Ballast bed and tunnel bottom defect regulating and constructing method as well as anchoring device

A construction method and disease control technology, applied in the directions of roads, tracks, ballast layers, etc., can solve problems such as the inability to fully control the dynamic settlement of the track slab, the difficulty in controlling the gap between the track slab and the bottom slab, evacuation, and the suspension of the track slab. Achieve the effect of ensuring the anchoring effect, simple structure and comprehensive management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] A construction method for disease control of ballast bed and tunnel bottom, the steps are:

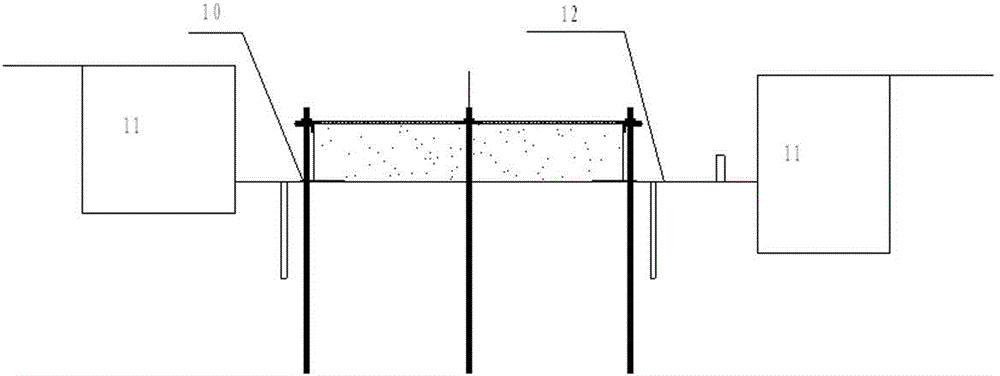

[0032] (1) Firstly, fast-setting materials are used to build drainage channels in the side ditch 12 between the integral ballast bed and the ditch 11, and the water in the damaged ditch is drained through the channel to ensure that the diseased area is in an anhydrous state;

[0033] (2) Insert steel plates 10 at intervals of 5 to 10 cm in the opening and closing area of the track bed plate and the bottom plate. The length of the steel plate 10 is 0.6 m to 1.2 m, the width is 0.1 m, and the thickness is 6 mm to 12 mm;

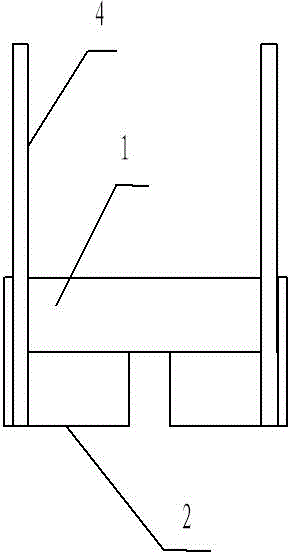

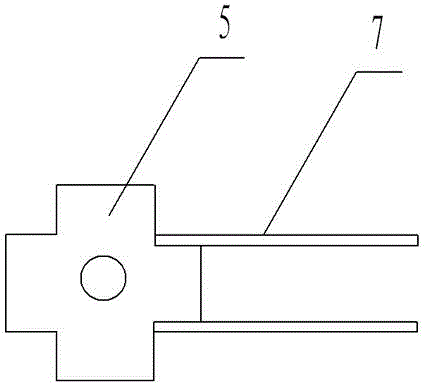

[0034] (3) Drill anchor holes in the side ditch between the ballast bed slab and the ditch on both sides, and drill another anchor hole in the middle of the ballast bed slab between the two anchor holes, so that the three anchor holes The rod holes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com