Monatomic catalyst, and preparation method and application thereof

A catalyst and atom technology, applied in the field of single-atom catalysts and their preparation, can solve the problems of poor cycle stability and decreased catalytic performance, and achieve the effects of enhancing catalytic activity and stability, improving stability and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

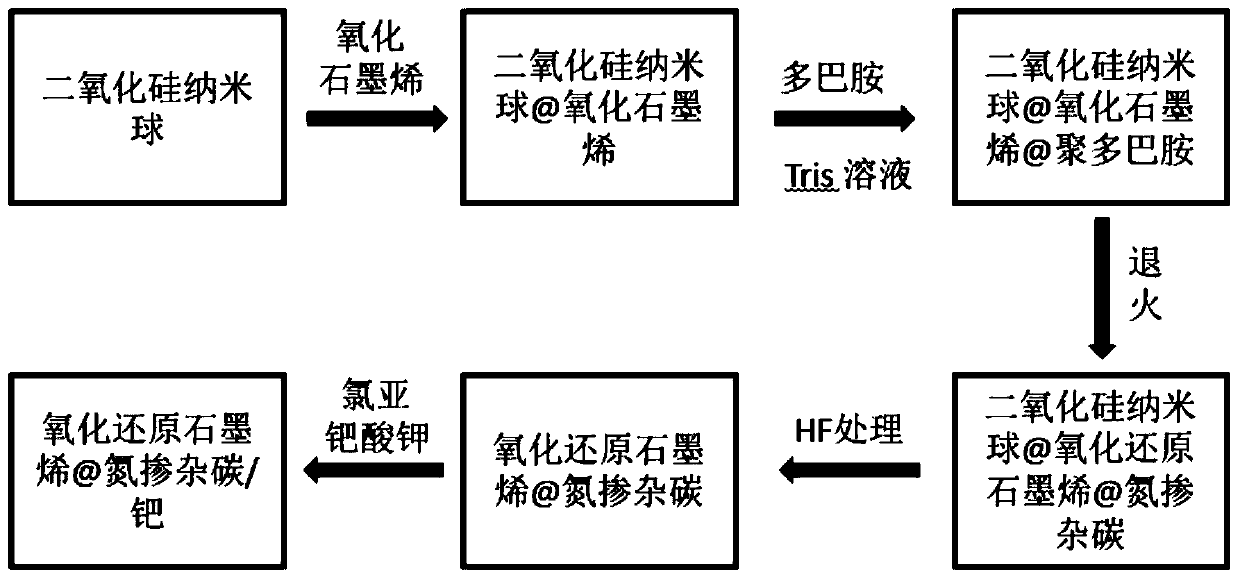

[0041] Synthesis of RGO@NC / Pd single-atom catalyst:

[0042] (1) SiO 2 Synthesis of @GO composite material: Disperse 200mg of aminated silica nanospheres (that is, grafted with amino groups on the surface of silica nanospheres; the size of silica nanospheres can be 100-200nm) in 100ml to In deionized water, add 30 mL of GO aqueous solution with a concentration of 0.2 mg / mL under stirring condition, and stir for 1 hour. In this process, graphene oxide nanosheets are electrostatically wrapped on the surface of aminated silica spheres to obtain SiO 2 @GO composites.

[0043] (2) SiO 2 Synthesis of @GO@PDA composite material: SiO was added to 100mL tris solution system (pH8.5, 10mM) 2 @GO composite material 200mg, to obtain a dispersion, then add 200mg of dopamine hydrochloride, stir and react for 36 hours, make the dopamine hydrochloride polymerize to form polydopamine and wrap it in SiO 2 On @GO nanospheres, get SiO 2 @GO@PDA composites;

[0044] (3) Synthesis of RGO@NC c...

Embodiment 2

[0064] Synthesis of RGO@NC / Pd single-atom catalyst:

[0065] (1) SiO 2 Synthesis of @GO composite material: Disperse 200mg of aminated silica nanospheres (300-400nm) in 80ml of deionized water, then add 30mL of GO aqueous solution with a concentration of 0.2mg / mL under stirring conditions, and stir for 1 hour. In this process, graphene oxide is wrapped on the surface of aminated silica spheres by electrostatic interaction to obtain SiO 2 @GO composites.

[0066] (2) SiO 2 Synthesis of @GO@PDA composite material: SiO was added to 100mL tris solution system (pH8.5, 10mM) 2 200mg of @GO composite material, to obtain a dispersion, then add 200mg of dopamine hydrochloride, stir and react for 48 hours, make the dopamine hydrochloride polymerize to form polydopamine and wrap it in SiO 2 On @GO nanospheres, get SiO 2 @GO@PDA composites;

[0067] (3) Synthesis of RGO@NC composite material: the SiO obtained in the step (2) 2 The @GO@PDA composite material was annealed at 800°C fo...

Embodiment 3

[0070] Synthesis of RGO@NC / Pd single-atom catalyst:

[0071] (1) SiO 2 Synthesis of @GO composite material: Disperse 200mg of aminated silica nanospheres (50-100nm) in 80ml of deionized water, then add 30mL of GO aqueous solution with a concentration of 0.5mg / mL under stirring conditions, and stir for 1 hour. In this process, graphene oxide is wrapped on the surface of aminated silica spheres by electrostatic interaction to obtain SiO 2 @GO composites.

[0072] (2) SiO 2 Synthesis of @GO@PDA composite material: SiO was added to 100mL tris solution system (pH8.5, 10mM) 2 @GO composite material 150mg, to obtain a dispersion, then add 400mg of dopamine hydrochloride, stir and react for 24 hours, make the dopamine hydrochloride polymerize to form polydopamine and wrap it in SiO 2 On @GO nanospheres, get SiO 2 @GO@PDA composites;

[0073] (3) Synthesis of RGO@NC composite material: the SiO obtained in the step (2) 2 The @GO@PDA composite material was annealed at 700°C for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com