Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Control extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

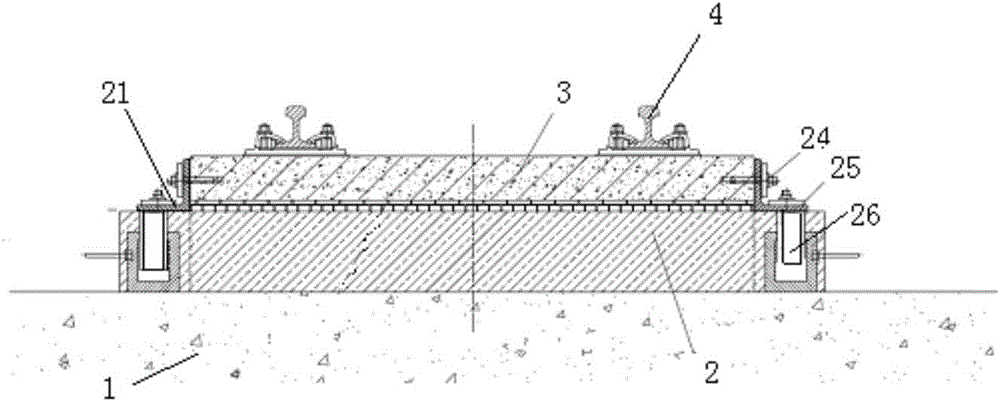

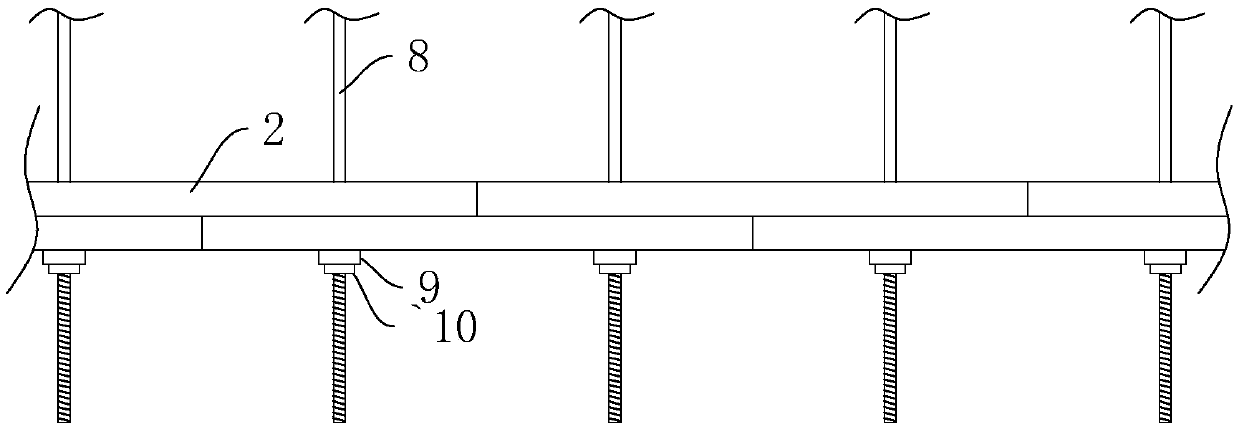

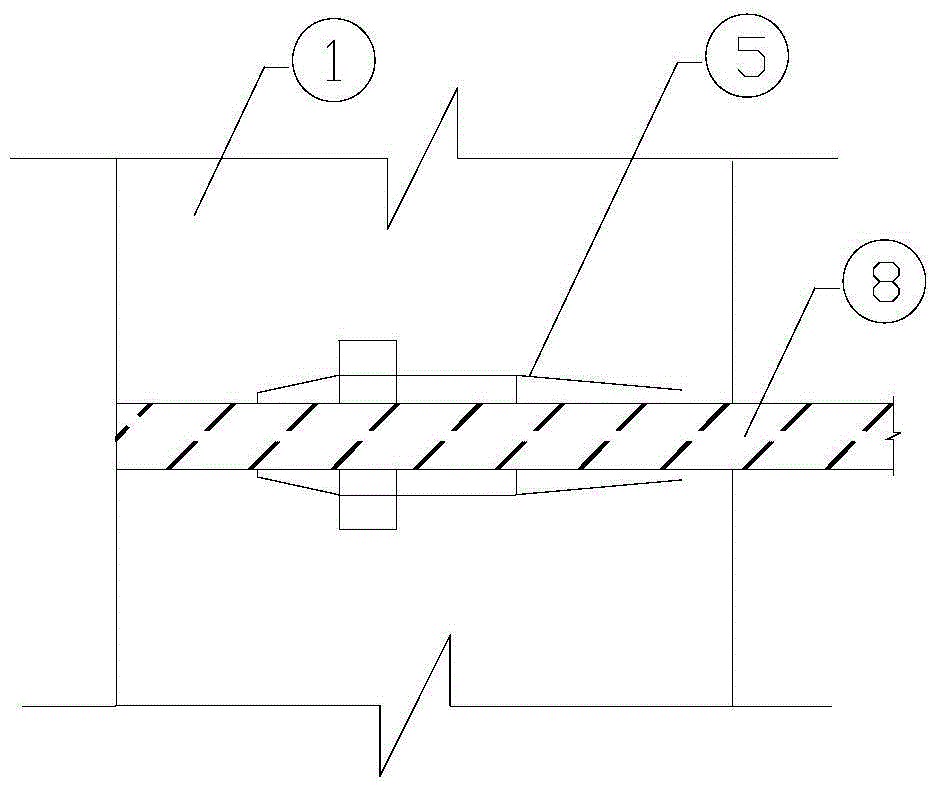

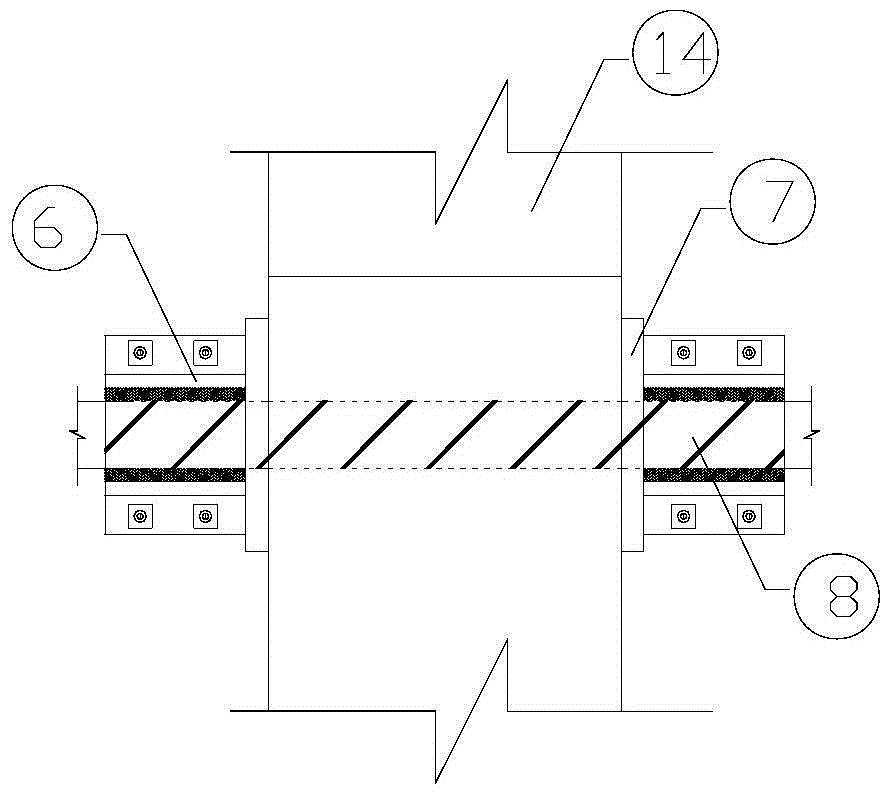

Repair method for ballastless track foundation settlement

InactiveCN104452484AControl extensionControl Lifting AccuracyBallastwayTrack maintainenceEngineeringRepair method

The invention relates to a repair method for ballastless track foundation settlement. The method includes the first step of lifting a supporting layer of a settlement area to make a corresponding track board lifted by a preset rising amount, the second step of conducting grouting and compacting on the lower portion of the lifted supporting layer, and the third step of finishing grouting and completing repair. By means of the method, the lifting accuracy can be accurately controlled.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

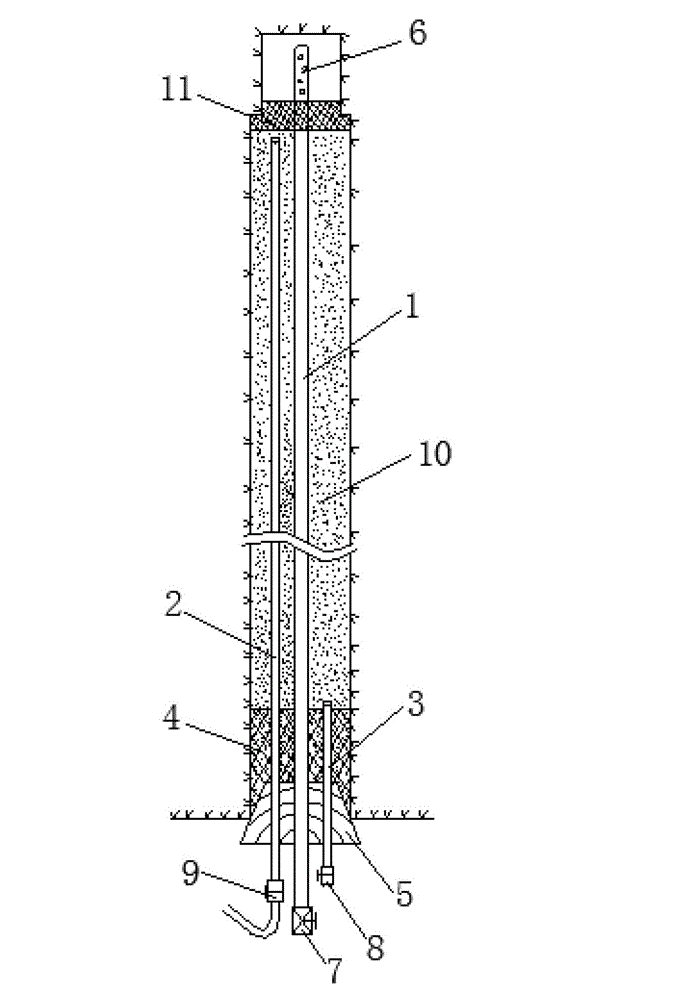

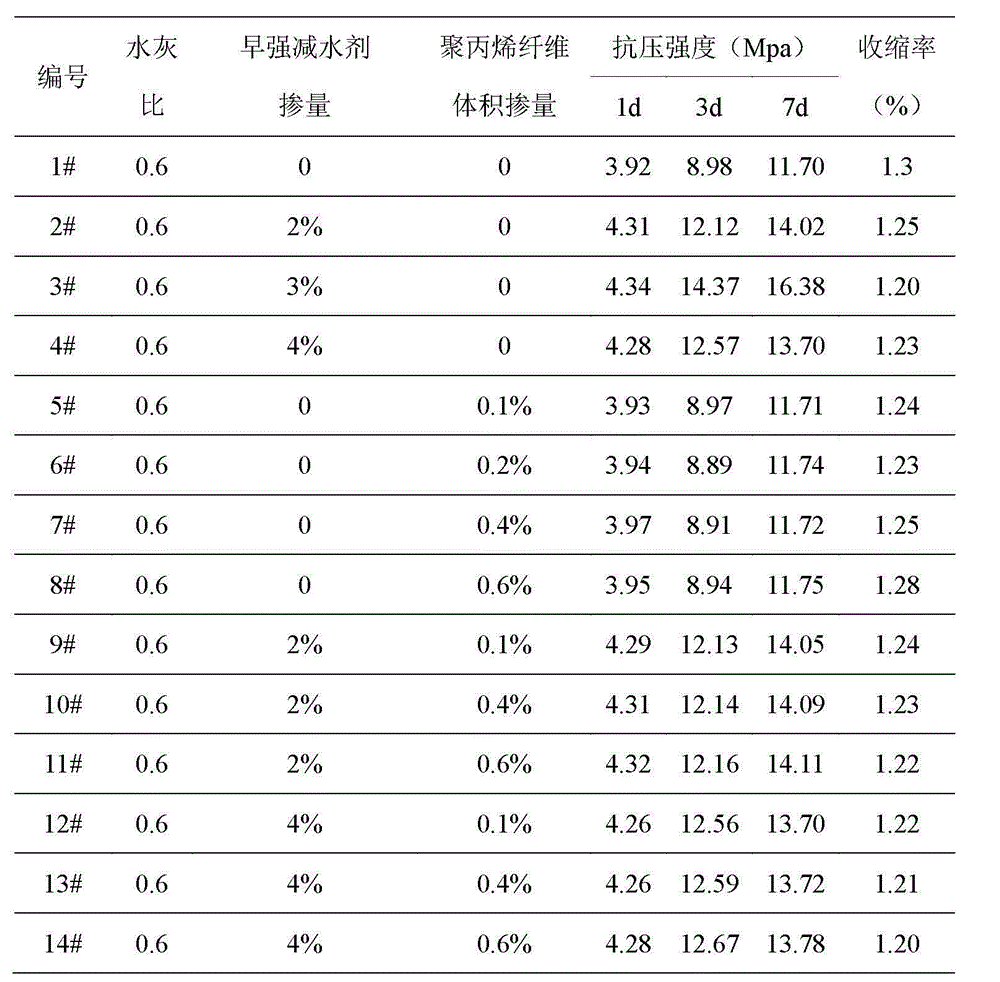

Underground high-pressure hydraulic fracturing hole sealing material for coal mine and hole sealing technology

ActiveCN102977869AImprove toughnessImprove impact resistanceDrilling compositionSealing/packingYarnAdhesive

The invention provides an underground high-pressure hydraulic fracturing hole sealing material for a coal mine and a hole sealing technology. The hole sealing material comprises the following components by weight: 100 parts of cement, 2 to 4 parts of Ms type early-strength slushing agent, 0.08 to 0.5 parts of polypropylene fiber, and 60 parts of water. The hole sealing technology comprises the following steps in sequence: drilling a hole on a coal-rock mass; constructing until reaching the a top plate at a coal seam; expanding the hole to a bottom plate at the coal seam; feeding a grouting pipe to the bottom plate at the coal seam; arranging a grout returning pipe to the front end of a blocking section of a hole port; blocking the hole port section through AB adhesive and cotton yarn; feeding the hole sealing material into the hole through the grouting pipe; closing a check valve of the grout returning pipe after returning the grout through the grout returning pipe; continuously grouting; completely draining the grout in the grouting pipe once water flows form a fracturing hole; grouting at the second time after the grout is condensed; and finally solidifying. The underground high-pressure hydraulic fracturing hole sealing material for the coal mine has the advantages of being less in contraction, and high in compressive strength and impact toughness; the hole sealing material is high in sealing performance and resistance to high pressure under the effect of high-pressure hydraulic fracturing impact load; simultaneously, the hole sealing material is low in cost and the construction is convenient; and the hole sealing technology is simple, the hole sealing depth meets the requirement, and the success rate is high.

Owner:CHONGQING UNIV

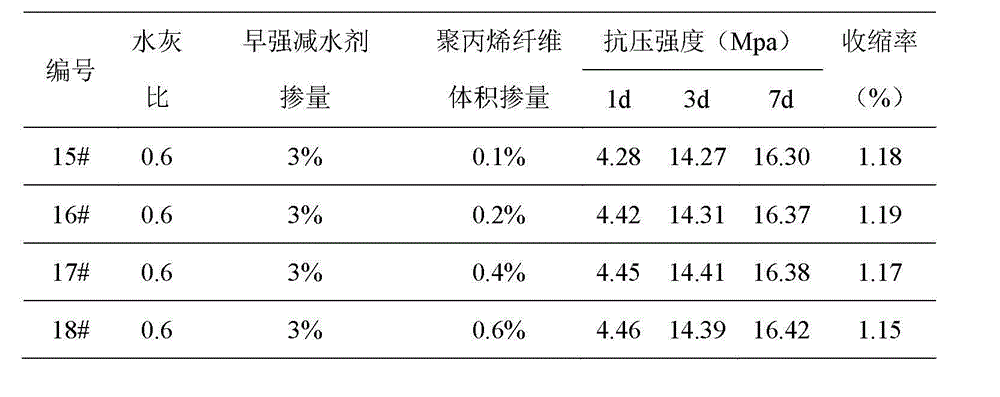

Maritime search and rescue system based on BeiDou satellite navigation and positioning

InactiveCN103761844AReduce casualtiesReduce property damageAlarmsSearch and rescueSatellite positioning

The invention relates to a maritime search and rescue system based on BeiDou satellite navigation and positioning. The maritime search and rescue system comprises an individual device, a command center and a search and rescue device. A BeiDou satellite positioning module and a first wireless communication module are arranged on the individual device and the individual device is used for sending position information and ID information to the command center. The command center comprises a second wireless communication module, a first GIS electronic map and a first judgment module. The position information and the ID information are reflected on the GIS electronic map by the command center, and the command center dispatches the corresponding search and rescue device to conduct rescue. A third wireless communication module, a second GIS electronic map and a second judgment module are arranged on the search and rescue device and the search and rescue device is used for receiving help seeking information sent within the range of 40 kilometers, and reflecting the help seeking information on the second GIS electronic map. By the adoption of the maritime search and rescue system based on BeiDou satellite navigation and positioning, an emergency reaction action to a maritime emergency can be rapidly, orderly and efficiently organized, persons in distress are rescued, extension of the maritime emergency is controlled, loss of life, personal injuries and property loss caused by the maritime emergency are reduced to the maximum extent.

Owner:柳州市锋威汽车科技有限公司

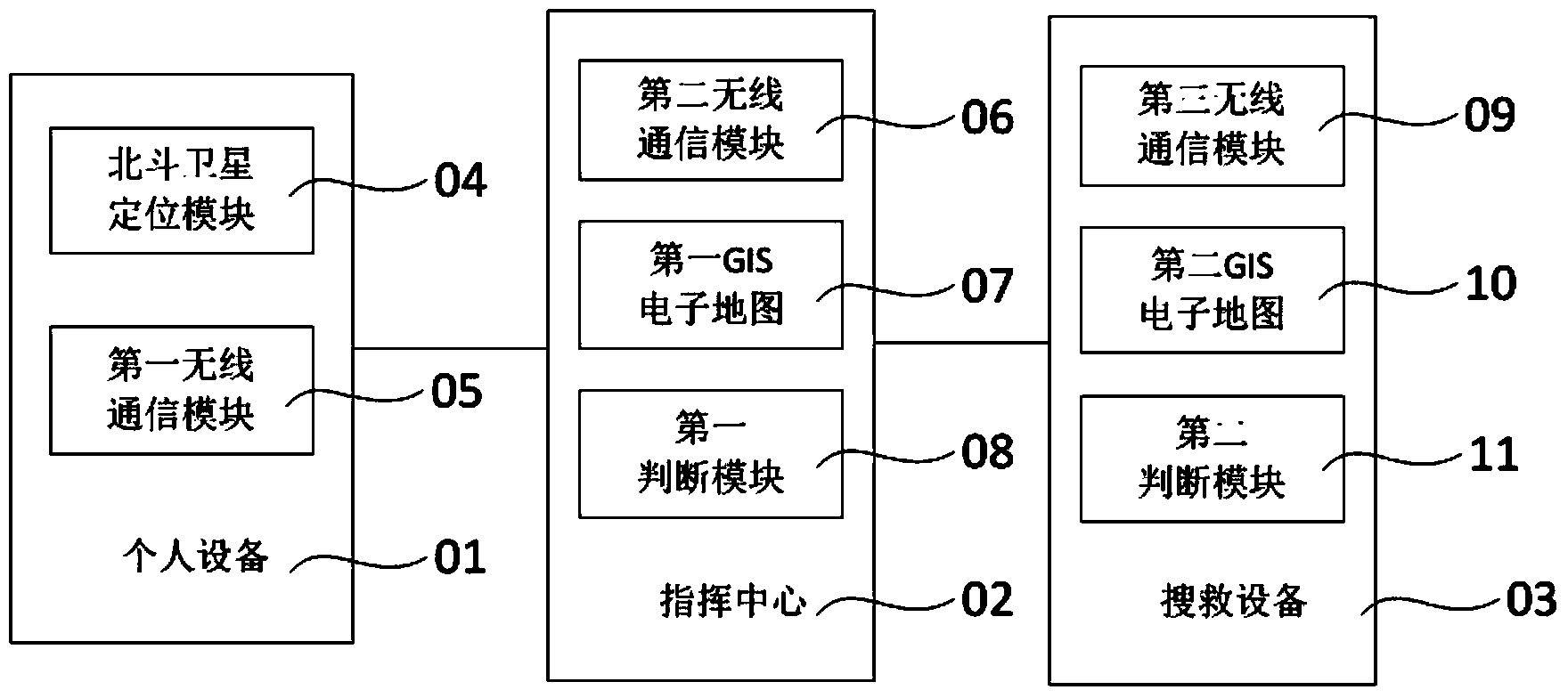

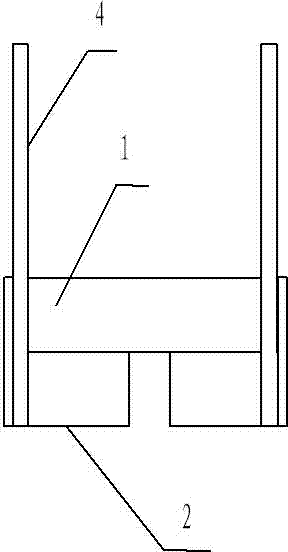

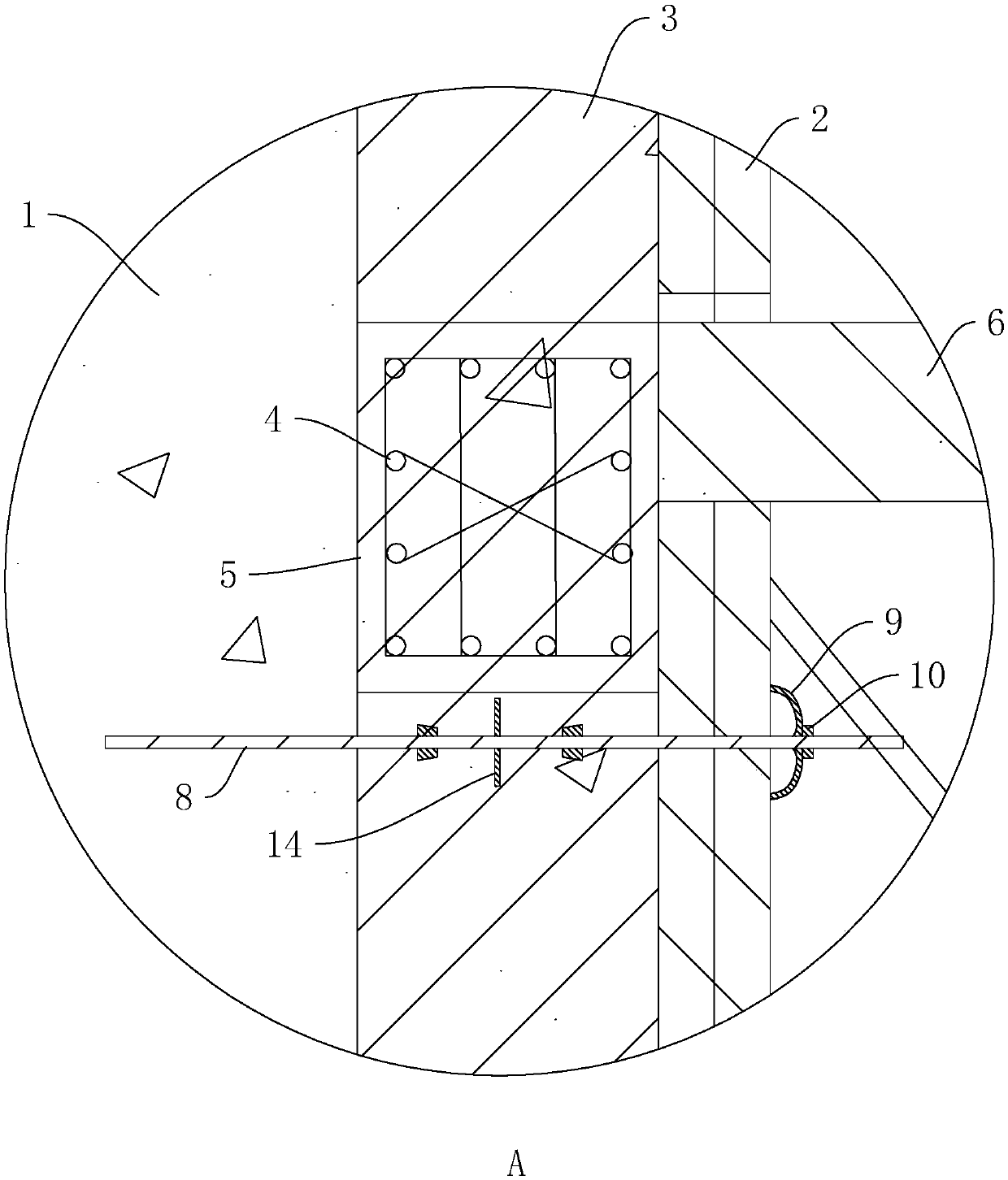

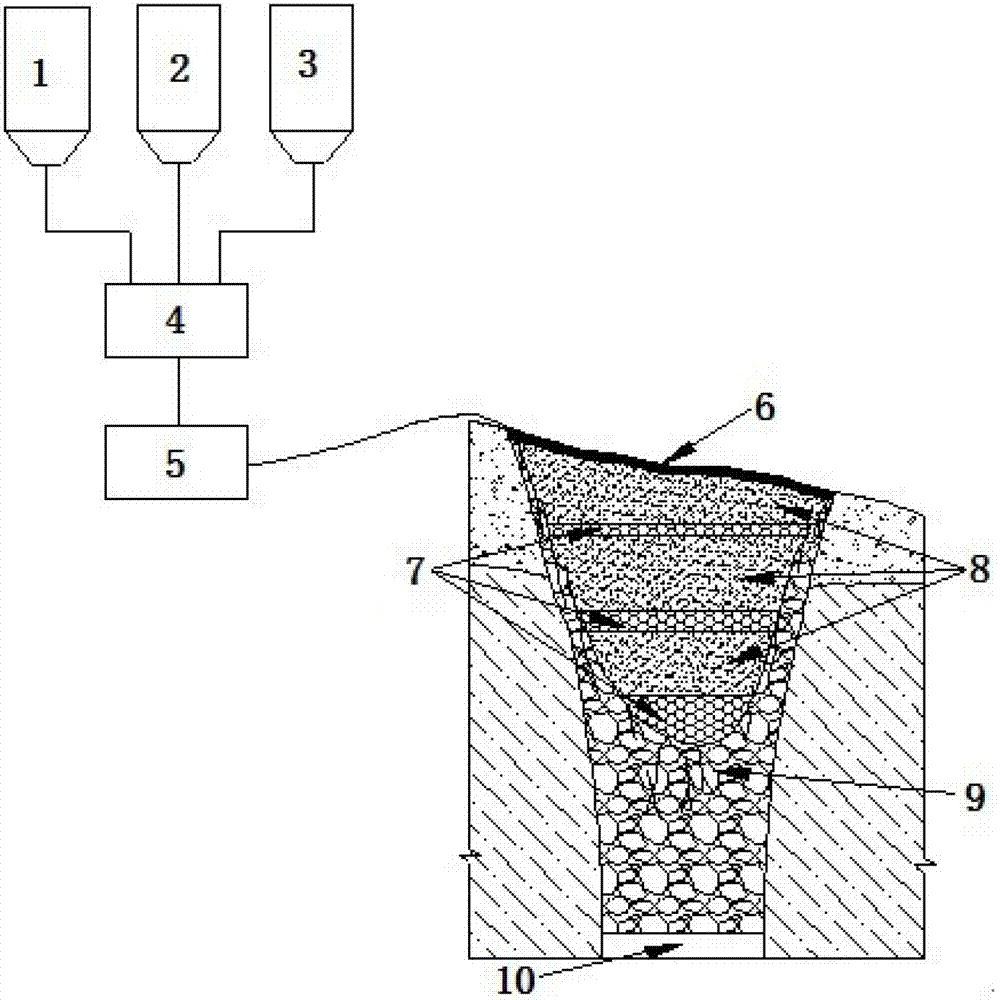

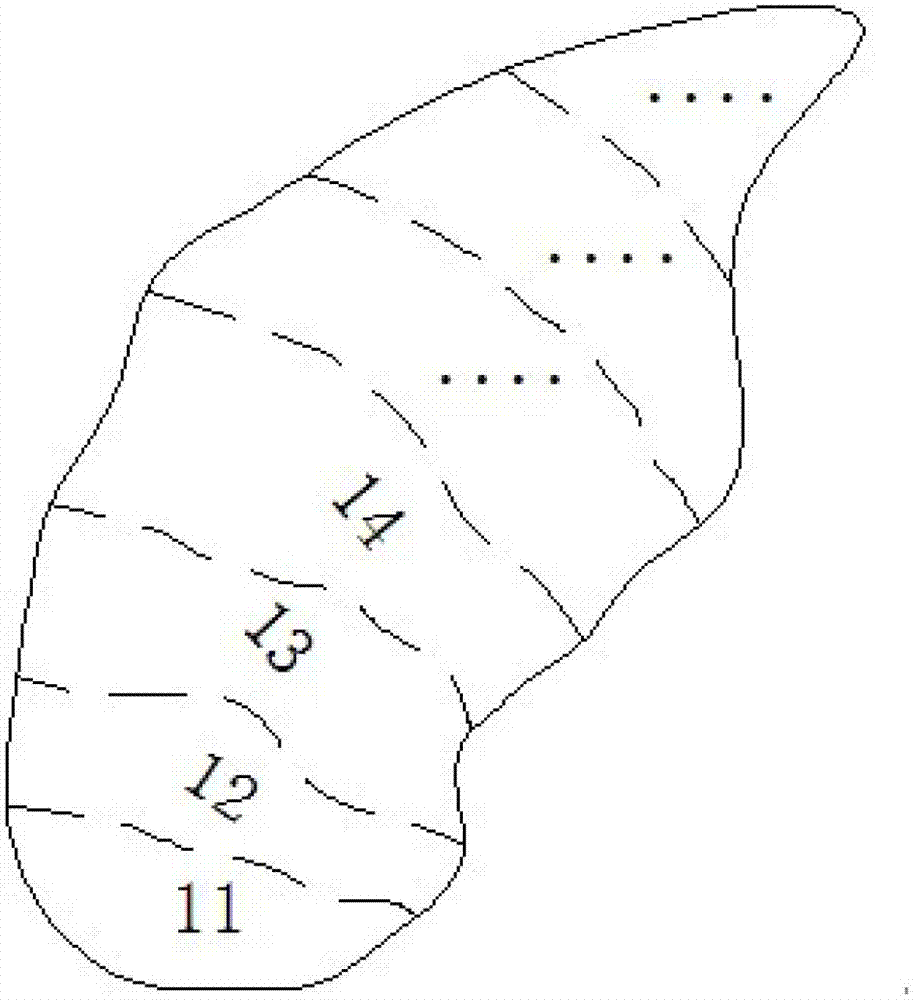

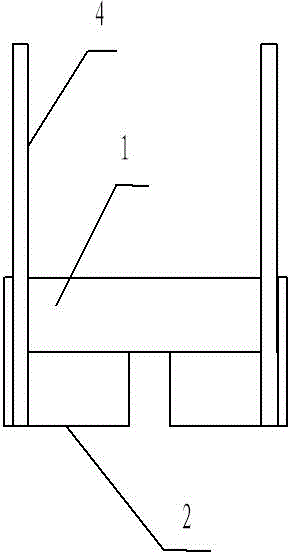

Backfill handling method for activity subsidence area of mine

InactiveCN103216239AImprove liquiditySuitable for permeabilityUnderground miningSurface miningHigh concentrationSoil science

The invention discloses a backfill handling method for an activity subsidence area of a mine. The backfill handling method is characterized in that mixed slurry is prepared by mixing high-concentration tail mortar which is obtained by densely dehydrating low-concentration tail mortar through a deep cone thickener (1) with rough aggregates and concrete which are discharged by an aggregate silo (2) and a power silo (3) through a mixer (4); and the slurry is pumped to the subsidence area (6) through a pump (5) so as to be discharged. During the discharging, the subsidence area is backfilled by a discharging mode of plane partitioning staggering and vertical cement and non-cement interbedding; according to the plane partitioning staggering discharging, the subsidence area is divided into a plurality of independent discharging areas on a plane according to a spatial distribution state of the subsidence area, and the mixed slurry is discharged in the staggered manner according to different areas; and according to the vertical cement and non-cement interbedding discharging, cement backfill layers (7) and non-cement backfill layers (8) discharge the slurry in the staggered interbedding manner in the vertical direction of the subsidence area. The backfill method has the characteristics of low backfill cost, safety and reliability in backfill and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

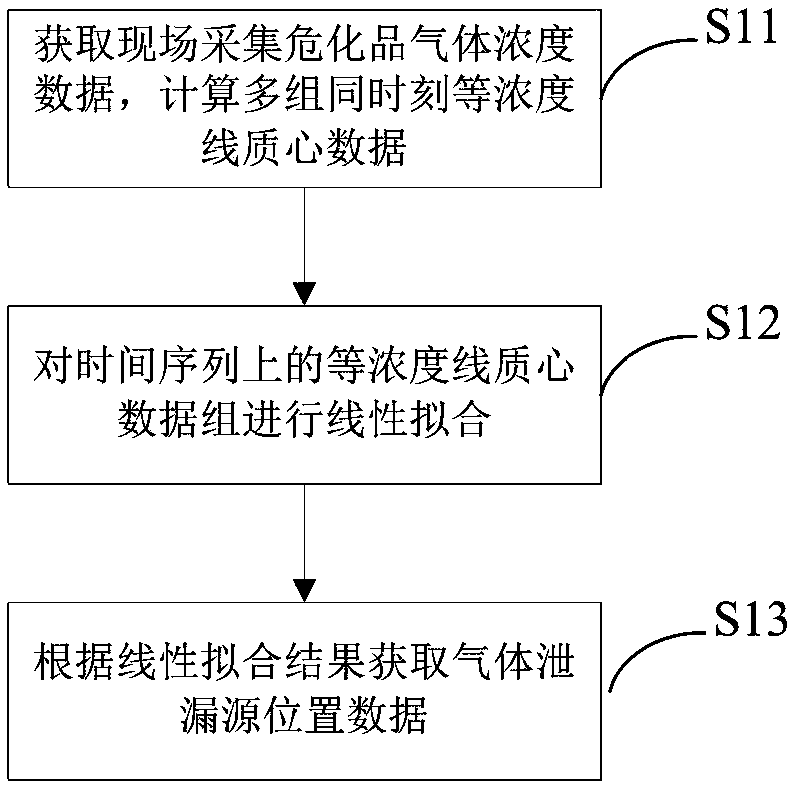

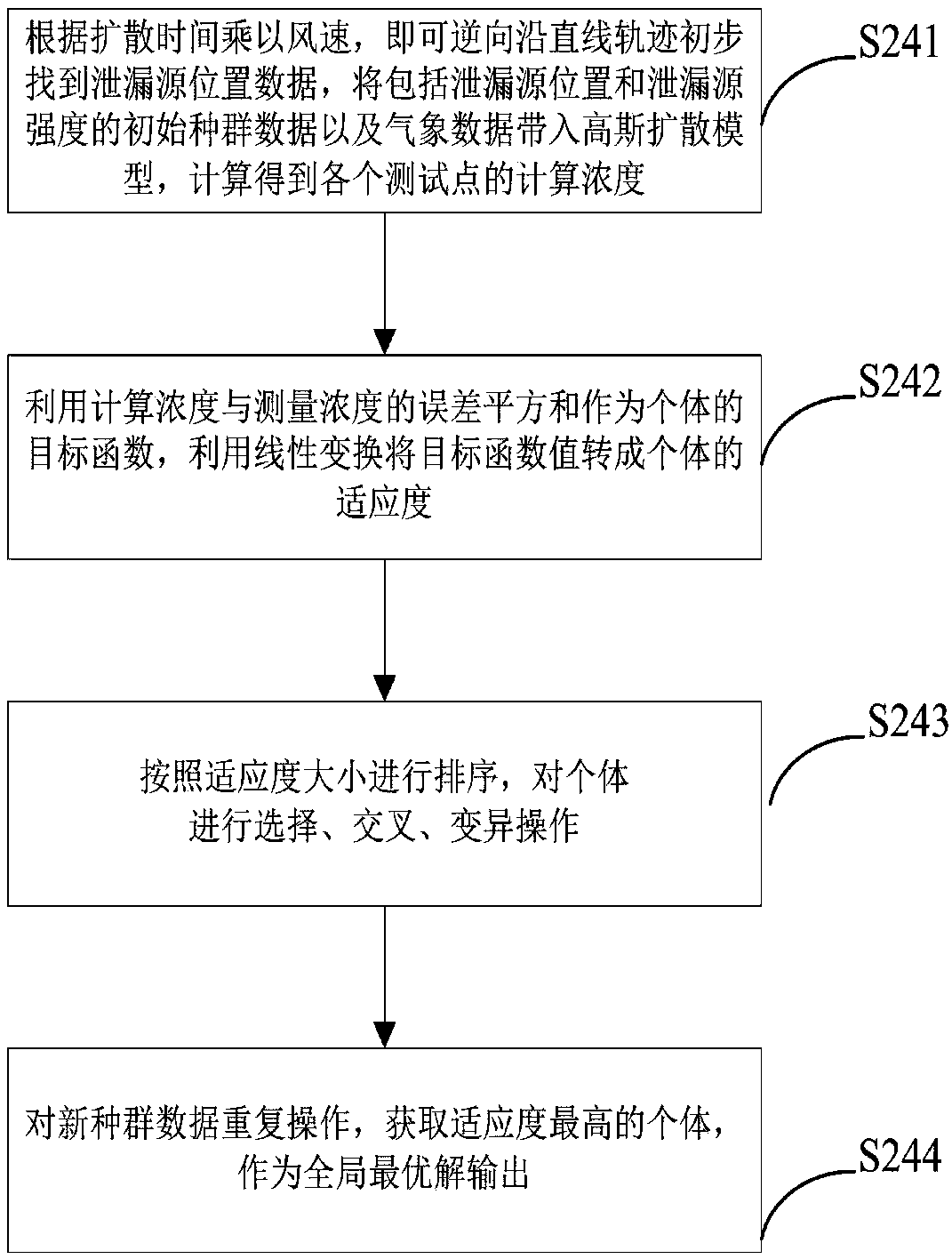

Dangerous chemical gas leakage isoconcentration line mass center track tracing algorithm

ActiveCN108920818AControl extensionShorten iterative calculation timeDesign optimisation/simulationSpecial data processing applicationsData setAlgorithm

The invention discloses a dangerous chemical gas leakage isoconcentration line mass center track tracing algorithm. The algorithm includes the following steps: acquiring dangerous chemical gas concentration data collected on site and calculating multiple sets of simultaneous isoconcentration line mass center data; conducting linear fitting on isoconcentration line mass center data sets in time sequence; acquiring gas leakage source position data according to a linear fitting result. First, the mass center of isoconcentration lines at each moment is obtained, and then the mass center of the isoconcentration lines in the time sequence is subjected to linear fitting by utilizing the linear moving track of the isoconcentration line mass center with the time. The location of a leakage source can be found quickly in the reverse wind direction of the fitted line to provide quick guidance for leakage emergency response, and the leakage accident expansion can be effectively controlled. The algorithm also provides a scientific theoretical basis for selection of initial population data and initial values for solving a genetic algorithm and a pattern search algorithm based on the optimized theoretical method, the iterative calculation time for the optimized theoretical method is shortened, and the calculation accuracy is improved.

Owner:CHINA ACAD OF SAFETY SCI & TECH

Method for reinforcing concrete structural part through fiber grid ribs and early-strength self-compacting mortar

ActiveCN104328924AShort operating timeNot conducive to reinforcementBuilding repairsFiberReinforced concrete

The invention relates to a method for reinforcing a concrete structural part through fiber grid ribs and early-strength self-compacting mortar. The method comprises the following steps of firstly removing floating dust and loose particles on the surface of the reinforced concrete structural part, then carrying out notching processing, and then removing concrete dust and wetting; then smearing or spraying the early-strength self-compacting mortar which is stirred in advance on the surface of the processed concrete structural part, wherein the thickness of the early-strength self-compacting mortar is higher than the surface of the processed concrete structural part; then laying the fiber grid ribs on the early-strength self-compacting mortar; and finally smearing or spraying the early-strength self-compacting mortar which is stirred in advance on the surfaces of the fiber grid ribs to guarantee that the early-strength self-compacting mortar uniformly covers the fiber grid ribs and exceeds the height of the fiber grid ribs. According to the construction process of the invention, the crack distribution of the concrete structural part is effectively improved, the crack propagation of the concrete structural part is effectively controlled, the structural rigidity, the bearing capacity and the durability are improved, and the method can be widely used for the anti-bending, anti-shearing, anti-pressing and anti-seismic reinforcing of concrete structures in various types.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Southern propagation and northern breeding method for plug seedlings of strawberries

ActiveCN108464202ASpeed up the breeding processPromote early differentiationGrowth substratesCulture mediaFragariaBEACH STRAWBERRY

The invention relates to a southern propagation and northern breeding method for plug seedlings of strawberries. The southern propagation and northern breeding method comprises the following steps: 1)breeding strawberries in a warm and suitable area in the south in spring to grow a great number of healthy creeping stems; and 2) transporting the creeping stems to a cold and suitable area in the north in summer, and breeding the creeping stems by using a plug seedling raising method until the creeping stems blossom and bear fruits. According to the southern propagation and northern breeding method, the creeping stems of the strawberries are propagated and bred by sufficiently utilizing the warm climate in a specific region in the south in spring, and then, blossom buds of the seedlings of the strawberries are promoted to differentiate by utilizing advantages of the climate in a cold area of a specific region in the north in summer.

Owner:北京市林业果树科学研究院

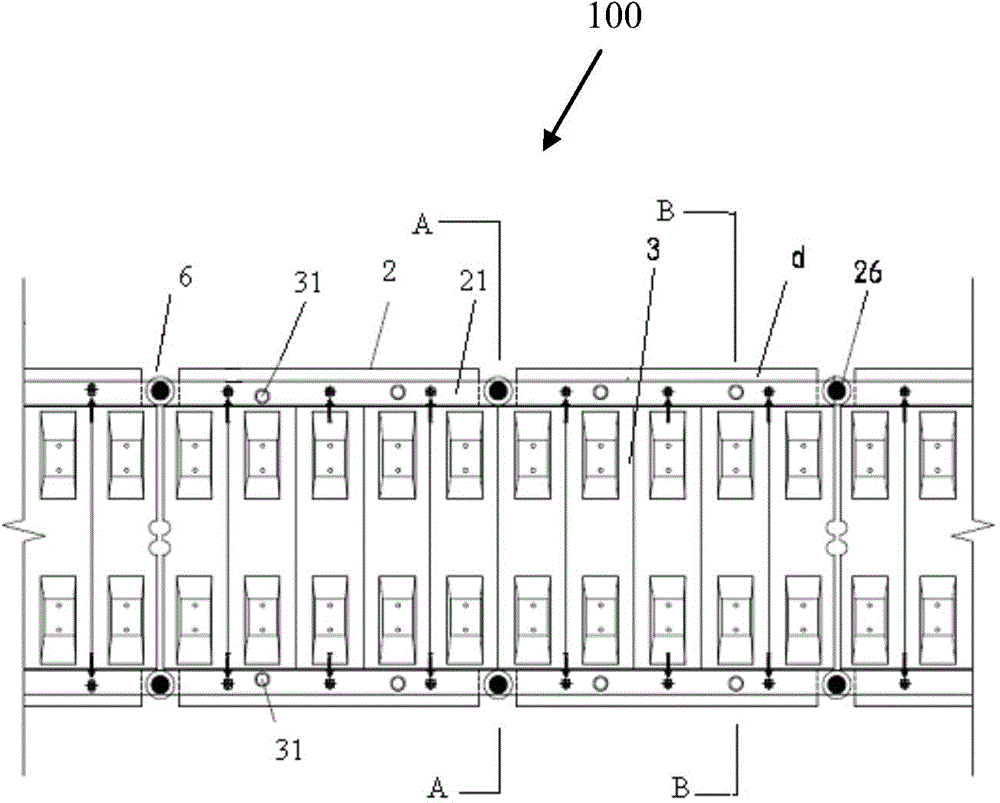

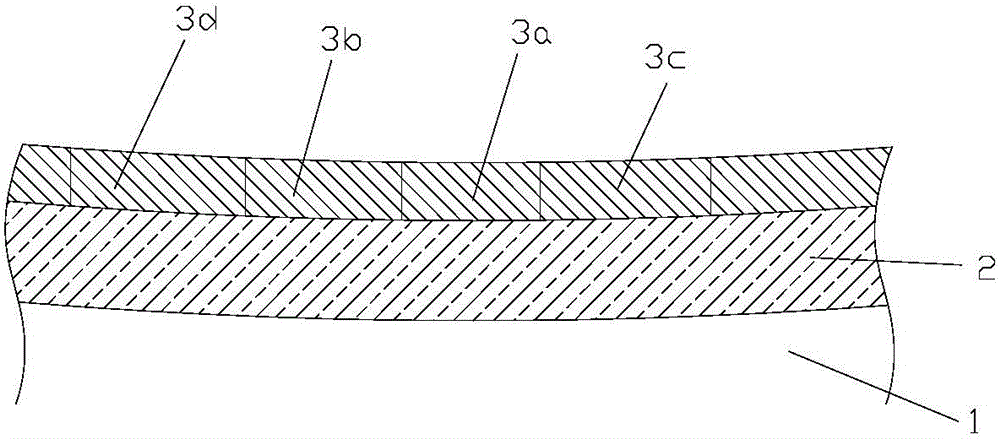

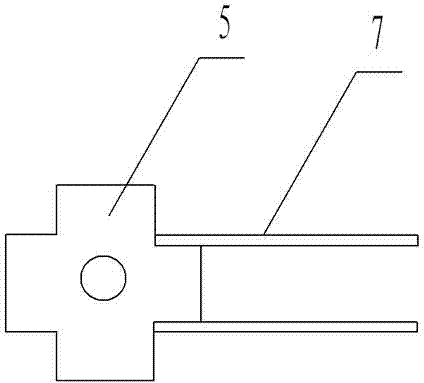

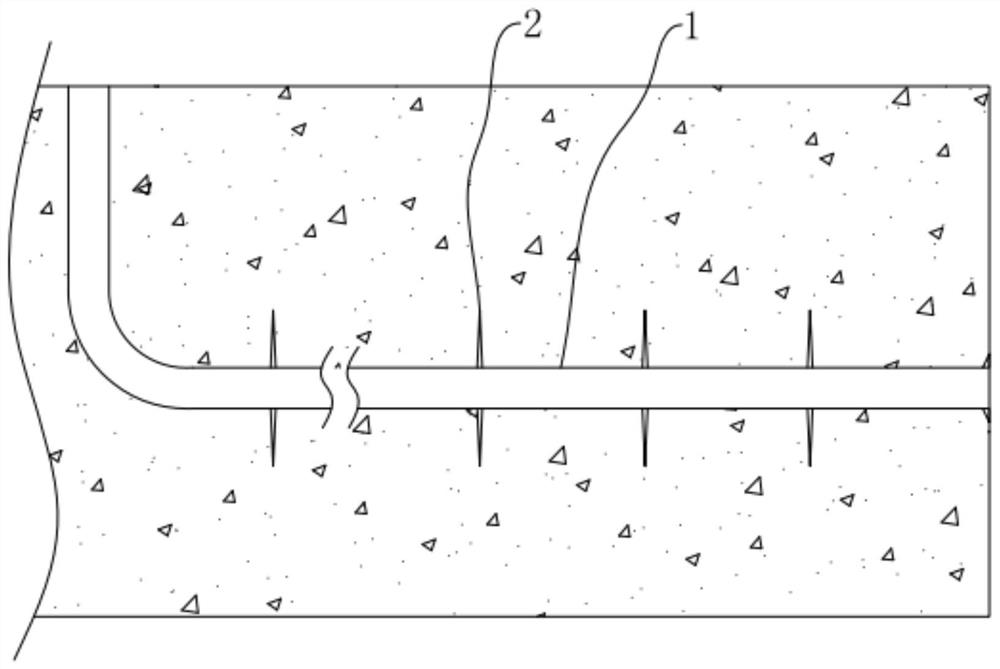

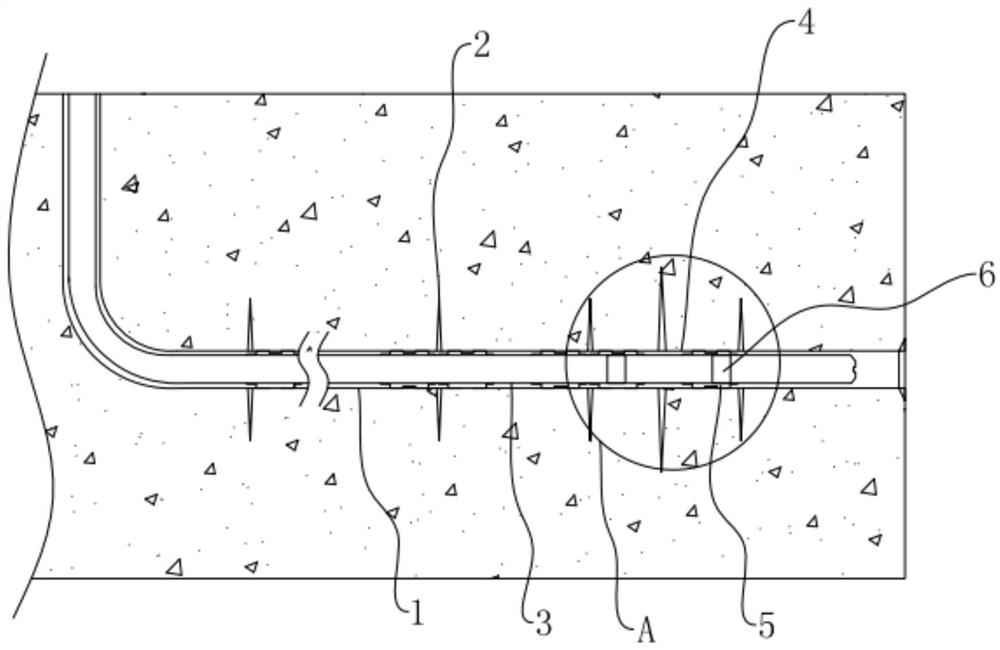

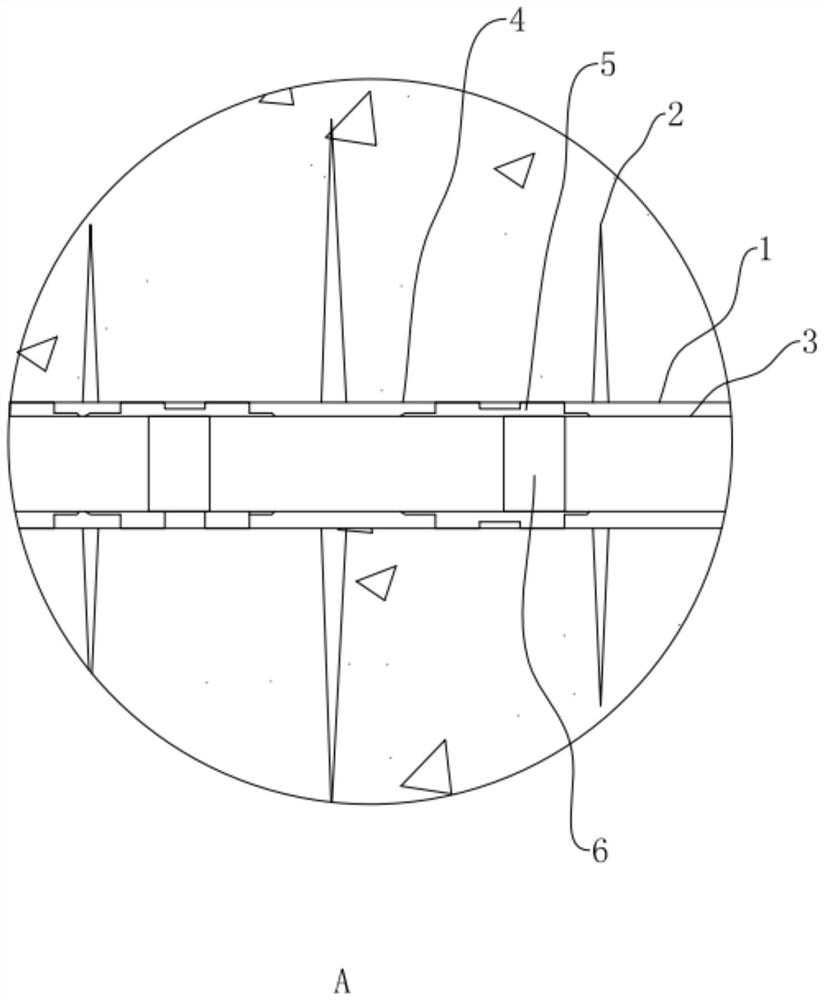

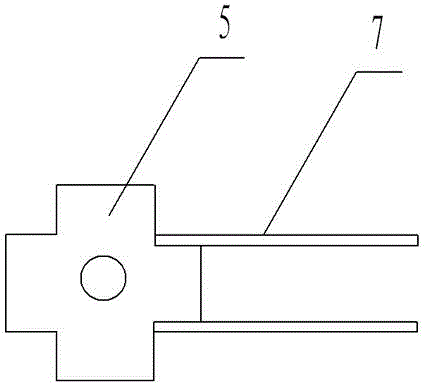

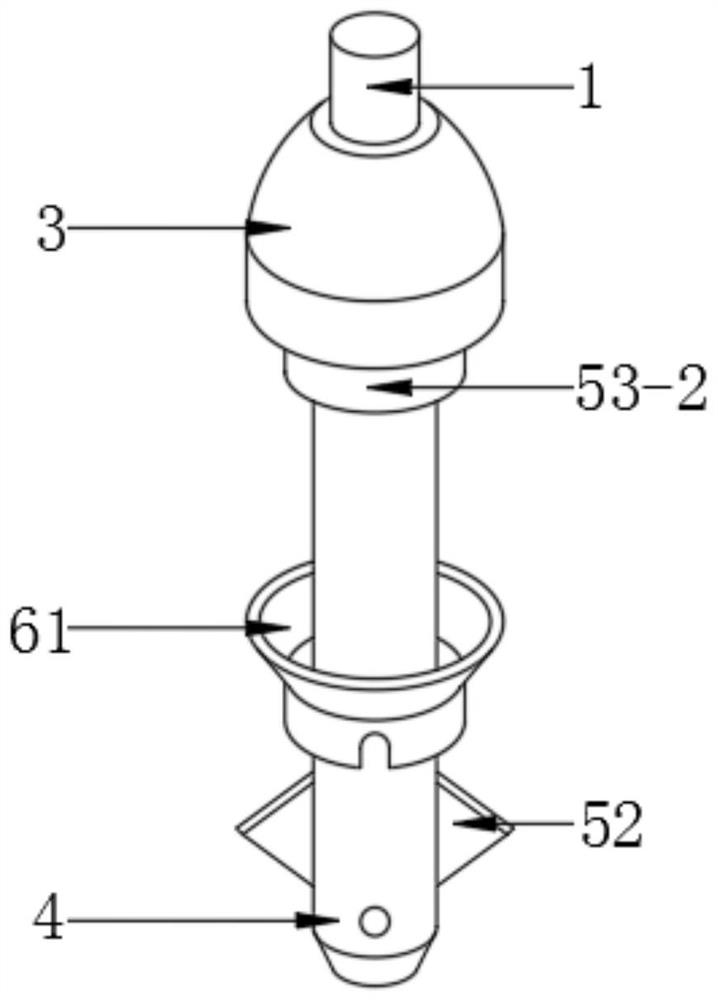

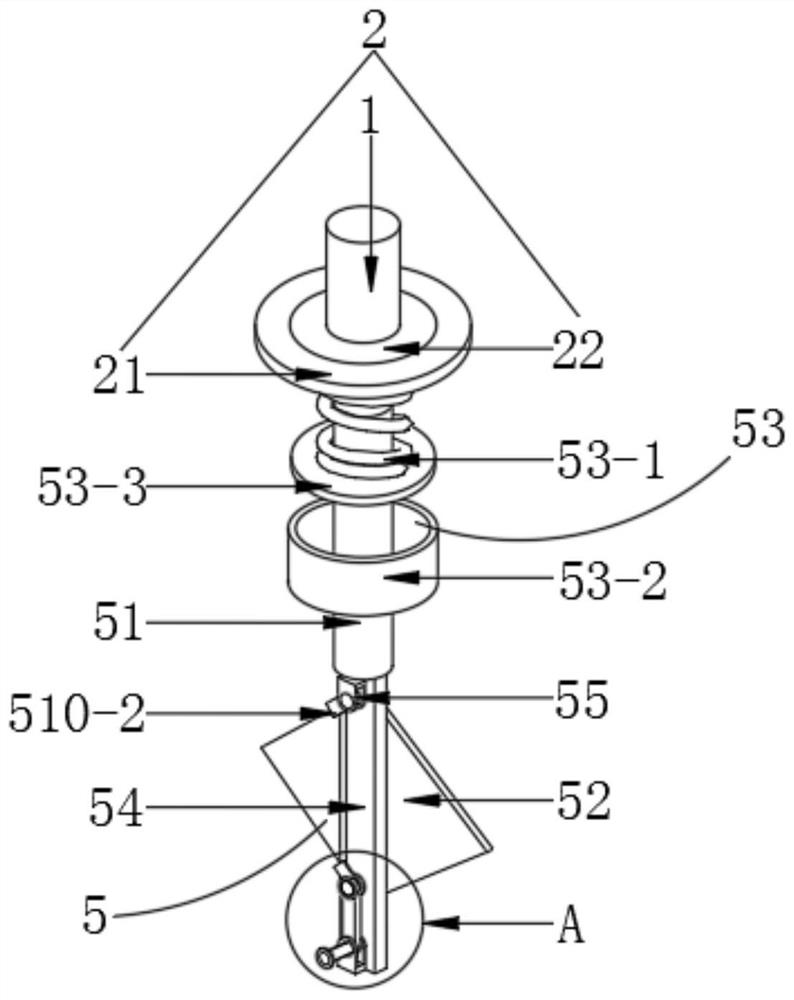

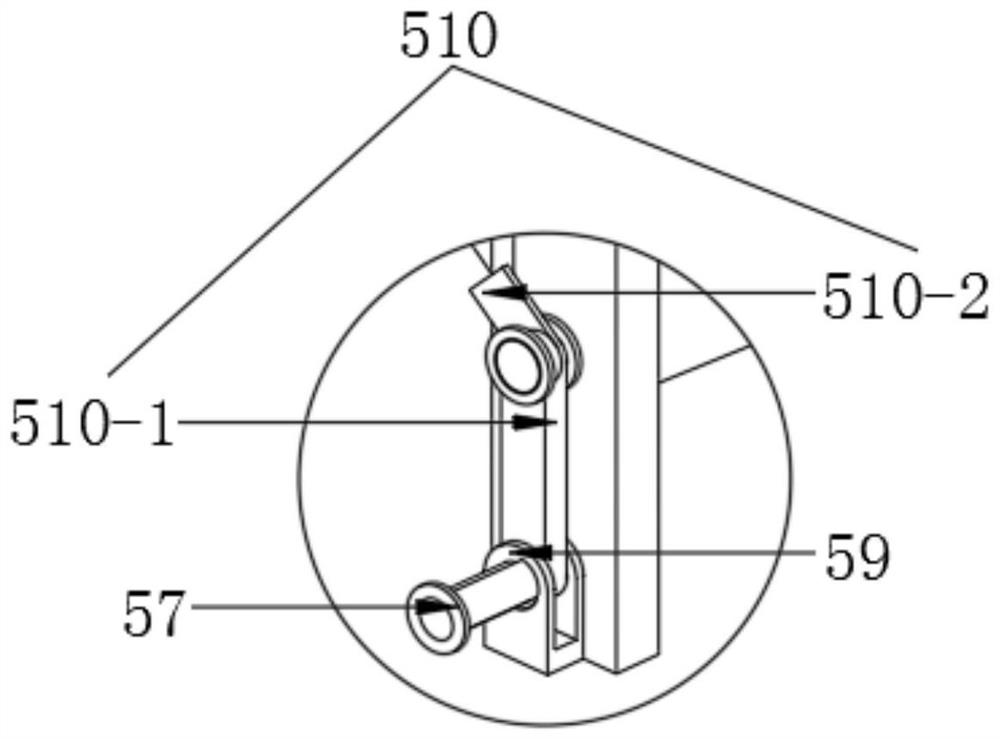

Ballast bed and tunnel bottom defect regulating and constructing method as well as anchoring device

The invention discloses a ballast bed and tunnel bottom defect regulating and constructing method as well as an anchoring device. The anchoring device comprises anchor rod and ballast bed slab anchoring ends and ballast bed slab middle anchoring ends, wherein each anchor rod and ballast bed slab anchoring end comprises a combination end, an anchor rod I and deformed steel bars I, the combination end is welded by two pieces of anchor rod clamp-fixing angle steel and a piece of ballast bed slab clamp-fixing angle steel, the two pieces of anchor rod clamp-fixing angle steel are welded on the same surface of the ballast bed slab clamp-fixing angle steel, and an interval allowing the anchor rod I to pass is reserved between the two pieces of angle steel, and the deformed steel bars I are welded on two sides of the combination end respectively; and each ballast bed slab middle anchoring end comprises a bearing plate, an anchor rod II and deformed steel bars II, the bearing plate adopts a crossed steel plate provided with a hole which is formed in the middle and allows the anchor rod II to pass, and the deformed steel bars II are welded on two sides of the bearing plate respectively. According to the ballast bed and tunnel bottom defect regulating and constructing method as well as the anchoring device, the structure is simple, the processing is easy, the problems of baseplate reinforcement and controlling and blocking of opening and closing cracks between the ballast bed slab and the baseplate can be solved effectively, and the purpose of quick, effective and comprehensive regulation of the ballast bed slab and tunnel bottom defects is achieved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

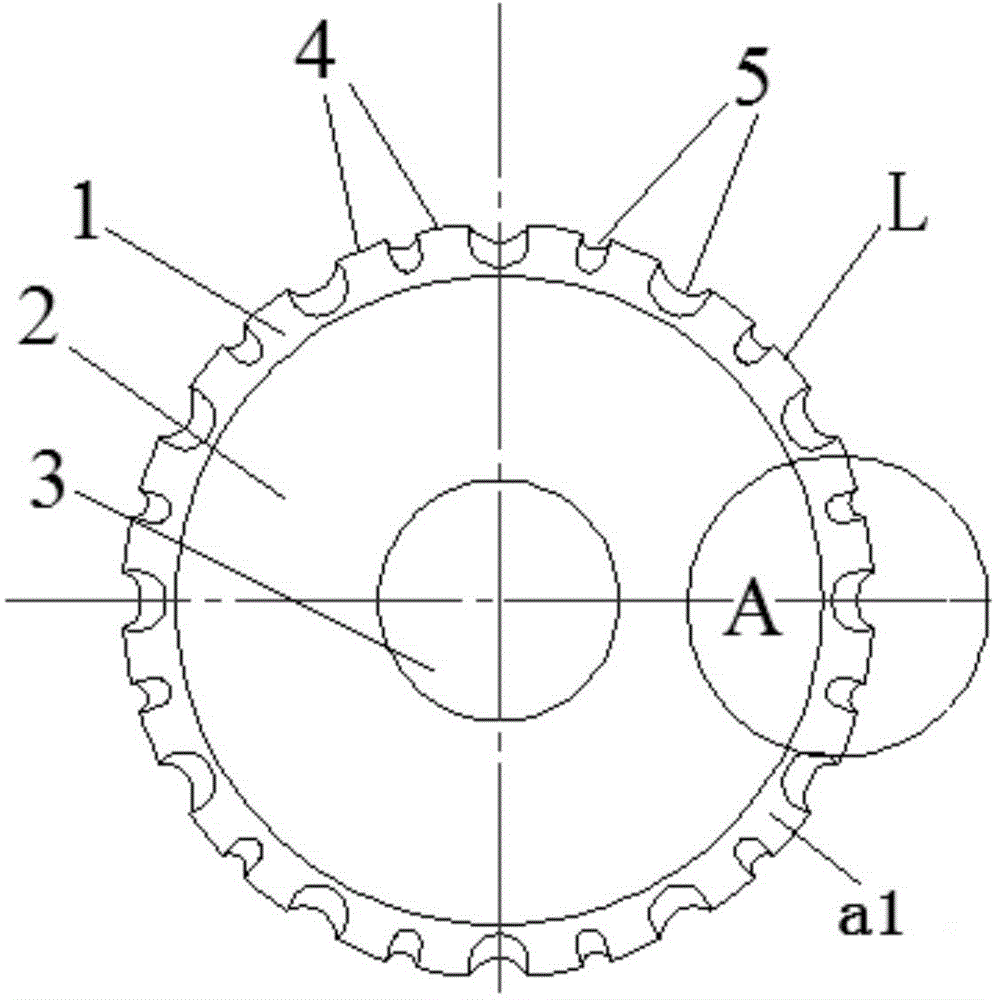

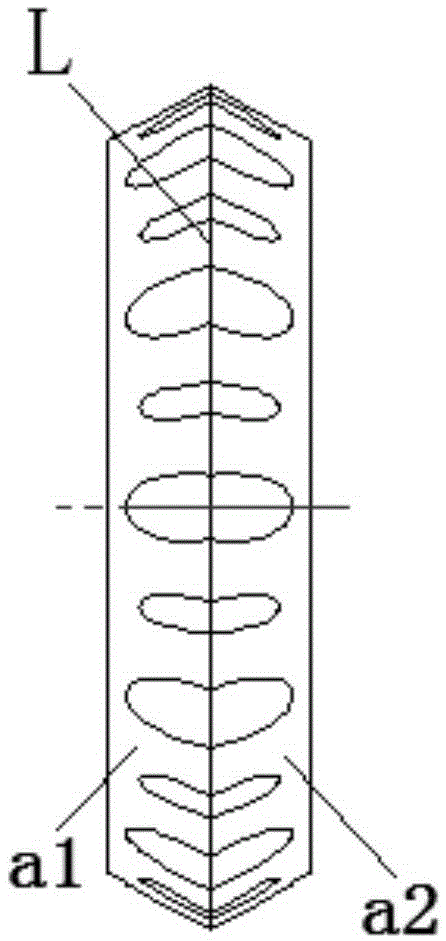

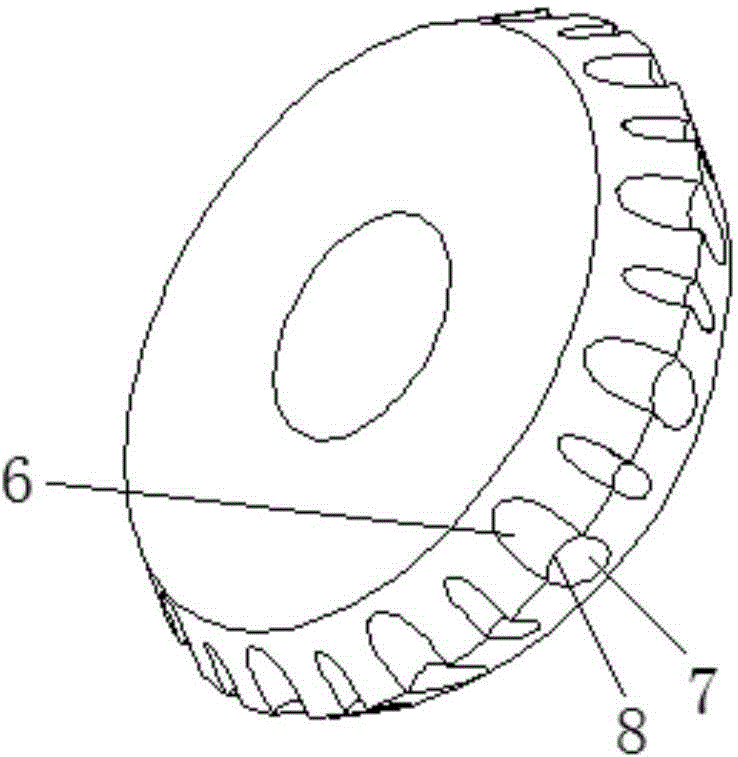

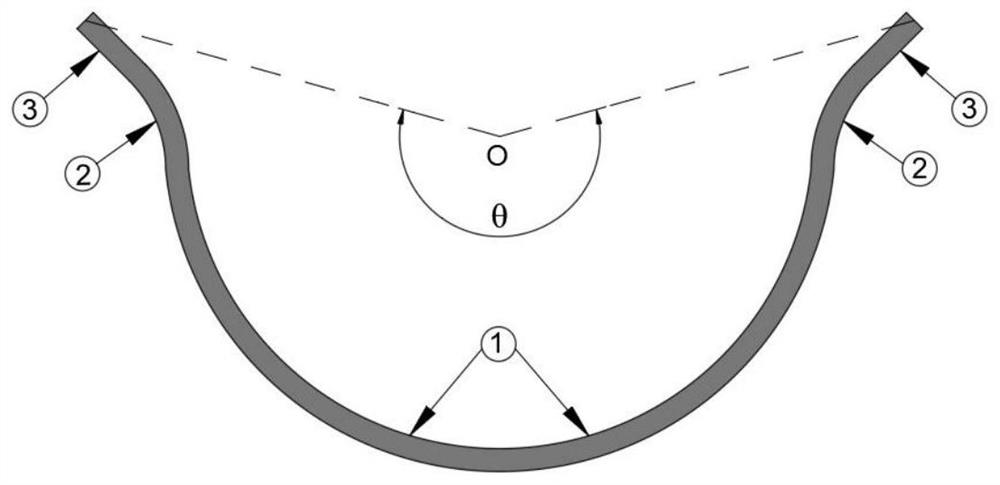

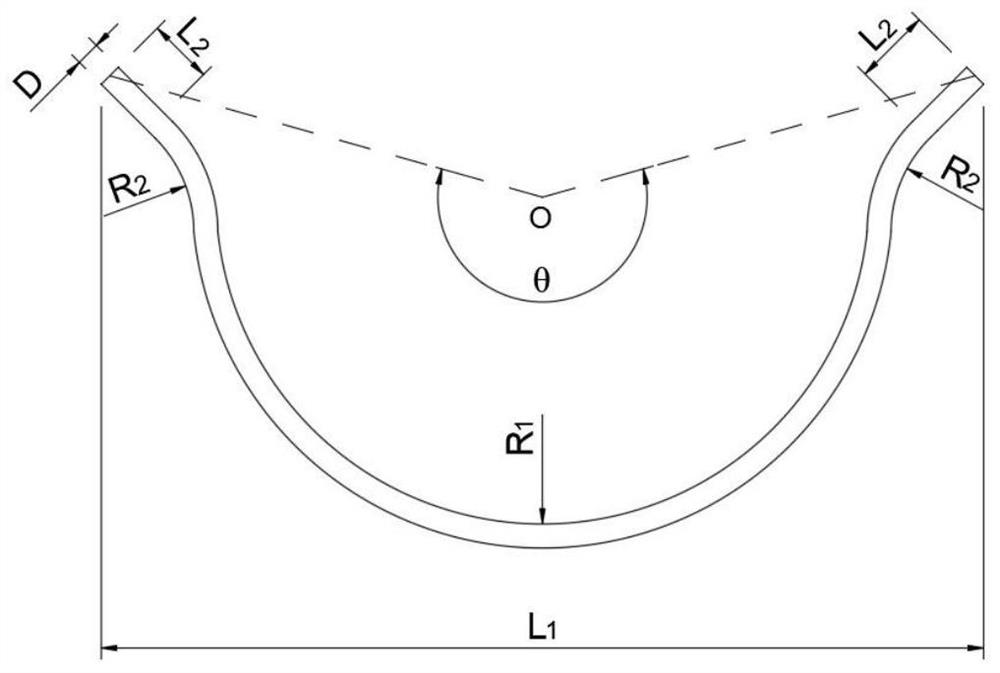

A cutting knife wheel for fragile materials

InactiveCN105365058AAvoid forksControl extensionGlass severing apparatusStone-like material working toolsEngineeringMechanical engineering

The invention provides a cutting knife wheel for fragile materials. The cutting knife wheel comprises a V-shaped cutting blade portion consisting of a first curved surface, a second curved surface and an outer edge ridge, a round disc surface and a central shaft hole. The outer edge ridge of the V-shaped cutting blade portion circumferentially has cutting blades and recessed structures distributed alternately. The outer edge ridge circumferentially has recessed structures of at least two different shapes and sizes, and the recessed structures are arranged in order or without order along the outer edge ridge. A first cutting tip and a second cutting tip are formed between each recessed structure and the corresponding two adjacent cutting blades. The first cutting tips and the second cutting tips on the two sides of at least one part of the recessed structures are used for cutting in glass and forming crack lines and the first cutting tips and the second cutting tips on the two sides of at least one part of the recessed structures are used for controlling the extension of the crack lines in the glass and preventing forking and over-cracking of the glass. The cutting knife wheel can effectively control the forking and over-cracking of fragile materials and is especially suitable for tempered glass.

Owner:孙春雨

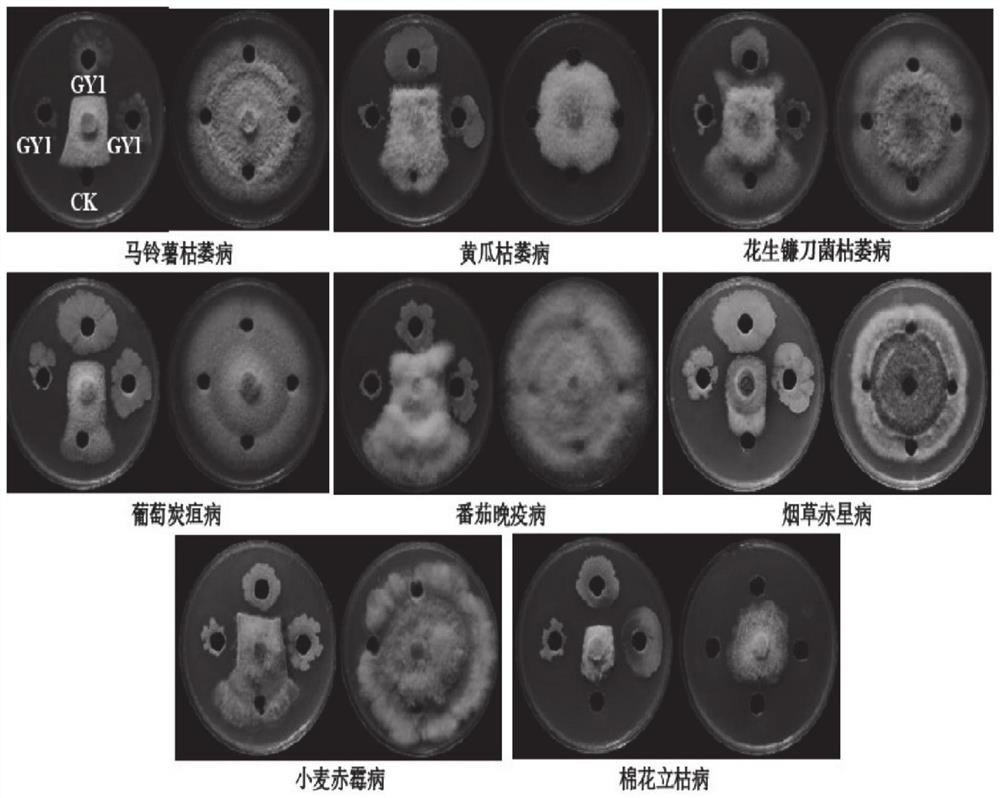

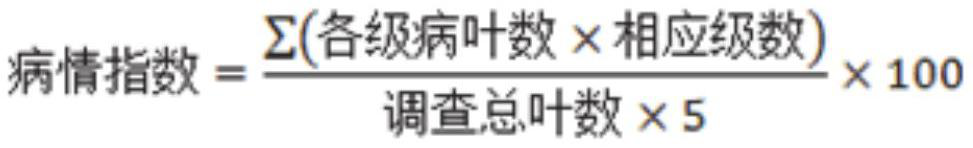

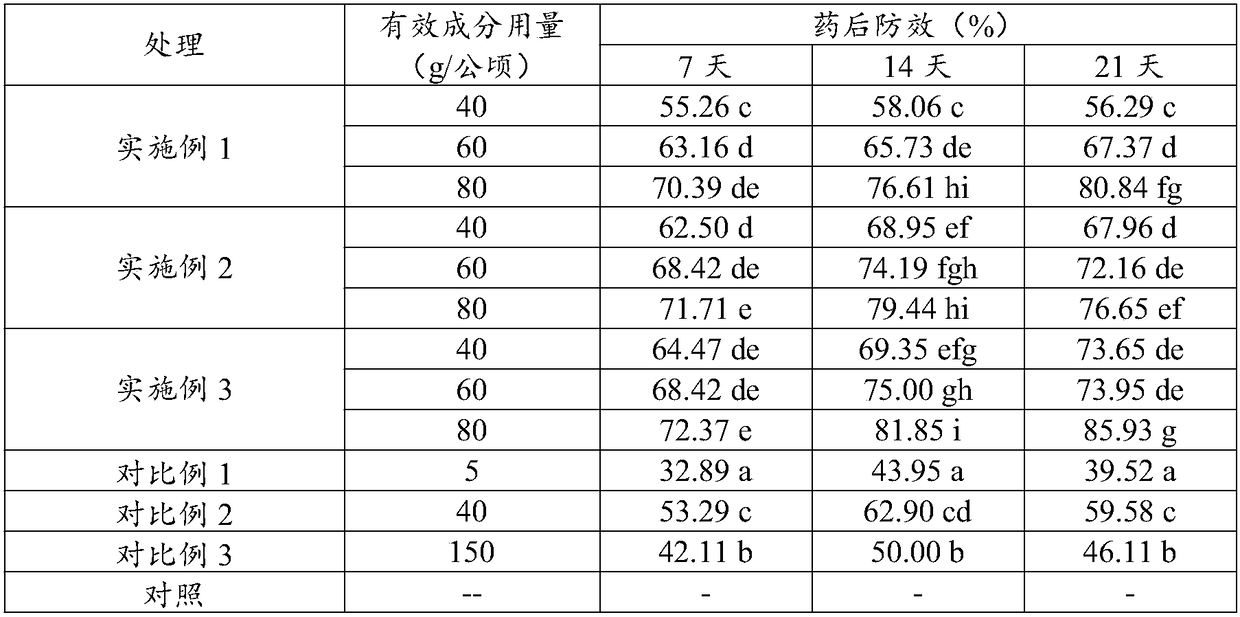

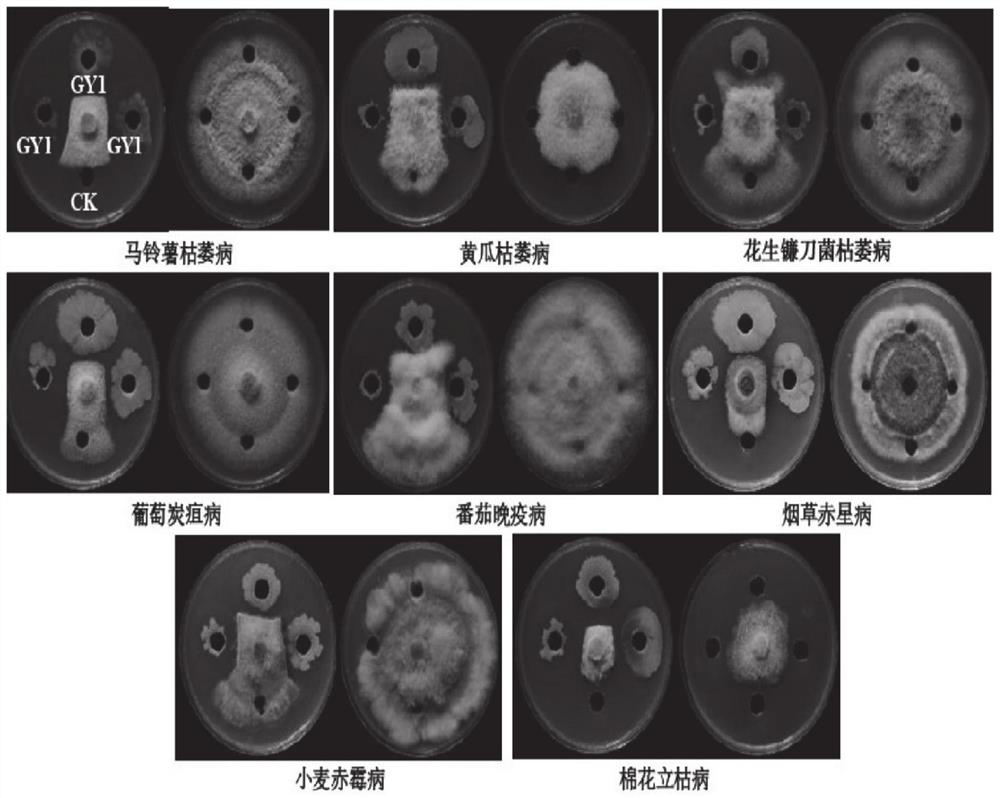

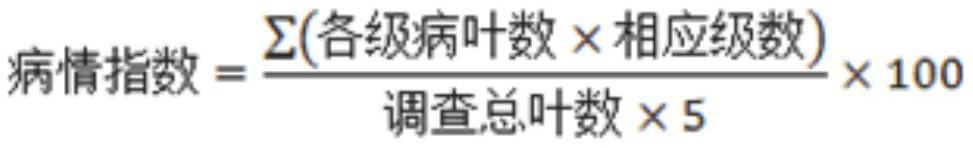

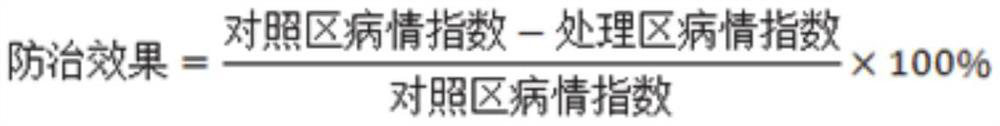

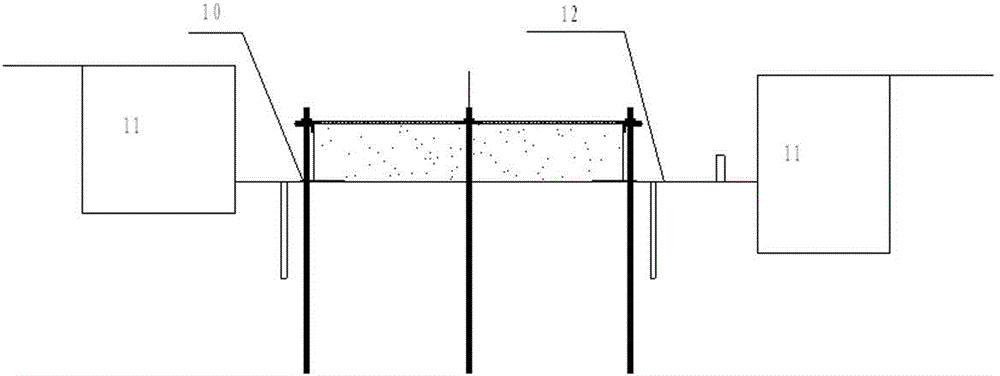

Bacillus velezensis as well as microbial inoculum and application thereof

ActiveCN112391315AStrong antagonistic effectControl extensionBiocideBacteriaBiotechnologyNicotiana tabacum

The invention provides bacillus velezensis as well as a microbial inoculum and application thereof, and belongs to the technical field of microorganisms. The biocontrol bacterium Bacillus velezensis GY1 is screened from rhizosphere soil of healthy tobaccos, has a remarkable antagonistic effect on various phytopathogens in the agricultural production, is wide in antibacterial spectrum, and is capable of effectively controlling tobacco mildew and rot and tobacco brown spot expansion in the baking period through testing, and therefore, the tobacco quality is improved, the tobacco use value is improved, so that the bacillus velezensis has wide application prospect and good practical application value in the field of biological prevention and control of plant diseases.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

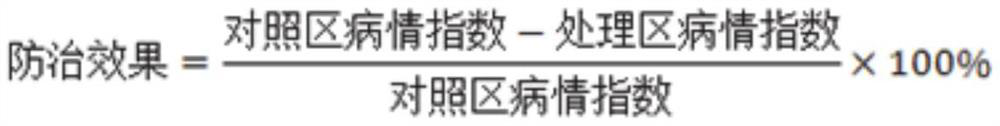

Basement exterior wall construction method and structure

PendingCN109629830AImprove waterproof strengthGeneration of controlProtective foundationCellarsSlurry wallBasement

The invention relates to the field of building engineering, in particular to a basement exterior wall construction method and structure. In the method, an underground continuous wall in foundation pitsupporting is used as a part of a basement side wall, so that a basement exterior wall is thinned; besides, by directly using the underground continuous wall as an outer form of a basement floor, a floor slab and the exterior wall, expansion force generated by concrete of the basement floor, the floor slab and the exterior wall in the pouring and setting process is effectively resisted; meanwhile, the concrete of the basement floor, the floor slab and the exterior wall has no exposed part on the outer side, so that the concrete is in a good curing state and not likely to crack; by taking themeasures of arranging a hidden beam in the floor of the basement exterior wall, arranging a flexible coiled material on the basement floor and the like, the generation of cracks in the basement concrete construction process is effectively controlled.

Owner:广州市天作建筑规划设计有限公司

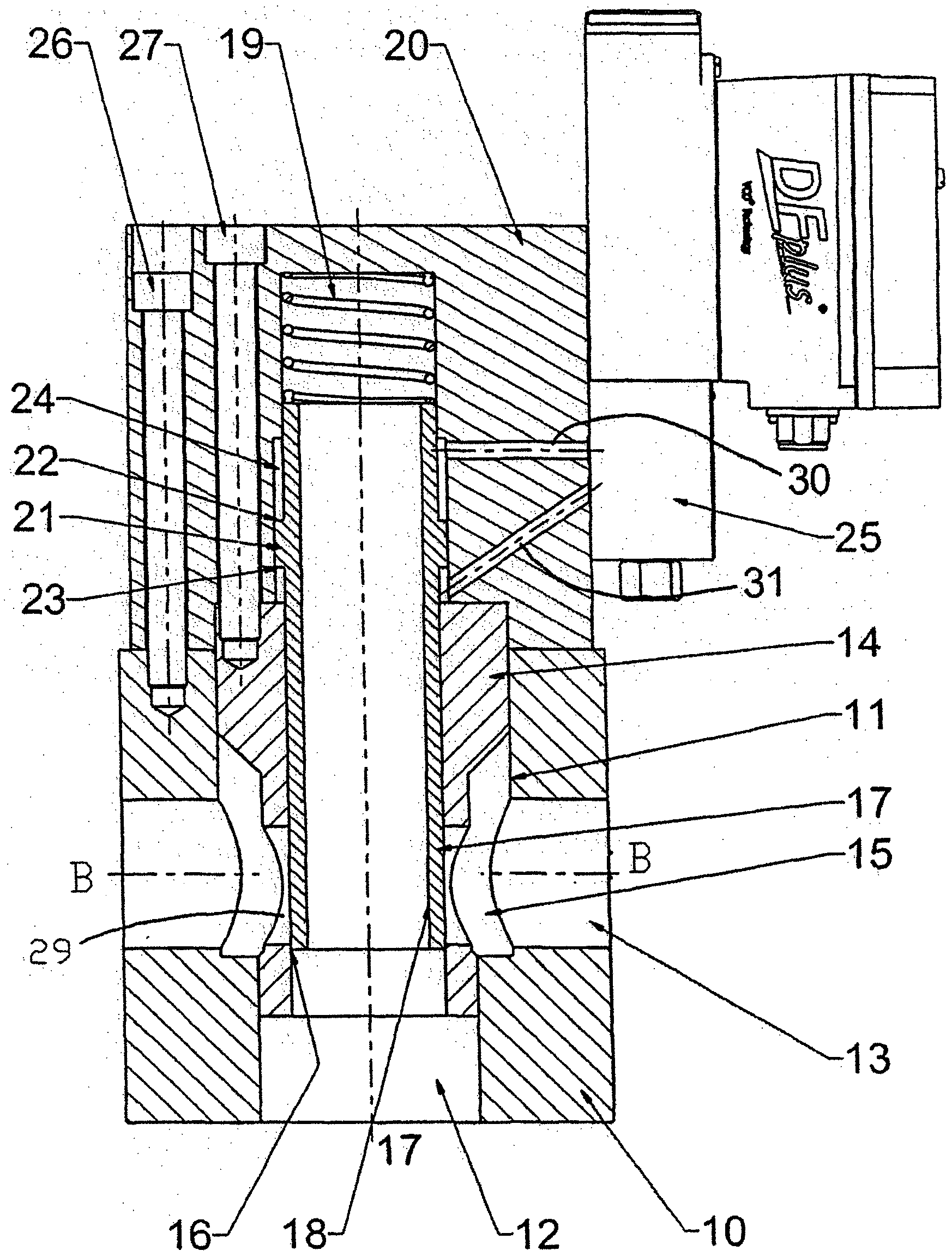

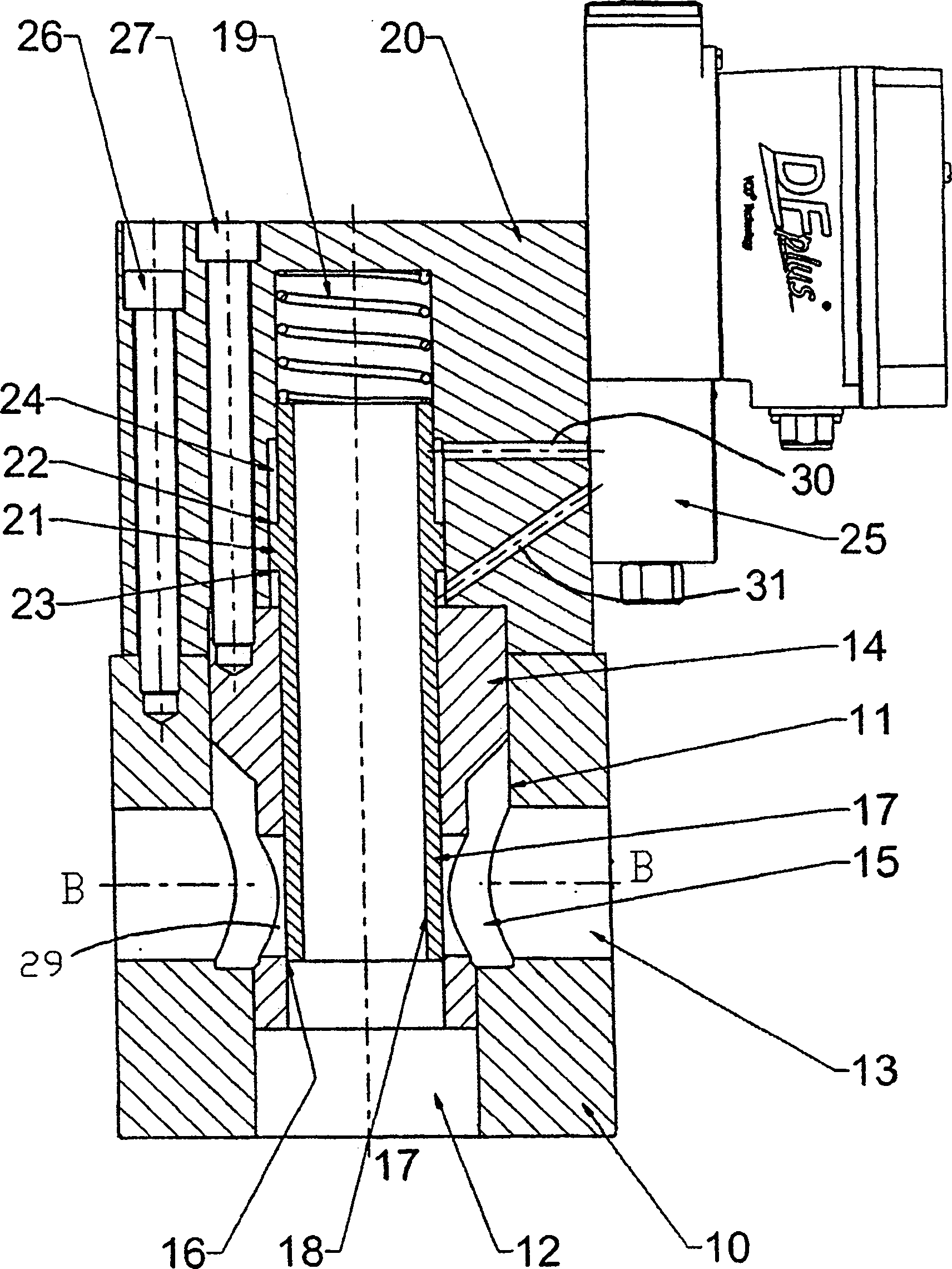

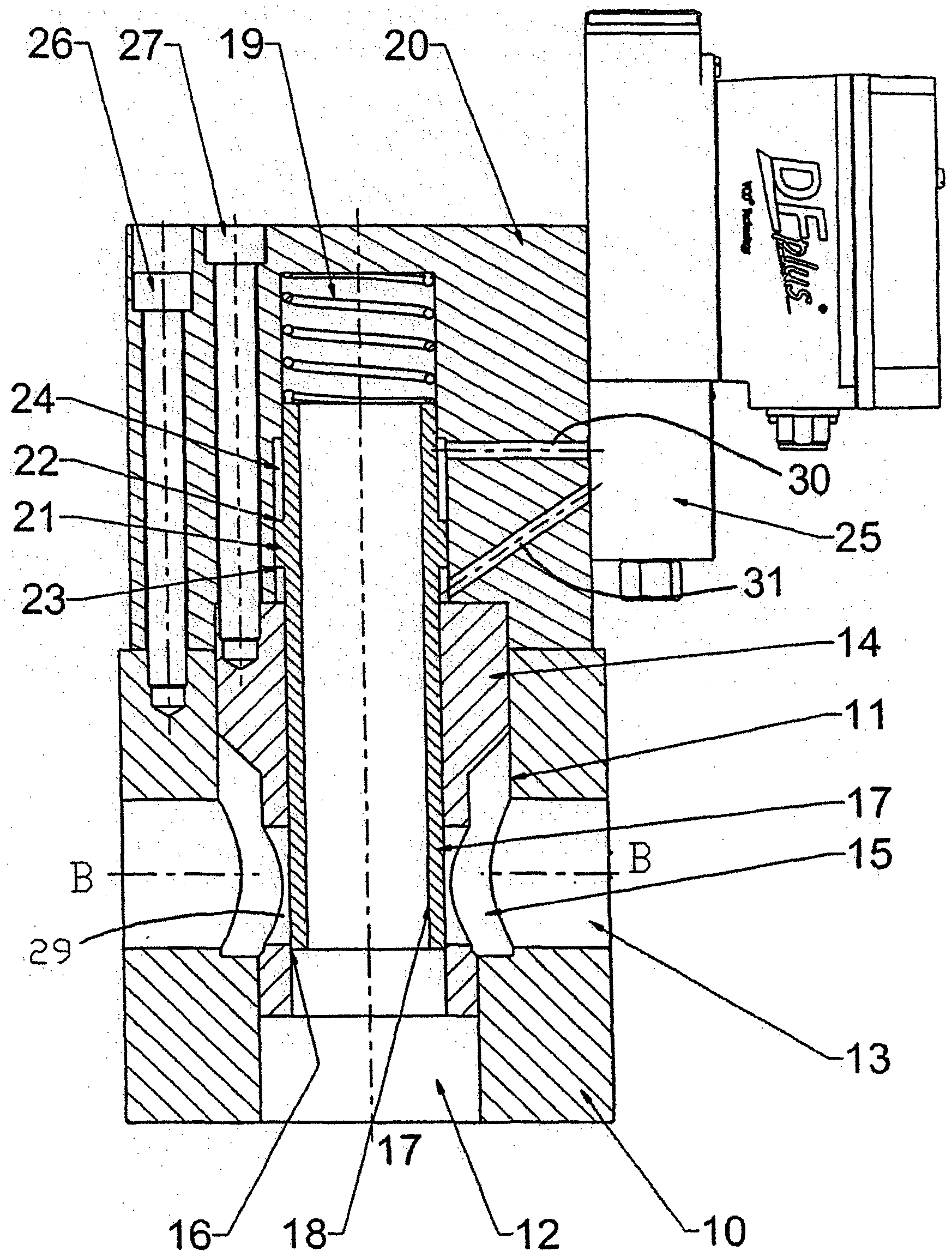

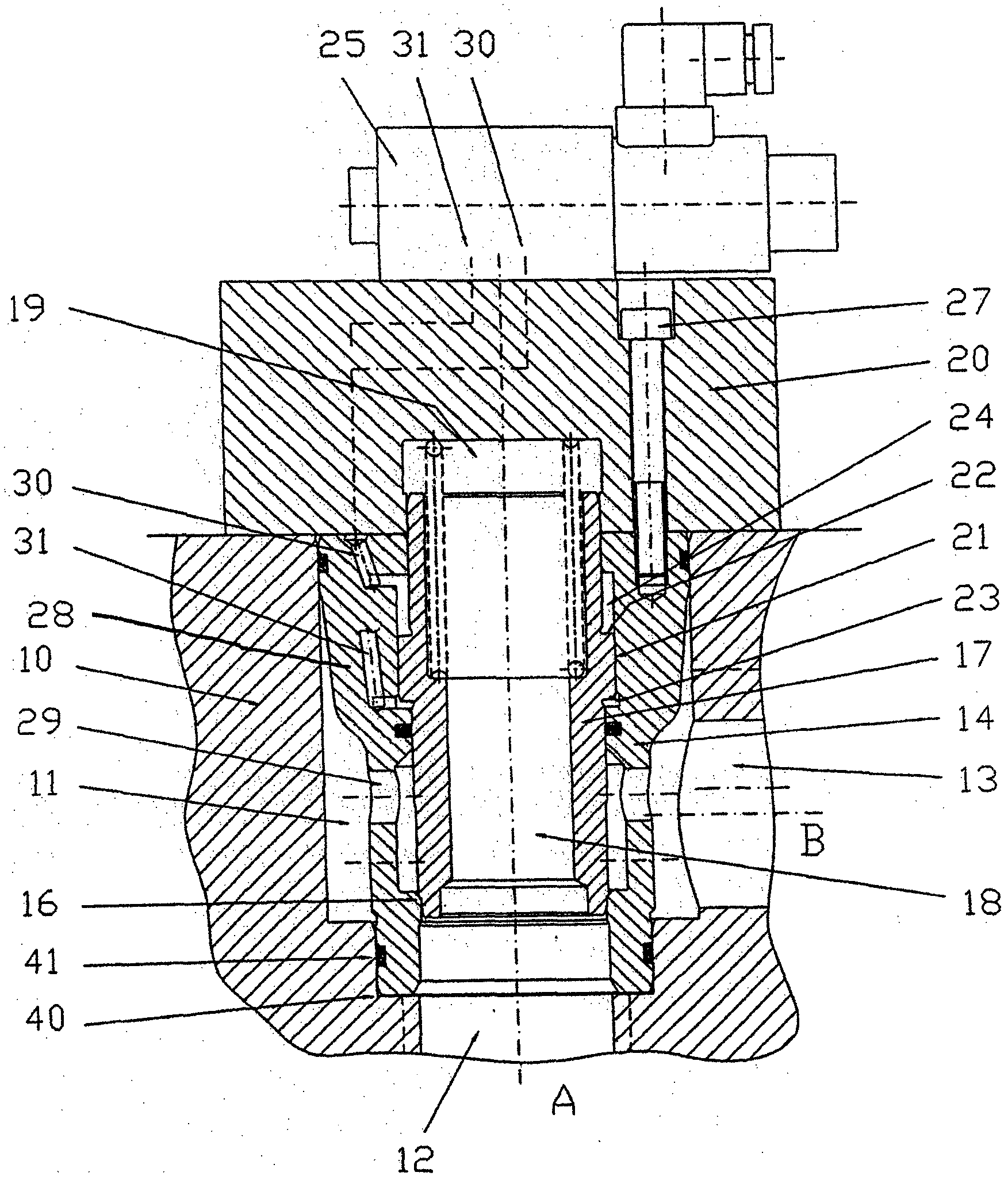

Hydraulic valve assembly having a cartridge insert valve exhibiting a closing element arranged in a pressure equalized manner

ActiveCN102308130AReduce control oil volumeControl extensionOperating means/releasing devices for valvesSlide valveEqualizationVALVE PORT

The invention relates to a hydraulic valve assembly having a cartridge insert valve in a bore hole designed in a valve block and connected to the flow channels arranged in the valve block, comprising a valve sleeve inserted in the bore hole and a closing member guided into said sleeve, wherein the valve sleeve forms a valve seat for the closing member in the closing position thereof and the closing member can be moved by means of a connected hydraulic pre-control between the closed position thereof seated on the valve seat and separating the flow channels from one another, and an opened position pushed into the valve sleeve, and the bore hole is sealed tight by the cartridge insert valve inserted therein via a valve cover connected to the valve block. The closing member forms a sleeve-shaped closing element (17) exhibiting a through-hole (18) and thus ring surfaces on both ends thereof, the surfaces having identical area, and a pressure equalization chamber (19) corresponding with thethrough-hole (18) of the closing element (17) is formed in the valve cover (20) such that the closing element (17) is engaged on both sides with the pressure enacting in the adjustment direction of the element, which is seated completely pressure-equalized in the valve sleeve (14), wherein a radially protruding collar (21) having control surfaces (22, 23) opposite one another in the adjustment direction is arranged on the outer circumference of the closing element (17) for adjustment thereof. The control surfaces can be loaded by the control oil conducted via the hydraulic pre-control (25) for moving the closing element (17) in the valve sleeve (14), and the valve sleeve (14) inserted in the bore hole (11) of the valve block is fastened on the valve cover (20), the valve seat (16) formed on the valve sleeve (14) thereby maintaining an unaltered distance from the valve cover (20) during operation of the valve assembly.

Owner:PARKER HANNIFIN CORP

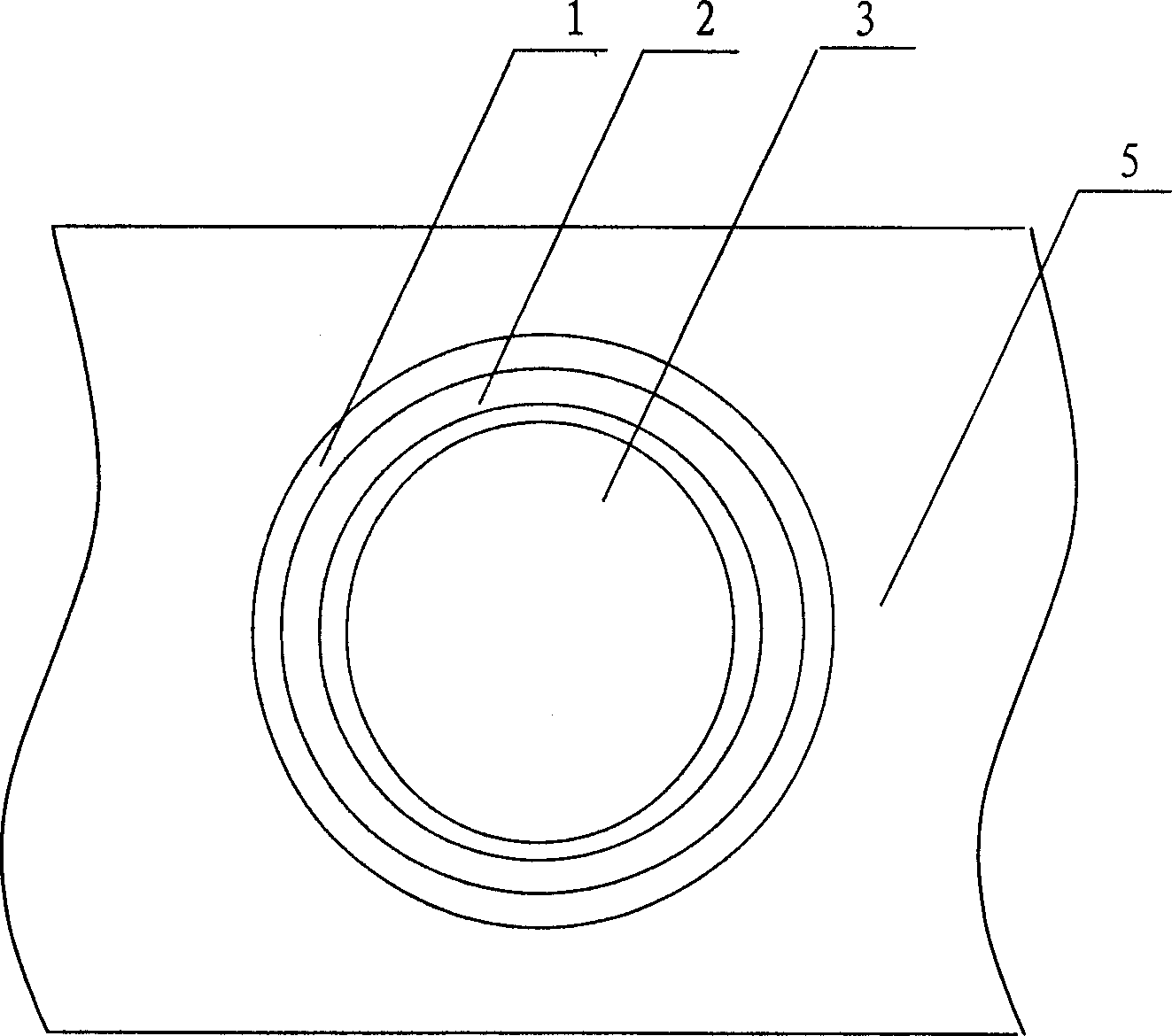

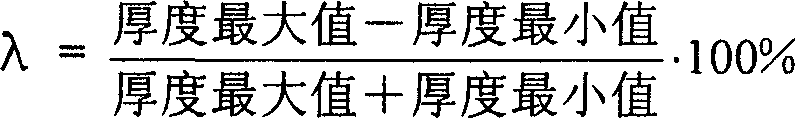

Homogeneous-thickness silicon-phase epitaxial-layer growth device and method

InactiveCN1896340AAvoid temperature differenceConsistent thicknessPolycrystalline material growthFrom chemically reactive gasesMetal impuritiesEngineering

The present invention discloses a growth device and process of a silicon vapor epilayer and aims at providing a growth device and a process with homogeneous epilayer, convenient operation and high efficiency. The growth device includes a base body, a fixing slot on the base body, a step of 1-3mm wide on the edge of the fixing slot bottom, an annular groove of 1-3mm deep on the step and an arcual concave of 1-5mm deep below the step. The top of the annular groove is 1-3mm wide. The growth process includes the following steps: the silicon substrate wafer is positioned in the fixing slot with the upper surface of the substrate wafer 0.1-1mm lower than the upper surface of the base, and the epilayer grows. This invention has simple arts and crafts, provides homogeneous epilayer, controls the distribution area of the slip lines and removes the contaminative layer of metal impurities on the surface, improving the quality of the silicon epilayer and ensuring the performance of the product.

Owner:HEBEI UNIV OF TECH

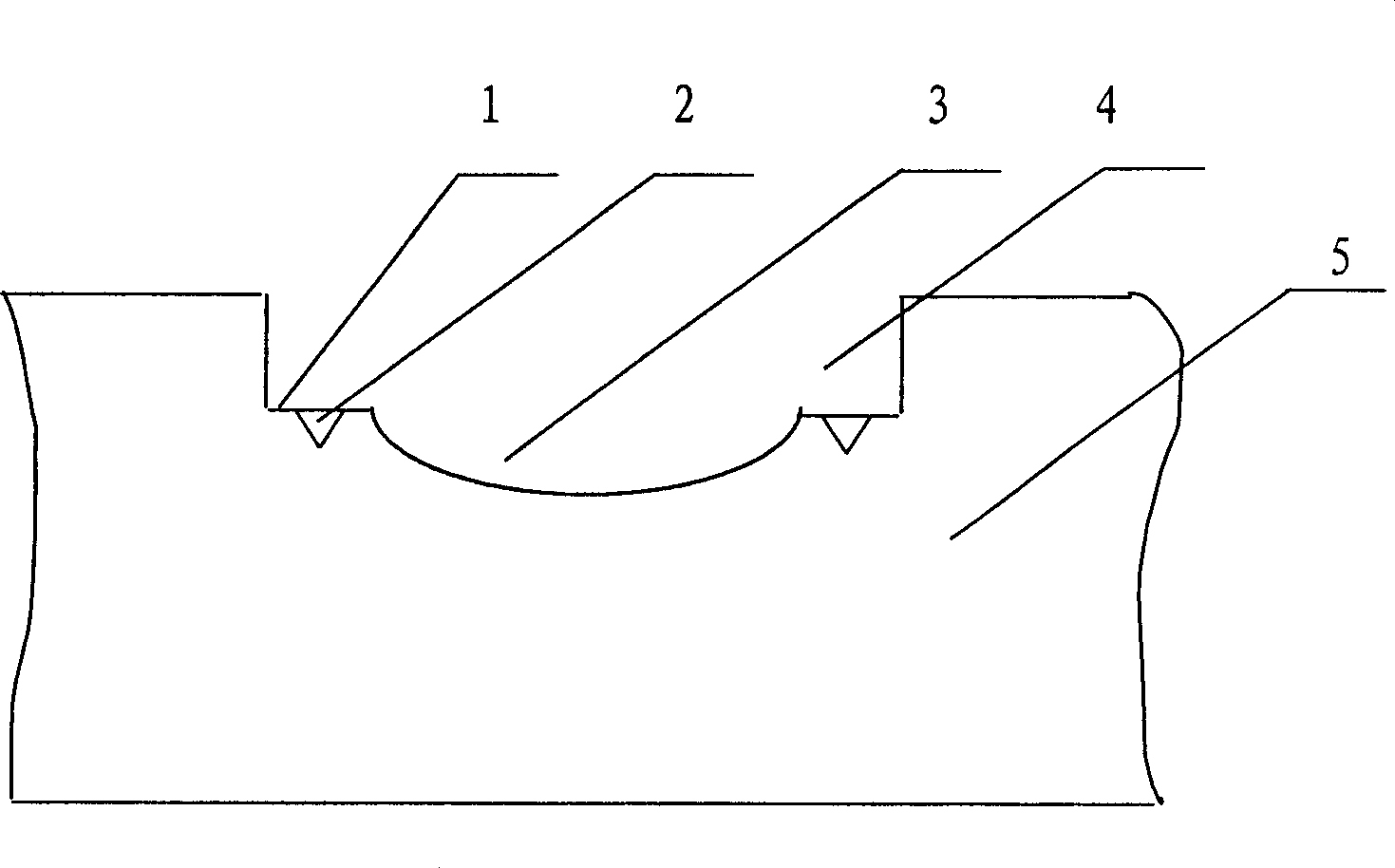

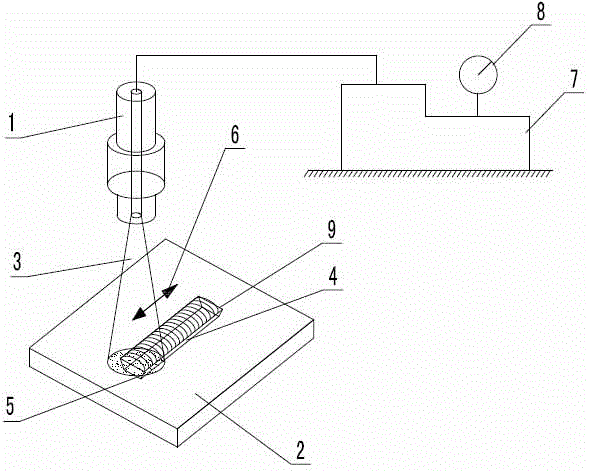

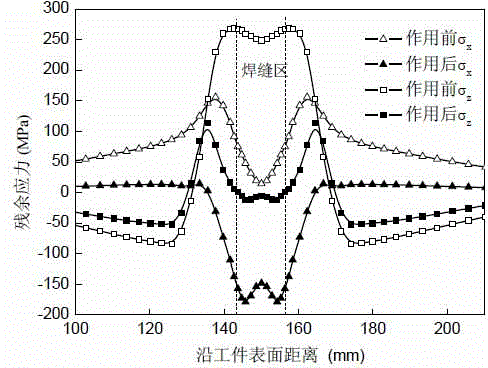

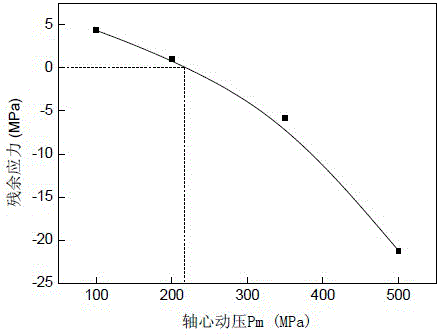

A Method of Eliminating Welding Residual Stress Using High Pressure Water Jet

ActiveCN103805760BGood effectLow costMetal recyclingFurnace typesWelding residual stressHigh pressure water

A method for eliminating the welding residual stress by utilizing high-pressure water jet belongs to technical field of welding. The high-pressure water jet (3) sprayed by a nozzle (1) moves on a weld (4), the axial dynamic pressure of the water jet (3) is adjusted to be 220-700MPa; the distance between the water outlet of the nozzle (1) and the weld (4) is kept to be 5-10mm, the water jet (3) moves back and forth for 4 to 8 times along the weld track and perpendicular to the workpiece surface, and the stress eliminating effect is reinforced. The method for eliminating the welding residual stress is easy to operate, and quickly eliminates the residual stress on the welding part after welding. The stress on the weld in a narrow space can be eliminated, such as dead angle part and repair welding part, and can ensure that the whole weld stress eliminating effect is good, stable and average.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

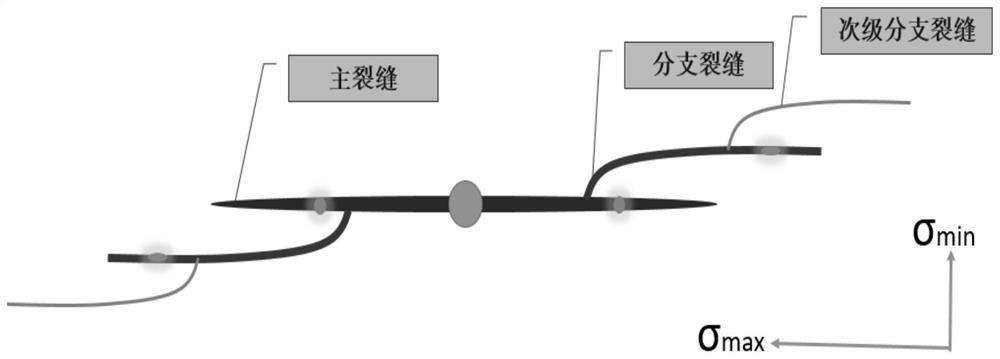

Fine fracture control temporary plugging diversion fracturing method

ActiveCN114562245ARaise the level of implementationRealize developmentSurveyData processing applicationsFracture controlPetroleum engineering

The invention discloses a fine fracture control temporary plugging diversion fracturing method. The method comprises the steps that when temporary plugging steering fracturing is conducted on a target well, micro-seismic monitoring is adopted in the fracturing process of all stages of fracturing sections of the target well to conduct fracture extension dynamic real-time monitoring; when it is monitored that fracture extension which is not beneficial to fracturing occurs on a fracturing section in the fracturing process of a certain stage of the fracturing section, a temporary plugging adjustment scheme is determined in real time, and follow-up fracturing is completed after temporary plugging adjustment is conducted on the fracturing section according to the temporary plugging adjustment scheme; wherein the temporary plugging adjustment scheme comprises the number of times of delivery of a temporary plugging agent, and the number of times of delivery of the temporary plugging agent is determined on the basis of monitored crack extension characteristics of crack extension which is not beneficial to fracturing.

Owner:博丰石油科技发展(辽宁)有限公司

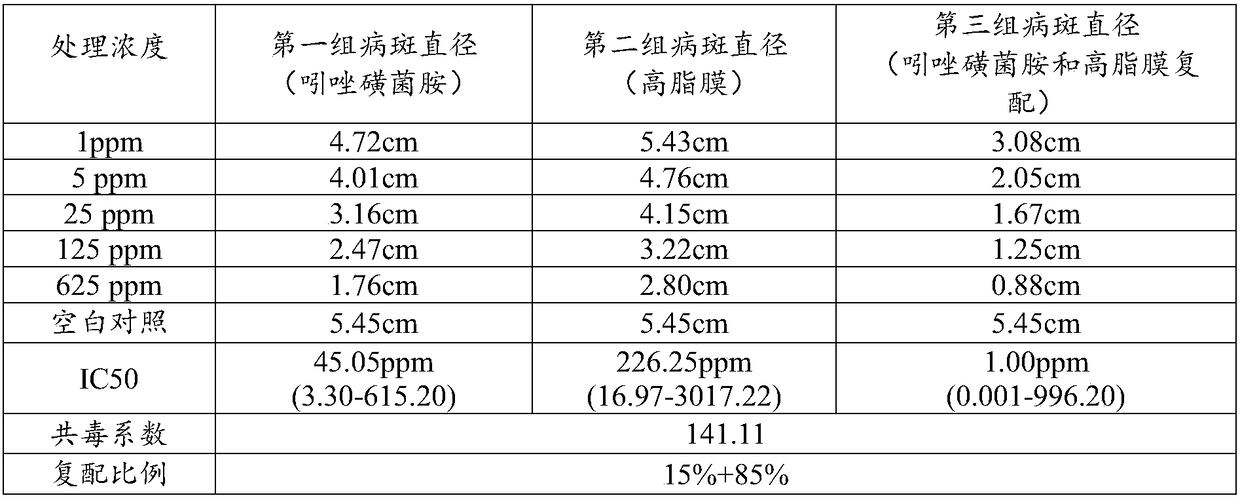

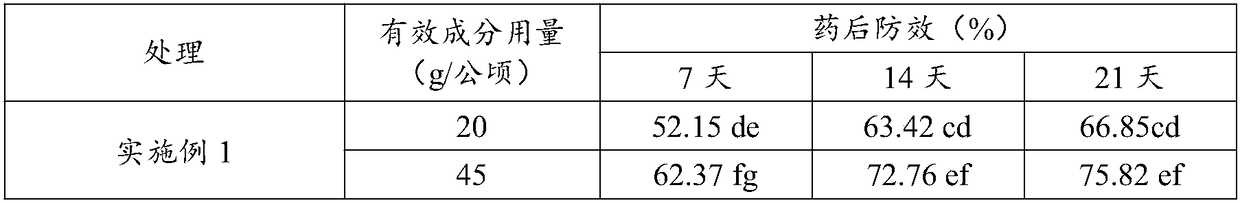

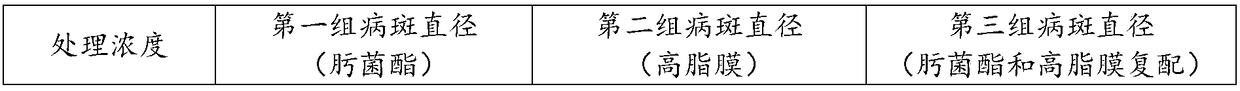

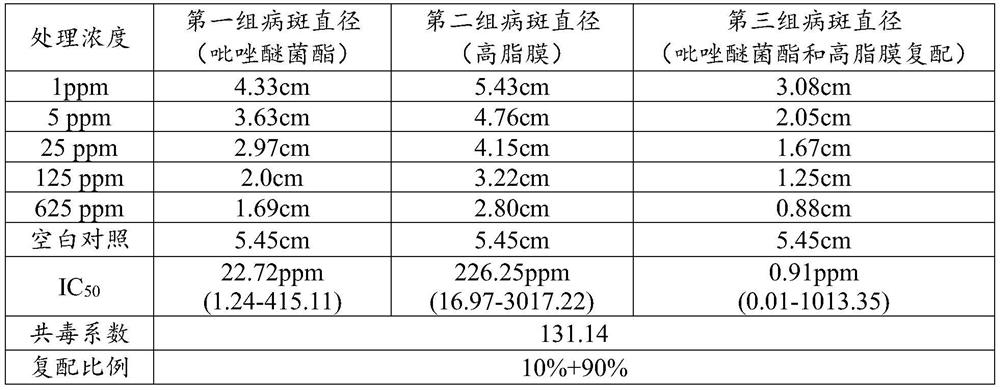

Medicinal composition containing amisulbrom, pesticide and application thereof

InactiveCN108207968ADefoliationImprove the growing environmentBiocideFungicidesBiotechnologyPathogenic microorganism

The invention relates to the technical field of pesticides, and in particular relates to a medicinal composition containing amisulbrom. The medicinal composition comprises the following active ingredients by weight: 0.5-5 parts of pyraflufen-ethyl, 3-30 parts of the amisulbrom and 40 to 120 parts of a high fat film. In the active ingredients of the medicinal composition, the pyraflufen-ethyl playsa defoliation effect, and after application, the growth environment of cotton bolls in the middle and lower part of a cotton plant can be improved, and an environment which is not conducive to the infection and growth of pathogenic microorganisms can be created; the amisulbrom can effectively prevent the occurrence of cotton boll rot caused by oomycetes; the high fat film can effectively controlthe expansion of infected lesions and reduce the incidence of the cotton bolls infected by other weak pathogenic pathogens. After compounding of the pyraflufen-ethyl, the amisulbrom and the high fat film, by adjustment of the external environment of the cotton bolls and inhibition of the pathogen activity and the infection probability of the cotton boll rot, the development of the cotton boll rotcan be effectively controlled, and the incidence of the cotton bolls infected by other weak pathogenic pathogens can be reduced after the medicinal composition is applied in the initial stage of the cotton boll rot.

Owner:SHANDONG COTTON RES CENT

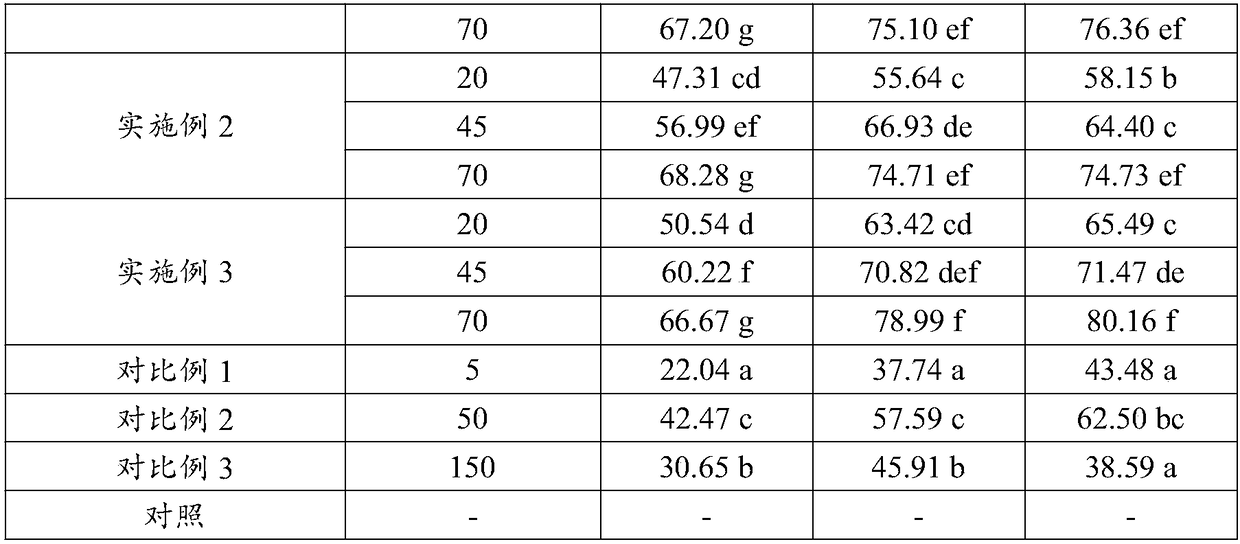

Pharmaceutical composition containing trifloxystrobin, pesticide and application thereof

InactiveCN108294010ADefoliationImprove the growing environmentBiocidePlant growth regulatorsPathogenic microorganismDisease

The invention relates to the technical field of pesticides, and particularly provides a pharmaceutical composition containing trifloxystrobin. The composition is prepared from, by weight, 0.5-5 partsof pyraflufen-ethyl, 8-30 parts of trifloxystrobin and 90-180 parts of palmityl alcohol-lauryal alcohol. Among effective substances of the pharmaceutical composition, pyraflufen-ethyl has a defoliation function, the growth environment of cotton bolls at the middle lower portions of cotton plants can be improved after application, and an environment which is not conducive to the infection and growth of pathogenic microorganisms is created; trifloxystrobin can effectively prevent and control the occurrence of cotton boll rot caused by oomycetes; palmityl alcohol-lauryal alcohol can effectively control the expansion of infected lesions and reduce the probability of cotton bolls infected by other weak pathogenic pathogens. Through compounding of pyraflufen-ethyl, trifloxystrobin and palmityl alcohol-lauryal alcohol, the external environment of the cotton bolls can be adjusted, and the pathogen activity and infection probability of the cotton boll rot are inhibited; after the composition isapplied at the initial period of the cotton boll rot, the disease condition development can be effectively controlled, and the probability of the cotton bolls infected by other weak pathogenic pathogens can be reduced.

Owner:SHANDONG COTTON RES CENT

Backfill handling method for activity subsidence area of mine

InactiveCN103216239BImprove liquiditySuitable for permeabilityUnderground miningSurface miningHigh concentrationSlurry

Owner:UNIV OF SCI & TECH BEIJING +1

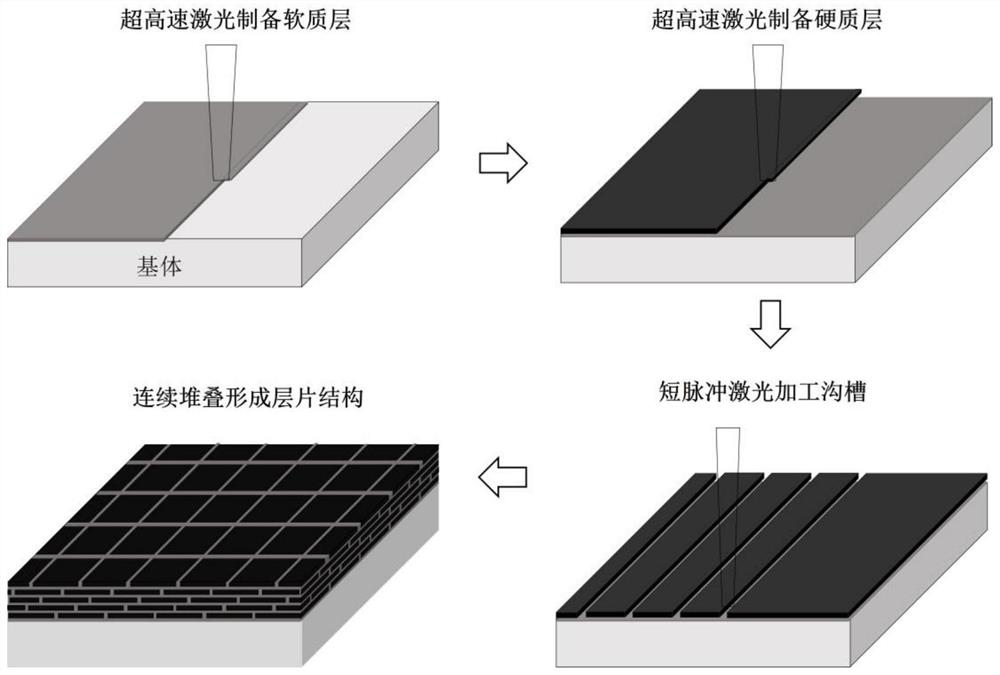

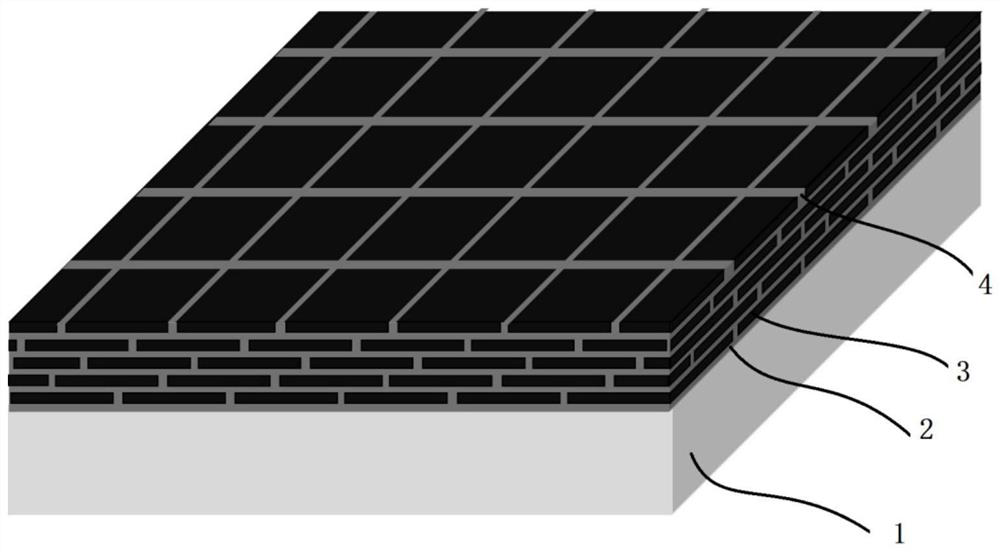

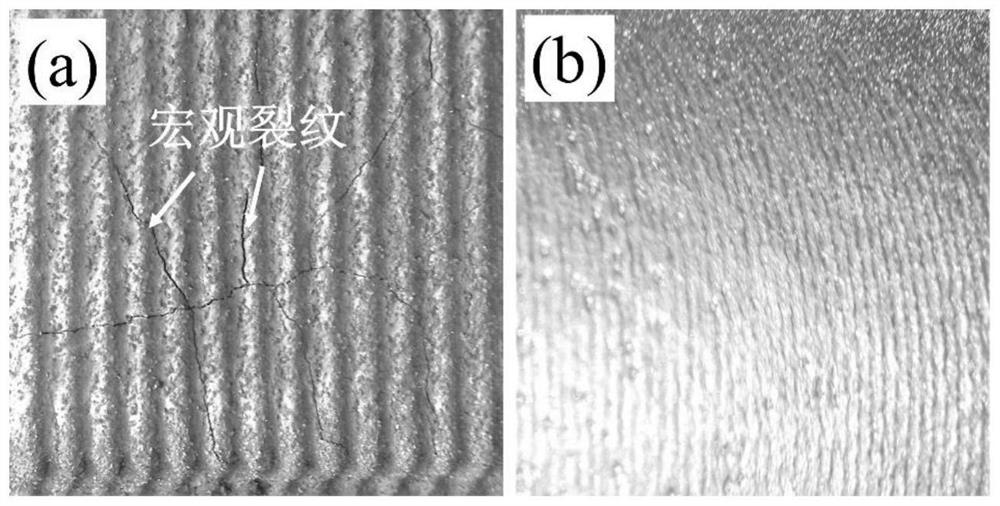

Laser-induced formed mother-of-pearl layered steel bond hard alloy and preparation method thereof

PendingCN114351137AEffective control extensionControl extensionMetallic material coating processesLaser beam welding apparatusLaser technologyUltra high speed

The preparation method mainly comprises the following steps: preparing each hard ceramic material layer and each soft material layer of the layered steel bond hard alloy by utilizing an ultra-high-speed laser cladding technology, and after each layer of material is prepared, preparing the hard ceramic material layer and the soft material layer of the layered steel bond hard alloy by utilizing an ultra-high-speed laser cladding technology; a grid structure in a'mud brick '-shaped structure is prepared by using an ultrafast laser processing technology, and finally, the steel bond hard alloy with the imitated mother-of-pearl layered structure is formed through continuous stacking forming. The obtained layered steel bond hard alloy structure is of a mud brick-shaped structure which is formed by alternately arranging hard ceramic material layers and soft material layers and is similar to nacre in the nature. According to the method, the technical characteristics of an ultra-high-speed laser cladding technology and an ultra-fast laser technology can be effectively coupled, a'mud brick '-shaped steel bond hard alloy structure similar to a mother-of-pearl is prepared, a good strengthening effect is achieved, and the problems of cracking and the like caused by a conventional laser steel bond hard alloy layer in the laser cladding preparation process are effectively controlled.

Owner:JIANGSU UNIV

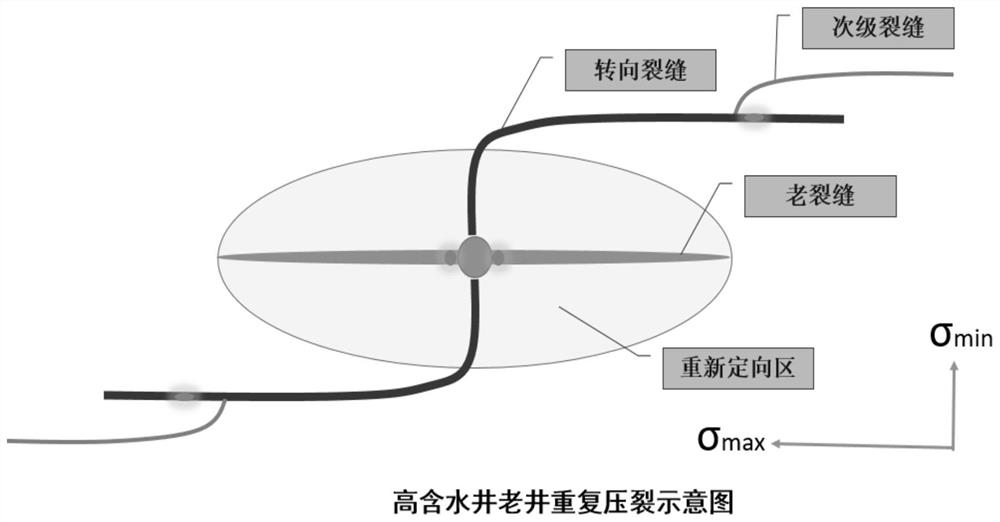

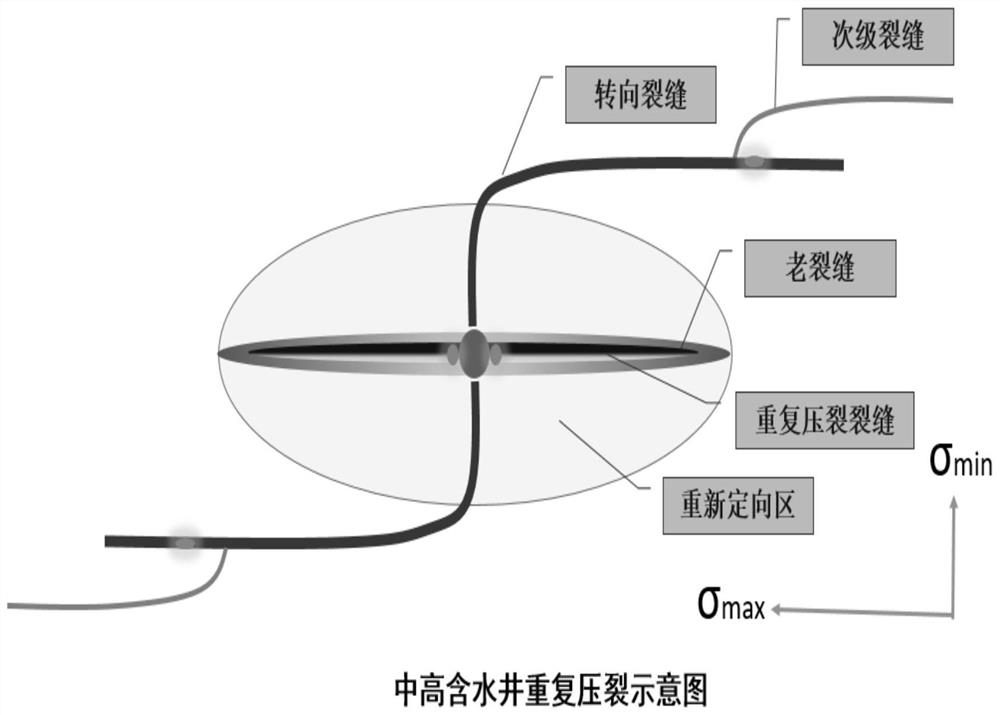

Shale gas horizontal well refracturing method

ActiveCN114382455AImprove sealingImprove the success rate of fracturingFluid removalSealing/packingHorizontal wellsFracturing fluid

The invention discloses a shale gas horizontal well refracturing method, which relates to the technical field of refracturing, and is characterized by comprising the following steps: S1, preparing a refracturing sleeve, and arranging packers at two ends of a refracturing interval; s2, the repeated fracturing casing pipe is put into a shaft; s3, plugging is conducted, temporary plugging liquid is conveyed in a circulating mode, temporary plugging is conducted on primary fracturing, the packer is plugged after temporary plugging, and reconstruction of the re-fracturing shaft is completed; and S4, re-fracturing is carried out, and re-fracturing is carried out on the re-fractured interval so as to generate a new crack. According to the method, the sealing performance of plugging of the primary perforation hole can be improved, the shale gas production shaft is reconstructed through the refracturing sleeve, the fracturing success rate is increased, refracturing cracks of all sections are independently treated, the effectiveness and accuracy of refracturing transformation are improved, the flowing direction of fracturing fluid is predicted more accurately, crack expansion is controlled more accurately, and the fracturing efficiency is improved. And the reservoir transformation volume is increased to the maximum extent.

Owner:北京科源博慧技术发展有限公司

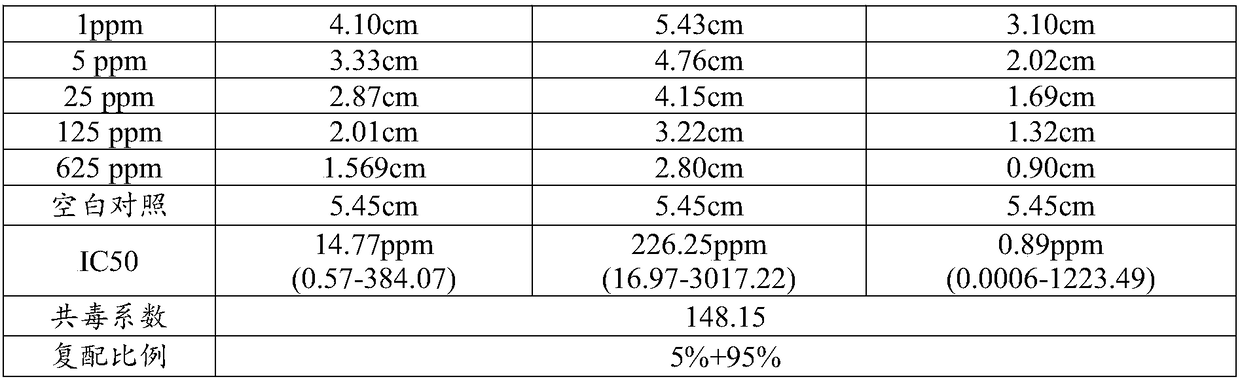

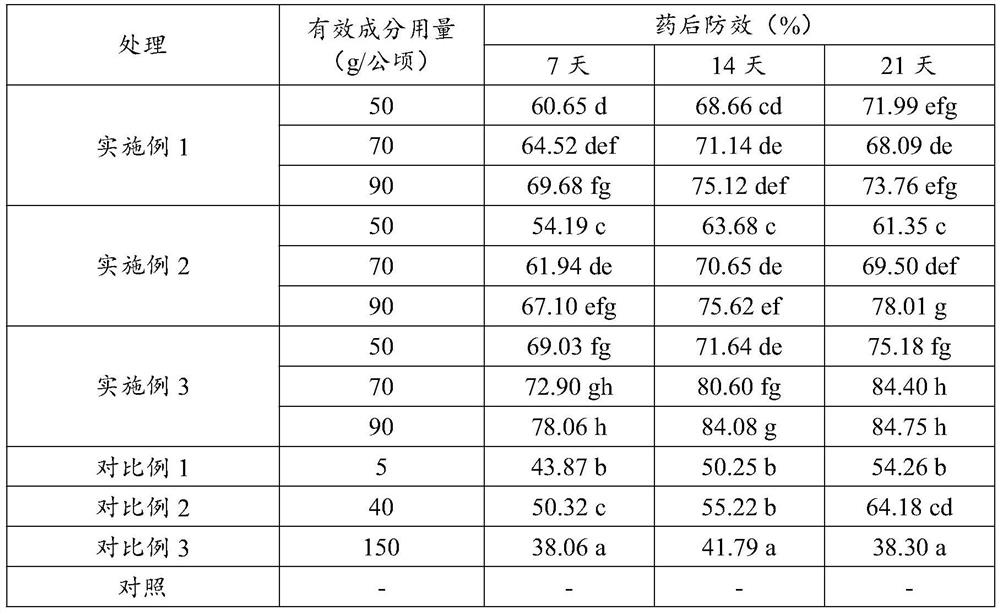

A kind of pharmaceutical composition, pesticide and application containing pyraclostrobin

ActiveCN108378055BImprove the growing environmentReduce the chance of infestationBiocideFungicidesBiotechnologyDisease

Owner:SHANDONG COTTON RES CENT

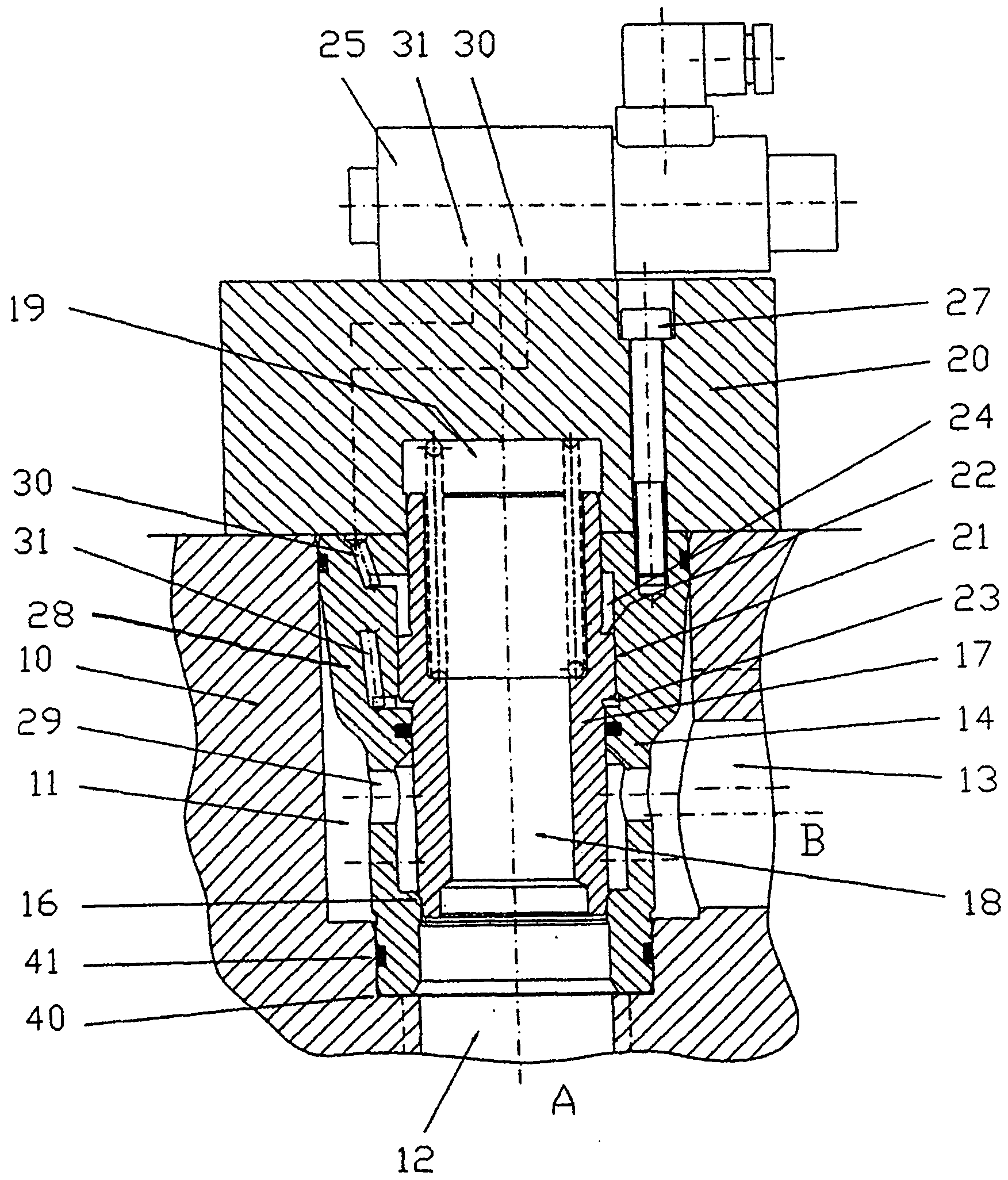

Hydraulic valve assembly having a cartridge insert valve exhibiting a closing element arranged in a pressure equalized manner

ActiveCN102308130BReduce control oil volumeControl extensionOperating means/releasing devices for valvesSlide valveEngineeringEqualization

The invention relates to a hydraulic valve assembly having a cartridge insert valve in a bore hole designed in a valve block and connected to the flow channels arranged in the valve block comprising a valve sleeve inserted in the bore hole and a closing member guided into said sleeve, wherein the valve sleeve forms a valve seat for the closing member in the closing position thereof and the closing member can be moved by means of a connected hydraulic pre-control between the closed position thereof seated on the valve seat and separating the flow channels from one another, and an opened position pushed into the valve sleeve, and the bore hole is sealed tight by the cartridge insert valve inserted the rein via a valve cover connected to the valve block. The closing member forms a sleeve-shaped closing element (17) exhibiting a through-hole (18) and thus ring surfaces on both ends thereof, the surfaces having identical area, and a pressure equalization chamber (19) corresponding with the through-hole (18) of the closing element (17) is formed in the valve cover (20) such that the closing element (17) is engaged on both sides with the pressure enacting in the adjustment direction of the element, which is seated completely pressure-equalized in the valve sleeve (14), wherein a radially protruding collar (21) having control surfaces (22, 23) opposite one another in the adjustment direction is arranged on the outer circumference of the closing element (17) for adjustment thereof. The control surfaces can be loaded by the control oil conducted via the hydraulic pre-control (25) for moving the closing element (17) in the valve sleeve (14), and the valve sleeve (14) inserted in the bore hole (11) of the valve block is fastened on the valve cover (20), the valve seat (16) formed on the valve sleeve (14) thereby maintaining an unaltered distance from the valve cover (20) during operation of the valve assembly.

Owner:PARKER HANNIFIN CORP

A method for breeding strawberry plug seedlings from south to north

ActiveCN108464202BExpand sourcePromote differentiationGrowth substratesCulture mediaFragariaSeedling

The invention relates to a method for growing strawberry plug seedlings from south to north, comprising the following steps: 1) cultivating strawberries in a warm and suitable area in the south in spring, so that a large number of healthy stolons can grow; 2) transporting the stolons to the north in summer In cool and suitable areas, the stolons are cultivated until flowering and fruiting by the plug seedling raising method. The invention makes full use of the warm spring climate in a specific area in the south to breed strawberry stolons, and then utilizes the climate advantage in the cool and cool area in summer in a specific area in the north to promote the flower bud differentiation of strawberry seedlings.

Owner:北京市林业果树科学研究院

A strain of Bacillus Velez and its agent and application

ActiveCN112391315BStrong antagonistic effectControl extensionBiocideBacteriaBiotechnologyNicotiana tabacum

The invention provides a strain of Bacillus Velez and its bacterial agent and application, which belong to the technical field of microbes. The present invention screens out a strain of biocontrol bacteria Bacillus velezensis GY1 from the rhizosphere soil of healthy tobacco, which has significant antagonism to various plant pathogenic bacteria that occur seriously in agricultural production, and has a wide antibacterial spectrum. At the same time, it has been proved by experiments that it can effectively control the occurrence of tobacco leaf mildew and the expansion of tobacco red spot disease spots during the curing period, thereby improving the quality of tobacco leaves and increasing the use value of tobacco leaves, indicating that the strain has broad application prospects in the field of biological control of plant diseases and Good practical value.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

Rare earth permanent magnet material surface corrosion-resistant coating and preparation method thereof

PendingCN114574806AGood uniformityLow costVacuum evaporation coatingSputtering coatingSurface corrosionThin layer

The invention discloses a rare earth permanent magnet material surface corrosion-resistant coating and a preparation method thereof. A rare earth oxide / nitride thin layer is formed on the surface of a rare earth permanent magnet material through magnetron sputtering and in-situ oxidation / nitridation treatment. The preparation method comprises the following steps: (1) depositing a high-abundance light rare earth La / Ce / Y / Nd single-layer film or multi-layer composite film on the surface of the rare earth permanent magnet material by adopting a vacuum magnetron sputtering method; and (2) an atmosphere heat treatment method is adopted, and the surface corrosion-resistant coating is generated through in-situ oxidation / nitridation. According to the method, magnetron sputtering and in-situ oxidation / nitriding treatment are combined, a uniform, compact and stable coating is formed, the corrosion resistance of the rare earth permanent magnet material can be greatly improved, and the service life of the material is prolonged.

Owner:ZHEJIANG UNIV

Homogeneous-thickness silicon-phase epitaxial-layer growth device and method

InactiveCN100425744CAvoid temperature differenceConsistent thicknessPolycrystalline material growthFrom chemically reactive gasesSlip lineVapour phase epitaxy

The present invention discloses a growth device and process of a silicon vapor epilayer and aims at providing a growth device and a process with homogeneous epilayer, convenient operation and high efficiency. The growth device includes a base body, a fixing slot on the base body, a step of 1-3mm wide on the edge of the fixing slot bottom, an annular groove of 1-3mm deep on the step and an arcual concave of 1-5mm deep below the step. The top of the annular groove is 1-3mm wide. The growth process includes the following steps: the silicon substrate wafer is positioned in the fixing slot with the upper surface of the substrate wafer 0.1-1mm lower than the upper surface of the base, and the epilayer grows. This invention has simple arts and crafts, provides homogeneous epilayer, controls the distribution area of the slip lines and removes the contaminative layer of metal impurities on the surface, improving the quality of the silicon epilayer and ensuring the performance of the product.

Owner:HEBEI UNIV OF TECH

Ballast bed and tunnel bottom defect regulating and constructing method as well as anchoring device

The invention discloses a ballast bed and tunnel bottom defect regulating and constructing method as well as an anchoring device. The anchoring device comprises anchor rod and ballast bed slab anchoring ends and ballast bed slab middle anchoring ends, wherein each anchor rod and ballast bed slab anchoring end comprises a combination end, an anchor rod I and deformed steel bars I, the combination end is welded by two pieces of anchor rod clamp-fixing angle steel and a piece of ballast bed slab clamp-fixing angle steel, the two pieces of anchor rod clamp-fixing angle steel are welded on the same surface of the ballast bed slab clamp-fixing angle steel, and an interval allowing the anchor rod I to pass is reserved between the two pieces of angle steel, and the deformed steel bars I are welded on two sides of the combination end respectively; and each ballast bed slab middle anchoring end comprises a bearing plate, an anchor rod II and deformed steel bars II, the bearing plate adopts a crossed steel plate provided with a hole which is formed in the middle and allows the anchor rod II to pass, and the deformed steel bars II are welded on two sides of the bearing plate respectively. According to the ballast bed and tunnel bottom defect regulating and constructing method as well as the anchoring device, the structure is simple, the processing is easy, the problems of baseplate reinforcement and controlling and blocking of opening and closing cracks between the ballast bed slab and the baseplate can be solved effectively, and the purpose of quick, effective and comprehensive regulation of the ballast bed slab and tunnel bottom defects is achieved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

Yarn guide tension self-adjusting bobbin hanger improvement device for textile yarn-dyed fabric production

InactiveCN114262978AEasy to collectEasy to operateWeft knittingTextile yarnManufacturing engineering

The invention discloses a spinning yarn-dyed fabric production doffing tension self-adjusting bobbin hanger improvement device which comprises a hanger rod fixedly installed on a spinning machine, the bottom of the hanger rod enables an upper cover cap to rotate through a rotating assembly, a winding rod is fixedly connected to the bottom of the upper cover cap, and an adjusting mechanism is arranged in the winding rod. The adjusting mechanism comprises a pull rod and a triangular block. The invention relates to the technical field of weaving production. According to the yarn guide tension self-adjusting bobbin hanger improvement device for textile yarn-dyed fabric production, by arranging the adjusting mechanism, a triangular block is driven to move through the weight wound on the surface of a winding rod, so that a moving plate drives a pulling rod to move, an elastic assembly extends, and an extension assembly is driven to unfold; therefore, the range of the yarn guide tension for producing the textile yarn-dyed fabric is expanded, the yarn guide tension can be better wound and unwound, the processing efficiency is improved, and a bobbin hanger can be used more smoothly.

Owner:东台立文色织有限公司

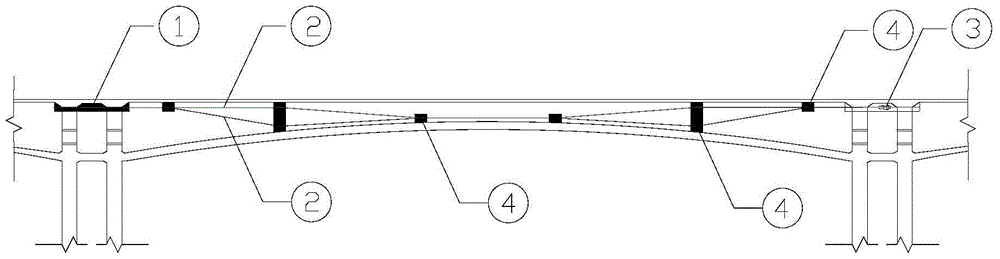

An external prestressed multi-point anchorage reinforcement method for bridge structures

InactiveCN104963300BClear forceAdaptableBridge erection/assemblyBridge strengtheningPre stressBearing capacity

Owner:CHONGQING JIAOTONG UNIVERSITY

Arc-shaped steel fiber, manufacturing mold and method and concrete applying steel fiber

ActiveCN113636771ARemote load transferGreat load transferSolid waste managementStructural engineeringMaterials science

The invention provides an arc-shaped steel fiber which is characterized in that a main body of the arc-shaped steel fiber is an arc, anchoring sections can be arranged at the two ends of the fiber in order to improve anchoring of the fiber in a base body, each anchoring section can be composed of one or more continuously-arranged end hooks, and each end hook is composed of an arc section and a linear section. Aiming at overcoming that a one-dimensional size fiber in a base body has defects in a bridging mechanism and the crack inhibition capability, the arc-shaped steel fiber with the two-dimensional size characteristic is prepared,the arc-shaped steel fibers are paved on the whole mold in advance, through the mutual hooking effect of the arc-shaped steel fibers, the two-time bridging effect of the arc-shaped steel fibers on base body cracks and the advantage effect that two fibers can form a closed space in a base body to restrain crack propagation, the inhibition efficiency of crack propagation is improved, and the basic mechanical property of the seepage pouring fiber concrete is greatly improved.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com