Semi-solid forming method of high-melting-point equal-component high-entropy alloy

A semi-solid forming, high-entropy alloy technology, applied in the field of metal materials, can solve the problems that the high-entropy alloy's excellent properties cannot be fully utilized, and achieve the effects of no splashing and turbulence, energy saving, and stable mold filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

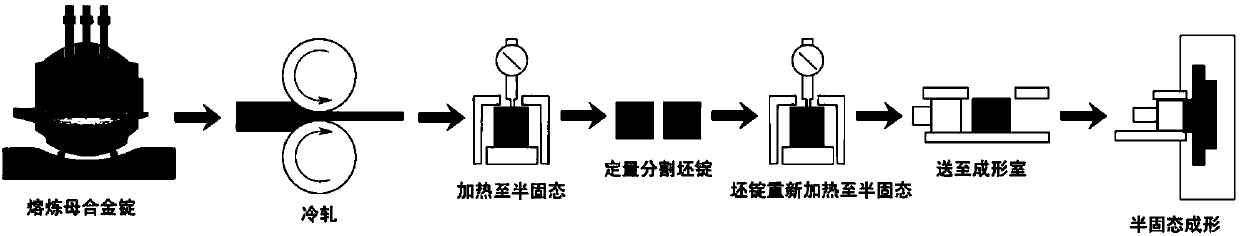

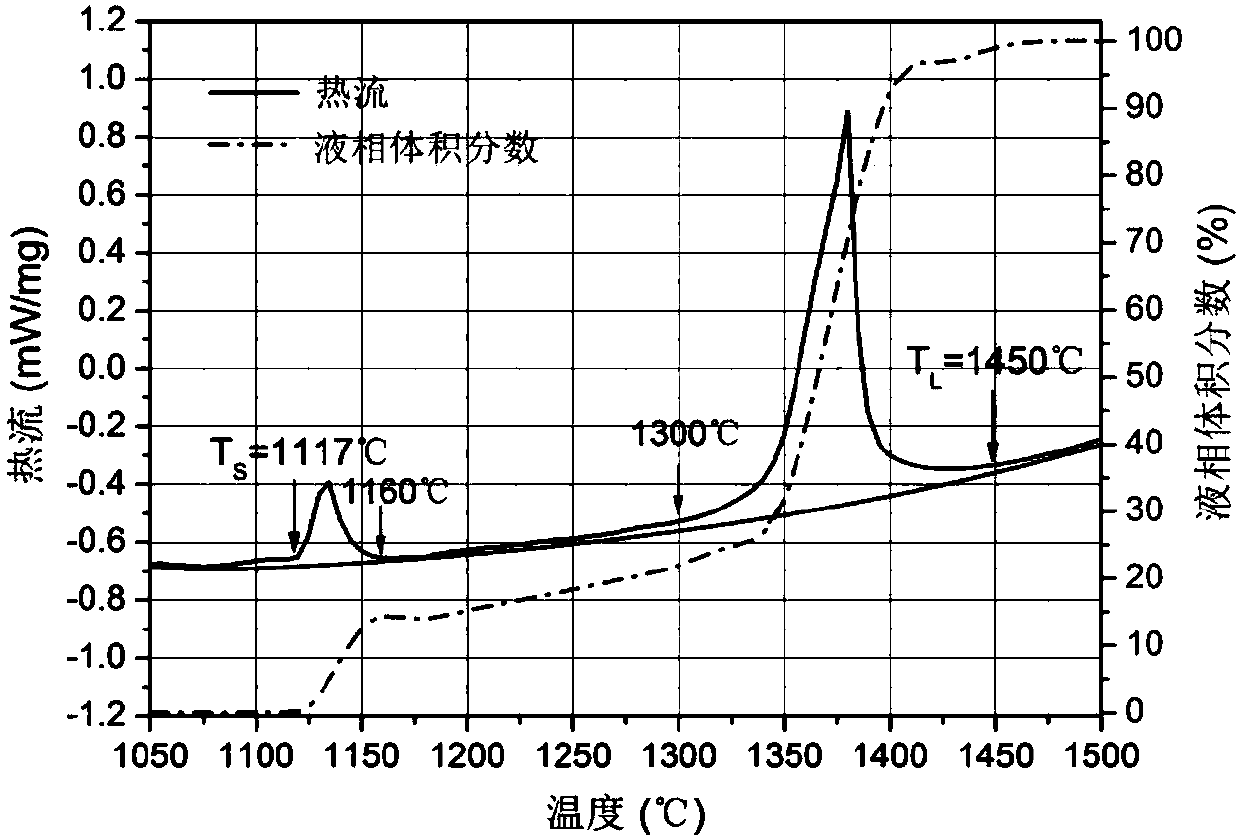

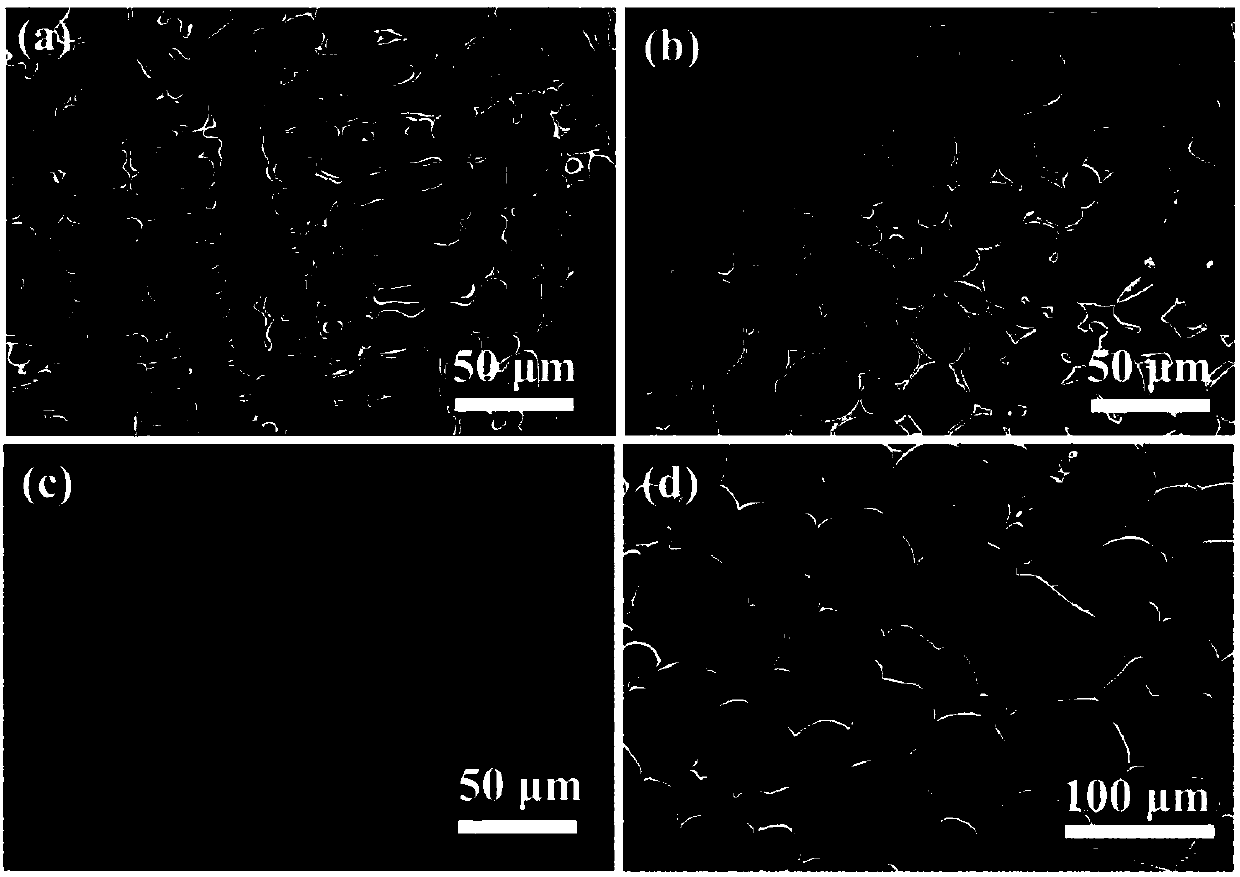

[0026] according to figure 1 The process flow chart of the semi-solid forming method for high-entropy alloys with high melting point and other components is shown. The components of CoCrCuFeNi high-entropy alloys with equiatomic ratios are converted into weight percentages, and 101.95g of pure cobalt, 89.95g of pure chromium, and pure copper are weighed respectively. 109.94g, 96.62g of pure iron, 101.54g of pure nickel, 0.5kg in total; each raw material was ultrasonically cleaned for 10 minutes to remove impurities on the surface of the material, and then the above-mentioned purified raw materials were put into the crucible of the arc melting furnace. Melting was repeated seven times in an argon atmosphere to ensure the uniformity of the alloy composition during the melting process. XRD, SEM and DSC were carried out on the prepared as-cast alloy, and the structure was determined to be the continuous dendrite structure of dual-phase FCC. from figure 2 It can be seen that the...

Embodiment 2

[0030] The components of CoCrCuFeNi high-entropy alloys with equiatomic ratios were converted into weight percentages, and 101.95 g of pure cobalt, 89.95 g of pure chromium, 109.94 g of pure copper, 96.62 g of pure iron, and 101.54 g of pure nickel were weighed, totaling 0.5 kg. Each raw material was ultrasonically cleaned for 10 minutes to remove impurities on the surface of the material. Then put the above-mentioned purified raw materials into the crucible of the electric arc melting furnace, and repeat the melting seven times in an argon atmosphere to ensure the uniformity of the alloy composition during the melting process. XRD, SEM and DSC were performed on the prepared as-cast alloy, and its structure was determined to be the continuous dendrite structure of dual-phase FCC, and its semi-solid range was determined to be from 1117°C to 1450°C. from figure 2 It can be seen that the solidus temperature of CoCrCuFeNi high entropy alloy is T S =1117°C, liquidus temperature ...

Embodiment 3

[0034] The CoCrCuFeNi high-entropy alloy composition of equiatomic ratio is converted into percentage by weight, respectively weighs 101.95g of pure cobalt, 89.95g of pure chromium, 109.94g of pure copper, 96.62g of pure iron, 101.54g of pure nickel, totaling 0.5kg; The raw materials were ultrasonically cleaned for 10 minutes to remove impurities on the surface of the materials, and then the above-mentioned purified raw materials were put into the crucible of the arc melting furnace, and smelted repeatedly in an argon atmosphere for 7 times to ensure the uniformity of the alloy composition during the smelting process. XRD, SEM and DSC were performed on the prepared as-cast alloy, and its structure was determined to be the continuous dendrite structure of dual-phase FCC, and its semi-solid range was determined to be from 1117°C to 1450°C. from figure 2 It can be seen that the solidus temperature of CoCrCuFeNi high entropy alloy is T S =1117°C, liquidus temperature is T L =14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com