An integrated forming pipe bending device for bulging pipe bending

A pipe bending device and an integrated technology, applied in the field of bulging pipe manufacturing, can solve the problems of resource sharing, low labor production efficiency, resource waste, etc., and achieve high production efficiency, shortened production cycle, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

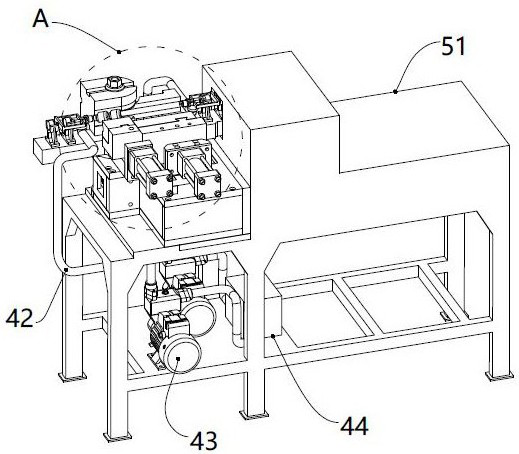

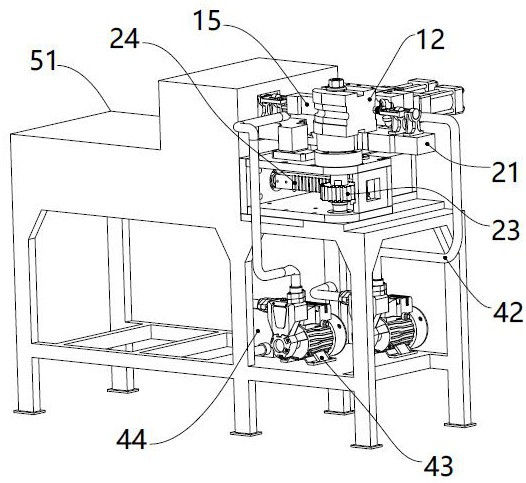

[0028] Embodiment: a kind of integral forming pipe bending device of bulging pipe, the structure is as follows Figure 1 to Figure 3 As shown, it includes a mold set, a pipe bending mechanism, a hydraulic system and a sealing mechanism arranged at both ends of the mold set; the mold set is used for clamping and bulging of the pipe to be processed, and the hydraulic system provides bulging for the pipe to be processed Internal pressure; the mold set includes a first mold 11 and a second mold 12 which are arranged oppositely; the structure of the bending mechanism is as Figure 7 , 8 As shown, it includes a rotatable bending arm 21. The bending arm 21 is in the shape of "L" as a whole, and the horizontal and vertical intersections of the "L" shape are its turning points. When the bending arm 21 rotates, it drives the first mold 11 and the second mold 11. The mold 12 rotates synchronously; the second mold 12 is provided with an elbow groove 121, and the structure is as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com