Preparation method and application of fibrous catalyst

A catalyst and fibrous technology, which is applied in the field of preparation of fibrous catalysts, can solve the problems of complex recovery of supported nano-precious metal catalysts and inability to continuously react, and achieve the effects of reducing application costs, easy infiltration and penetration, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

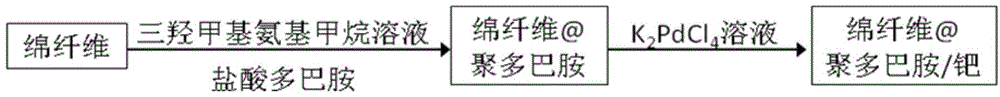

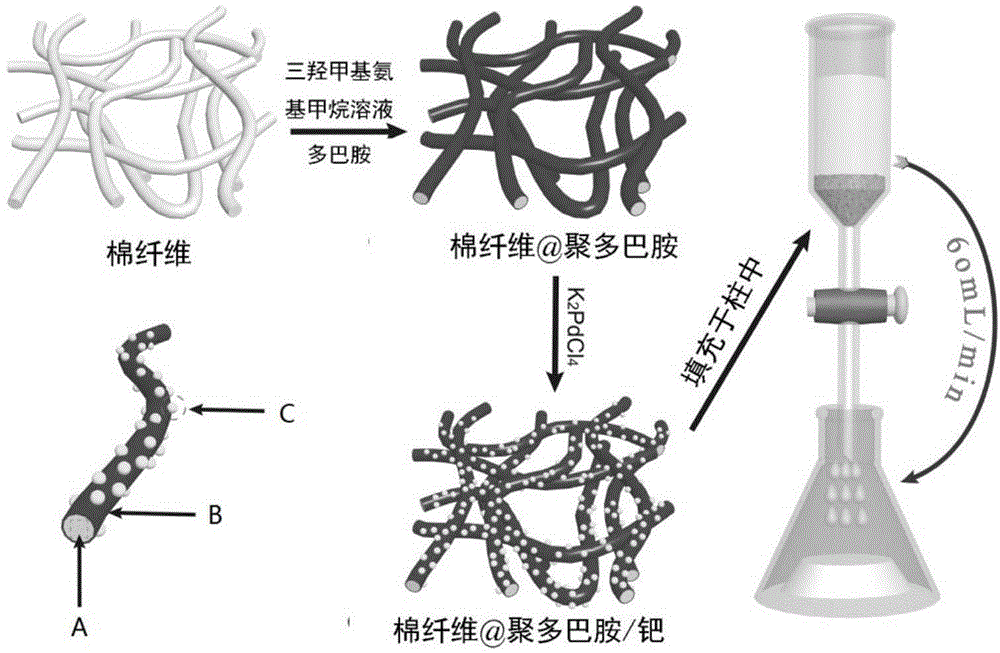

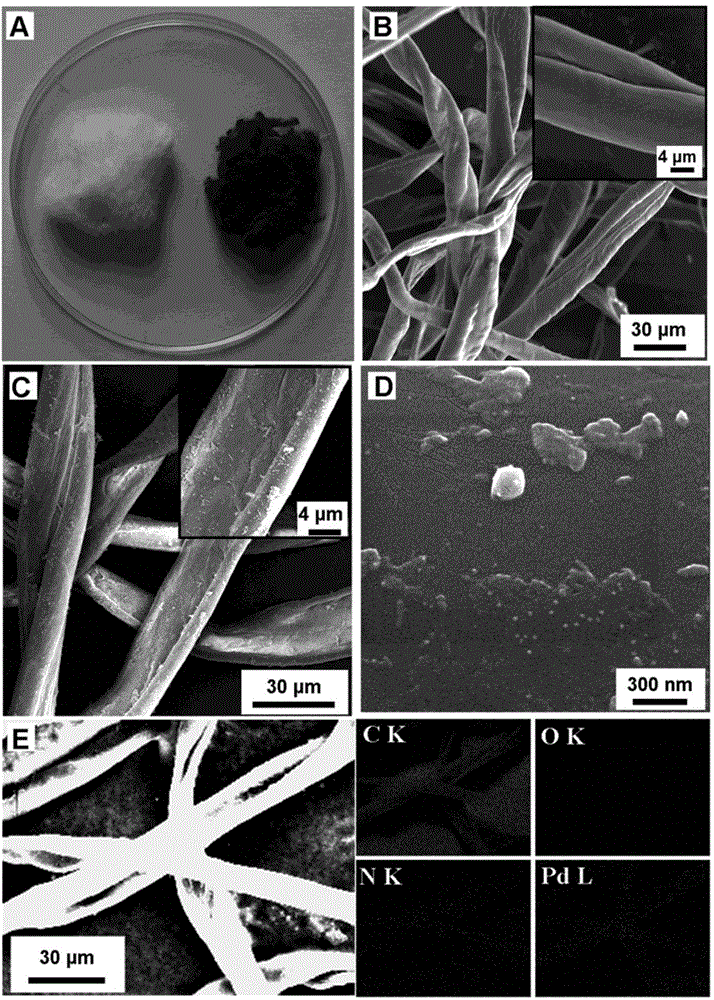

[0026] Synthesis of Cellulose Polydopamine / Palladium Composite:

[0027] 1) Synthesis of cotton fiber polydopamine (that is, cotton fiber wrapped in polydopamine, cotton fiber wrapped in polydopamine) composite material: Dissolve tris in water to prepare 100mM tris aqueous solution 100mL , at 20°C, add 300 mg of fiber to 10 mM tris aqueous solution, then add 300 mg of dopamine hydrochloride, stir and react for 48 hours, during which dopamine hydrochloride polymerizes and wraps on the cotton fiber to obtain cotton fiber Polydopamine composite material;

[0028] 2) Preparation of cotton fiber polydopamine / palladium (that is, cotton fiber wrapped by polydopamine / palladium) composite material: Dissolve potassium chloropalladate in water to obtain 100mL of 10mM aqueous solution, pre-cool the solution in an ice bath, The cotton fiber polydopamine composite material was added therein, stirred and reacted at 0° C. for 0.5 hour, then excess potassium chloropalladate was removed by fil...

Embodiment 2

[0034] Synthesis of glass fiber polydopamine / palladium complex:

[0035] 1) Synthesis of glass fiber polydopamine (that is, glass fiber wrapped by polydopamine) composite material: Dissolve tris in water to prepare 10 mM tris aqueous solution, and at 25 °C, add 100 mg of glass The fiber was added to 100mL of 10mM tris aqueous solution, then 200mg of dopamine hydrochloride was added, and stirred for 36 hours. During this process, dopamine hydrochloride was polymerized and wrapped on the fiber to obtain a glass fiber polydopamine composite material;

[0036] 2) Preparation of glass fiber polydopamine / palladium (that is, glass fiber wrapped by polydopamine / palladium) composite material: Dissolve potassium chloropalladate in water to obtain 100mL of 10mM aqueous solution, pre-cool the solution in an ice bath , the glass fiber polydopamine composite material was added therein, stirred and reacted at 5°C for 0.5 hour, then excess potassium chloropalladate was removed by filtering an...

Embodiment 3

[0038] Synthesis of Quartz Wool Fiber Polydopamine / Palladium Composite:

[0039] 1) Synthesis of quartz wool fiber polydopamine composite material: Dissolve tris in water to prepare 100 mL of 10 mM tris aqueous solution, add 100 mg of quartz wool fiber to 10 mM tris at 60 °C In the aminomethane aqueous solution, add 400mg of dopamine hydrochloride again, stir and react for 3 hours, during which the dopamine hydrochloride is polymerized and wrapped on the quartz wool fiber to obtain the quartz wool fiber polydopamine composite material;

[0040] 2) Preparation of quartz wool fiber polydopamine / palladium composite material: dissolving potassium chloropalladate in water to obtain 100 mL of a 10 mM aqueous solution, precooling the solution in an ice bath, adding the quartz wool fiber polydopamine composite material, Stir and react at 0°C for 2 hours, then remove excess potassium chloropalladate by filtering and rinsing, and then freeze-dry to obtain a quartz wool fiber polydopamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com