Plant fiber reinforced geopolymer for 3D printing of Zhaozhou Bridge, and preparation method thereof

A plant fiber and 3D printing technology, applied in the field of 3D printing materials, can solve the problems of poor bonding between plant fibers and geopolymers, increase bond strength, and reduce water absorption, so as to reduce water absorption, improve material strength, The effect of increasing the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

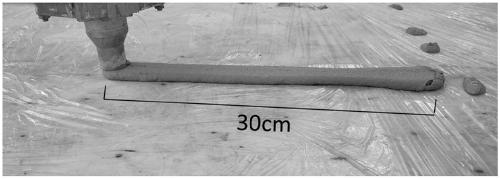

Image

Examples

preparation example Construction

[0063] A preparation method of plant fiber reinforced geopolymer for 3D printing Zhaozhou Bridge, the preparation method comprising the following steps:

[0064] (1) In terms of parts by weight, the above raw materials are divided into four groups, the first group is 0.015-0.035 parts of plant fiber, 0.02-0.05 parts of polyvinyl alcohol solution, the second group is 0.95-1.35 parts of fly ash, hydrogen oxidized 0.025-0.055 parts of calcium powder, 0.03-0.09 parts of slag, 0.08-0.13 parts of silica fume, 0.05-0.08 parts of clay, 1.2-1.4 parts of quartz sand, 0.005-0.012 parts of sodium bentonite, and the third group is coupling agent 0.0035- 0.0065 parts and 0.65-1.2 parts of compound base activator; the fourth group is 0.005-0.009 parts of viscosity modifier and 0.05-0.15 parts of water;

[0065] (2) Mix the two raw materials of the first group until the surface of the plant fiber is covered with a layer of polyvinyl alcohol solution, so that the plant fiber does not stick tog...

Embodiment 1

[0072] This embodiment 3D prints the plant fiber reinforced geopolymer for Zhaozhou Bridge. The composition and content of the geopolymer are as follows in parts by weight:

[0073] 1.1 parts of fly ash;

[0074] 0.03 parts of calcium hydroxide powder;

[0075] 0.02 part of plant fiber;

[0076] 0.04 parts of slag;

[0077] 0.09 parts of silica fume;

[0078] 0.05 parts of clay;

[0079] 1.2 parts of quartz sand;

[0080] 0.75 parts of compound base activator;

[0081] 0.006 parts of sodium bentonite;

[0082] 0.005 part of viscosity modifier;

[0083] 0.025 parts of polyvinyl alcohol solution;

[0084] 0.004 parts of coupling agent;

[0085] 0.05 parts of water;

[0086] The main composition contained in the fly ash is SiO 2 、Al 2 o 3 and CaO, the contents are 48.37%, 28.9% and 4.47%, respectively, and the CaO content is less than 10%, which belongs to low-calcium fly ash. The loss on ignition of fly ash is 5.95%, the moisture content is 0.1%, and the water deman...

Embodiment 3

[0089] In this embodiment, the preparation method of plant fiber reinforced geopolymer for 3D printing Zhaozhou Bridge comprises the following steps:

[0090] (1) In parts by weight, the above raw materials are divided into four groups, the first group is 0.02 part of plant fiber, 0.025 part of polyvinyl alcohol solution, the second group is 1.1 part of fly ash, 0.03 part of calcium hydroxide powder, slag 0.04 parts, 0.09 parts of silica fume, 0.05 parts of clay, 1.2 parts of quartz sand, 0.006 parts of sodium bentonite, the third group is 0.0035 parts of coupling agent and 0.75 parts of compound alkali activator, and the fourth group is 0.005 parts of viscosity modifier 0.06 parts with water;

[0091] (2) Mix the two materials of the first group until the surface of the fiber is slightly covered with a layer of polyvinyl alcohol solution, and the fibers will not stick together, and then dry the material in a natural state for use.

[0092] (3) Put all the materials in the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com