Arc-shaped steel fiber, manufacturing mold and method and concrete applying steel fiber

A fiber-reinforced concrete and arc-shaped technology, which is applied in the field of manufacturing molds and methods and concrete and arc-shaped steel fibers using the steel fiber, can solve the problems of limited crack control effect, small improvement of control effect, and restriction of SIFCON performance, etc., to achieve Good bonding effect and enhanced bridging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Based on the above-mentioned infiltrated fiber concrete, the present invention also proposes a preparation method of infiltrated fiber concrete, comprising the following steps,

[0042] 1) Cover the entire mold with arc-shaped steel fibers, so that a plurality of arc-shaped steel fibers are connected;

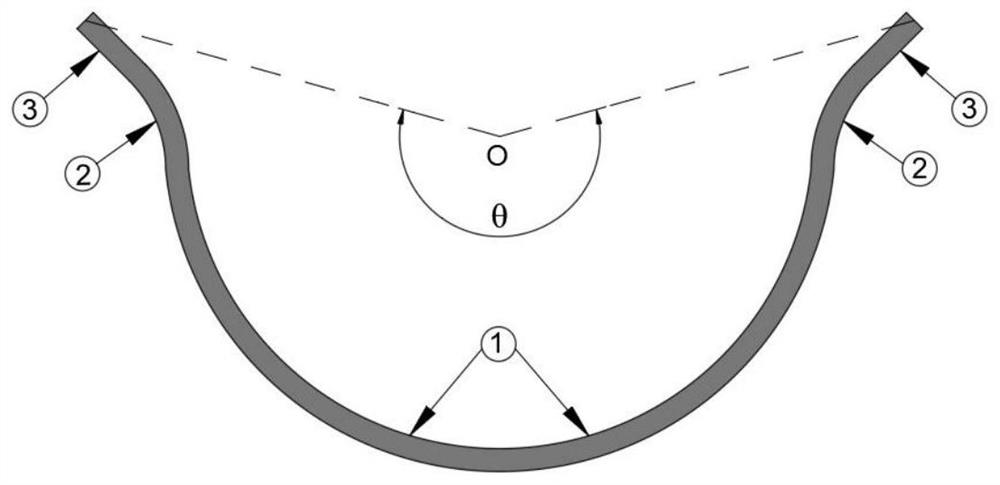

[0043] 2) Inject cement slurry (or mortar) into the mold to form infiltrated fiber concrete. Because its main body is in the shape of an arc, the fibers in the matrix are connected with each other, please refer to image 3 , and the "occlusal force" generated by mutual hooking is theoretically much greater than the mechanical interlocking force produced by the end "interlocking" effect between the traditional end-hook steel fibers, making it more difficult for the present invention to be pulled out from SIFCON, and the fibers The interconnection between them helps the load to transmit farther, allowing the larger volume of SIFCON to participate in the force

[0044] In a...

Embodiment 1

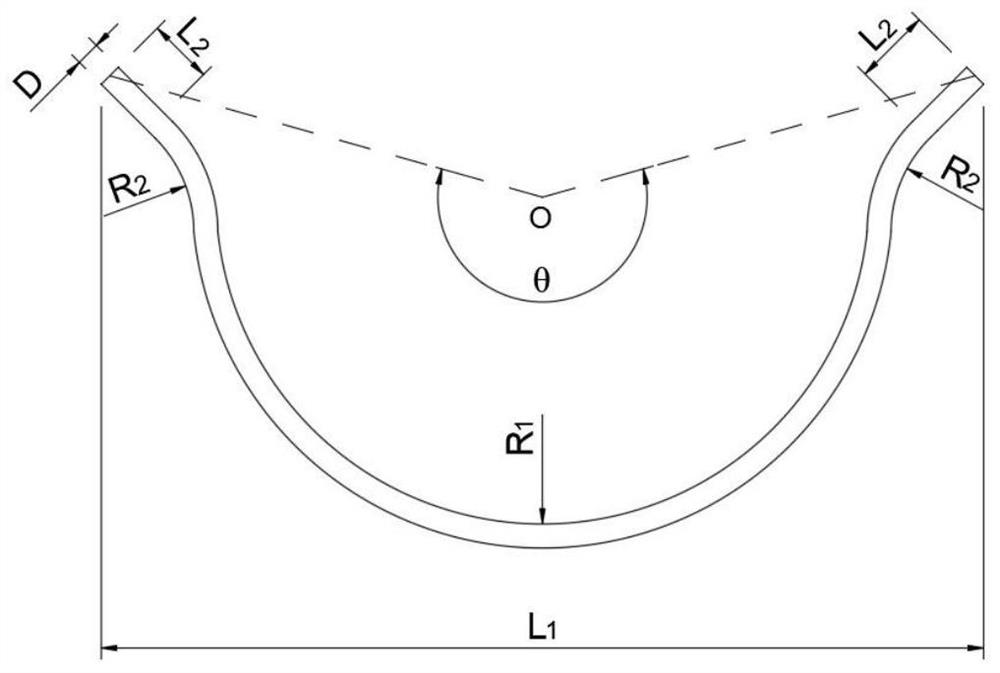

[0055] Use a steel wire with a nominal tensile strength of 1100MPa, a diameter of 0.55mm, and a length of 44.00mm, which is prepared according to the above steps, and the anchorage section is set, wherein the radius R of the arc section 1 1 is 10.00mm, the radius R of the small arc segment 2 2 is 4.50mm, the length L of the straight line segment 3 2 is 2.48mm, the radian θ from the center of the circle to the two ends of the fiber is 5π / 4, and the straight-line distance L between the two ends of the fiber 1 It is 25.53mm, and the aspect ratio of steel fiber is 80.

Embodiment 2

[0057] Use a steel wire with a nominal tensile strength of 600MPa, a diameter of 0.50mm and a length of 31.00mm, prepare it according to the above steps, and set the anchoring section, where the radius R of the arc section 1 1 is 7.00mm, the radius R of the small arc segment 2 2 is 2.55mm, the length L of the straight line segment 3 2 is 2.15mm, the radian θ from the center of the circle to the two ends of the fiber is 4π / 3, and the straight-line distance L between the two ends of the fiber 1 It is 15.21mm, and the aspect ratio of steel fiber is 62.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com