A precision machining process for stamping process of thin film parts

A precision machining and parts technology, applied in the field of precision parts technology manufacturing, can solve problems such as the inability to accurately determine the mold distance, and achieve the effect of being conducive to mass production and easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

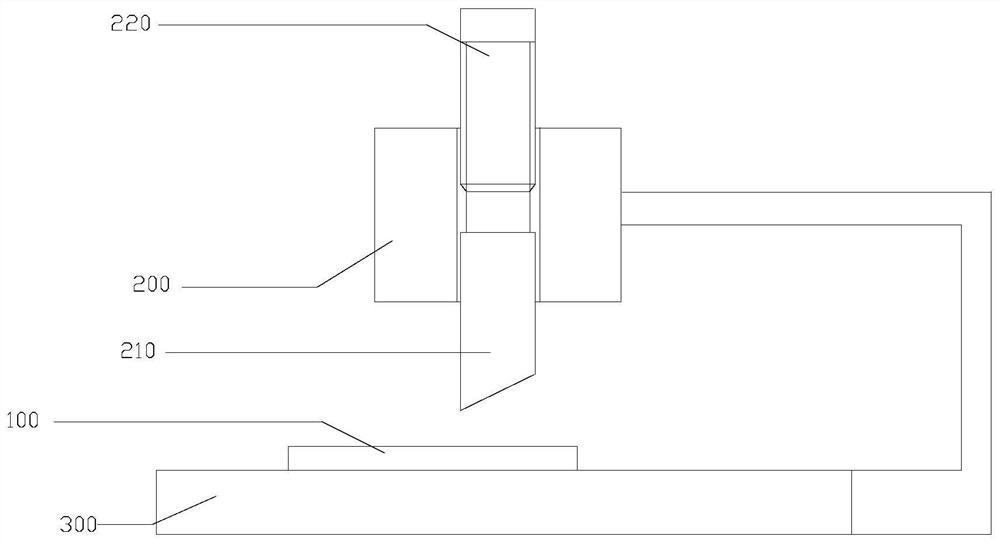

[0021] refer to figure 1 As shown, a precision machining process of a film part stamping process is performed on a film part 100 for stamping and cutting, including the following steps:

[0022] (1) The stamping assembly is fixed on the stroke module 200 , and the stamping assembly is placed in the stroke module 200 and screwed to the stroke module 200 . The stamping assembly includes a stamping upper die 210, an adjustment ruler 220 fixedly connected to the stamping upper die 210;

[0023] (2) Debug stamping: start the stroke module 200 to carry out a stamping, when the stroke module moves downward, rotate the adjustment ruler 220 to make the stamping upper die 210 and the stamping lower die 200 contact each other, record the adjustment ruler 220 and the stroke The upper surface of the module 200 is flush with the scale; start the stroke module 200 to reset, and then according to the thickness d of the thin film part 100 to be processed, the rotation adjustment ruler 210 mov...

Embodiment 2

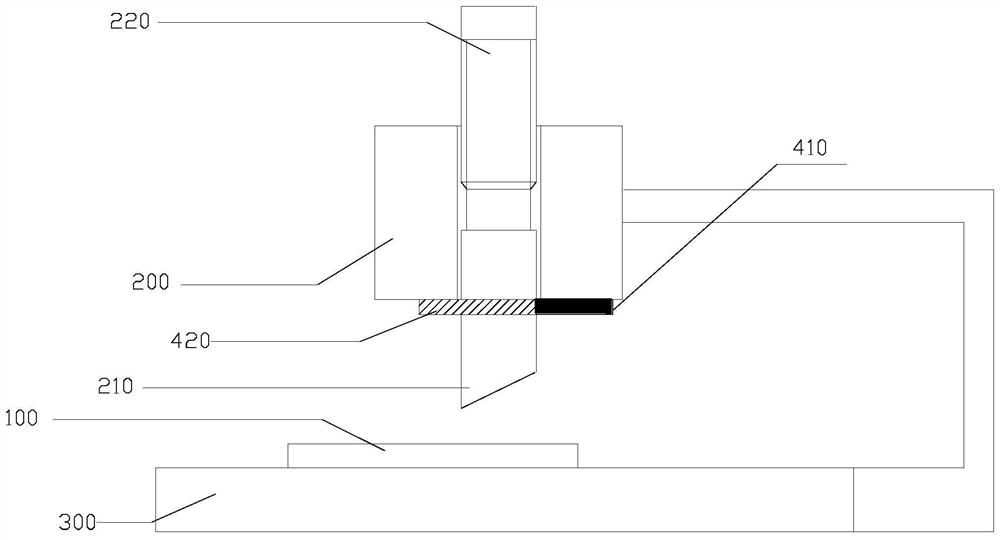

[0030] refer to figure 2 As shown, a precision machining process of a film part stamping process is performed on a film part 100 for stamping and cutting, including the following steps:

[0031] (1) The stamping assembly is fixed on the stroke module 200 , and the stamping assembly is placed in the stroke module 200 and screwed to the stroke module 200 . The stamping assembly includes a stamping upper die 210 and an adjustment ruler 220 fixedly connected to the stamping upper die 210 . A connection fixture is fixed below the stroke module 200 , the fixture includes a fixedly connected base 410 and an elastic clip 420 , and the base 410 is fixed below the stroke module 200 .

[0032] (2) Debug stamping: start the stroke module 200 to perform a stamping, when the stroke module moves downward, open the elastic jaw 420, rotate the adjustment ruler 220 to make the stamping upper die 210 and the stamping lower die 200 touch each other , then reset the elastic jaw 420, record the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com