Temperature-resistant and salt-resistant hydrophobic association polymer preparation method

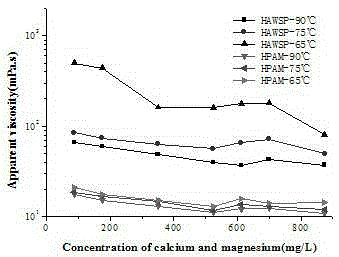

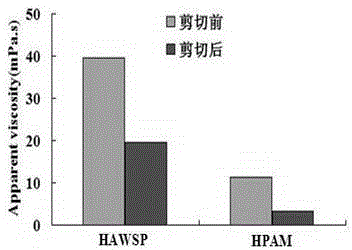

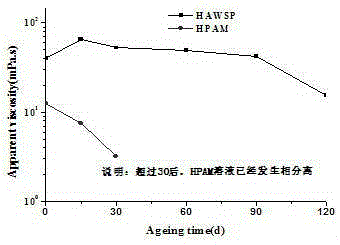

A hydrophobic association, temperature-resistant and salt-resistant technology, applied in the direction of drilling compositions, chemical instruments and methods, can solve the problem of rising temperature and salinity, which cannot meet the requirements of high-temperature and high-salt reservoirs, and harsh reservoir environments Adaptability and other issues, to achieve the effect of promoting intermolecular association, improving temperature and salt resistance performance, and improving temperature and salt resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 96.48kg of deionized water into the polymerization kettle, add 0.0025kg of disodium edetate, 25kg of acrylamide, 0.5kg of DiC 8 AM, 30% AMPS-Na solution 1.25kg, 0.0125kg OP-10, 0.5kg thiourea, 0.0025kg sodium acetate and 1.25kg potassium chloride, stir evenly, after each component is fully dissolved, cool down to 10°C; High-purity nitrogen for 1 hour, then add 0.125kg of 2% ammonium persulfate solution, 0.625kg of 2% sodium sulfite solution and 1.25kg of 2% azobisisobutylamidine hydrochloride solution, and carry out low temperature in the temperature range of 5-10°C Initiate polymerization, when the temperature rises to 30-35°C, azobisisobutylamidine hydrochloride decomposes, automatically initiates the polymerization reaction at high temperature, and the total polymerization reaction is 6h; take out the colloid for granulation, and then add 2.5kg hydrogen Sodium oxide is hydrolyzed for 2 hours, dried at 90°C for 3 hours, then crushed and packaged to obtain a temper...

Embodiment 2

[0038] Put 55.33kg of deionized water into the polymerization kettle, add 0.125kg of disodium edetate, 25kg of acrylamide, 2kg of DiC 8 AM, 30% AMPS-Na solution 5kg, 0.05kgTX, 1.5kg urea, 0.03kg isopropanol and 0.25kg potassium sulfate, stir evenly, after each component is fully dissolved, cool down to 8°C; inject high-purity nitrogen for 1.5h , then add 0.625kg of 2% potassium persulfate solution, 2.5kg of 2% ethylenediamine solution and 1.25kg of 2% azobisisobutyronitrile solution, and initiate polymerization at a temperature of 5-10°C at a low temperature. When the temperature reaches 55-60°C, azobisisobutyronitrile decomposes, automatically triggers the polymerization reaction at high temperature, and the total polymerization reaction is 7 hours; take out the colloid for granulation, then add 3kg of sodium hydroxide for hydrolysis for 4 hours, then place it at 110°C Dry for 2 hours, then pulverize and pack to obtain a temperature-resistant and salt-resistant associative po...

Embodiment 3

[0040] Put 67.22kg of deionized water into the polymerization kettle, add 0.01kg of disodium edetate, 25kg of acrylamide, 0.75kg of DiC 8 AM, 30% AMPS-Na solution 4.2kg, 0.03kg Tween 20, 0.75kg urea, 0.015kg sodium formate and 0.25kg potassium chloride, stir evenly, after each component is fully dissolved, cool down to 10°C; Pure nitrogen for 60 minutes, then add 0.25kg of 2% potassium persulfate solution, 1.25kg of 2% sodium sulfite solution and 0.25kg of 2% azobisisobutylamidine hydrochloride solution, and conduct low-temperature initiation at a temperature range of 5-10°C Polymerization, when the temperature rises to 40-45°C, azobisisobutylamidine hydrochloride decomposes to initiate a polymerization reaction at a high temperature range, and the total polymerization reaction is 5 hours; take out the colloid for granulation, and then add 2.7kg of sodium hydroxide for hydrolysis After 1.5 hours, it is dried, pulverized and packaged to obtain a temperature-resistant and salt-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com