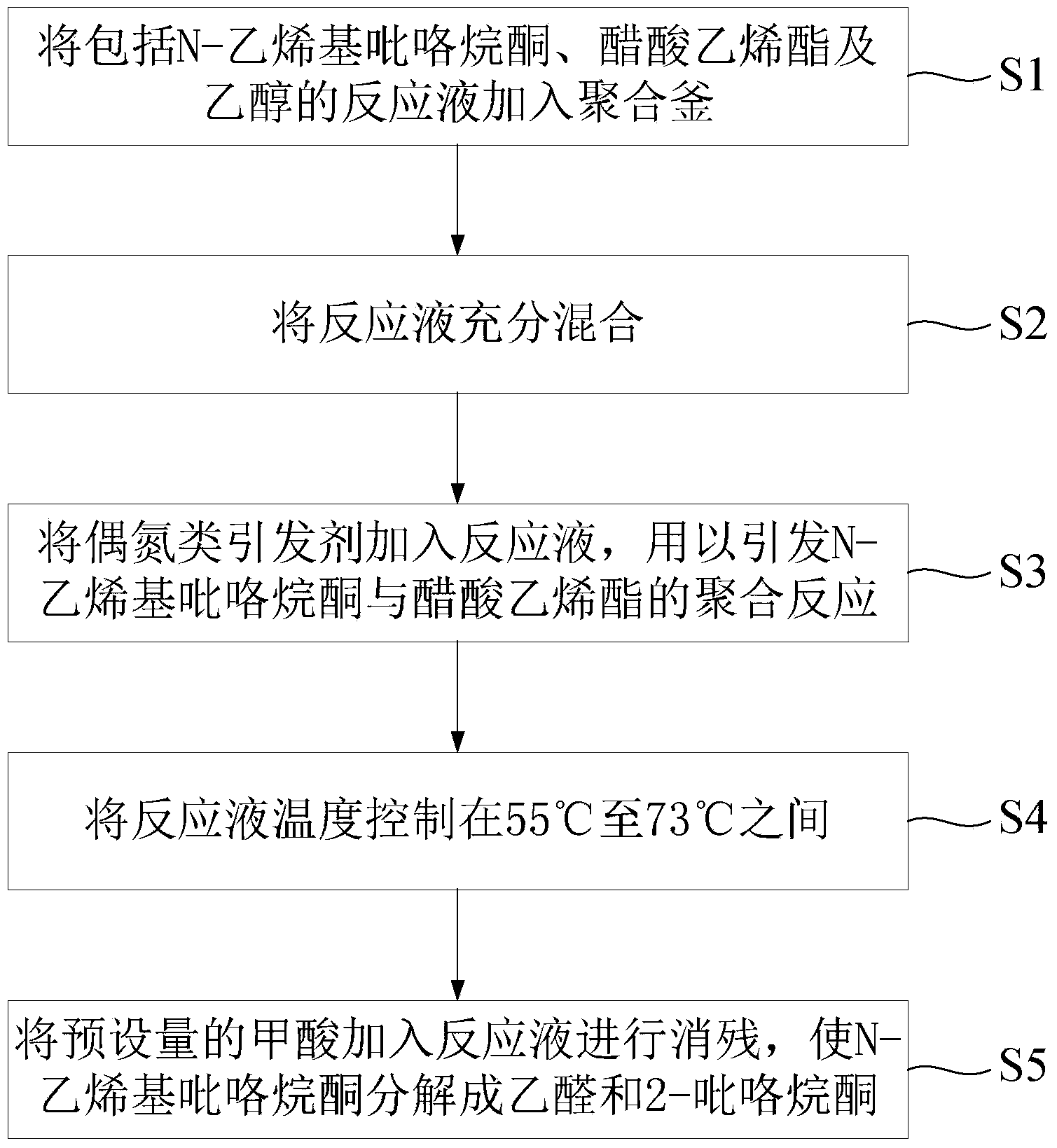

[0025] The common method used by those skilled in the art to prepare vinylpyrrolidone and vinyl acetate copolymer is to use ethanol, N-vinylpyrrolidone and vinyl acetate as raw materials, and then carry out polymerization reaction, wherein ethanol, N-vinylpyrrolidone and vinyl acetate The ratio of the amount between is determined according to actual needs, and can be any ratio. Of course, in the preparation method of the vinylpyrrolidone-vinyl acetate copolymer of the present invention, the ratio of ethanol, N-vinylpyrrolidone and vinyl acetate can still be any ratio. The process of preparing vinylpyrrolidone-vinyl acetate copolymer by using ethanol, N-vinylpyrrolidone and vinyl acetate in the prior art can also be applied to the present invention.

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

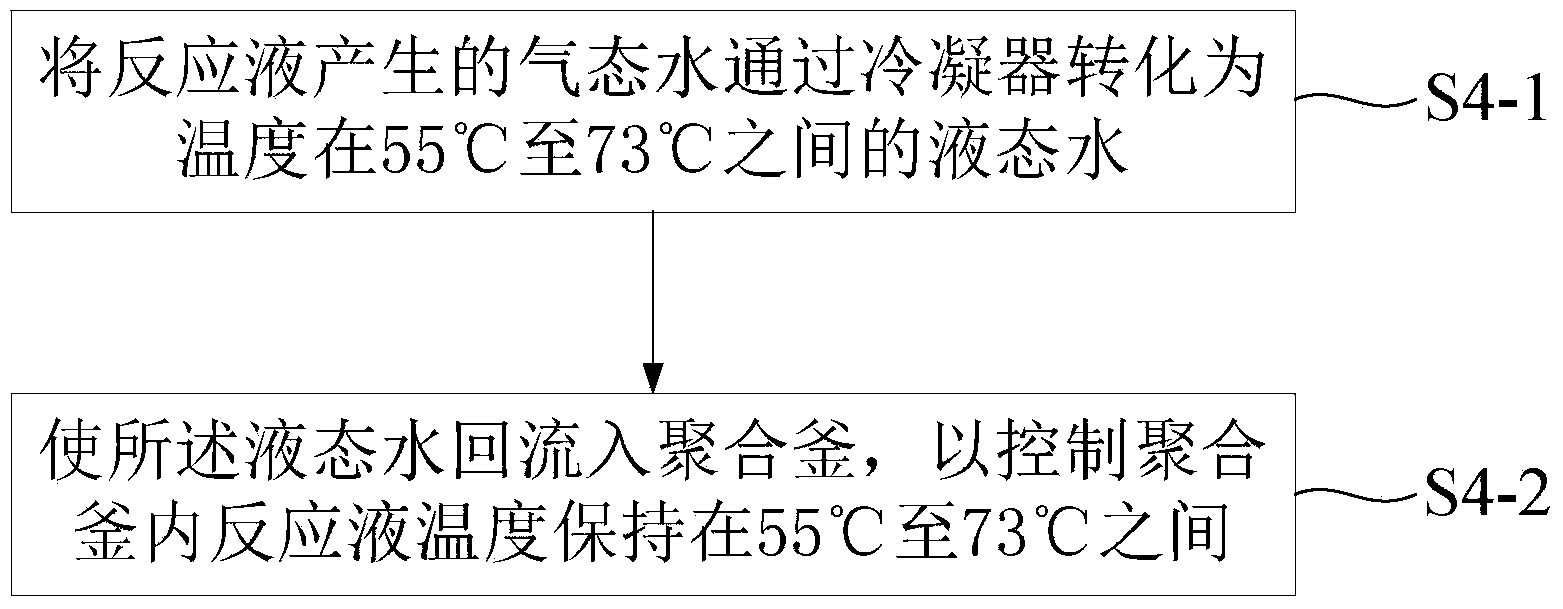

[0027] The preparation method of the vinylpyrrolidone-vinyl acetate copolymer of the present invention refers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com