Single-point longitudinal vibration controllable progressive forming system for metal plate

A longitudinal vibration and incremental forming technology, which is applied in the field of single-point longitudinal vibration controllable incremental forming systems for metal sheets, can solve the problems that the shape and size of the formed workpiece cannot reach the accuracy, the forming accuracy is restricted, and the indentation is easy to form. The effect of reducing high concentration, improving forming conditions, and avoiding wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

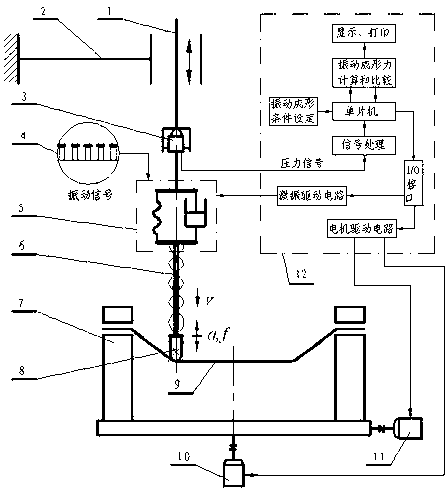

[0029] The schematic diagram of the single-point vibration progressive forming device for sheet metal is attached figure 1 shown.

[0030] Install the force sensor on the shaft end of the main shaft, connect one end of the exciter to the force sensor, connect the connecting rod to the output end of the vibrator, install the tool head on the connecting rod, and install the workbench under the tool head to be formed The sheet is clamped on the workbench.

[0031] The up and down movement of the spindle can make the tool head carry out axial feed during the machining process.

[0032] The force sensor installed on the main shaft collects the forming force signal of the sheet metal during processing, and provides raw data for the parameter controller.

[0033] Under the action of the pulse signal, the vibrator outputs a vibration signal of a certain frequency and amplitude to the connecting rod and the tool head, so that the tool head can obtain the impact load.

[0034] The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com