Shale gas horizontal well refracturing method

A technology for repeated fracturing and horizontal wells, which is applied in the direction of earthwork drilling, wellbore/well components, production fluids, etc., and can solve the problem that repeated fracturing intervals cannot be accurately controlled, and the fracturing intervals and fracturing fluids cannot be accurately known. The problem of uncontrolled flow direction can be solved to achieve the effect of improving effectiveness and accuracy, easy control of liquid flow direction, and improving the success rate of fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

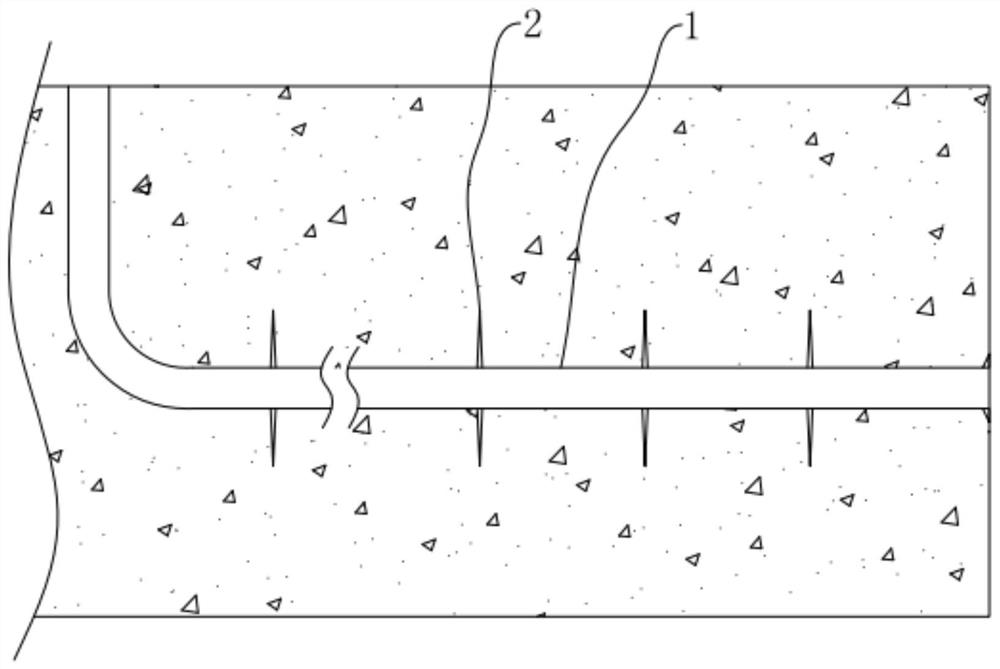

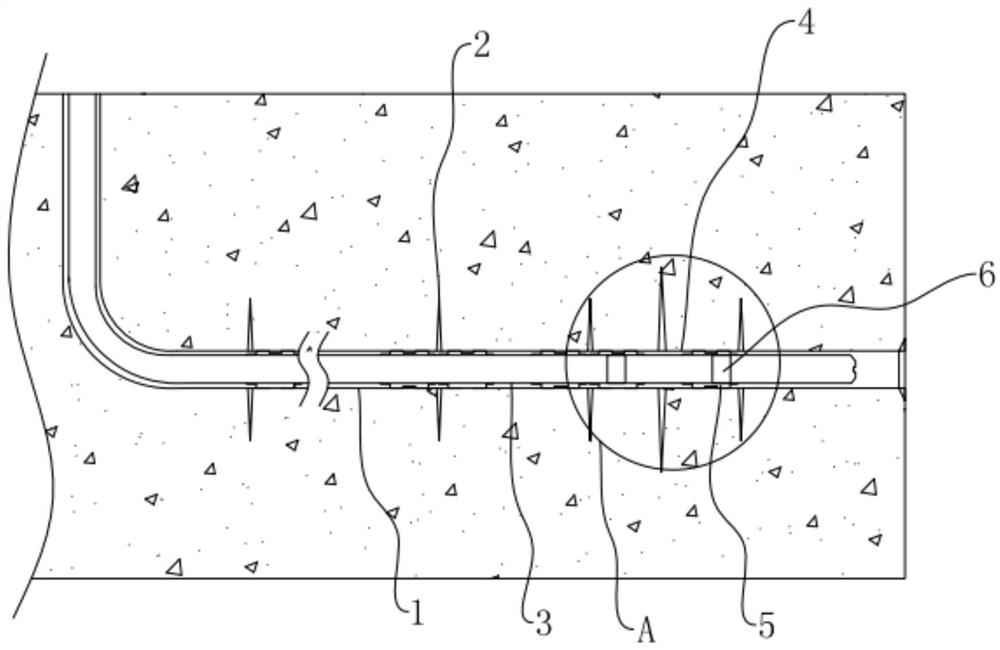

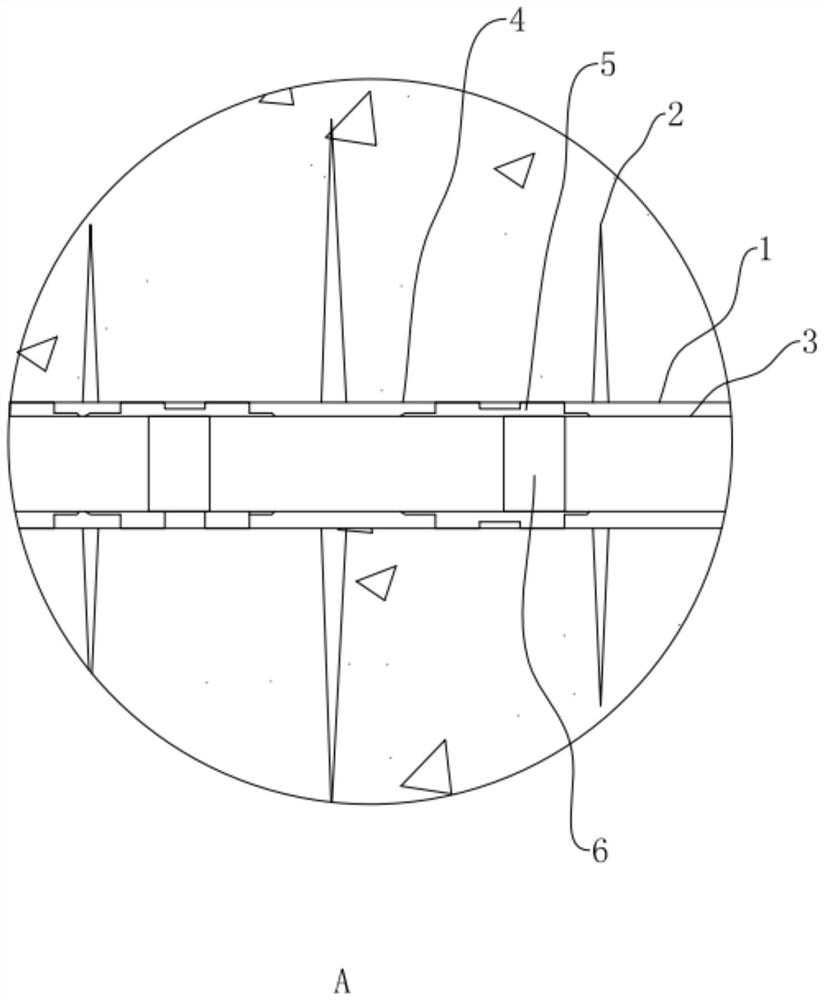

[0035] Example 1: A refracturing method for horizontal shale gas wells, which can effectively guide the refracturing construction of shale gas horizontal wells. The structure of the pipe string can cooperate with the implementation of the refracturing process, ensuring that the pipe string is Under the premise of the largest diameter, realize large displacement fracturing, greatly improve the refracturing of the reservoir, and maximize economic benefits. like Figure 1 to Figure 3 As shown, the horizontal well in this embodiment is a 1HF well with a depth of 5417m, a horizontal section length of 1750m, and 20 stages of primary fracturing. The casing specification is 139.7mm, and the inner diameter is 115.3mm. In the string structure, 10 stages of refracturing were implemented. The specification of refracturing casing 3 is 101.6mm, and the internal diameter is 80.2mm. It is a casing without coupling. The steps are as follows:

[0036] S1. After evaluating the horizontal wells ...

Embodiment 2

[0046] Embodiment 2: The difference between this embodiment and Embodiment 1 is that after the refracturing casing 3 is lowered into the primary fracturing casing 1, when the refracturing section 4 is refractured, the initial fracturing is synchronously fired. The casing at the location of the fracturing interval, and then after the full diameter of the wellbore, can realize the joint production of the initial fracturing interval and the re-fracturing interval 4, greatly improving the single well production and production cycle.

Embodiment 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 is that, after the plugging in step S5, the liquid with a concentration of 6% KCl brine is used for circulating transportation to expand the packer 5. The material It is low in cost and non-toxic, can improve the expansion effect of the packer 5, and avoid affecting the plugging effect of the degradable polymer temporarily plugging the primary perforation hole, thereby ensuring the gap between the refracturing interval 4 and the primary perforation hole. Partition tightness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com