Backfill handling method for activity subsidence area of mine

A technology for subsidence areas and activities, applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of complex blasting construction, high accident rate of operators and equipment, well flooding accidents, etc. Mechanical properties and coordinated deformation ability, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below, but the protection scope of the present invention is not limited to the scope of the specific embodiments described below.

[0025] Examples of the method are detailed below.

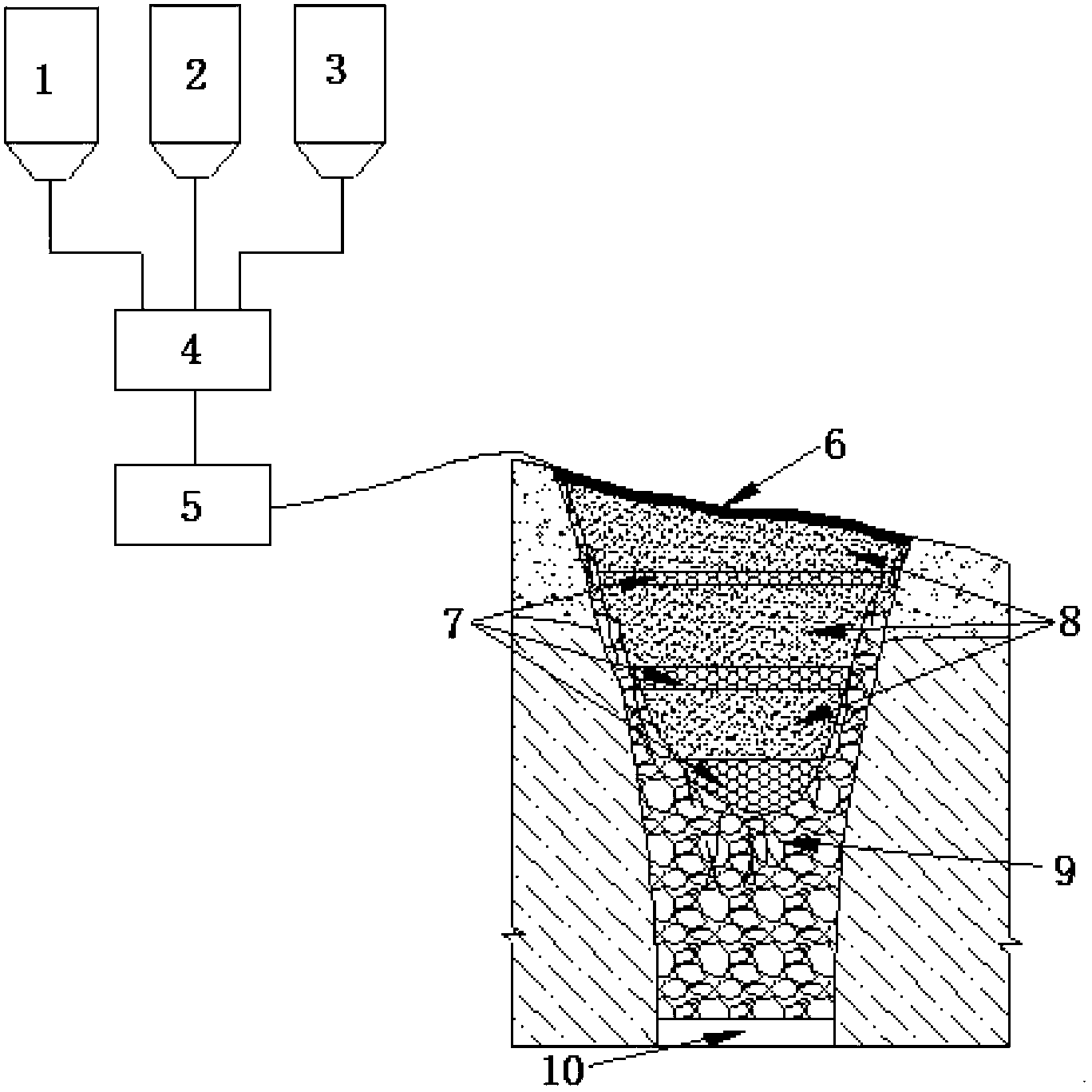

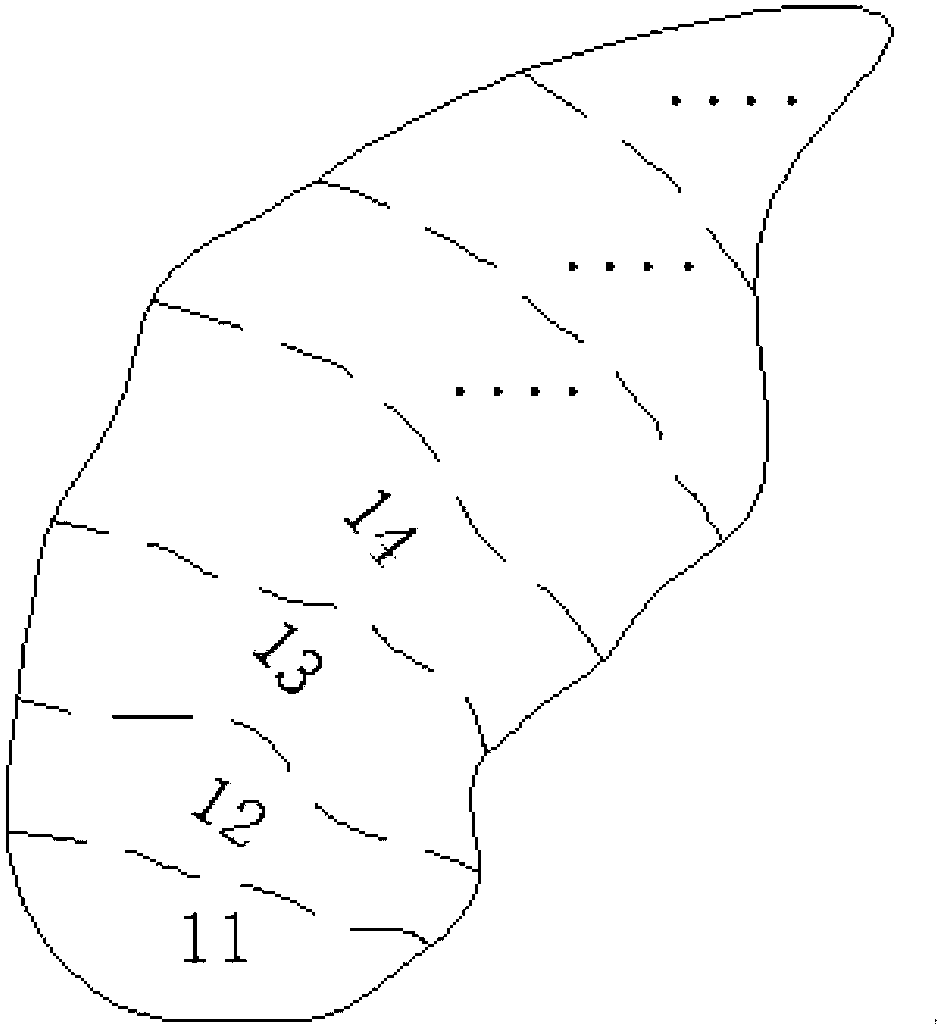

[0026] In the long-term mining process of a mining area, a surface subsidence area consisting of more than a dozen subsidence pits has been formed, with a volume of more than 2 million square meters. With the progress of underground mining, the subsidence area continues to expand, posing a great threat to the daily life of the local people and the normal production of the mine. The mine adopts the method of backfilling the mixed disposal body to control the subsidence area, the details are as follows:

[0027] The deep cone thickener 1 is used to dehydrate the whole tailings for one stage, and the mass concentration of the whole tailings after dehydration is controlled at 72%~76%. The crushed stone is discharged from the aggregate silo 2, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com