Production equipment and method of polyamide 5X

A kind of production equipment, polyamide technology, applied in the field of polyamide 5X production equipment, can solve the problems of low polymerization reaction efficiency, unsuitable polyamide 5X continuous preparation, complicated device structure, etc., to ensure integrity and high efficiency, and simple structure , good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

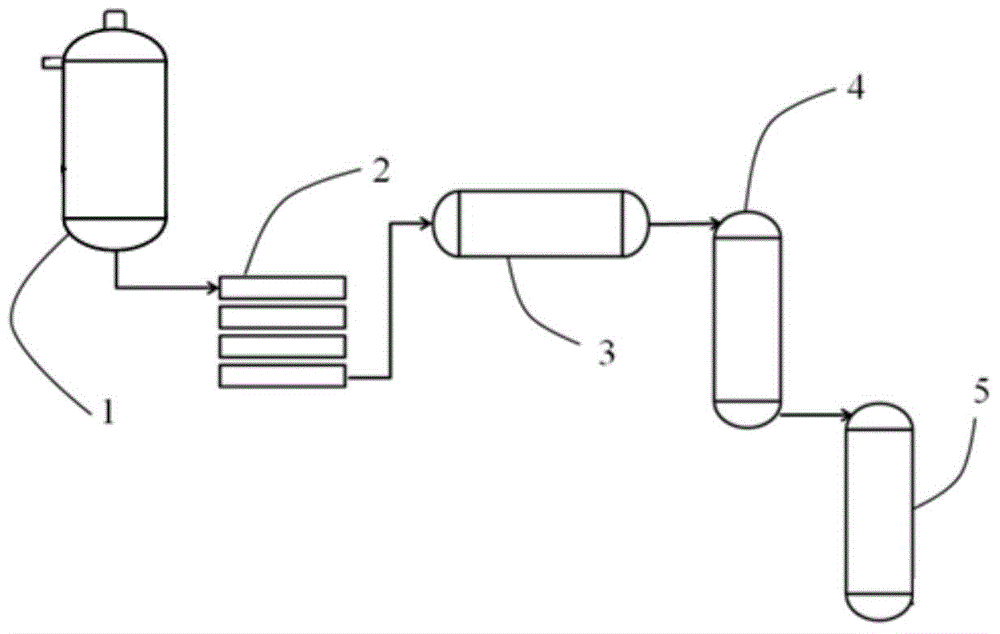

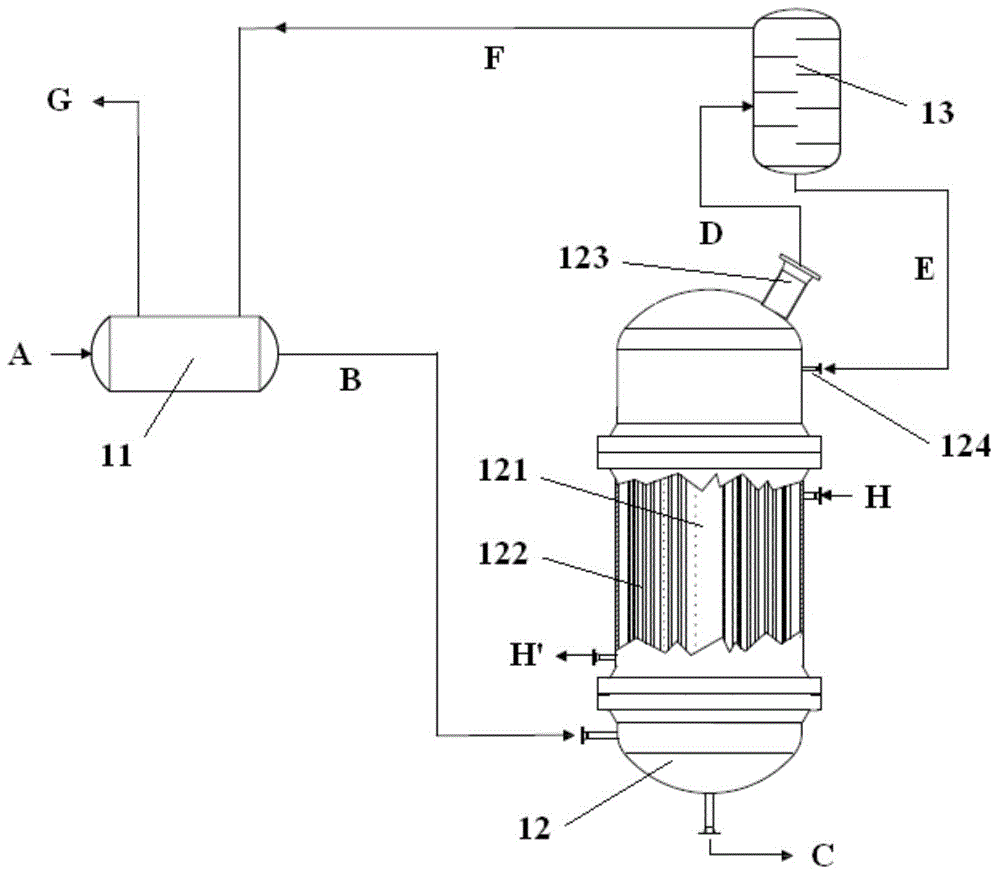

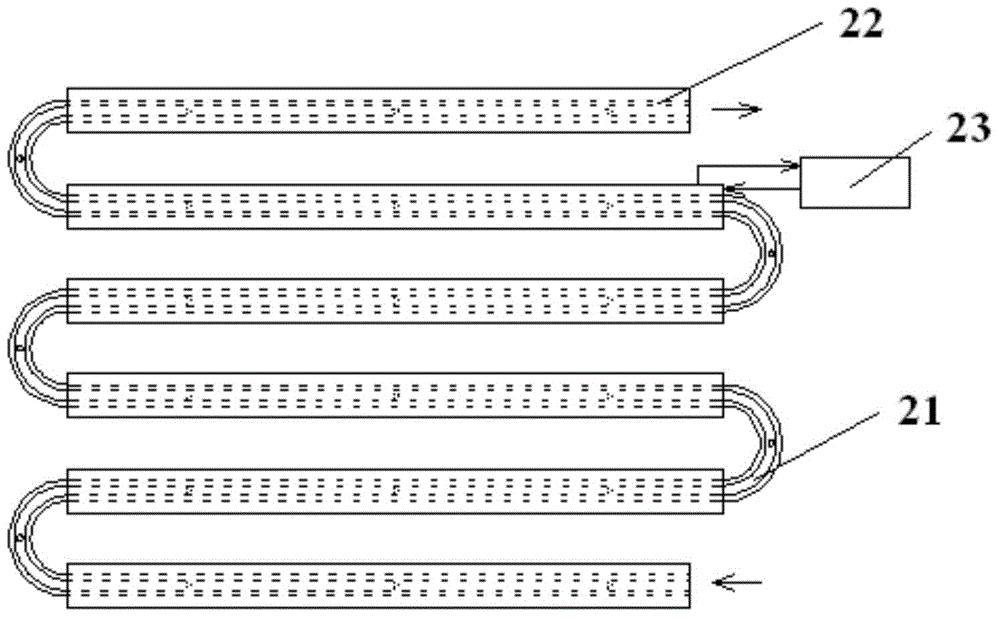

preparation example Construction

[0125] Preparation of polyamide salt solution

[0126] Under the protection of nitrogen, the high-concentration 1,5-pentanediamine is diluted with degassed deionized water to a certain concentration solution (30%-50%). The aliphatic dibasic acid and the diluted 1,5-pentanediamine are continuously added to the reactor at the same time, and the cooling water removes the heat of reaction during the neutralization reaction in time. During the neutralization process, the pH value of the solution is constantly detected, so that the mol ratio of the diamine / diacid in the reactor is slightly lower than 1. After stabilization, the resulting salt solution is transferred to the reactor in series behind (can be connected in series) multiple units, but generally not more than 3 units), use diamine aqueous solution to further neutralize step by step and adjust the molar ratio of diamine / diacid and the mass concentration of salt, and control the flow of diamine aqueous solution with the data...

Embodiment 1

[0141] Configuration pH is the 56 salt solution of 65% concentration of 7.95, carries out polymerization by the condition of table 1 through the production equipment of described polyamide 5X, and kettle body pressure is 210mmHgA, obtains the slice that relative viscosity is 68.9, and its terminal amino content is 40.4.

Embodiment 2

[0143] Configuration pH is the 56 salt solution of 65% concentration of 8.05, carries out polymerization according to the condition of implementing 1 through the production equipment of described polyamide 5X, but the pressure of still body is adjusted to 180mmHg A, and output improves 20% compared with embodiment 1 %, to obtain slices with a relative viscosity of 69.7 and an amino group content of 40.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com