Preparation of fibrous catalyst loaded with metal nanoparticles and application

A metal nanoparticle and nanoparticle technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as limited application range, achieve easy infiltration and penetration, mild conditions, reduce The effect of applying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

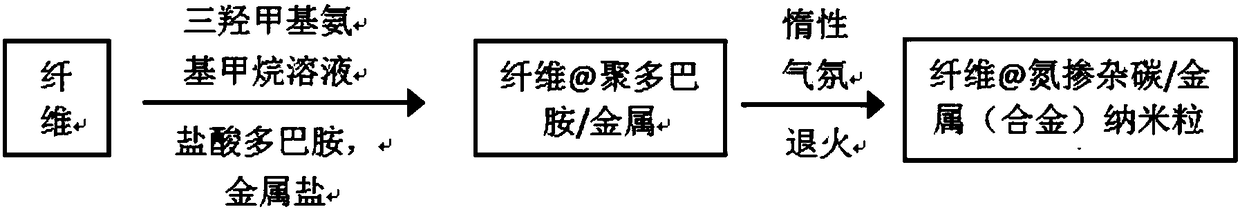

Method used

Image

Examples

Embodiment 1

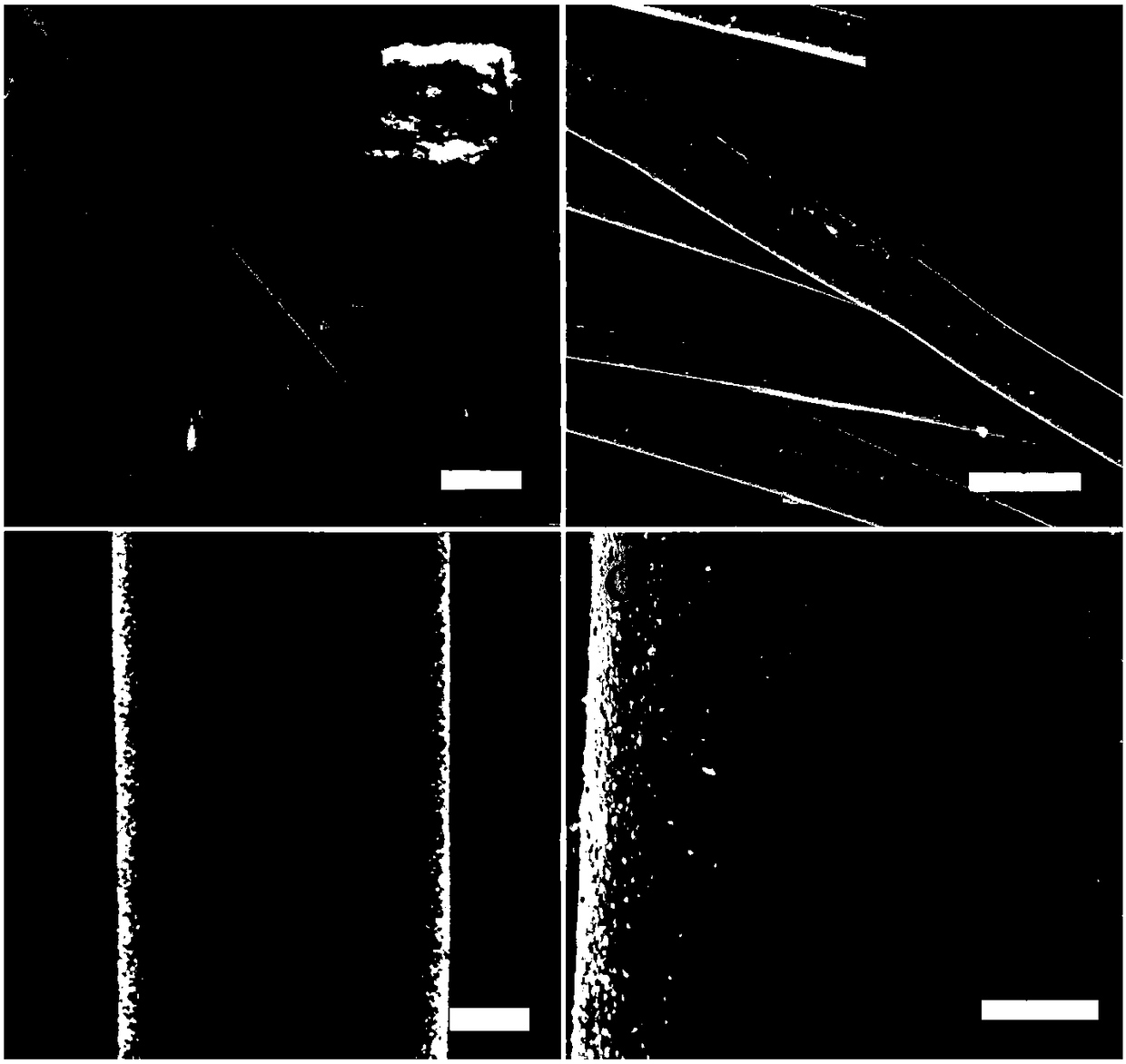

[0031] Synthesis of aluminum silicate fiber@nitrogen-doped graphite / iron-palladium alloy nanoparticle composite:

[0032] 1) Aluminum silicate fibers@polydopamine / iron-palladium nanoparticles (that is, aluminum silicate fibers wrapped by mixture polydopamine / iron-palladium nanoparticles, the mixture polydopamine / iron-palladium nanoparticles are simultaneously loaded with iron Synthesis of polydopamine mixture of nanoparticles and palladium nanoparticles) composite material: Dissolve tris in water to prepare 100 mL of 10 mM tris aqueous solution; then, at 20 ° C, 300 mg of aluminum silicate fiber Add to the above tris aqueous solution; then, add 300 mg of dopamine hydrochloride, then add ferric chloride to make the concentration 20 mM, add potassium chloropalladate to make the concentration 20 mM, and finally, stir and react for 48 hours , in this process, dopamine hydrochloride is polymerized and wrapped on aluminum silicate fibers, and iron-palladium nanoparticles are loaded,...

Embodiment 2

[0039] Synthesis of aluminum silicate fibers@nitrogen-doped graphite / cobalt nanoparticles composites:

[0040] 1) Synthesis of aluminum silicate fiber@polydopamine / cobalt nanoparticles (that is, aluminum silicate fiber wrapped by polydopamine / cobalt nanoparticles) composite material: 20mM trimethylolaminomethane was dissolved in water to prepare 20mM trimethylol 100 mL of an aqueous trisaminomethane solution; then, at 25° C., 300 mg of aluminum silicate fiber was added to the above aqueous trishydroxymethylaminomethane solution; then, 250 mg of dopamine hydrochloride was added, and cobalt nitrate was added to make the concentration 20 mM. Finally, the reaction was stirred for 30 hours, during which dopamine hydrochloride was polymerized and wrapped on the aluminum silicate fibers, and loaded with cobalt nanoparticles to obtain aluminum silicate fibers@polydopamine / cobalt nanoparticles composite material;

[0041] 2) Preparation of aluminum silicate fiber@nitrogen-doped graphit...

Embodiment 3

[0043] Synthesis of aluminum silicate fibers@nitrogen-doped carbon / copper nanoparticles composites:

[0044] 1) Synthesis of aluminum silicate fiber@polydopamine / copper nanoparticles (that is, aluminum silicate fiber wrapped by polydopamine / copper nanoparticles) composite material: dissolving trishydroxymethylaminomethane in water to prepare 20mM trimethylol 100 mL of an aqueous trisaminomethane solution; then, at 20° C., 400 mg of aluminum silicate fiber was added to the aqueous solution of trishydroxymethylaminomethane; then, 250 mg of dopamine hydrochloride was added, and copper sulfate was added to make the concentration 15 mM. Finally, the reaction was stirred for 24 hours, during which dopamine hydrochloride was polymerized and wrapped on the aluminum silicate fiber, and copper nanoparticles were loaded to obtain the aluminum silicate fiber@polydopamine / copper nanoparticle composite material;

[0045] 2) Preparation of aluminum silicate fiber@nitrogen-doped carbon / copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com