Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Avoid "wrinkling"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variable-diameter anti-slip textile conveying roller

The invention relates to the textile technical field, in particular to a variable-diameter anti-slip textile conveying roller. The conveying roller comprises a rotating shaft, an electromagnet is fixedly connected to the middle of the rotating shaft, uniformly distributed springs I are fixedly connected to the outer side of the rotating shaft, clamping blocks movably connected with the inner wallof the rotating shaft are fixedly connected to the outer sides of the springs I, magnetic blocks I are fixedly connected to the middles of the clamping blocks, the outer side of the rotating shaft ismovably connected with a conveying roller body, and clamping grooves are evenly distributed in the inner wall of the conveying roller body. According to the variable-diameter anti-slip textile conveying roller, through cooperative use of a rubber ring and piston blocks, when the conveying device is used, the electromagnet is powered on, the piston blocks can move outwards under the mutual repulsion acting force of the electromagnet and magnetic blocks II, electrorheological fluid is extruded outwards, the rubber ring is expanded, and the rotating radius of the conveying roller body is effectively increased, so that attachment of the conveying roller body and cloth can be effectively guaranteed, the effect of preventing the cloth from slipping is achieved, and wrinkling of the cloth is effectively avoided.

Owner:陈杨兵

Packaging heat sealing machine for sealing packaging bag

ActiveCN106586122AAvoid wrinklingImprove seal qualityWrapper twisting/gatheringHydraulic cylinderHeat sealer

The invention discloses a packaging heat sealing machine for sealing a packaging bag. The packaging heat sealing machine comprises a heat sealing machine body which is mainly formed by a hydraulic cylinder, a telescopic rod, a connecting rod, a base, a melt pressure plate and a heat sealing plate; a groove is formed in the heat sealing plate, and slide slots are formed in two sides of the groove; locating columns are fixedly connected to two sides of the base, the locating columns are slidably connected to sliding pieces, springs are arranged between the sliding pieces and a fixed plate, the bottom of the hydraulic cylinder is connected to the telescopic rod, the bottom of the telescopic rod is fixedly connected to a connecting piece, the bottom of the connecting piece is fixedly connected to a sliding plate, the bottom of the sliding plate is fixedly connected to the melt pressure plate, connecting rods are rotatably connected to two sides of the melt pressure plate, pressure rolls are arranged at the tail ends of the connecting rods, and the pressure rolls are rotatably connected through a rotary shaft. The heat sealing machine disclosed by the invention can avoid the condition that the sealing position is inaccurate as the melt pressure plate deviates in position after long-term use. The heat sealing machine sealing the packaging bag can avoid the condition that the buckle of the packaging bag wrinkles, and the sealing quality is good.

Owner:JIAXING NIYA OPTOELECTRONICS CO LTD

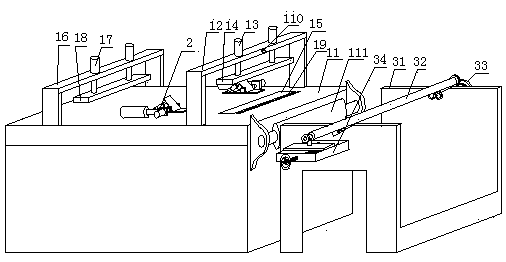

Continuous production device for preventing eccentricity and cockling of waterproof roll

InactiveCN105383143ASuitable for lamination operationsAvoid wrinklingLamination ancillary operationsLaminationContinuous productionContinuous feeding

The invention provides a continuous production device for preventing eccentricity and cockling of a waterproof roll. The continuous production device comprises a continuous rack, a material guide adjusting assembly, a positioning assembly, a clamping material conveying assembly, a hot jointing assembly, a winding temporary storage mechanism, a film covering assembly and a waste gas reusing treating assembly, wherein the positioning assembly, the clamping material conveying assembly and the hot jointing assembly are arranged on the continuous rack in sequence; the material guide adjusting assembly is arranged at the material feeding end of the continuous rack; the winding temporary storage mechanism is arranged at the material discharging end of the continuous rack; the film covering mechanism is arranged at the material discharging end of the winding temporary storage mechanism. The device can be used for treating waste gas generated in production and recycling the treated waste gas under a condition of relatively low cost, the continuous feeding of blanks can be realized, the film covering assembly can perform continuous production without interruption, the continuity of production is ensured and the working efficiency is improved. The winding temporary storage mechanism is arranged, so that the blanks can be temporarily stored with certain length, the continuous production of the blanks in continuous jointing can be realized, and the interruption of the production is avoided, so that the production efficiency is ensured.

Owner:安徽五星凯虹防水建材科技有限公司

Cloth winding device for spinning

The invention discloses a cloth winding device for spinning. The cloth winding device for spinning comprises a base, a first roller support, a first roller, a lower roller support, an upper roller support, an upper roller, a lower roller, a second roller and a winding drum, wherein the lower roller and the upper roller are oppositely installed, the height of the lower roller can be adjusted through jackscrews, therefore it is guaranteed that a gap between the upper roller and the lower roller meets the requirements of cloth, the height of a moving table is adjusted through an adjusting stud, the initial tensioning force of the cloth is determined, the second roller can float up and down under the action of a spring, it is guaranteed that certain tensioning force always exists in the clothwinding process, the winding drum is formed by splicing and inserting two half drum bodies, the width of the winding drum is adjustable, and the requirements of cloth of different specifications are met. When winding is started, the cloth is fixed to the winding drum through a U-shaped spring clamp, the cloth sequentially passes through the first roller, the upper roller, the lower roller and thesecond roller and is finally wound around the winding drum, and the cloth is wound and fixed to the winding drum through the U-shaped spring clamp.

Owner:SANYANG TEXTILE

Aluminium alloy plate press forming method

ActiveCN104117562AImprove molding performanceAvoid wrinklingShaping toolsDeep drawingForming processes

The invention discloses an aluminium alloy plate press forming method, and relates to the technical field of machining. The method comprises the following steps that an aluminium alloy plate is heated, the heating temperature is controlled to be 495-500 DEG C, and heat insulation is conducted for 30-60 minutes; after heating, the aluminium alloy plate is transferred to water of 75-85 DEG C within 20 s, and after cooling, press forming is conducted within eight hours; before pressing, the surface of a press die and the surface of the aluminium alloy plate are evenly coated with press oil; in the pressing process, the deforming temperature of pressing is controlled to be 250-290 DEG C, the deep drawing speed is 0.2-2 mm / s, and the edge pressing force is 2-3.5 N / mm<2>. According to the aluminium alloy plate press forming method, compared with the prior art, the problem that scratches, deformation and cracking can happen easily in the press forming process of the aluminium alloy plate is solved.

Owner:LIUZHOU MEINA MACHINERY

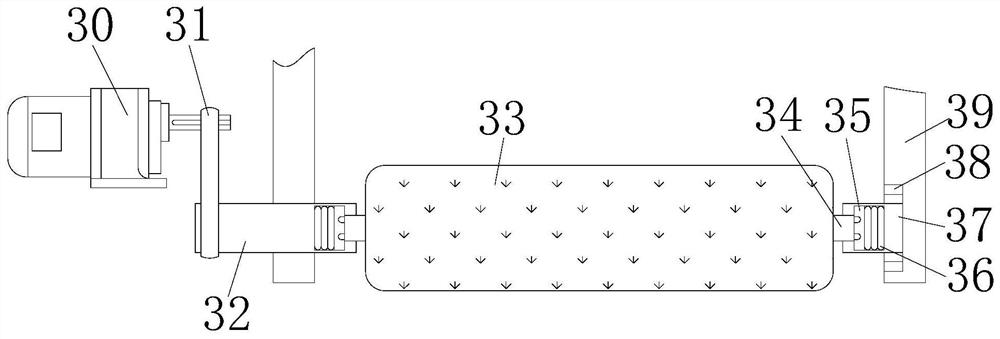

Structure device for solving wrinkling of adhesive tape during box sealing of box sealing machine, and use method thereof

InactiveCN106314893AAvoid wrinklingAvoid wrinklesWrapper twisting/gatheringEngineeringPre stretching

The invention relates to a device for solving wrinkling of an adhesive tape during box sealing of a box sealing machine, and a use method thereof, and belongs to the technical field of mechanical equipment. The invention designs a device for solving wrinkling of an adhesive tape during box sealing of a box sealing machine. According to the device, a part of the adhesive tape is pre-stretched from an adhesive tape coil to be separated from the adhesive tape coil and in a state of being neither completely relaxed nor greatly stretched; and in this way, the adhesive tape is located under different tensions respectively in a whole box sealing process so as to meet different requirements during the box sealing, that is, the adhesive tape is guaranteed to have no great tension at a head end and a tail end, and have a certain tension at a middle end, thus a high-quality box sealing effect is achieved. The two tensions and pre-stretching length of the adhesive tape can also be adjusted in a certain range through settings of the device. The device is simple in structure, convenient and reliable in use, and suitable for being popularized and used.

Owner:SUZHOU QUANXIN MACHINERY FITTING CO LTD

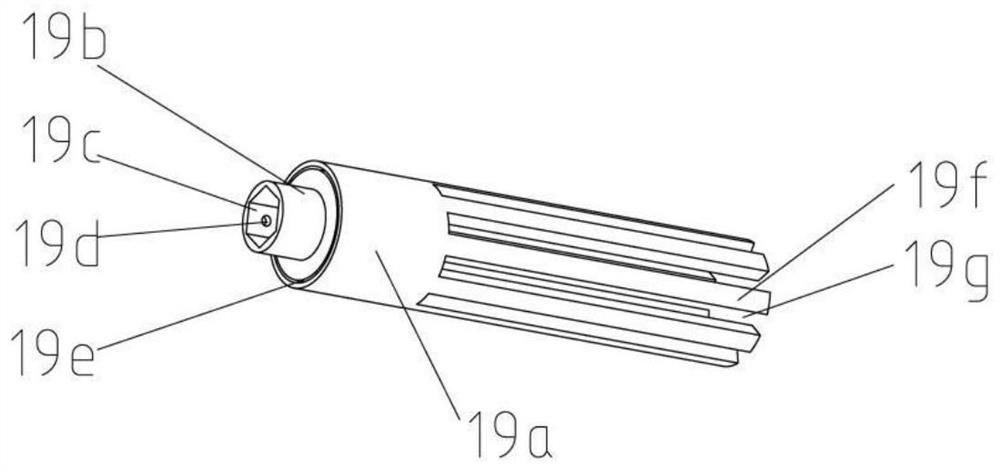

Cylinder rinsing device

InactiveCN101801670AImprove cleaning efficiencyAvoid wrinklingMixing methodsCleaning using toolsEngineeringConductor Coil

Intended is to provide a cylinder rinsing device having a novel constitution thereby to prevent the flapping phenomenon of a pressure pad and to mount the pressure pad easily. The cylinder rinsing device comprises a rinsing cloth winding roll having a pressure pad made of an elastic member for pushing a piece of rinsing cloth to a cylinder surface. A pressure pad (8) is fixed between a pad mounting plate (9) and a pad holding bar (20) and formed of an elastic material into a semicircular shape. The pressure pad (8) is made thin at the pushing portion of its central portion (16) and thick at the base portions (15) of its two end portions, and the base portions (15) have retained portions (17) to be pushed by the pad holding bar (20). The pressure pad (8) has an inward inclined face made thicker in the widthwise direction by inclining the inner faces (152) of the base portions (15) inward to the bottom face. The pad mounting plate (9) extends in the trunk length direction of the cylinder, and has such a recess (25) formed on the side to confront the cylinder as to receive the pressure pad. The pad holding bar (20) has such an inward inclined face (203) on the side wall to contact the inner face of the pressure pad (8) as is inclined inward in a converging state toward the bottom portion. The inward inclined face (203) of the pad holding bar (20) is pushed to abut on the inward inclined face of the pressure pad (8), and the inward inclined faces of the base portions (15) of the pressure pad (8) are pushed onto the wall face of the pad mounting plate (9) on the side of the recess (25).

Owner:JPE

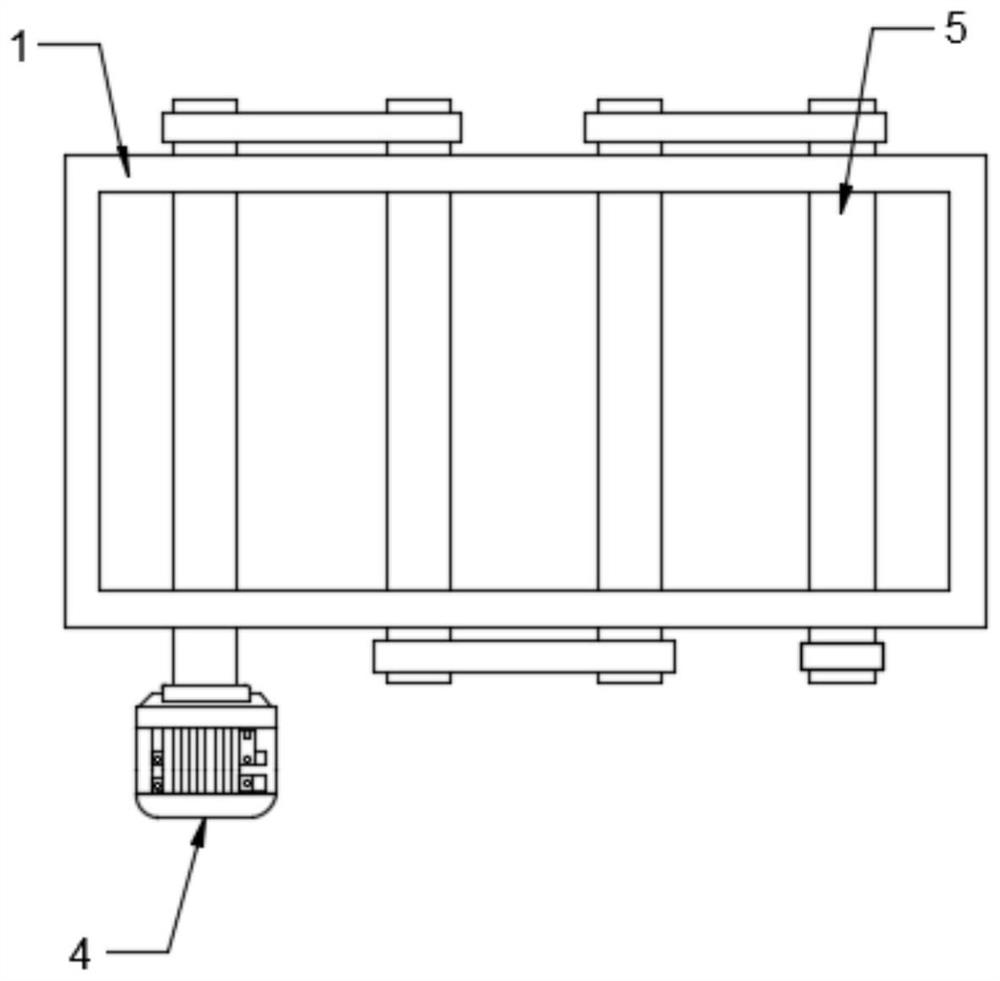

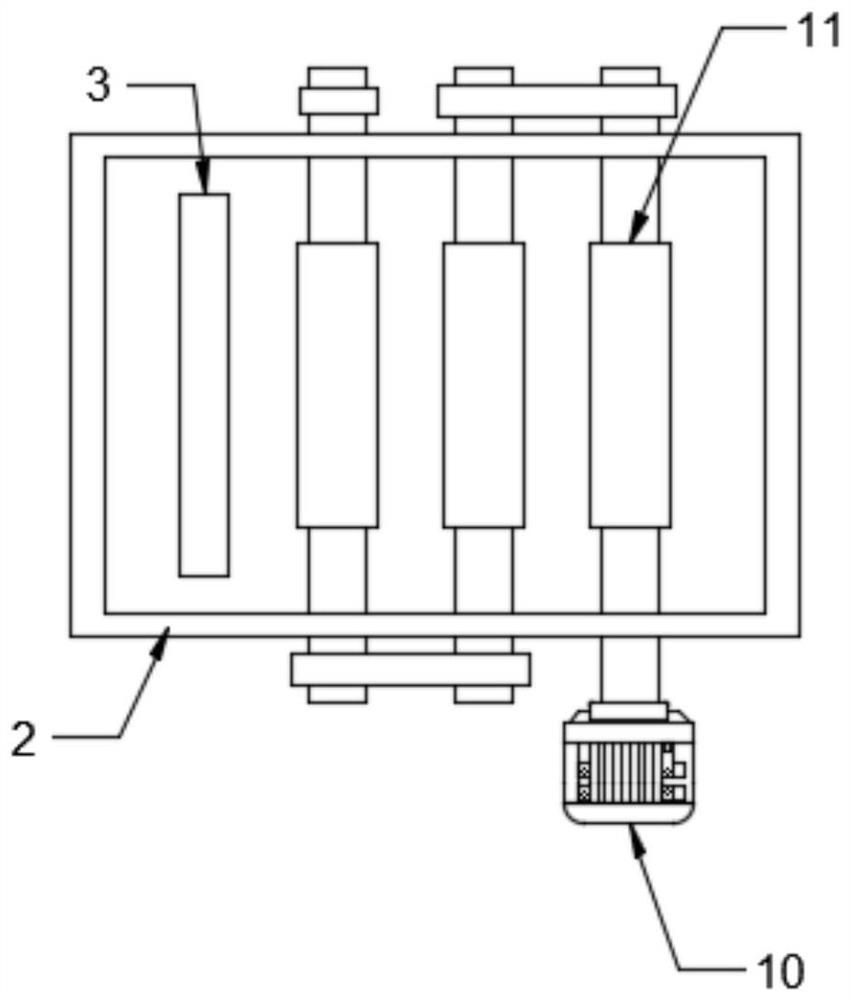

Jet printing platform device

PendingCN106956518AAvoid wrinklingFacilitate printing operationsOther printing apparatusSpray nozzleProcess engineering

The embodiment of the invention discloses a jet printing platform device applied to the technical field of jet printing. Jet printing paper to be printed is conveyed to at least three parallel carrier rollers and jet printing platform mechanisms between two corresponding and adjacent carrier rollers through a preposition driving mechanism, printed jet printing paper is conveyed through a postposition driving mechanism, the at least three carrier rollers are arranged in an arc shape, and therefore the jet printing paper conveyed on the carrier rollers are bent in an arc shape, the jet printing paper is tightened, and the jet printing paper is prevented from being folded; and in addition, the jet printing paper is attracted to a jet printing platform through air suction holes formed in the jet printing platform, and therefore the jet printing paper and the jet printing platform are tightly attached, printing operation is facilitated, and physical damage caused by the fact that the jet printing paper collides a spraying nozzle of a printing machine can be prevented; and meanwhile, the production cost is reduced, and the production process is simplified.

Owner:SHENZHEN HANDWAY IND DIGITAL EQUIP CO LTD

Rounded corner edge folding machine

InactiveCN110682606AReduce bending stressAvoid breakingMechanical working/deformationPaperboardStructural engineering

The invention discloses a rounded corner edge folding machine, and belongs to the technical field of rounded corner edge folding equipment. The rounded corner edge folding machine comprises an edge folding workbench, a cardboard feeding device, an edge folding bearing device, a down pressing edge folding device, a reciprocating sticking device and a finished product discharging device, the outputdirection of the down pressing edge folding device is vertically downward, the finished product discharging device is installed on the edge folding workbench and beside the edge folding bearing device, and the output direction of the finished product discharging device is perpendicular to the feeding direction of the cardboard feeding device. According to the rounded corner edge folding machine, When the edge folding of the cardboard is carried out, the folded edge with right angle edge can be transformed into a plurality of tooth-groove-shaped structures, so that the folding stress of the folded edge is reduced, the occurrence of folding phenomenon caused by the stack forming of the folding edge at a corner is further avoided, the damage of the paper at the corner is avoided, and the roundness degree of the folding paper at the corner of the hard board is improved.

Owner:雷源标

Ultraviolet ray proof automobile sunshade device having nano-polymer composite coating layer

An ultraviolet-shielding sunshade with a coated nano-class high-molecular layer is composed of a casing with an opening, a reel, a sunshade cloth wound around said reel and able to be drawn out from said opening on casing and a guider arranged at the opening position of casing.

Owner:王红

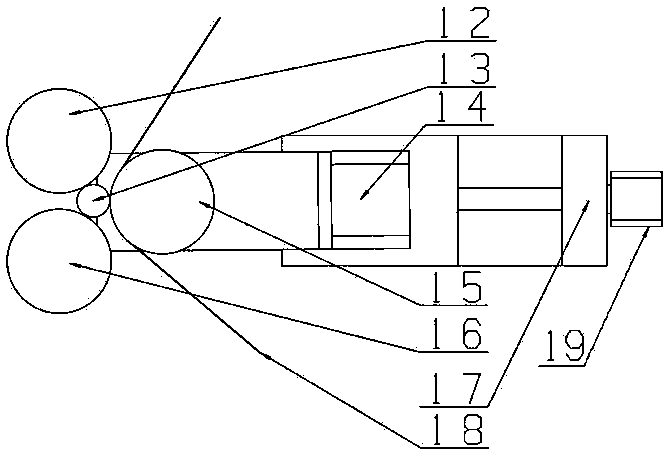

Method for preparing electrode plate by dry rolling

ActiveCN112802987AAvoid uniformityAvoid fragmentsElectrode rolling/calenderingProcess equipmentComposite material

The invention relates to the technical field of lithium ions, and discloses a method for preparing an electrode plate through dry rolling. The method comprises the following steps: (1) enabling a first membrane material and a foil material to simultaneously pass through a space between opposite first rollers, adding first powder into a gap between the first membrane material and the foil material, carrying out first rolling, and forming a first powder material tabletting layer on one side surface of the foil material; (2) enabling the first membrane material, the second membrane material and the foil material with the first powder tabletting layer to simultaneously pass through opposite second rollers, adding second powder into a gap between the second membrane material and the other side surface of the foil material, carrying out second rolling, and forming a second powder tabletting layer on the other side surface of the foil material; and 3) separating the first membrane material and the second membrane material from the side surface of the foil material to obtain the electrode plate. According to the method, double-sided simultaneous rolling and laminating flaking can be realized, the process flow is simplified, the process equipment is reduced, and the electrode plate with uniform thickness can be continuously prepared.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

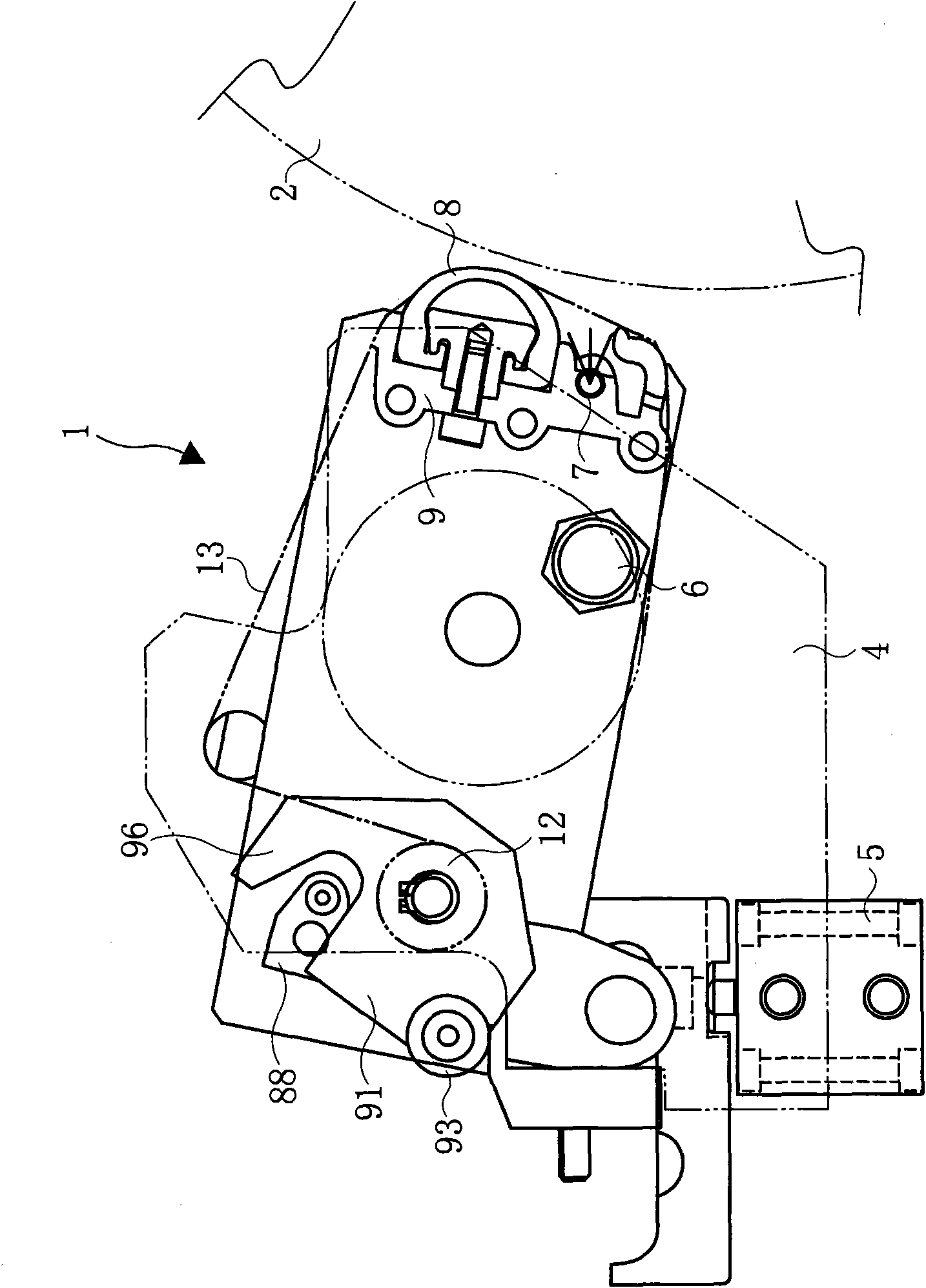

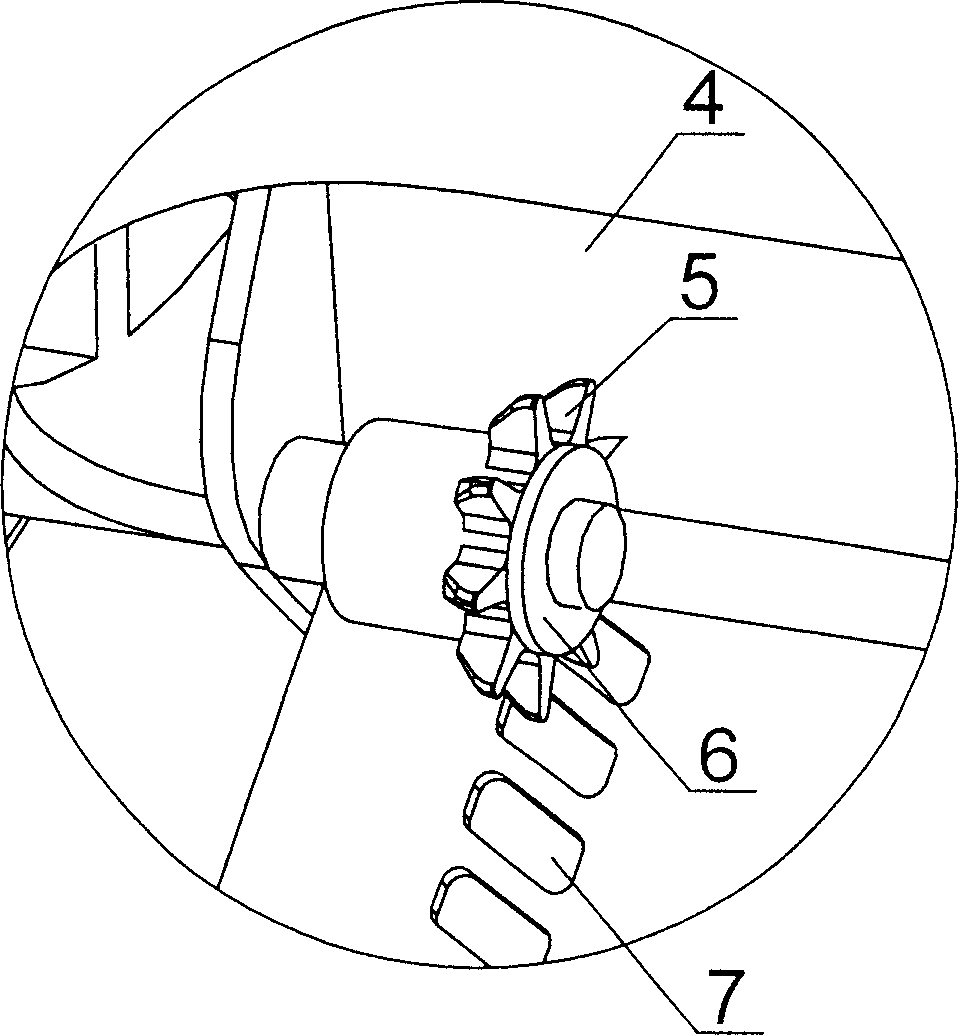

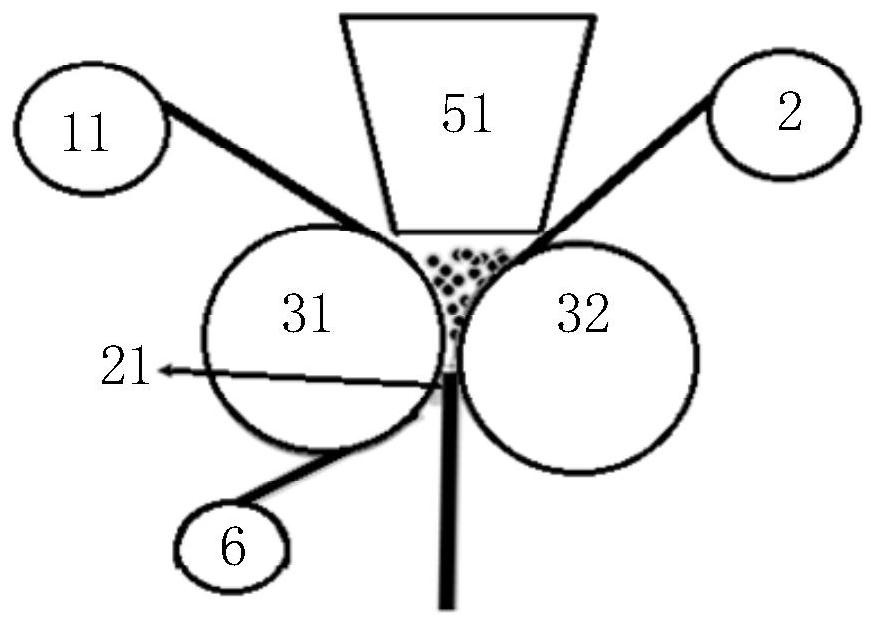

Full-automatic barcode device for vacuum blood-collection tube

ActiveCN104354943AAvoid wrinklingEasy to readLabelling machinesLabelling elongated objectsCentrifugal pumpBarcode

The invention discloses a full-automatic barcode device for a vacuum blood-collection tube. The full-automatic barcode device comprises a hopper, two concentric centrifugal pans, tube falling slots and a reversing device, wherein the inner circumference of one centrifugal pan is connected with the outer circumference of the other centrifugal pan, the tube falling slots are formed in the edge of the outer circumference of the centrifugal pan, and the reversing device is arranged below the tube falling slots. A label adhesion device is arranged below the reversing device and comprises a first auxiliary pinch roller, a second auxiliary pinch roller and a label wheel, wherein the first auxiliary pinch roller and the second auxiliary pinch roller rotate around a fixed shaft, and the label wheel is rotatably arranged on a rotary shaft and moves along the rotary shaft; intervals among the first auxiliary pinch roller, the second auxiliary pinch roller and the label wheel form a vacuum blood-collection tube falling channel. By utilizing the technical scheme provided by the invention, the label adhesion device can highly effectively and automatically adhere a label on each vacuum blood-collection tube; furthermore, the labels are prevented from being folded under the rolling action of the label wheel, the first auxiliary pinch roller, and the second auxiliary pinch roller, thereby facilitating the reading of a barcode gun at the later stage of operations.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

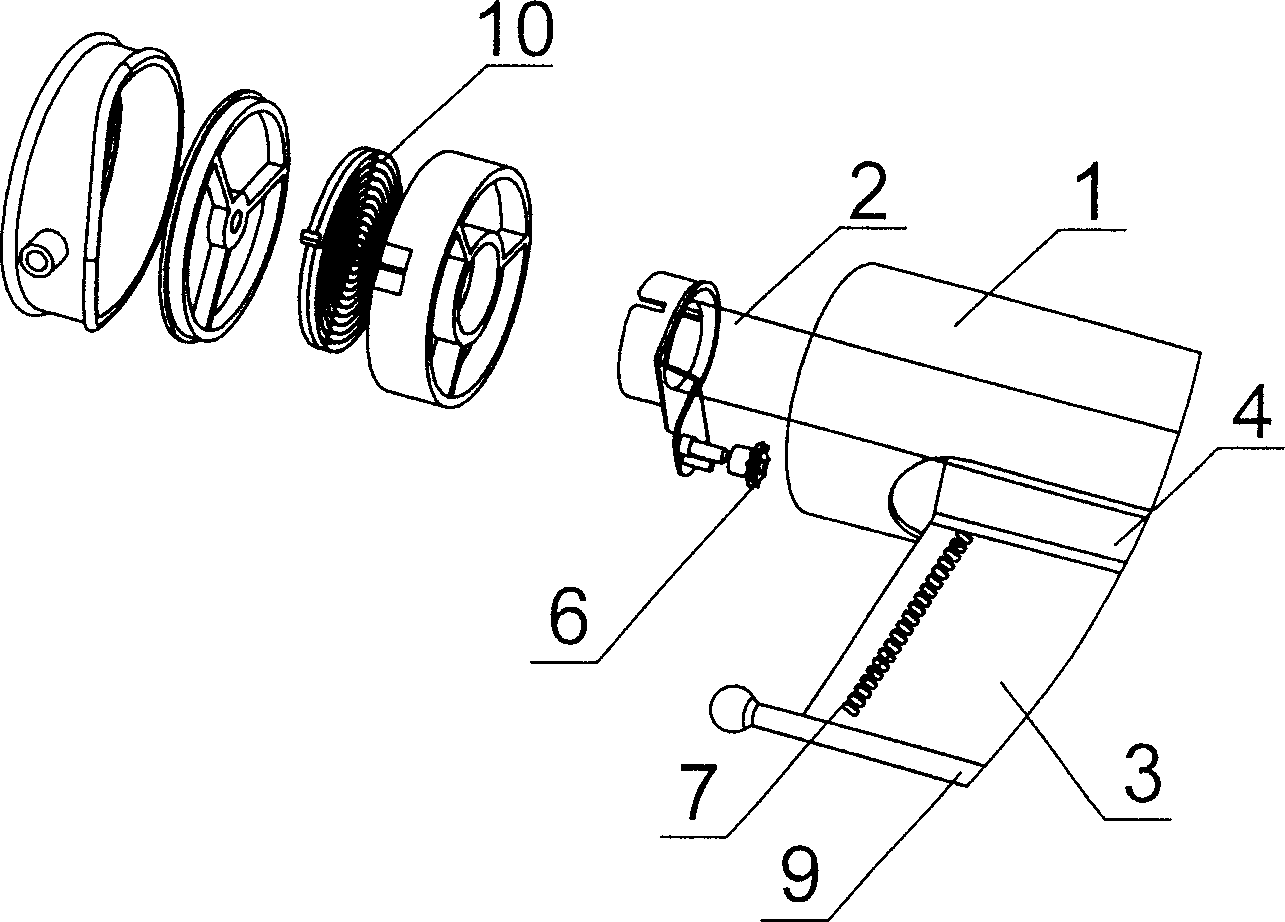

Manufacturing method of film on concrete surface

The invention discloses a method for manufacturing a film applied on the surface of concrete, which includes the following steps: firstly, one end of the film is wound on a take-up roller, a spring is used to make the pressure wheel compress the film on the take-up roller, the motor is turned on, and the motor drives The driven shaft rotates, so that the take-up roller rotates, and the film is wound on the take-up roller evenly. When the take-up roller needs to be replaced, take off the positioning rod on the drive roller, and quickly pull the take-up roller from the drive roller. Take it off, put a new winding roller on the driving roller, reinstall the positioning rod, fix the winding roller on the driving roller, complete the quick replacement of the winding roller, and continue to wind the film. The invention can quickly replace the winding roller and improve the processing efficiency of the film. Meanwhile, during the film winding process, the film can be wound on the winding roller smoothly to avoid wrinkling.

Owner:何宝玉

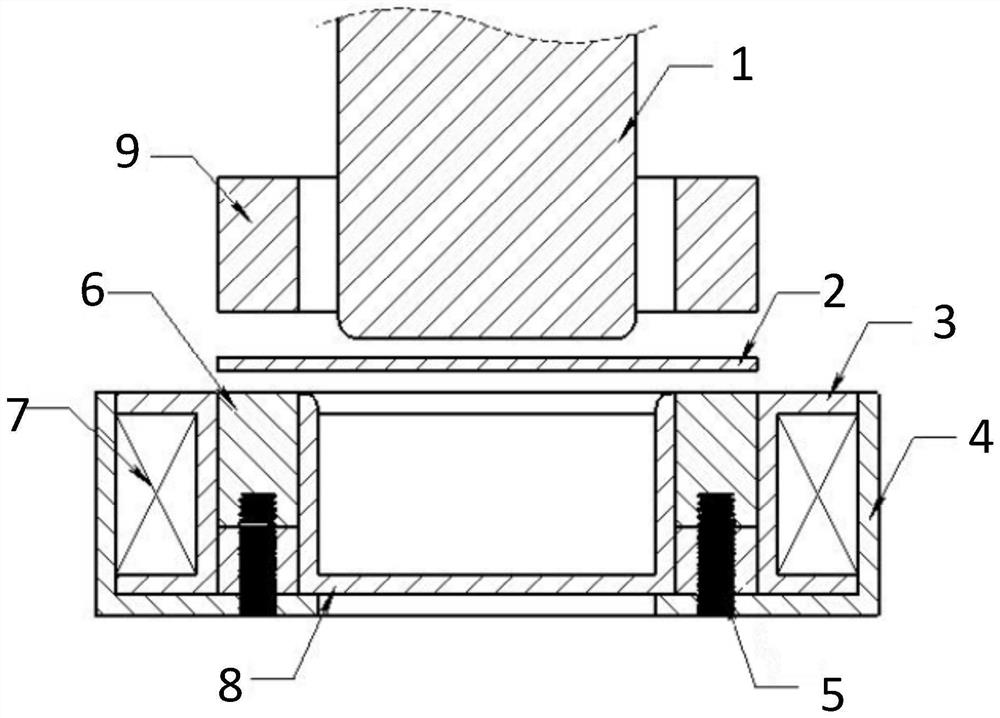

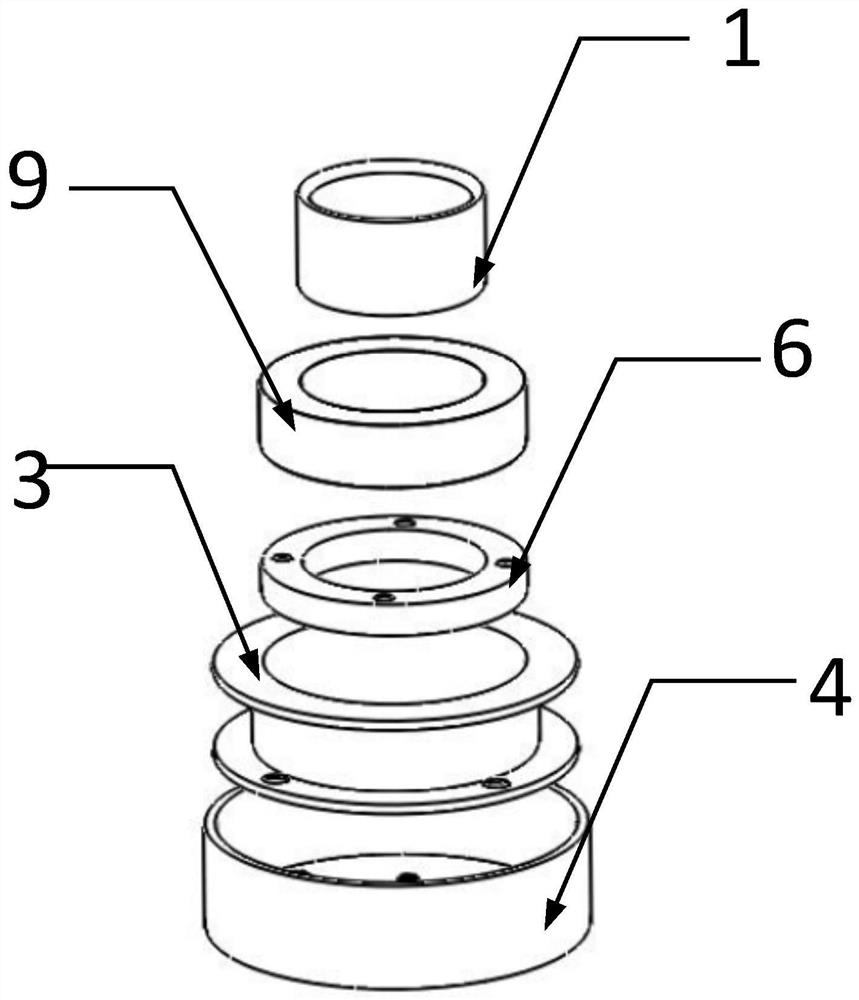

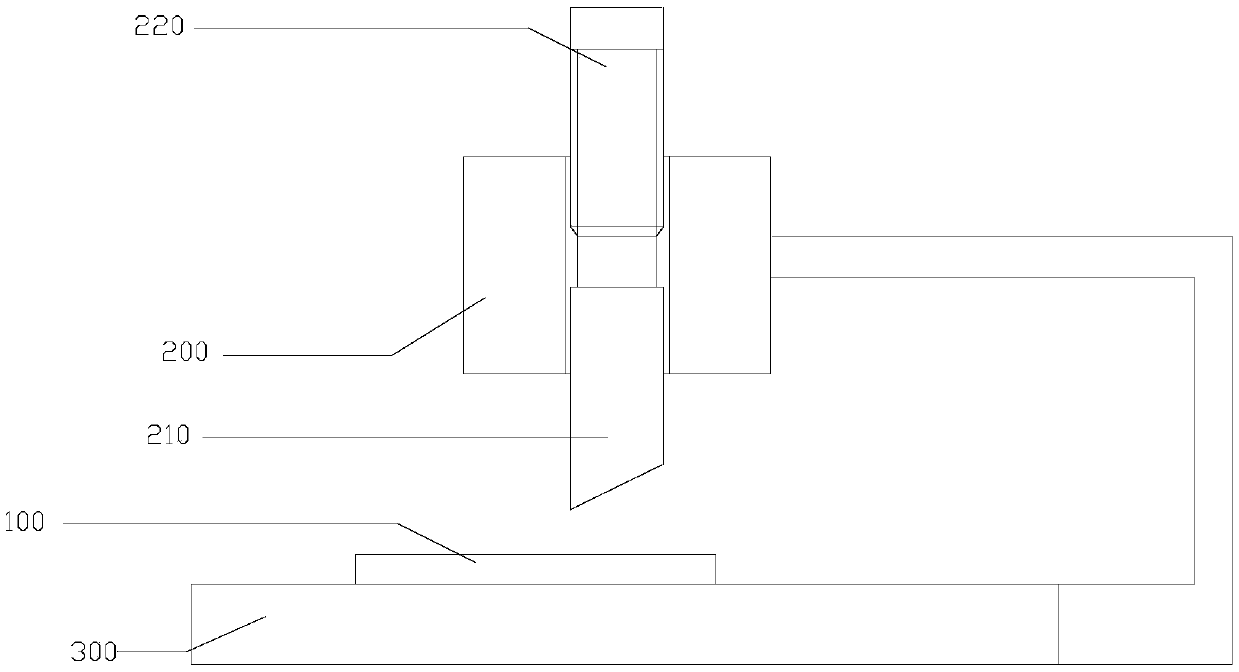

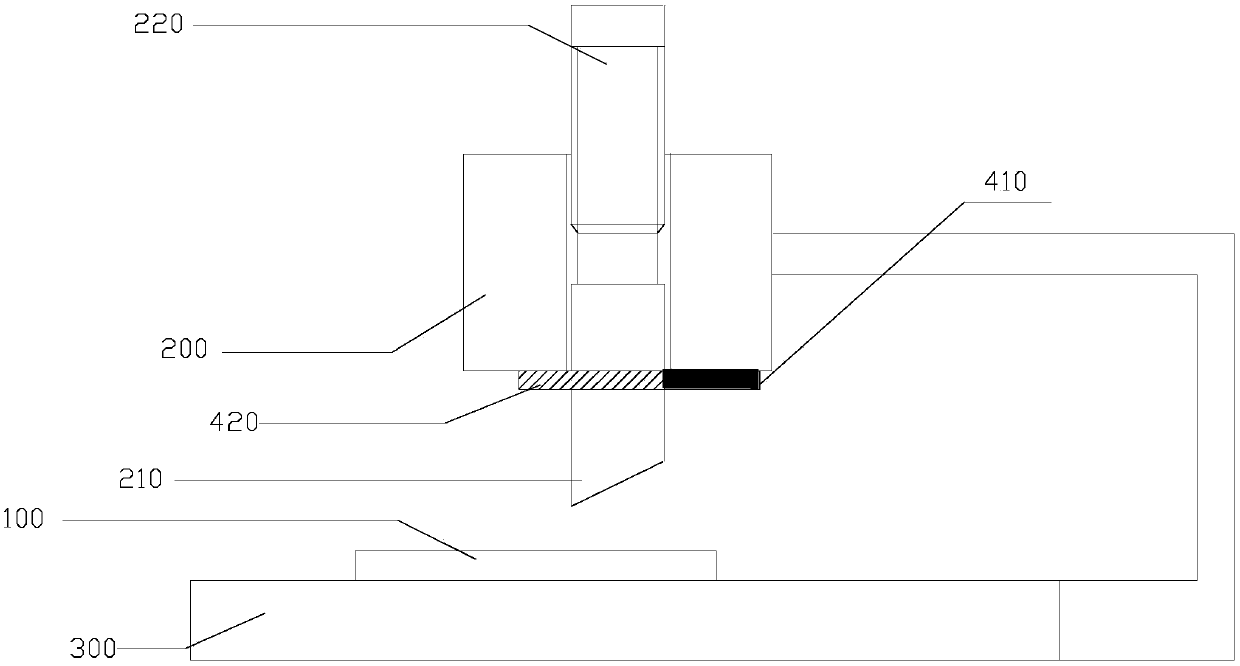

Die blank holder device and application method thereof

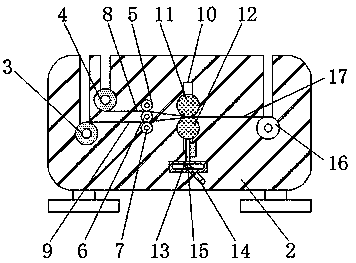

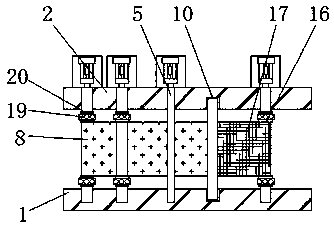

PendingCN112517726AAvoid wrinklingThe workpiece is evenly stressedShaping toolsMetal-working feeding devicesMagnetoMagnet

The invention discloses a die blank holder device and an application method thereof. The die blank holder device comprises a shell and a die body. The die body comprises a male die, a female die, a magneto-rheological elastomer blank holder, an excitation coil, a coil framework and a permanent magnet. The excitation coil is wound on the coil framework; the permanent magnet is fixedly arranged in the coil framework; the magneto-rheological elastomer blank holder is arranged in the coil framework and is fixedly connected with the permanent magnet; the female die is arranged at the inner side ofthe magneto-rheological elastomer blank holder, and the male die is connected with a stamping mechanism to stamp a plate on the female die; the excitation coil generates a magnetic field after being electrified; and the size of the magnetic field is controlled, and the rigidity of the magneto-rheological elastomer blank holder is adjusted so as to control the blank holding force and the distance between the magneto-rheological elastomer blank holder and the plate. By means of the material characteristics of the magneto-rheological elastomer, the blank holder force in deep drawing forming is controlled, a workpiece is prevented from being broken in deep drawing forming, the workpiece forming rate is increased, lubrication is not needed, the cost is reduced, the structure is compact, and thepracticability is high.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE +2

Edge correcting device used for thread-free sewing machine

InactiveCN109023821AAvoid wrinklingPrevent movementPattern makingStretchingEngineeringElectrical connection

The invention discloses an edge correcting device used for a thread-free sewing machine. The device includes: a controller, a first support, a workbench, a transversal beam, an adjustment device, a driving device, a detector, and two groups of symmetrically arranged hairbrush flattening devices. The workbench is fixedly connected to the top of the first support. The transversal beam is fixedly connected to the first support. The adjustment is movably connected to the bottom of the workbench. The driving device is drivingly connected to the adjustment device. The detector is connected to the top of the workbench. The hairbrush flattening devices are connected to the top of the workbench. The detector, the driving device and the controller are in electrical connection. Through continuous dynamic adjustment, a fabric roll can be fixed on the initial position without deviation. The hairbrushes press the fabric roll, wherein the rotating direction of the hairbrushes is same as the forward direction of the fabric roll; therefore, the fabric roll is effectively prevented from wrinkling by brushing the fabric roll with the hairbrushes.

Owner:LIXIN FUYA GAUZE CO LTD

Wood veneer softening process

InactiveCN109318326AAccelerateAvoid wrinklingRadiation/waves wood treatmentWood treatment detailsChemistryPolyethylene glycol

The invention discloses a wood veneer softening process. The process comprises the following steps: a, spraying a softening solution on a wood veneer, standing for 3-5h, and thus obtaining a product A, wherein the softening solution comprises the following components in part by weight: 20-30 parts of polyethylene glycol, 3-5 parts of glacial acetic acid, 1-3 parts of sodium dodecyl benzene sulfonate, 0.5-1 part of fatty alcohol polyoxyethylene ether sodium sulfate, 0.5-1.5 parts of boric acid and 30-40 parts of deionized water; b, conducting microwave irradiation for the product A for 5-9min by a microwave generator, and thus obtaining a product B, wherein the microfiltration frequency is 80-90KHz, and the power is 1-3W / cm2; c, putting the product B into a steam box, heating for 0.5-2h with steam, and thus obtaining a product C; d, clamping the product C by two pore plates to keep the product C smooth, and thus obtaining a product D; e, drying the product D, and thus obtaining a product E; f, painting boiled tung oil on the two sides of the product E, and thus obtaining a product F; and g, heating the product F to 80-120 DEG C to enable the tung oil to completely penetrate into theproduct F, and thus obtaining a finished product. The wood veneer handled by the process has the advantage of fitting to furniture with the surface with a large curvature.

Owner:湖州南浔登越家居有限公司

Weaving device for kapok and wool fiber two-color denim

InactiveCN109130447AAvoid wrinklingEasy to repair and replaceLaminationLamination apparatusDrive motorEngineering

The invention discloses a weaving device for kapok and wool fiber two-color denim. The device comprises a front side plate, first fabric, and a supporting rod, wherein a rear side plate is mounted onthe rear side of the front side plate; a second transmission wheel is mounted on the right side of a first transmission wheel; a second guiding wheel is mounted below a first guiding wheel; limiting grooves are respectively formed in the middles of the front side plate and the rear side plate; a second middle wheel is mounted below a first middle wheel; the supporting rod is mounted on the inner side of a connecting rod in a clamped manner; a connecting wheel is mounted on the right side of the second middle wheel; driving motors are respectively mounted at the bottom ends of the outer sides of the front side plate and the rear side plate; and first connecting blocks are respectively arranged in the first transmission wheel and the second transmission wheel in a penetrating manner. The weaving device for the kapok and wool fiber two-color denim has the advantages that the denim can be flattened through pressing, so that folds of the denim are avoided; the rolling wheels can be conveniently repaired and replaced; and the denim can be prevented from deviation during conveyance.

Owner:JIANGSU DELIHENG COTTON

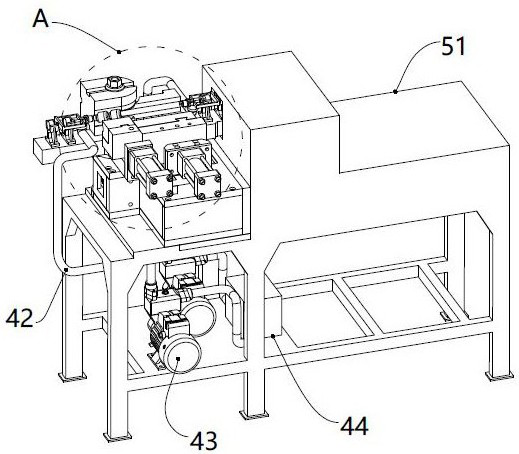

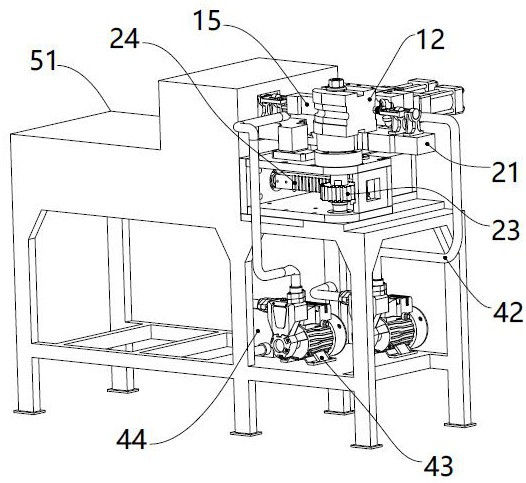

An integrated forming pipe bending device for bulging pipe bending

ActiveCN111957807BShorten the production cycleIncrease productivityShaping toolsMechanical engineeringPhysics

The invention discloses an integrated forming and pipe-bending device for bulging and pipe-bending. The integrated forming and pipe-bending device for bulging and pipe-bending comprises a die group, apipe-bending mechanism, a hydraulic system and sealing mechanisms arranged at the two ends of the die group, wherein the die group is used for clamping and bulging for a pipe to be machined; the hydraulic system provides a bulging inner pressure for the pipe to be machined; the die group comprises a first die and a second die which are oppositely arranged; the pipe-bending mechanism comprises a rotatable bending arm, and the bending arm drives the first die and the second die to synchronously rotate while rotating; a pipe-bending groove is formed in the second die, and acts on the pipe to bend the pipe along with the rotation of the second die; and each sealing mechanism comprises a plug head sealing the end part of the pipe, and when the pipe is bent, the plug heads synchronously move along with the movement of the end part of the pipe. The integrated forming and pipe-bending device for bulging and pipe-bending realizes the double action of bulging and pipe-bending on one piece of equipment, and then realizes resource sharing and increases the production efficiency; and the manufacturing period for the bent pipe manufactured by the device is shortened, and a high yield is achieved.

Owner:浙大宁波理工学院

Gray fabric pressing device

ActiveCN114524308AAvoid wrinklingImprove qualityTextile disintegration and recoveryTextile shapingTouch switchCam

The invention provides a gray fabric pressing device. A first pressing structure comprises a cross beam, a heating ring is fixedly arranged on the outer side of a rolling shaft, a cam can intermittently press a push plate downwards during continuous rotation, and a first transmission wheel is arranged in a first transmission belt; the second pressing structure comprises a frame plate, a rotating motor is fixedly arranged on the inner wall of the frame plate, a winding drum is arranged on a center shaft in a sleeving mode, a trigger rod can make contact with a touch switch when rotating, the touch switch is in signal connection with a time delay relay, a concave shell is fixedly arranged on a push rod, and the concave shell is in signal connection with the touch switch. And a pressing plate is connected into a groove of the concave shell through a buffer spring. According to the gray fabric pressing device, the first pressing structure and the second pressing structure which are matched with each other are arranged in the gray fabric pressing device, gray fabric can be better rolled and pressed, a yardage roll is effectively prevented from loosening and falling, the gray fabric is loosened and the yardage roll is effectively prevented from deviating, and the gray fabric pressing device is convenient to use and very worthy of popularization.

Owner:江苏松柏纺织品有限公司

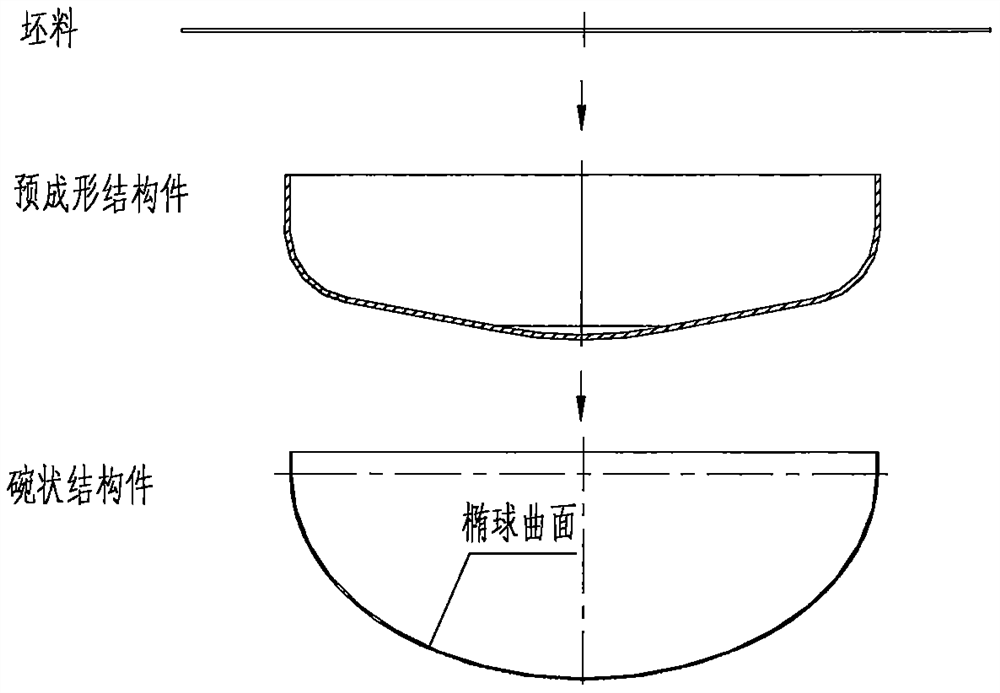

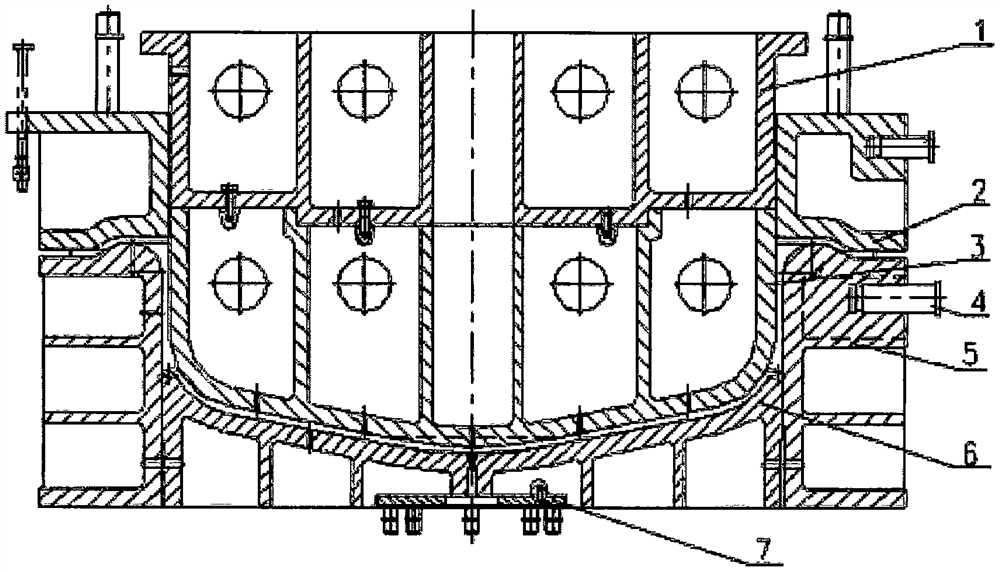

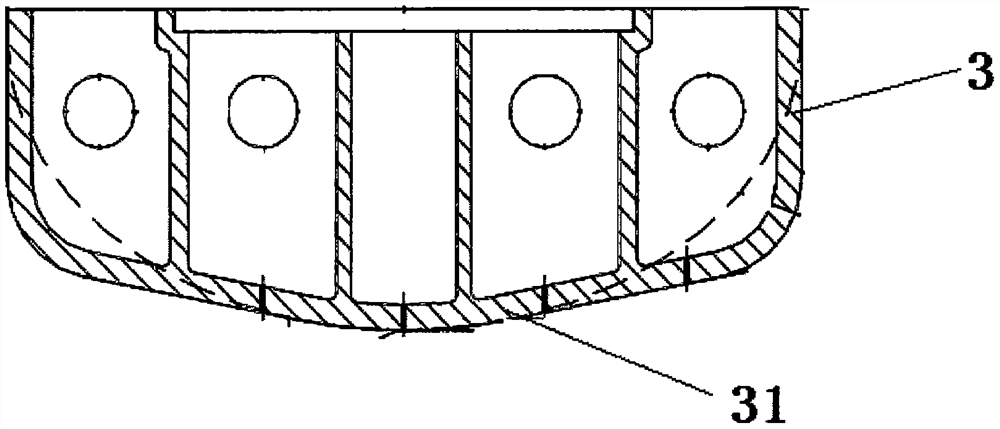

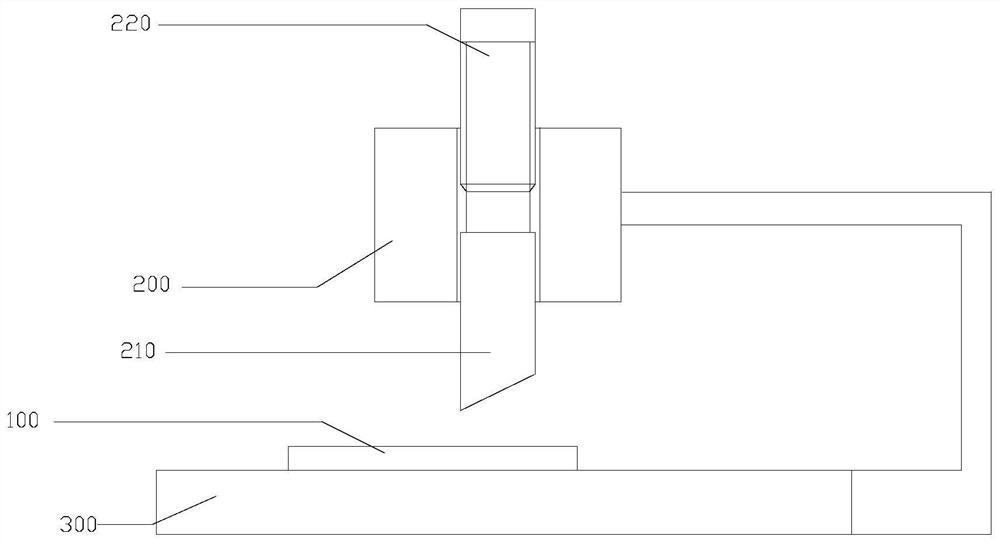

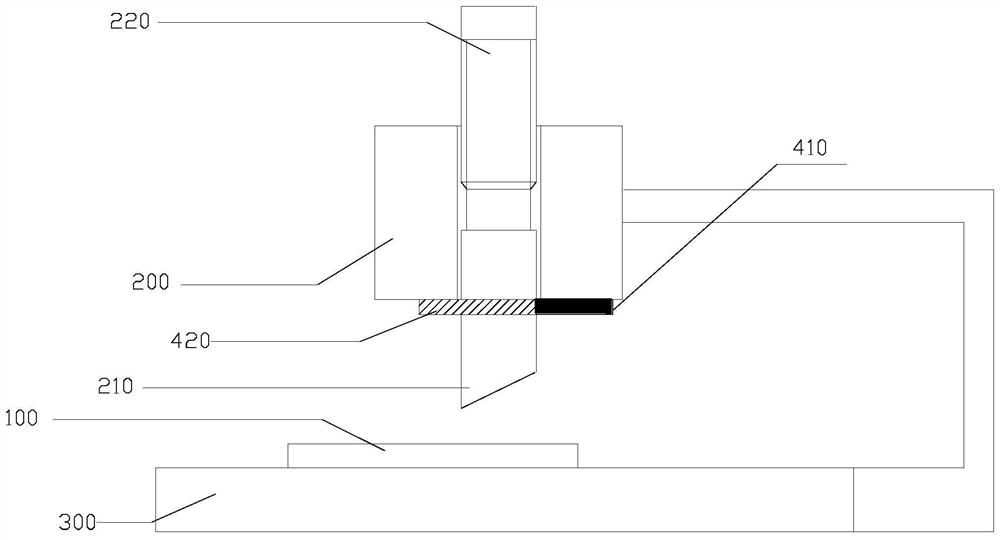

Process equipment used for large-size bowl-shaped structural part preforming

InactiveCN112453164AImprove the ability to resist instabilityAvoid wrinklingShaping toolsMetal-working feeding devicesMetal forming processStructural engineering

The invention discloses process equipment used for large-size bowl-shaped structural part preforming, and belongs to the technical field of sheet metal forming process equipment. The process equipmentcomprises a hydraulic machine tool, and further comprises a convex die holder, a blank holder, a convex die, a concave die and a material returning device. An upper platform allowing the convex die holder to be fixedly mounted and a lower platform allowing the concave die to be fixedly mounted are arranged on the hydraulic machine tool. The material returning device is arranged in the concave die, the blank holder is arranged beside the convex die holder, an ejector rod for providing pressure for the blank holder is arranged at the top of the blank holder, and a material returning ejector plate used for ejecting a preformed structural part on the material returning device is arranged at the bottom of the material returning device. By means of drawing ribs arranged on the blank holder andthe concave die, flowing materials are delayed to fully release deformation stress, the forming gap between the concave die and the convex die is set to be several times of the thickness of the materials, and wrinkling and cracking of blanks in the forming process can be avoided.

Owner:CAPITAL AEROSPACE MACHINERY

Discharging pre-pressing device and battery cell winding machine

PendingCN112736295AAvoid wrinklingReduce corner clearanceAssembling battery machinesFinal product manufactureEngineeringPole piece

The invention discloses a discharging pre-pressing device and a battery cell winding machine, and relates to the technical field of battery cell production. The discharging pre-pressing device comprises a first supporting mechanism, a second supporting mechanism and two clamping mechanisms. The clamping mechanism comprises an inner clamping needle, the inner clamping needle penetrates through a battery cell, and the first supporting mechanism and the second supporting mechanism are oppositely arranged at the two ends of the inner clamping needle. A first supporting base and a second supporting base are oppositely connected to the two sides of a bidirectional displacement assembly, the first supporting base is used for abutting against one inner clamping needle, and the second supporting base is used for abutting against the other inner clamping needle. The bidirectional displacement assembly is used for driving the first supporting base and the second supporting base to get away from each other so as to push the two inner clamping needles to get away from each other. According to the discharging pre-pressing device, the inner clamping needle can be prevented from inclining and deforming, a pole piece and a diaphragm of an inner ring of the battery cell are prevented from wrinkling, a corner gap of the battery cell is reduced, the uniformity of the corner gap is improved, and the quality of the battery cell is guaranteed.

Owner:GEESUN AUTOMATION TECH

Precision processing technology of film part stamping process

The invention relates to a precision processing technology of a film part stamping process. The precision processing technology includes the following steps: (1) fixing a stamping assembly in a strokemodule by threaded connection, wherein the stamping assembly includes a stamping upper die and an adjustment ruler fixedly connected above the stamping upper die; (2) carrying out a step of commissioning stamping, namely a step of starting the stroke module for one time of stamping, rotating the adjustment ruler to make the stamping upper die to be in contact with a stamping lower die after the stroke module is finished moving downward, recording a calibration on the adjustment ruler that is flush with the upper surface of the stroke module, starting the stroke module for resetting, and rotating the adjustment ruler to move down h relative to the stroke module according to the thickness d of a to-be-processed film part, wherein h=d; and (3) placing the to-be-processed film part on the stamping lower die, and starting the stroke module for stamping processing. The technology provided by the invention can avoid ''wrinkling'' of the part caused by excessive stamping depth, which destroysthe surface flatness of the film part, and avoid too deep cutting of a blade to damage die equipment.

Owner:陈志刚

Convenient and rapid printing equipment for animal leather production and manufacturing in leather factory

ActiveCN112779364AAvoid wrinklingImprove printing effectSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentAnimal skinManufacturing engineering

The invention discloses convenient and rapid printing equipment for animal leather production and manufacturing in a leather factory. The convenient and rapid printing equipment comprises a base, wherein a leather box is fixedly arranged at the top of the base; animal leather is arranged on the inner wall of the leather box; an auxiliary roller is movably arranged on the outer wall of the animal leather; and an equipment box is fixedly arranged on the right side of the auxiliary roller. According to the convenient and rapid printing equipment for animal leather production and manufacturing in the leather factory, an extrusion table, fixing cylinders, supporting springs, extrusion rollers and the like are used in cooperation, so that the extrusion rollers on the two sides coincide with grooves in the extrusion table; and when the leather is processed, the two sides of the leather can be extruded and fixed; due to the fact that the extrusion table is a concave groove, the extrusion rollers can stretch the leather conveniently, the wrinkle phenomenon is avoided, then the leather printing effect of the printing equipment is enhanced, and the finished product quality of leather processing is improved; and a method is convenient in treatment and good in effect, so that the use requirements of people can be well met, and convenience is brought to daily printing processing of people.

Owner:嘉兴倍创网络科技有限公司

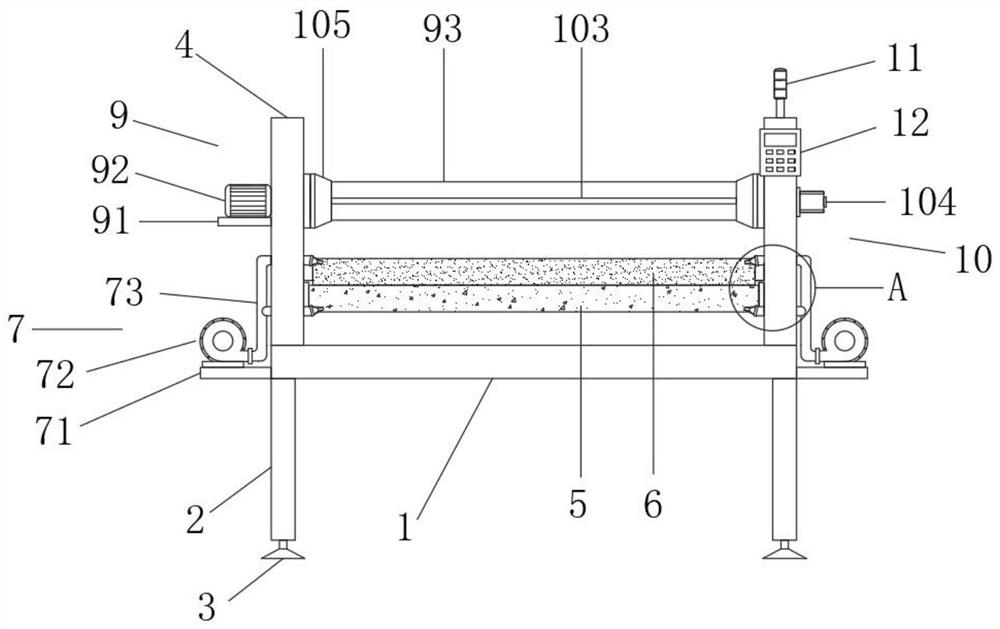

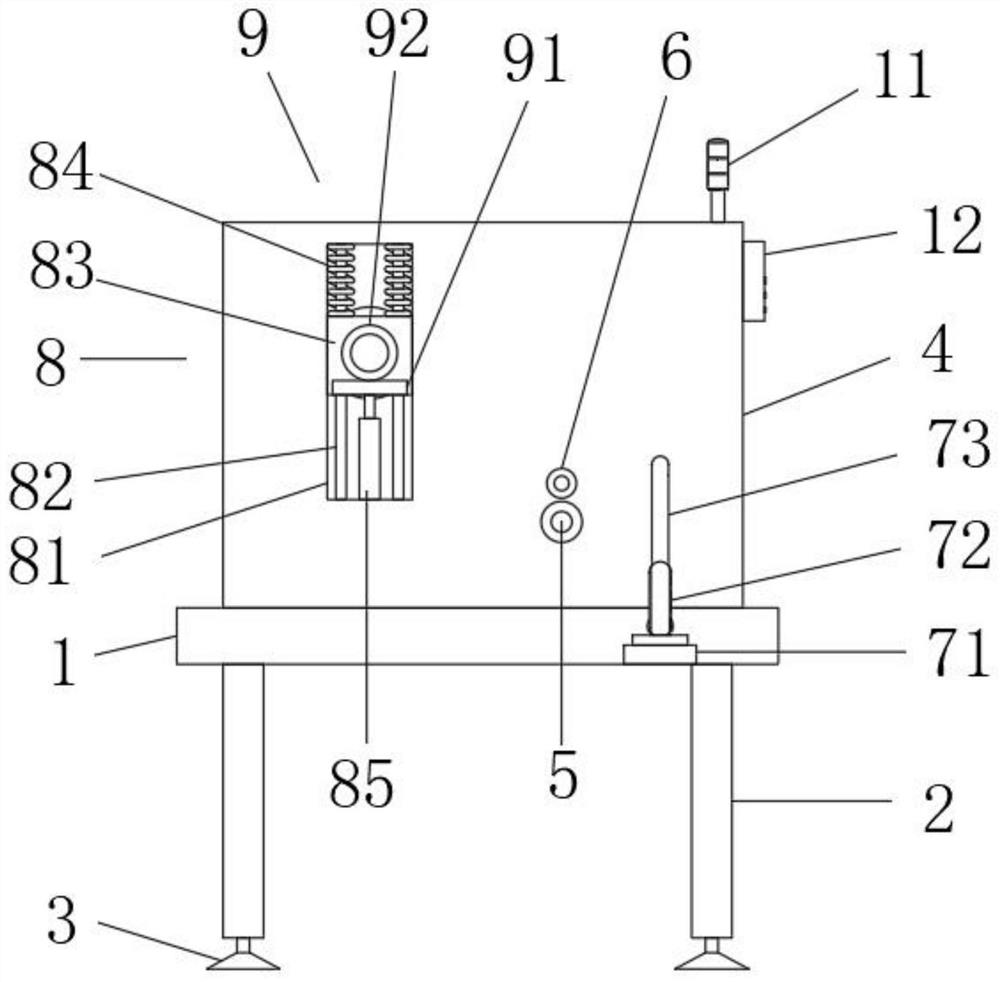

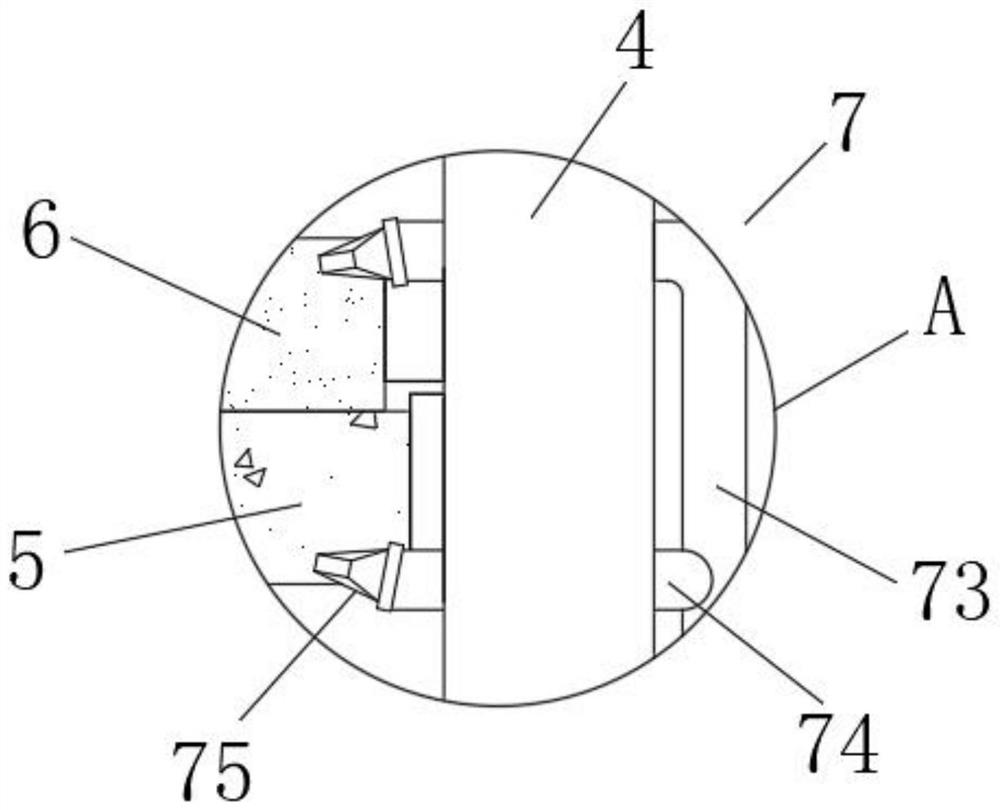

Anti-wrinkling temporary storage type film coating device used for waterproof coiled material production

InactiveCN105365329ASuitable for lamination operationsAvoid wrinklingLaminationLamination apparatusAnti wrinkleExhaust gas

The present invention provides an anti-wrinkling temporary storage type film coating device used for waterproof coiled material production, the anti-wrinkling temporary storage type film coating device includes a winding temporary storage mechanism, a film coating component and an exhaust gas recycling processing component, the material outlet end of the winding temporary storage mechanism is provided with the film coating component, the winding temporary storage mechanism includes a temporary storage rack, a temporary storage upper frame, a plurality of temporary storage upper rollers, a plurality of temporary storage lower rollers and a height adjusting component, and the film coating component includes a coating rack, a glue dipping tank, a glue dipping roller, a lower film guide roll, a lower film coating member, an upper film guide roll and an upper film coating member. By arrangement of the winding temporary storage mechanism, a certain length of tire base temporary storage can be achieved, the film coating component can be continuous in production without interruption, the production continuity can be ensured, and the processing efficiency is improved. Through use of the device, exhaust gas produced in production can be processed and then recycled in a relatively low cost, continuous production can be achieved when a tire base needs to continue, the production disruption may not be caused, and the production efficiency is ensured. The successful tire base succession can be ensured, and production and use can be facilitated.

Owner:安徽五星凯虹防水建材科技有限公司

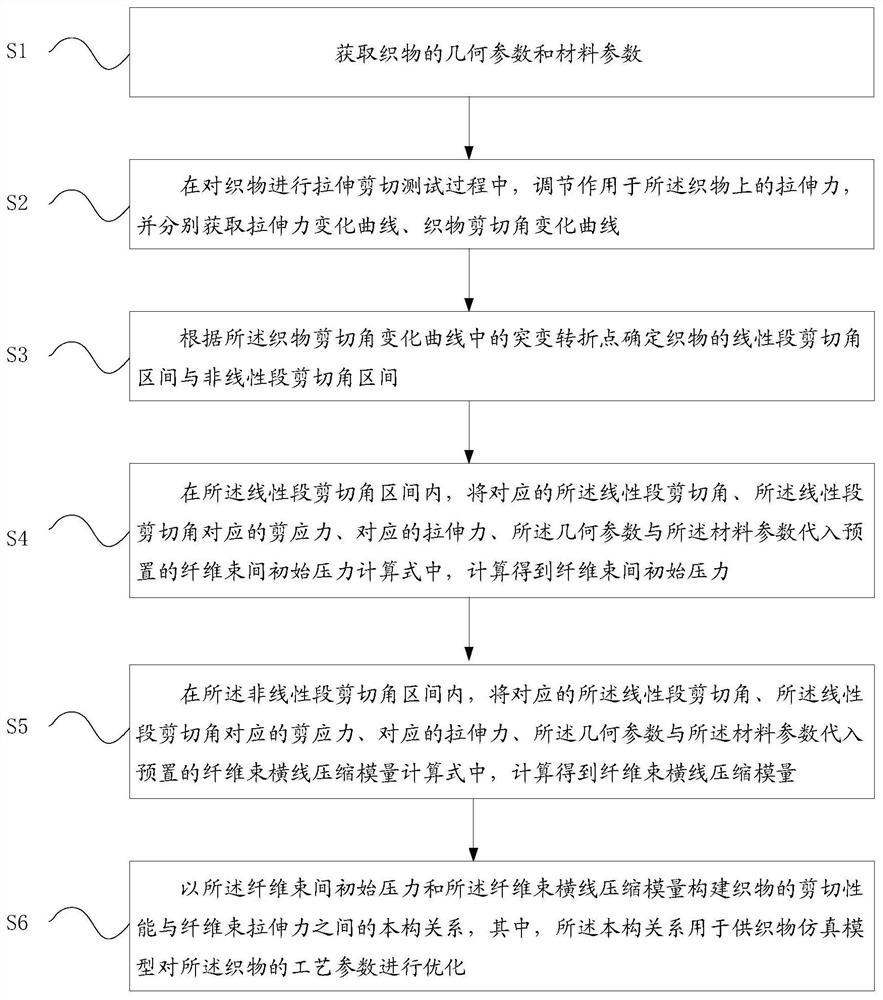

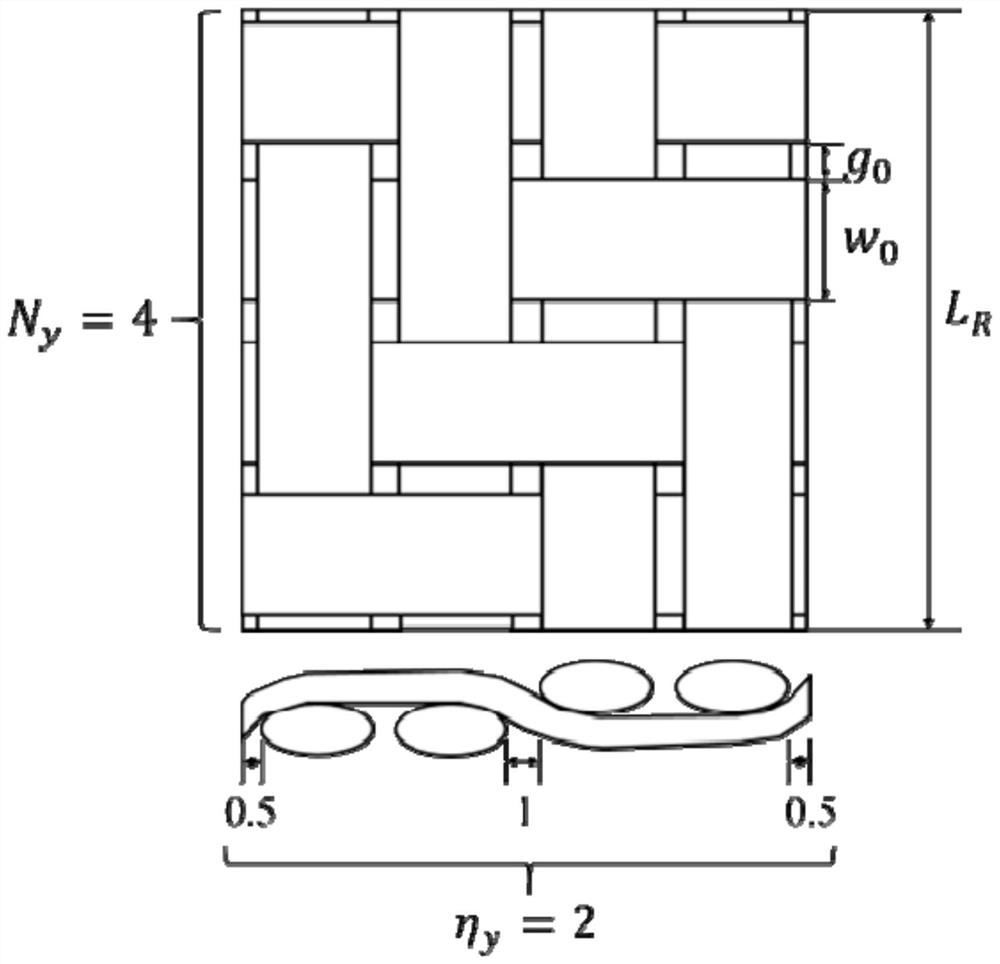

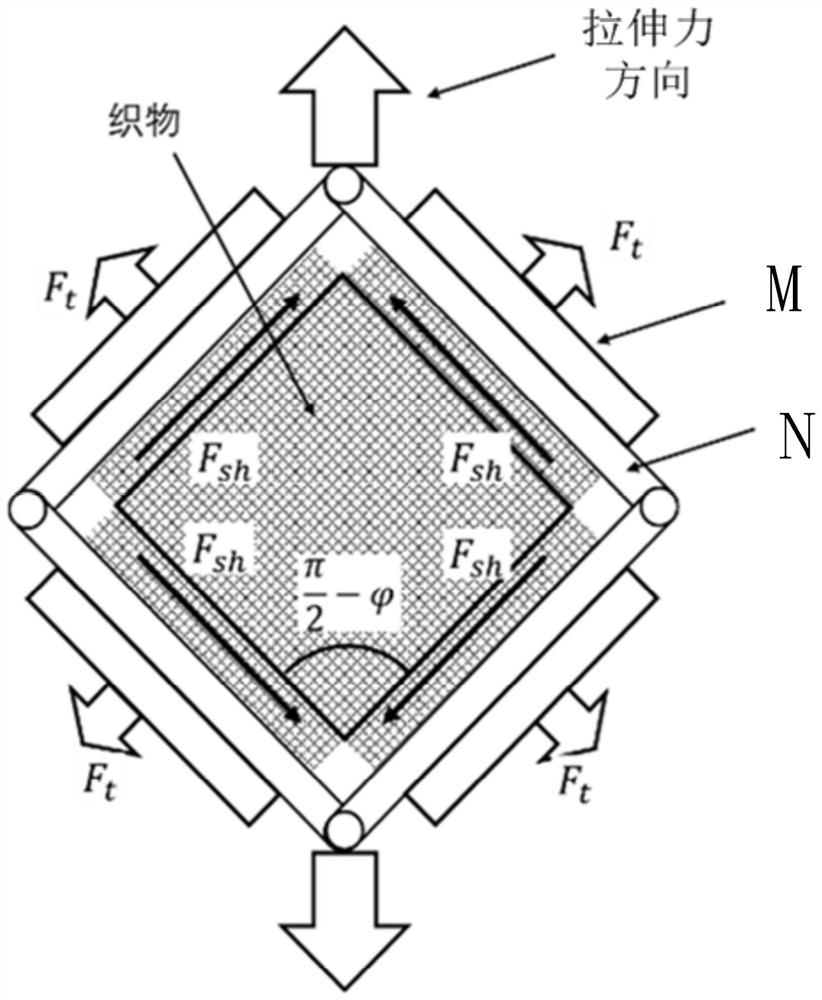

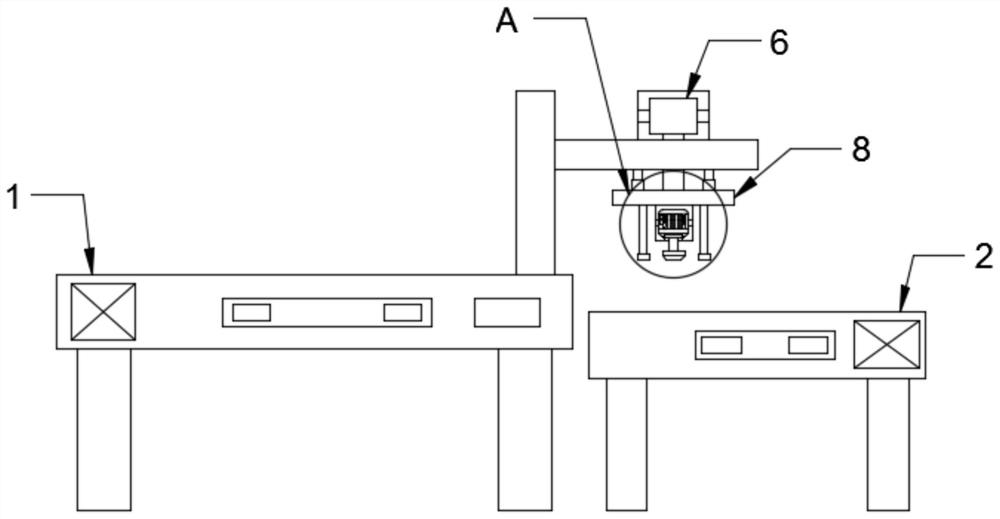

Method and device for testing shearing performance parameters of fabric

PendingCN114184497AImprove Simulation AccuracyAvoid wrinklingMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesShear angleEngineering

The invention discloses a method and a device for testing shearing performance parameters of a fabric. The method comprises the following steps: acquiring geometric parameters and material parameters of the fabric; adjusting the drawing force acting on the fabric to obtain a drawing force change curve and a fabric shear angle change curve; determining a linear section shear angle interval and a nonlinear section shear angle interval according to a sudden change turning point in the fabric shear angle change curve; calculating the initial pressure between the fiber bundles according to a preset calculation formula of the initial pressure between the fiber bundles; calculating the transverse compression modulus of the fiber bundle according to a preset calculation formula of the transverse compression modulus of the fiber bundle; and constructing a constitutive relationship between the shearing performance of the fabric and the drawing force of the fiber bundle. According to the method and the device for testing the shearing performance parameters of the fabric provided by the embodiment of the invention, the constitutive relationship reflecting the shearing performance of the fabric and the drawing force of the fiber bundle is obtained, so that the simulation precision of the fabric is improved, and the forming quality of a product is further improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Automatic cutting device for thin film production

PendingCN112743599AAvoid wrinklingGuaranteed flatnessMetal working apparatusWebs handlingThin membraneStructural engineering

The invention discloses an automatic cutting device for thin film production, which comprises a conveying frame and a cutting frame, a conveying mechanism is arranged in the conveying frame, a rack is arranged on one side of the upper end of the conveying frame, a cutting mechanism is arranged on one side of the rack through a transverse frame, the cutting frame is arranged on one side of the conveying frame, and the cutting mechanism is arranged on the other side of the conveying frame. A cutting-off plate is arranged on one side of the interior of the cutting-off frame, a cutting-off groove is formed in the cutting-off plate, and a winding mechanism is arranged on the other side of the interior of the cutting-off frame. By arranging the conveying mechanism, the end cutting mechanism and the winding mechanism, automatic conveying, cutting and winding of the thin film are achieved, the conveying, cutting and winding quality and efficiency of the thin film are improved, and then the production quality and efficiency of the thin film are improved.

Owner:昆山竹言薄膜特殊材料有限公司

Dyeing finishing process for anti-static ultra-clean fabric

InactiveCN103015105AGood anti-wrinkle effectAvoid wrinklingHeating/cooling textile fabricsSizingDyeing

The invention discloses a dyeing finishing process for an anti-static ultra-clean fabric. The dyeing finishing process comprises the following steps of: dehydration, sizing, checking and packaging, wherein the sizing step comprises the following substeps of: placing the anti-static ultra-clean fabric in a sizing machine at the temperature of 200 to 210 DEG C, and sizing the anti-static ultra-clean fabric at speed of 30 to 40m / min. By the technical condition, the process is applied to dyeing finishing of the anti-static ultra-clean fabric, so that the finished anti-static ultra-clean fabric can achieve a relatively good anti-draping effect; a draping phenomenon in the subsequent using process can be avoided; furthermore, high rebounce and high flatness are realized; and the forcible damage to the anti-static ultra-clean fabric is relatively small.

Owner:SUZHOU TA&A ULTRA CLEAN TECH

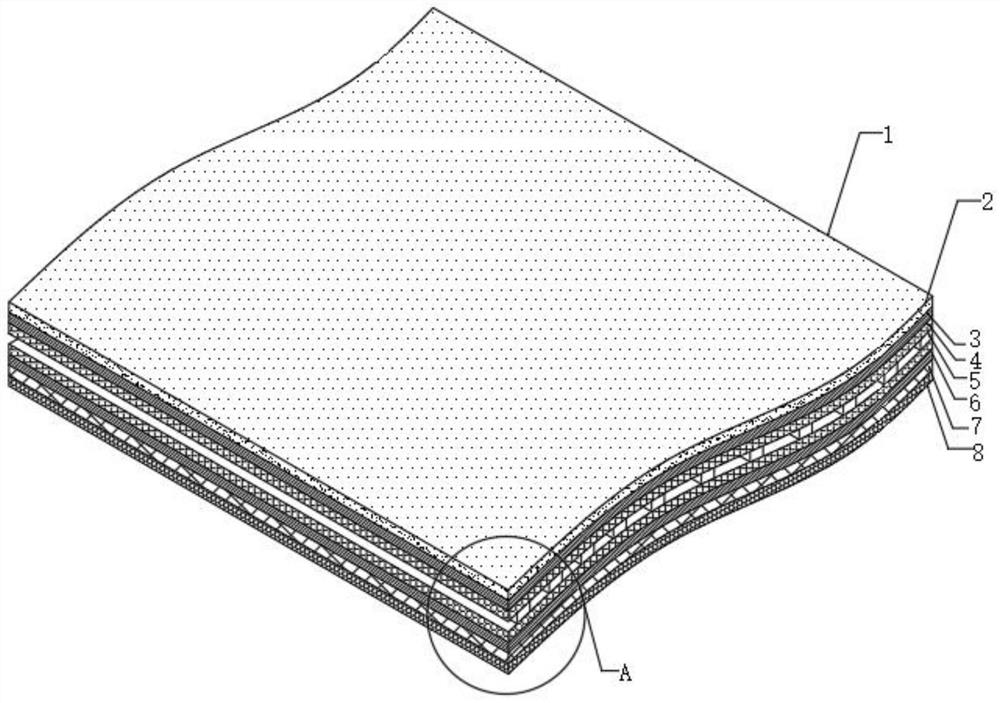

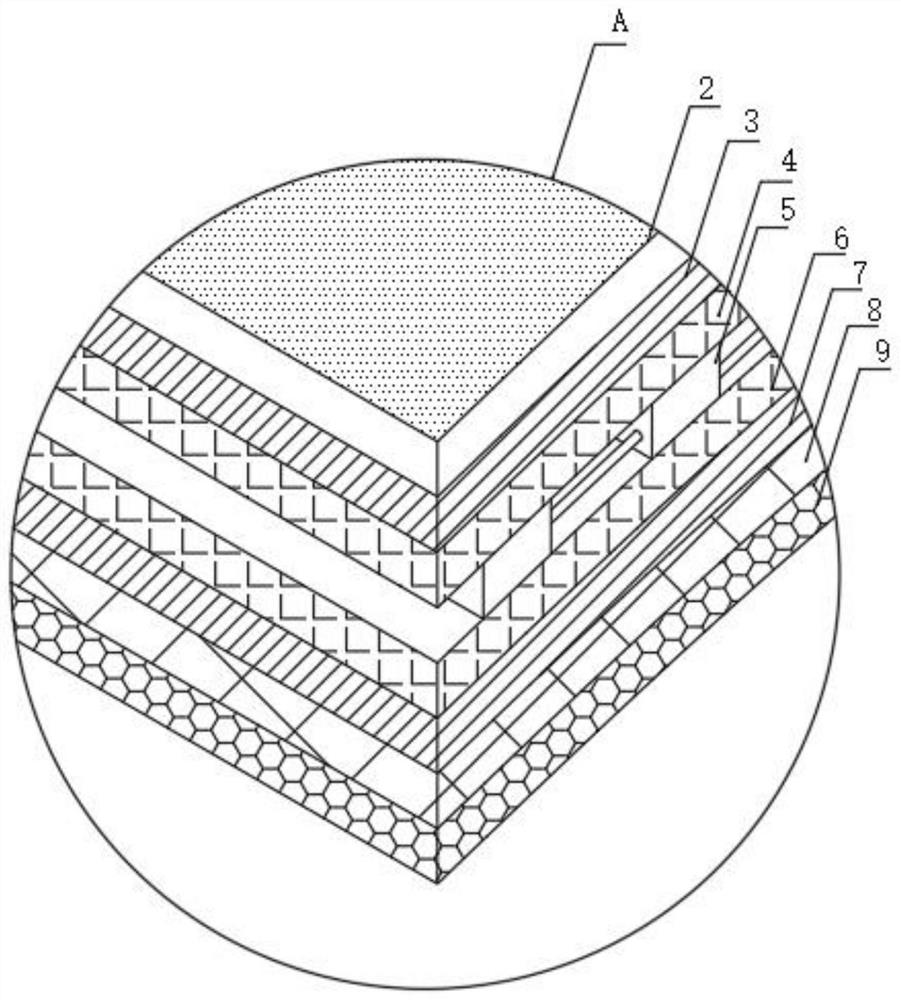

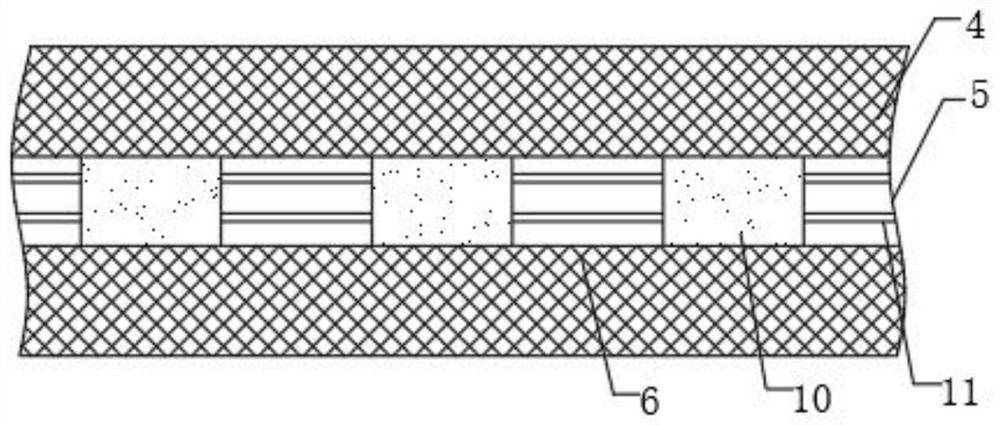

Carcass-free waterproof roll expansion force balancing device

InactiveCN112297542AGood tensile strengthAvoid wrinklingSynthetic resin layered productsMetal layered productsPhysicsEngineering

The invention discloses a carcass-free waterproof roll expansion force balancing device which comprises a carcass-free waterproof roll body, the carcass-free waterproof roll body comprises a protective layer, a first waterproof layer, a first elastic layer, a balancing layer, a second elastic layer, an isolation layer, a second waterproof layer and a slope making layer; the second waterproof layeris bonded to the top end of the slope making layer; the isolation layer is bonded to the top end of the second waterproof layer, the second elastic layer is bonded to the top end of the isolation layer, the balancing layer is bonded to the top end of the second elastic layer, and the first elastic layer is bonded to the top end of the balance layer. According to the carcass-free waterproof roll,the balancing layer is arranged, a tensile adhesive tape is arranged between the plastic strips of the balancing layer, so that the carcass-free waterproof roll has relatively high tensile resistance,and the expansion force balance of the carcass-free waterproof roll is ensured through the tensile force of the tensile adhesive tape when the waterproof roll is pasted; and protruding caused by unbalanced expansion force of the waterproof coiled material at the slope and the corner is effectively avoided, and the waterproof effect of the waterproof coiled material is prevented from being affected.

Owner:福建铜浪建材科技发展有限公司

Textile fabric winding device

PendingCN112722960AChange the tensionAvoid wrinklingMechanical cleaningPressure cleaningEngineeringTextile

The invention discloses a textile fabric winding device. The textile fabric winding device comprises a main table top, a dust removal mechanism, a lifting mechanism, a winding mechanism and an adjusting mechanism, supporting legs are fixedly connected to the periphery of the bottom of the main table top, and cup-shaped supporting feet are fixedly connected to the bottoms of the supporting legs. The textile fabric winding device has the beneficial effects that the upper surface and the lower surface of cloth can be uniformly dedusted through two duckbilled nozzles with different heights and angles in the dust removal mechanism, the winding mechanism is conveniently driven to ascend and descend through the lifting mechanism, the distance between a winding roller and two guide rollers is changed, then the tension degree of the cloth is changed, and fabric wrinkling is prevented; and meanwhile, the equipment can wind more fabric at a time, the fabric can be better wound on the outer side of the winding roller through the winding mechanism, the positions of two adjusting rings can be better adjusted through the adjusting mechanism, the fabric of different sizes can be better limited, it is kept that the fabric is wound in the middle of the winding roller in a centralized mode, and the position deviation of the fabric during winding is prevented.

Owner:安徽君翰纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com