Ziegler-Natta polyethylene catalyst with wide molecular weight distribution, and preparation method thereof

A wide molecular weight distribution, Ziegler technology, applied in the field of catalysts, can solve the problems of low catalytic activity, complicated preparation process, high preparation cost, etc., and achieve the effect of stable polymerization reaction and easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

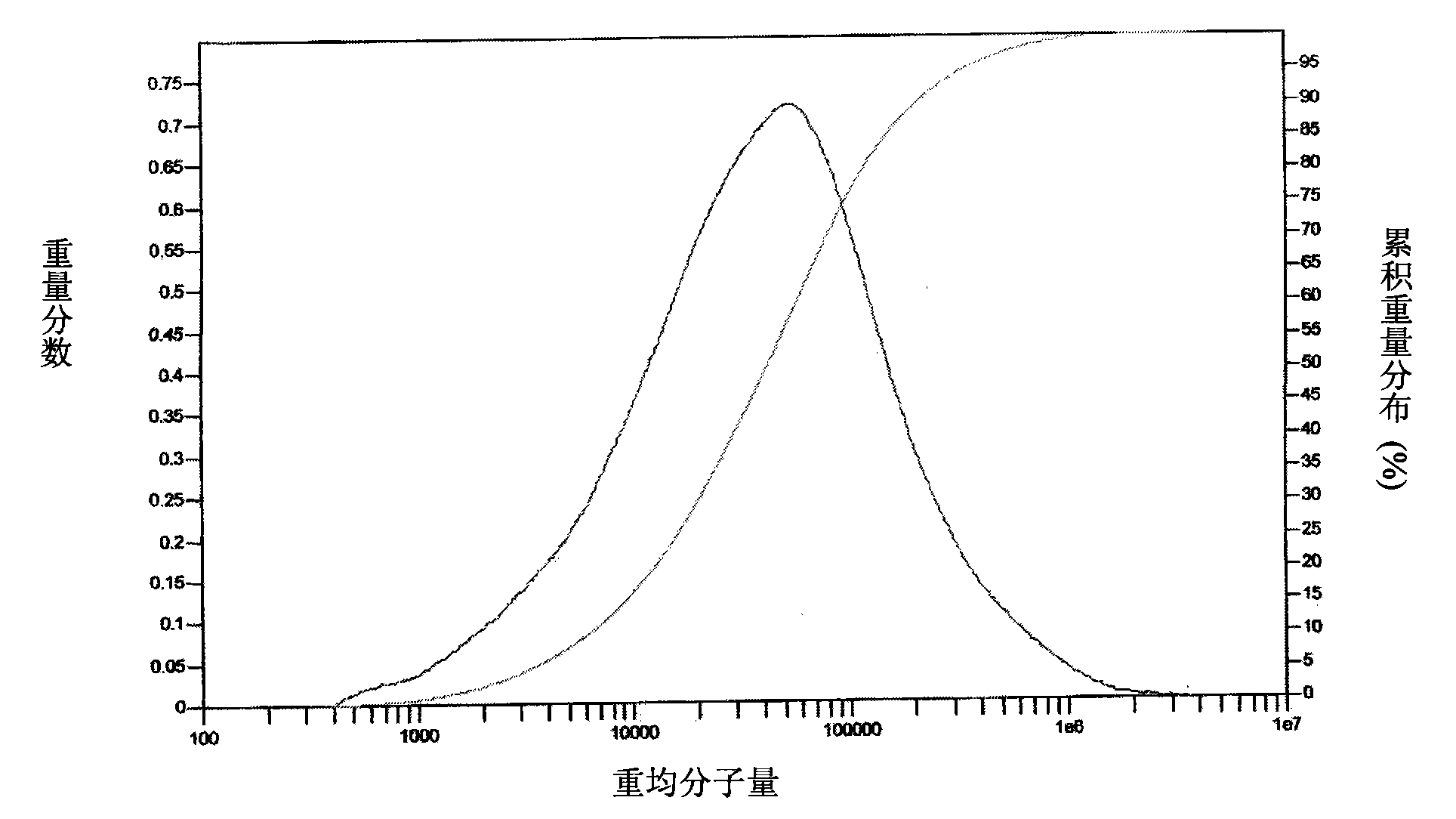

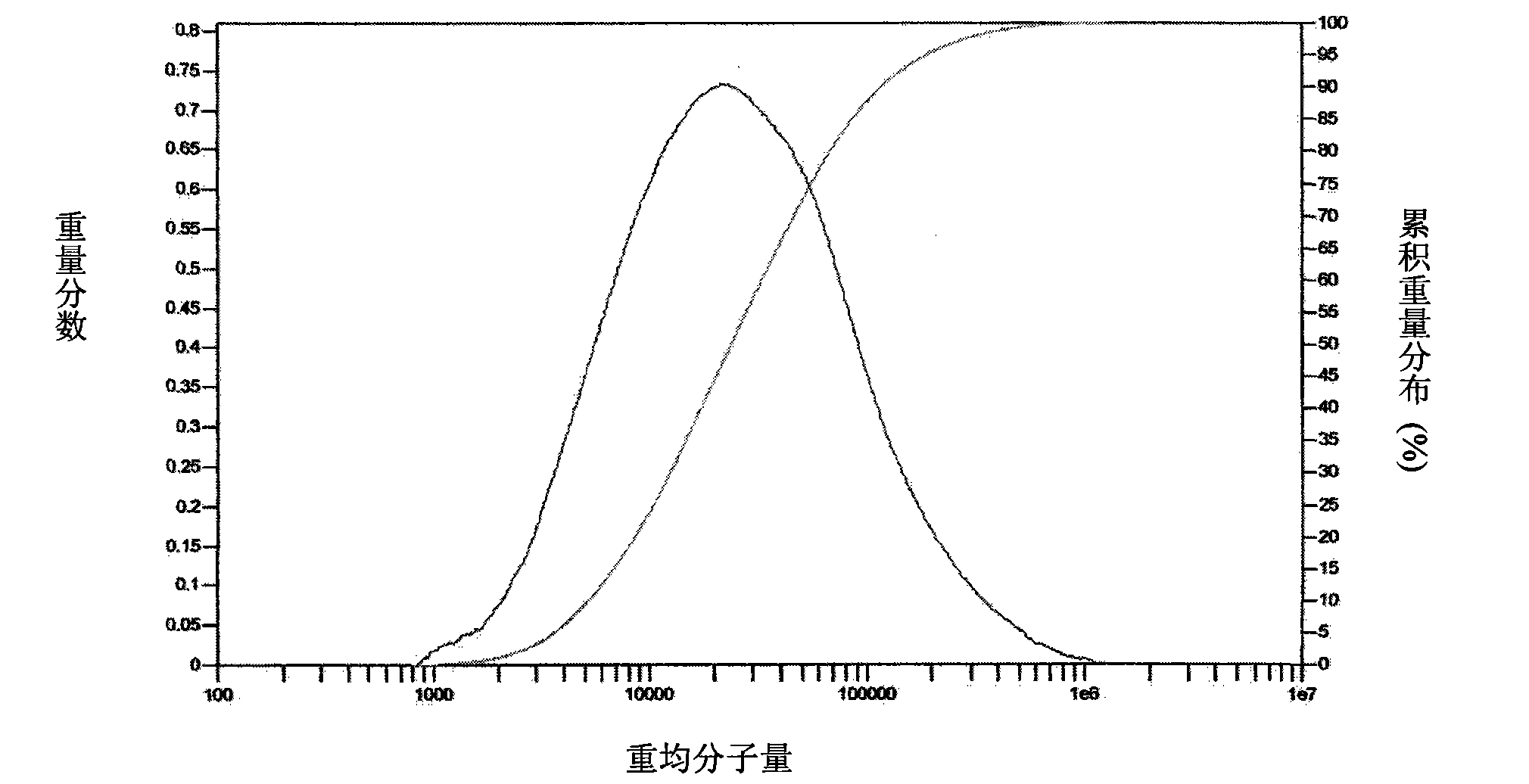

Image

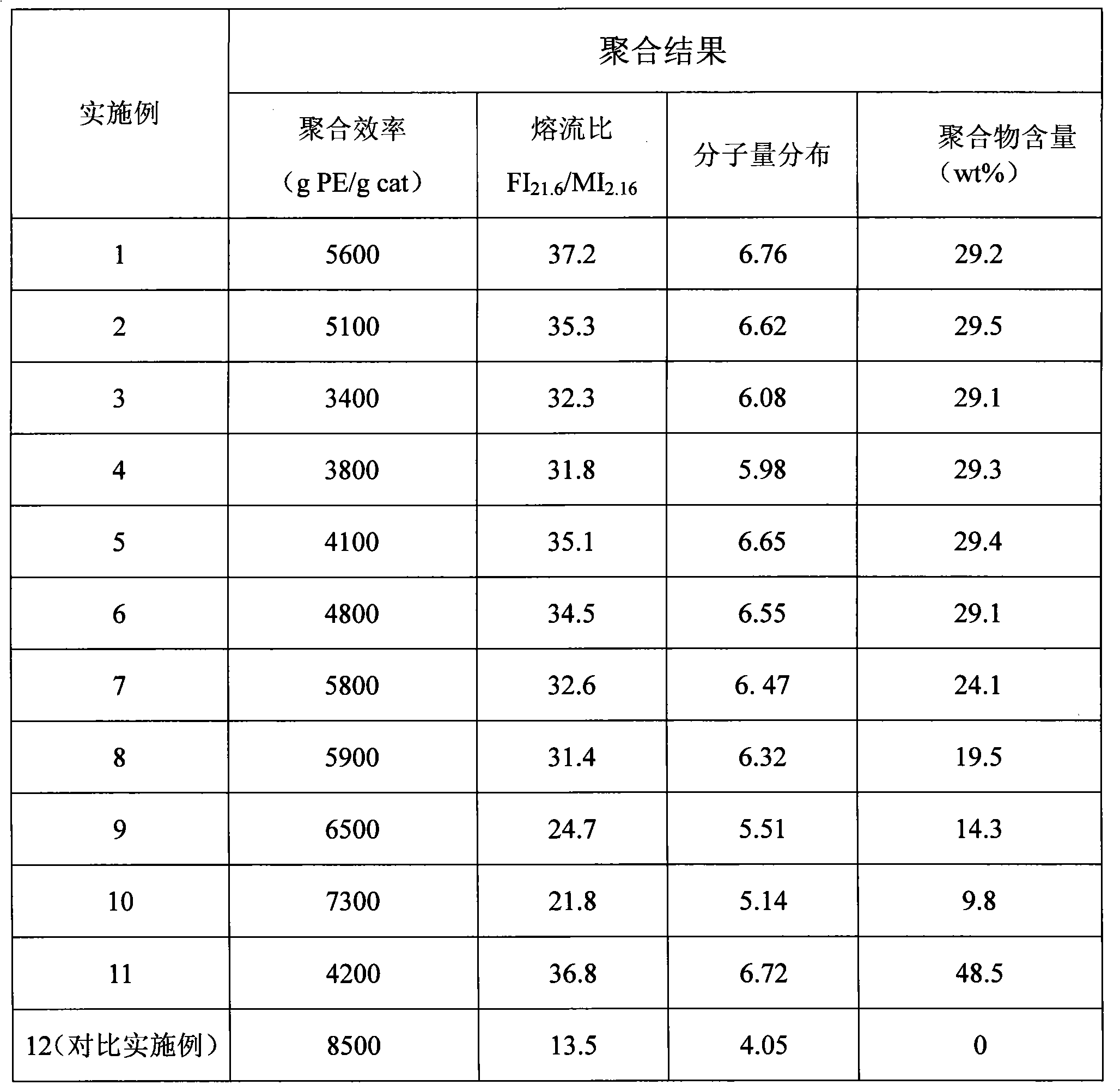

Examples

Embodiment 1

[0061] A. Preparation of main catalyst

[0062] (1) Treatment of silica carrier

[0063] The temperature of silicon dioxide (Grace Davison 955) was continuously raised to 600° C. under nitrogen fluidization, and kept for 10 hours, and then gradually cooled to room temperature before use. Add thermally activated silica (SiO 2 ) 20g, add 40ml hexane and 1.3ml triethylaluminum (Et 3 A1) Stir to form a slurry, mix and react for 2.5 hours, and then dry to obtain a silica carrier with good fluidity.

[0064] (2) Preparation of new ecological magnesium chloride

[0065] In a 500ml five-necked reaction flask equipped with a stirrer, condenser, dropping funnel and heating device, add 300ml of n-hexane and 7.2500g of magnesium powder, and 64ml of chlorobutane (BuCl ) was added dropwise in the reaction flask, after the dropwise addition was completed, the reaction was continued at 60° C. for 4.5 hours to obtain a black new ecological magnesium chloride solid suspension. The solvent ...

Embodiment 2

[0078] (1) Treatment of silica carrier

[0079] Method and consumption ratio are with embodiment 1 (1).

[0080] (2) Preparation of new ecological magnesium chloride

[0081] In a 500ml five-necked reaction flask equipped with a stirrer, condenser, dropping funnel and heating device, add 250ml of n-hexane and 6.4g of magnesium powder, and add 56ml of chlorobutane dropwise at 65°C for 3.5 hours Into the reaction bottle, after the dropwise addition, the reaction was continued at 63° C. for 5 hours to obtain a black new ecological magnesium chloride solid suspension. The solvent was distilled off at 70° C., and after cooling, 300 ml of tetrahydrofuran was added to the reaction flask, and stirred evenly to obtain a black solution. Sampling and analysis yielded Mg=0.863 mol / l, Cl=1.58 mol / l, and Cl / Mg=1.83.

[0082] The structural formula that obtains new ecological magnesium chloride is: (MgBuCl) 0.20 (MgCl 2 )

[0083] (3) Preparation of the main catalyst component

[0084...

Embodiment 3

[0094] (1) Treatment of silica carrier

[0095] Method and consumption are with embodiment 1 (1).

[0096] (2) Preparation of new ecological magnesium chloride

[0097] In a 500ml five-necked reaction flask equipped with a stirrer, condenser, dropping funnel and heating device, add 300ml of n-hexane and 10.5g of magnesium powder, and add 68ml of chlorobutane dropwise at 60°C for 3.5 hours into the reaction bottle, after the dropwise addition, the reaction was continued at 45° C. for 4.5 hours to obtain a black new ecological magnesium chloride solid suspension. The solvent was distilled off at 70° C., and after cooling, 240 ml of tetrahydrofuran was added to the reaction flask and stirred evenly to obtain a black solution. Sampling and analysis obtained: Mg=1.75 mol / l, Cl: 2.66 mol / l, Cl / Mg=1.52. The structural formula that obtains new ecological magnesium chloride is: (BuMgCl) 0.92 (MgCl 2 )

[0098] (3) Preparation of the main catalyst component

[0099] In the five-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com