Method of preparing ethylene propylene diene monomer graft polymer through solution grafting copolymerization and application thereof

A technology of EPDM rubber and graft copolymer, which is applied in the field of preparation of graft copolymer, can solve the problems such as aging resistance to yellowing that needs improvement, large content of AN monomer unit, yellowing and brown color, etc. The effect of improving monomer conversion rate, easy heat transfer, and stable polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 EPDM-g-MAN

[0042] This embodiment adopts the solution graft copolymerization method, uses EPDM as the graft matrix, and MMA and AN as the graft monomers to prepare EPDM graft copolymer-EPDM-g-MAN, and its specific preparation steps are as follows:

[0043] (1) Use a 1000mL four-necked flask as a reactor, equipped with a stirrer, an automatic temperature control oil bath heating device, a return pipe, a nitrogen pipe and a material thermometer; 117.7g of n-heptane is mixed with 254.7g of toluene to become 372.4g of Mix the solvent, add the mixed solvent and 41.60g EPDM into the four-neck flask, stir for 4-6 hours to dissolve it into a uniform EPDM glue;

[0044] (2) Add 37.44g of methyl methacrylate and 4.16g of acrylonitrile mixed monomer into the above EPDM glue, stir for 30 minutes to make the system a uniform solution; dissolve 0.8325g of BPO in 20g of toluene, drop it into EPDM / MMA-AN solution system, stirred for 20 minutes to mak...

Embodiment 2

[0055] The preparation of embodiment 2 EPDM-g-MAS

[0056] The present embodiment adopts the solution graft copolymerization method, with EPDM as the graft base, MMA, AN and St as graft monomers to prepare EPDM graft copolymer-EPDM-g-MAS, in its preparation process, EPDM and monomer ( The mass ratio of MMA, AN and St) is 50:50, and the consumption of BPO is 1.0 mass %, and the mass ratio of n-heptane and toluene in the mixed solvent is 30:70, and the consumption of mixed solvent is 82.5 mass %, and polymerization reaction temperature is 80°C, the polymerization reaction time is 20 hours, the amounts of MMA, AN and St are shown in Table 2, and the rest of the operations are the same as in Example 1.

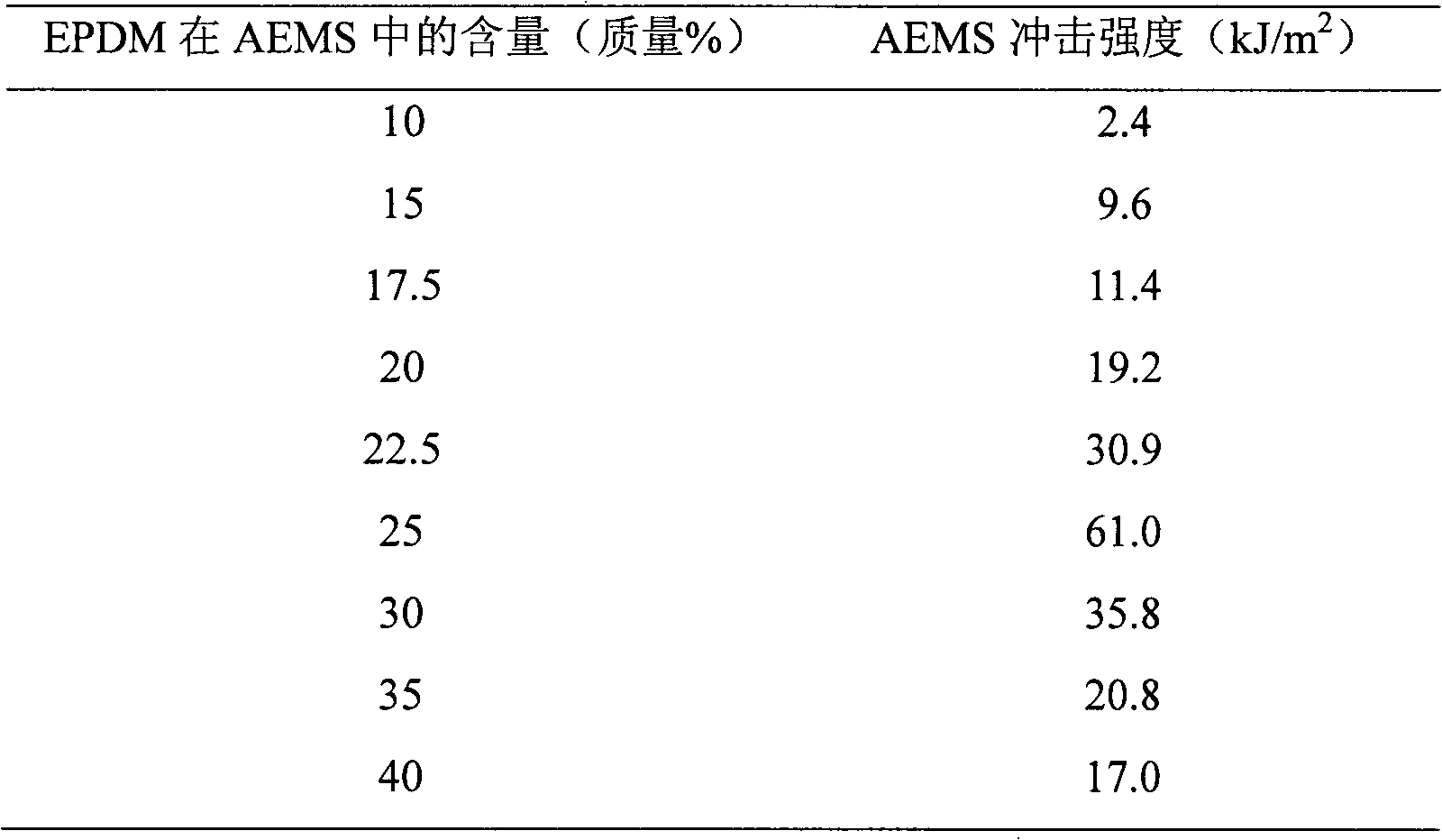

[0057] Embodiment 2 prepares gained EPDM-g-MAS, the monomer conversion (CR), grafting rate (GR) and grafting efficiency (GE) of its grafting system are as shown in table 2, use this toughening agent EPDM- The AEMS prepared by blending g-MAS and SAN resin, the mass ratio of SAN re...

Embodiment 3

[0062] The different mass ratio of embodiment 3 EPDM and monomer influences on grafting system and AEMS

[0063] The present embodiment adopts the solution graft copolymerization method, with EPDM as the graft base, MMA and AN as graft monomers to prepare EPDM graft copolymer-EPDM-g-MAN, in its preparation process, EPDM and monomer (MMA and The mass ratio of AN) is a series of ratio values shown in table 3, the consumption of BPO is 1.0 quality %, the mass ratio of n-heptane and toluene in the mixed solvent is 30: 70, the consumption of mixed solvent is 82.5 quality %, polymerization reaction temperature 80°C, the polymerization reaction time was 20 hours, the mass ratio of MMA and AN was 90:10, and the rest of the operations were the same as in Example 1.

[0064] Embodiment 3 prepares gained EPDM-g-MAN, the monomer conversion rate (CR), grafting rate (GR) and grafting efficiency (GE) of its grafting system are as shown in table 3, use this toughening agent EPDM-g-MAN The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com