Repair method for ballastless track foundation settlement

A technology of foundation settlement and ballastless track, applied in tracks, track maintenance, roads, etc., can solve the problems of uncontrollable slurry expansion, difficult to accurately lift the track structure, etc., and achieve the effects of convenient construction, fast construction speed, and simple construction machinery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

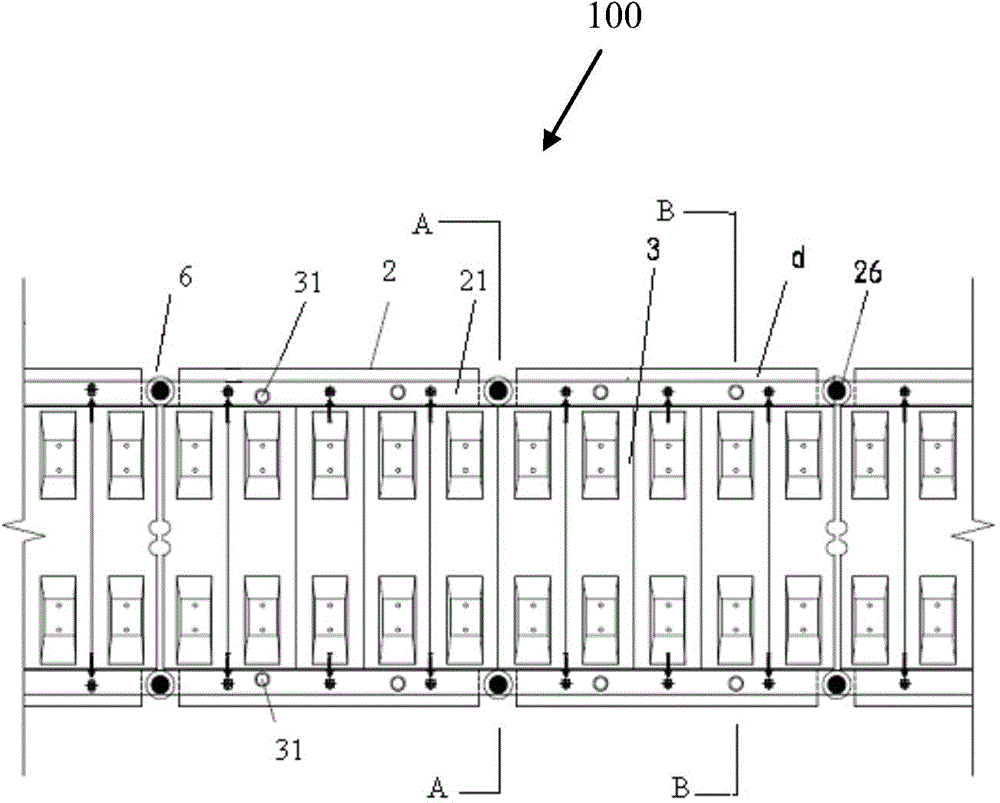

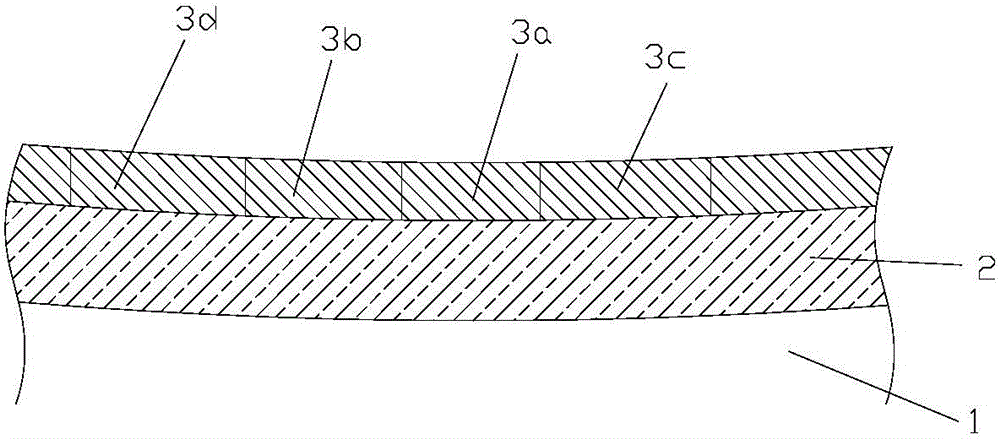

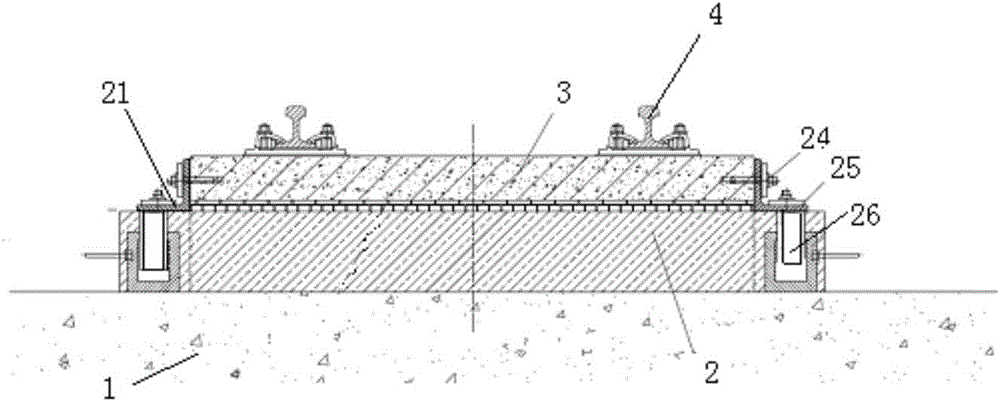

[0024] figure 1 It is a schematic diagram of using the method according to the invention to repair the foundation settlement of the ballastless track. Ballastless track 100 generally comprises foundation 1 (see image 3 with Figure 5 ), the supporting layer 2 above the foundation 1 and the track plate 3 arranged above the supporting layer 2, and the rail 4 is arranged above the track plate 3 (such as image 3 shown). Usually, the foundation 1 is graded gravel, the support layer 2 is a continuous plain concrete slab poured on site, the track slab 3 is a prefabricated short concrete slab, and multiple track slabs 3 are continuously laid on the support layer 2 . Usually the width of the track plate 3 is less than the width of the supporting layer 2, such as figure 1 The width difference shown in d.

[0025] When the foundation 1 settles, the supporting layer 2 will also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com