Green, safe and environment-friendly device and method for industrial continuous large-scale production of formaldehyde-free aqueous adhesive

A water-based adhesive, safe and environmentally friendly technology, used in combination devices, adhesive types, chemical instruments and methods, etc., can solve the production goals that do not meet the reaction principle of atomic economy, are not suitable for continuous large-scale production, and are disadvantageous. Continuous large-scale production and other problems, to achieve the effect of improving molecular weight and polymerization conversion rate, reducing evaporation heat consumption, and avoiding explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

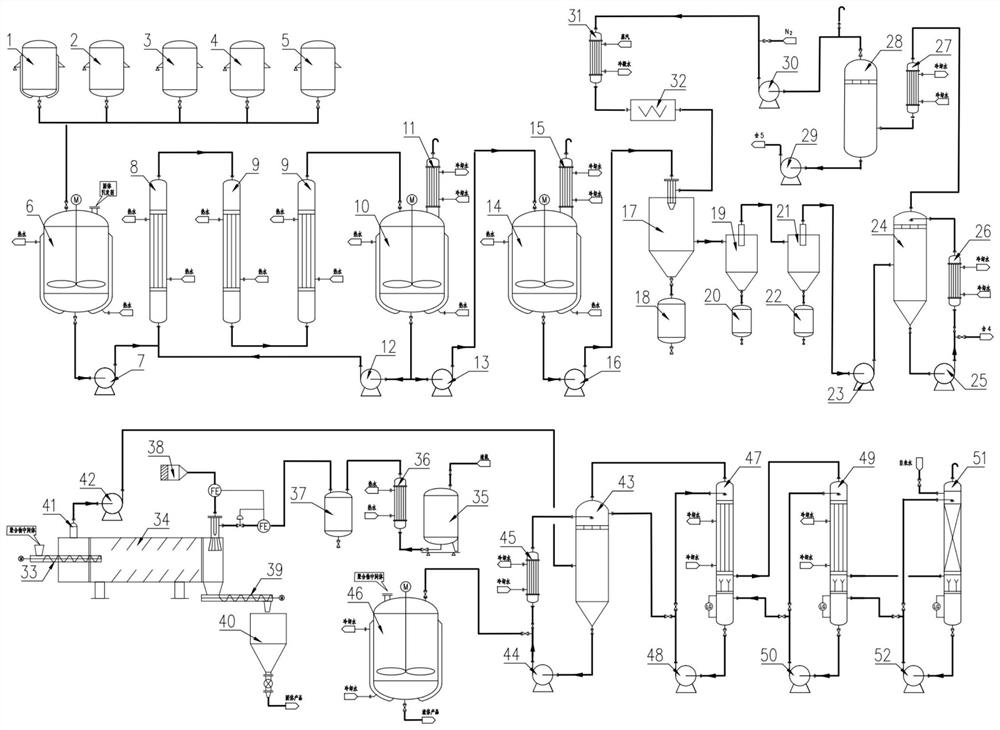

[0075] A green, safe and environment-friendly production device for an aldehyde-free water-based adhesive, which includes three parts: a polymerization reaction system, a solvent recovery system, and an ammoniation reaction system;

[0076] The polymerization reaction system includes a raw material metering tank, and the raw material metering tank is connected with a tubular reactor 9 through a dissolution mixing tank 6;

[0077] Described solvent recovery system comprises that spray drying tower 17 is connected, and described tubular reactor 9 is connected with spray drying tower 17 by feed kettle 14; Described spray drying tower 17 top is passed electric heater 32 and steam heater 31 is connected with the gas-liquid separator 28, and the bottom of the spray drying tower 17 is connected with the spray drying tower receiving tank 18; the steam heater 31 is also connected with the inert carrier gas pipeline, and the bottom of the gas-liquid separator 28 is connected with the raw...

Embodiment 2

[0080] The green safety environment-friendly production device of the non-aldehyde water-based adhesive described in embodiment 1, difference is:

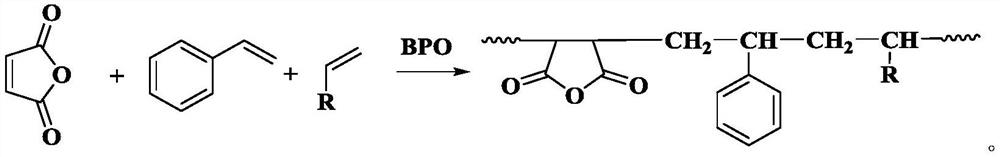

[0081] The raw material metering tank described in the polymerization reaction system includes a maleic anhydride metering tank 1, a styrene metering tank 2, a diene monomer metering tank 3, a solvent metering tank 4, and a recovery solvent tank 5, which are respectively connected to a dissolution mixing tank 6.

[0082] The dissolution mixing tank 6 described in the polymerization reaction system is connected to the tubular reactor 9 through the feed pump 7 and the preheater 8 respectively. Preheating the mixed raw materials in the dissolution mixing tank 6 through the preheater 8 is more beneficial to the polymerization reaction.

[0083] The tubular reactor 9 is arranged in series with 2 to 10 stages of tubular reactors. The multi-stage tubular reactors are arranged in series, which is beneficial to prolong the reaction residen...

Embodiment 3

[0089] The green, safe and environment-friendly production device of the aldehyde-free water-based adhesive as described in embodiment 2, the difference is:

[0090] In the solvent recovery system, the feed tank 14 is connected to the spray drying tower 17 through a metering pump 16;

[0091] Described spray drying tower 17 is also connected with gas-liquid separator 28 by primary cyclone separator 19, secondary cyclone separator 21, induced draft fan 23, spray washing tower 24 and condenser 27, and gas-liquid separator 28 is connected Connect with steam heater 31 through blower 30; This setting can make the vaporized component (mainly solvent) and inert carrier gas in spray drying tower 17 carry a small amount of dust, and pass through primary cyclone separation 19, secondary cyclone separation 21 successively , for solid particle separation;

[0092] The first-level cyclone separator 19 and the second-level cyclone separator 21 are respectively connected with the first-leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com