Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

225results about "Labelling elongated objects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

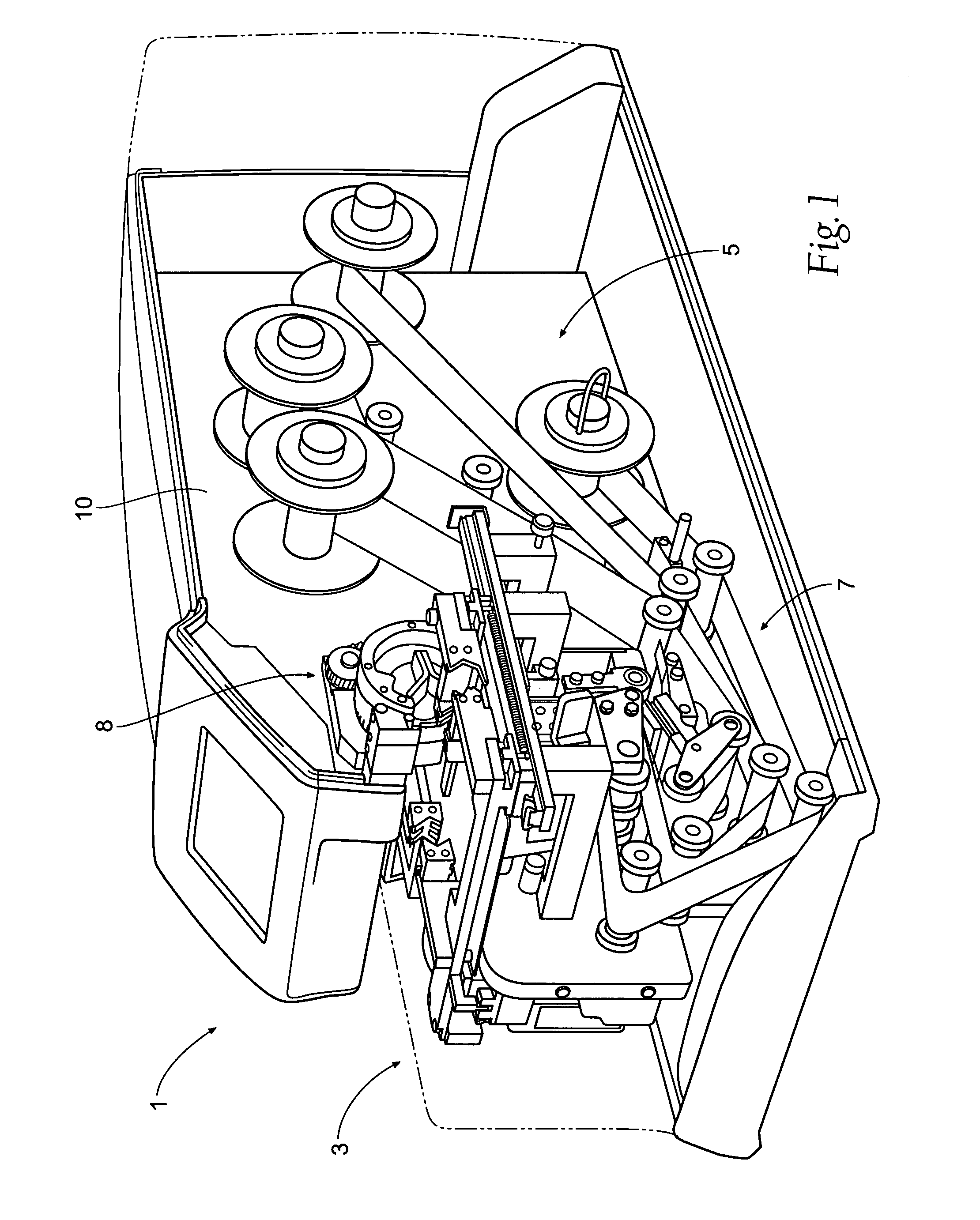

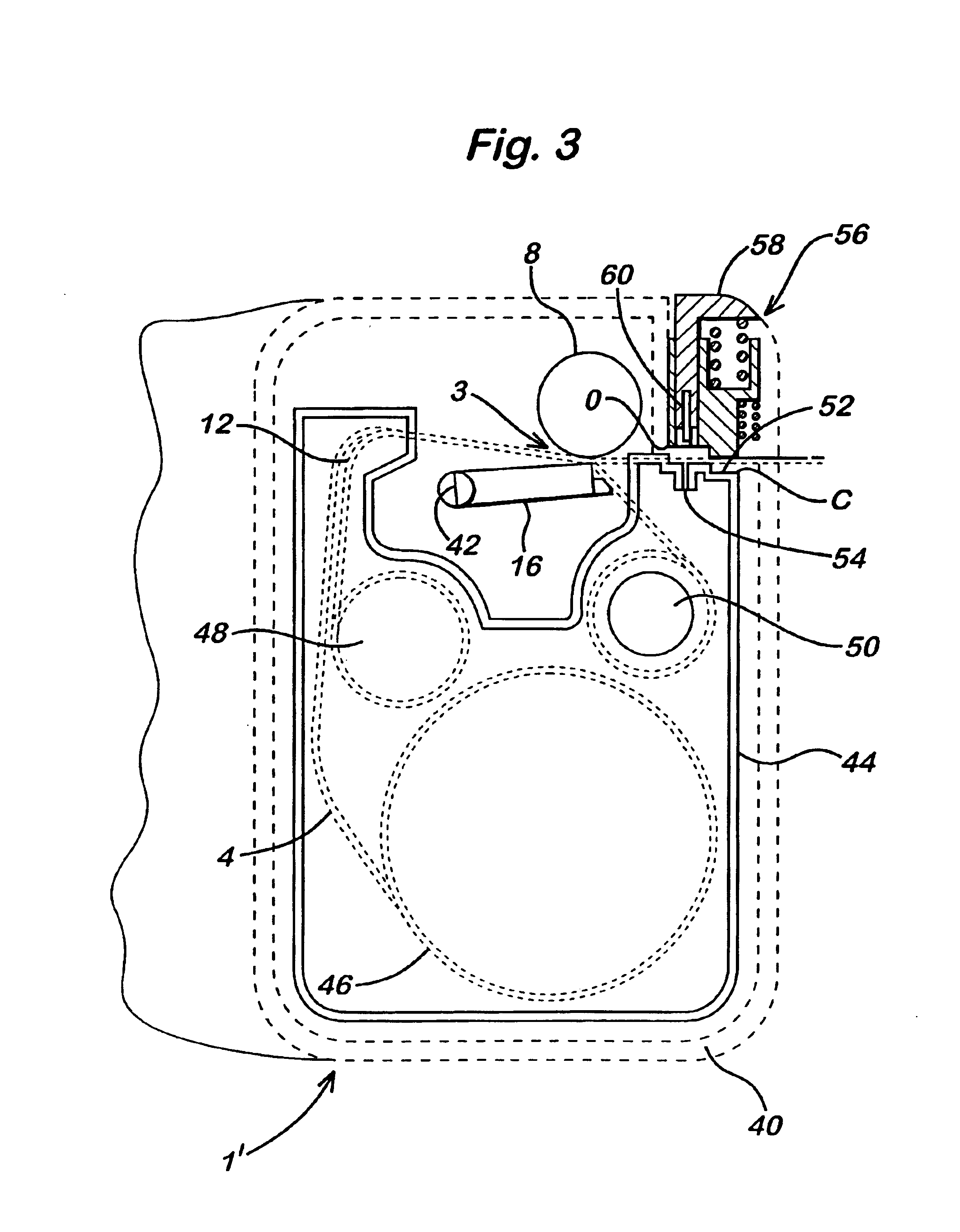

Incentive coupon-based system and apparatus for treating shopping carts

InactiveUS6090218AQuick changeShort timeCash registersService system furnitureHypochloriteSpray nozzle

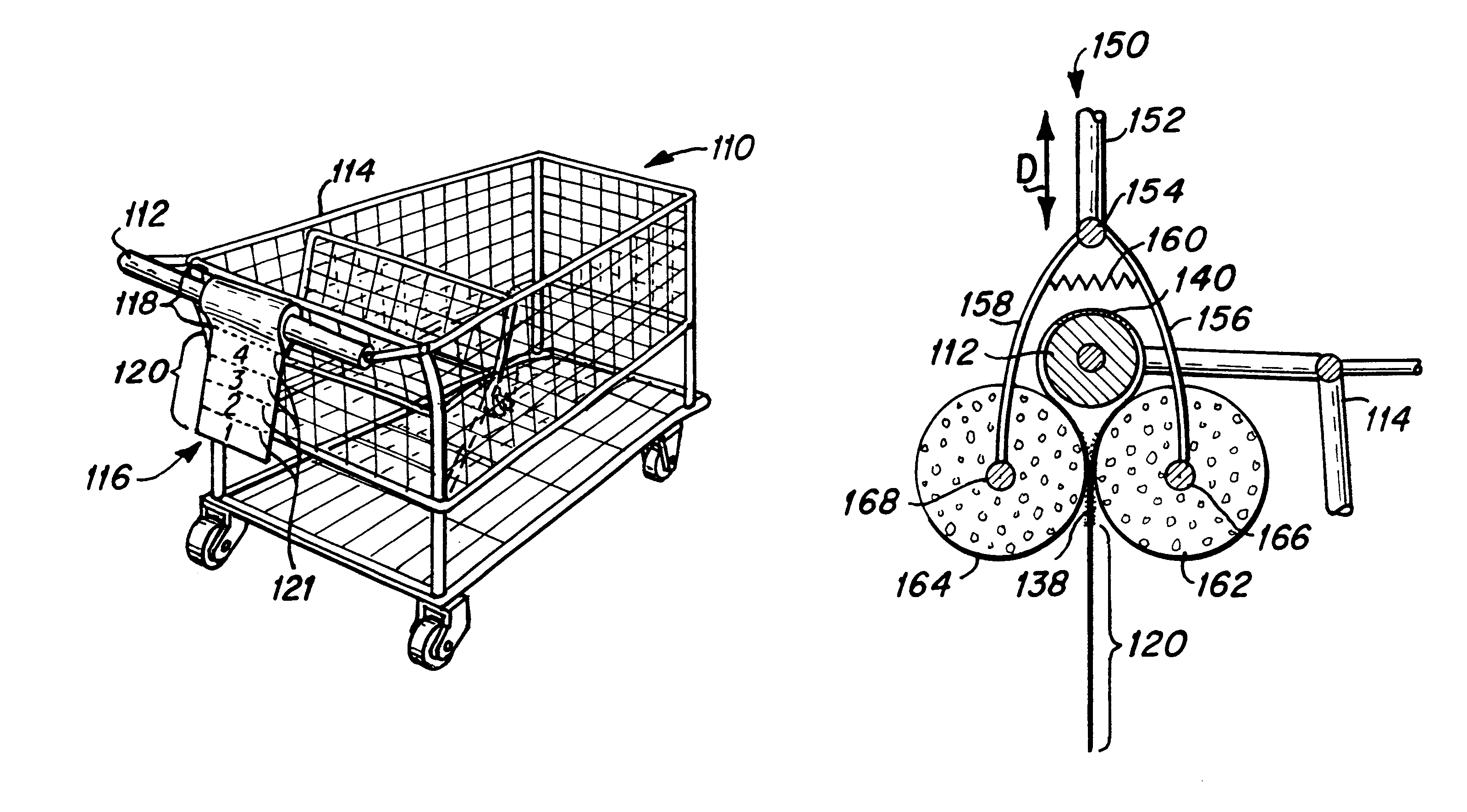

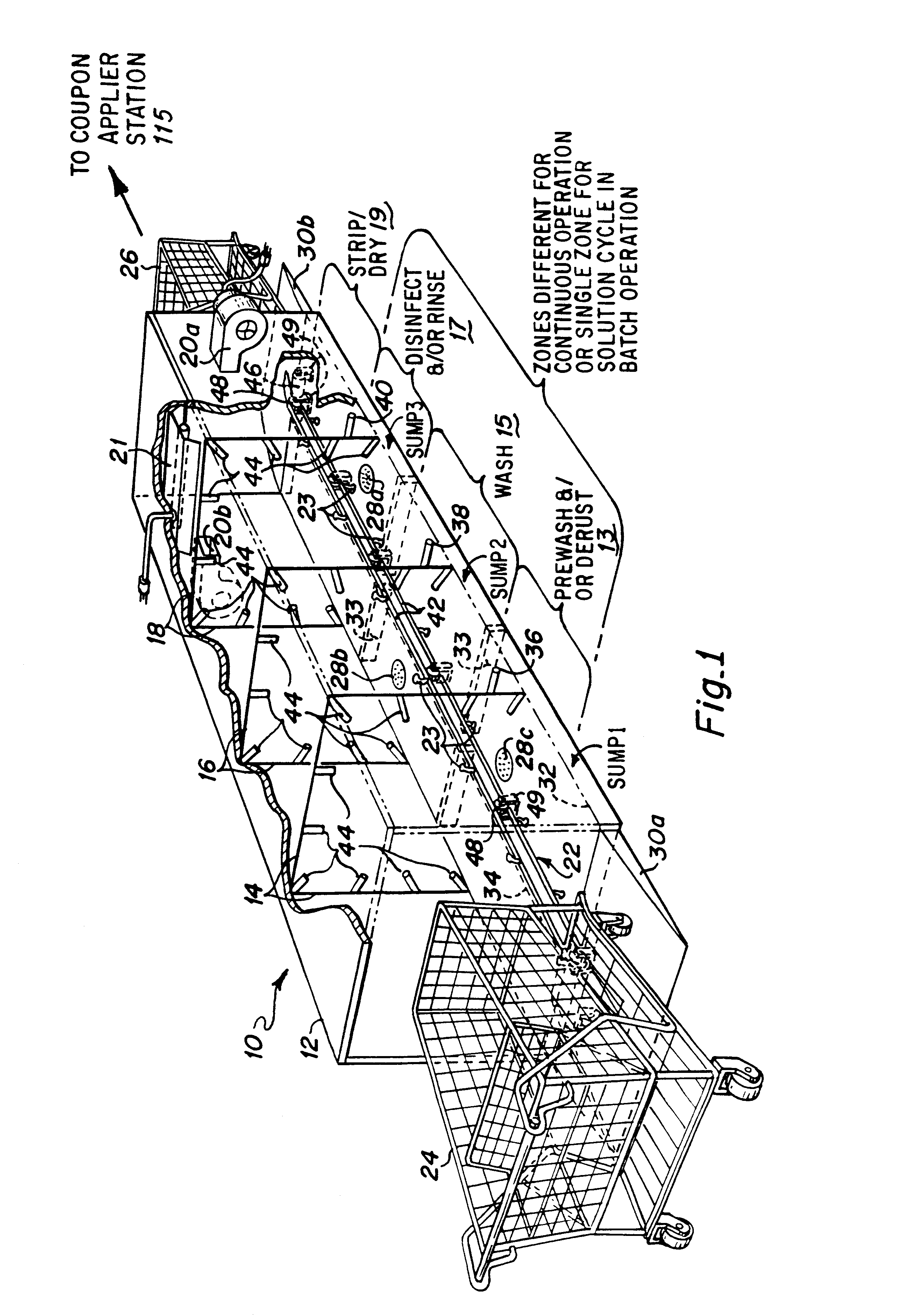

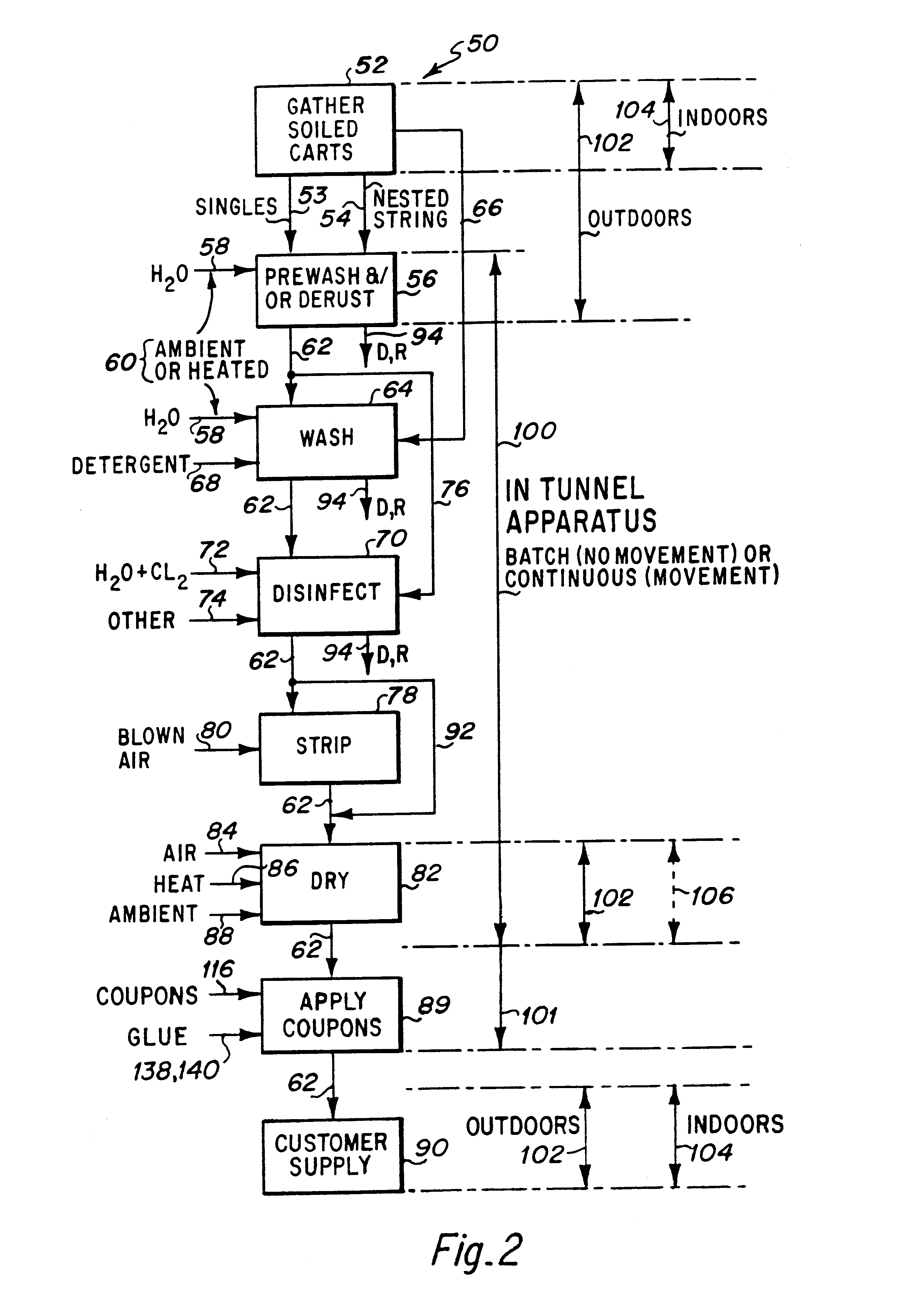

An incentive-based grocery cart washing and disinfecting system including a consumer special-offer coupon applying apparatus, for use in a batch or continuous process comprising a housing having at least one pipe manifold with nozzles positioned therein to provide at least one treatment zone selected from pre-wash, wash, disinfecting, and rinse zones. In addition, blown air water-stripping / drying zones may be provided, with a heating source to assist drying. Following drying, a strip of specially adapted grocery coupons is optionally applied to the grocery cart handle, so that the coupons can be redeemed by customers during their subsequent shopping. The housing is generally a linear tunnel permitting access of soiled carts at one end and removal of the clean, disinfected carts at the other end. A cart pusher system may be employed to transport the carts through the tunnel either singly or in nested groups. A convenient antimicrobial disinfecting solution is a water solution of hypochlorite. A single zone system is disclosed in which in a selected, optionally preprogrammed, sequence of application of pre-wash, wash, rinse, and disinfecting fluids are delivered to selected surfaces of the cart, followed by blown air, preferably heated, for stripping / drying,. The coupon strip comprises a leader portion and a coupon portion, and the leader can be wrapped and fixed around the grocery cart handle manually or by means of the automated machinery described. The system of the invention may be a fixed or mobile system, with the use preferably being on site at stores.

Owner:DM & BB

Label printer and applicator

InactiveUS20080073023A1Avoid artificial pollutionDecorative surface effectsLaminationCircular discEngineering

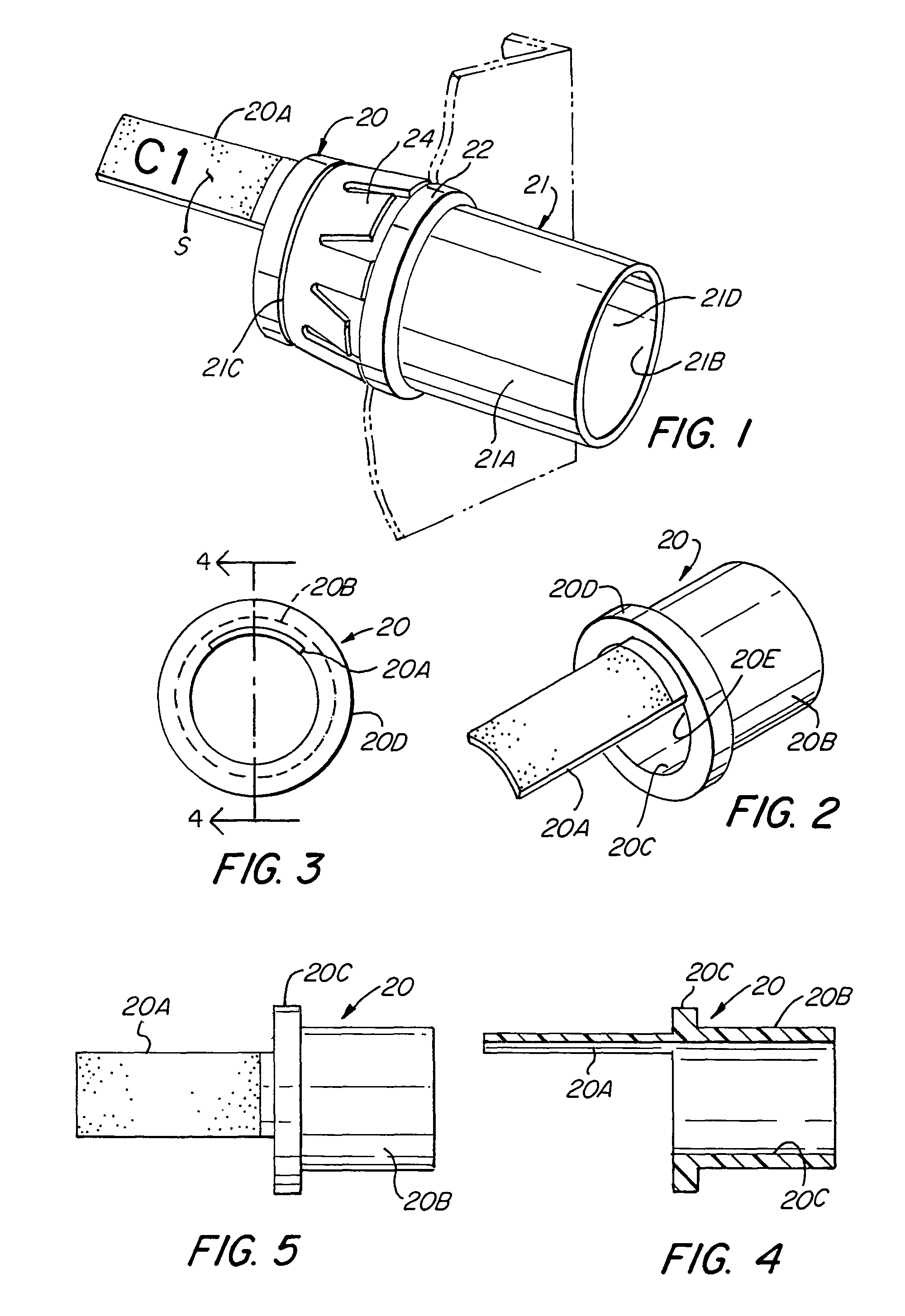

An apparatus and method for printing and wrapping adhesive backed labels around elongate articles such as electrical wires, including a rotatable puck assembly having an interrupted circumferential surface defining an opening for receiving an elongate object to be labeled and wing members for applying said label during rotation.

Owner:HELLERMANNTYTON CORP

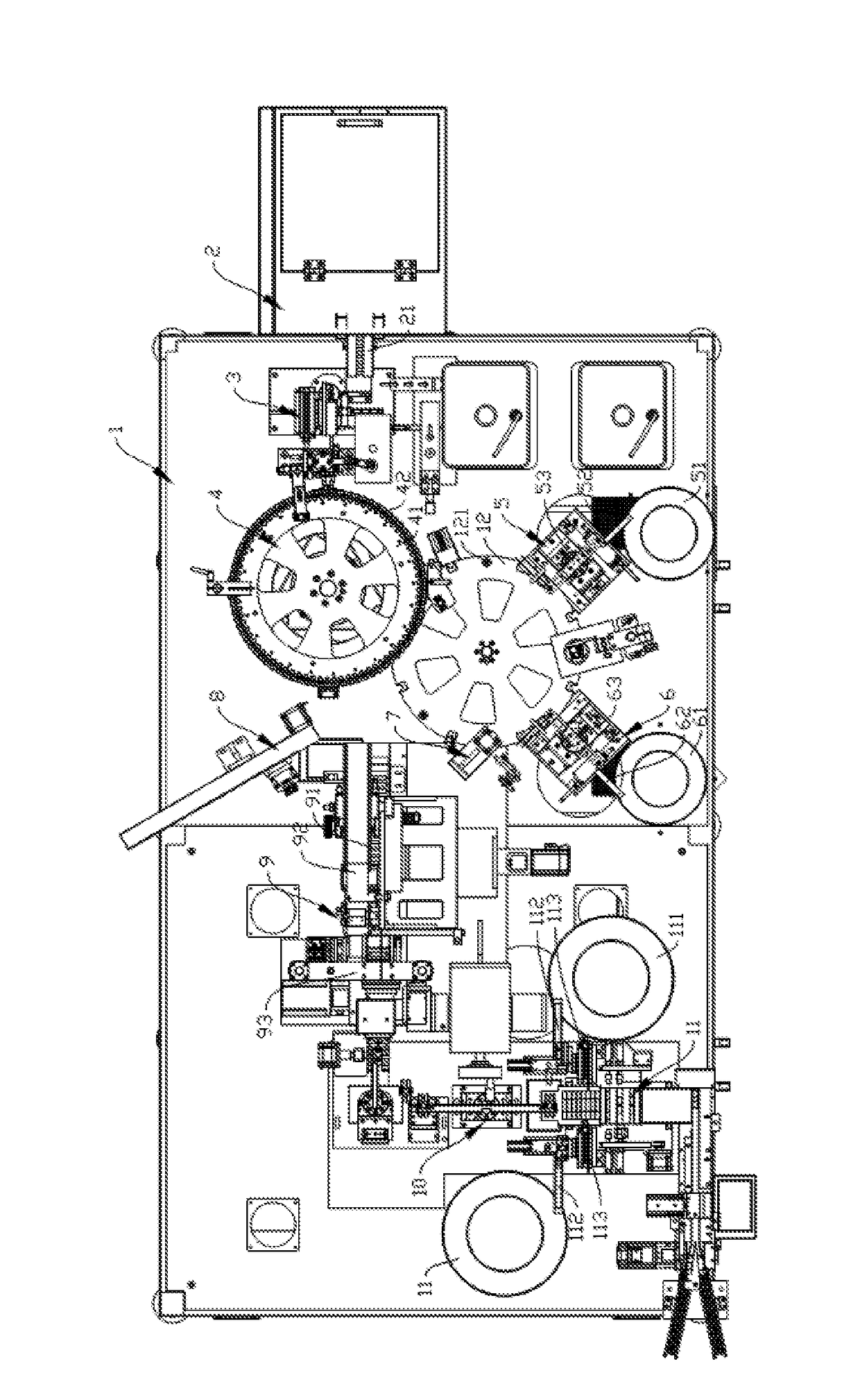

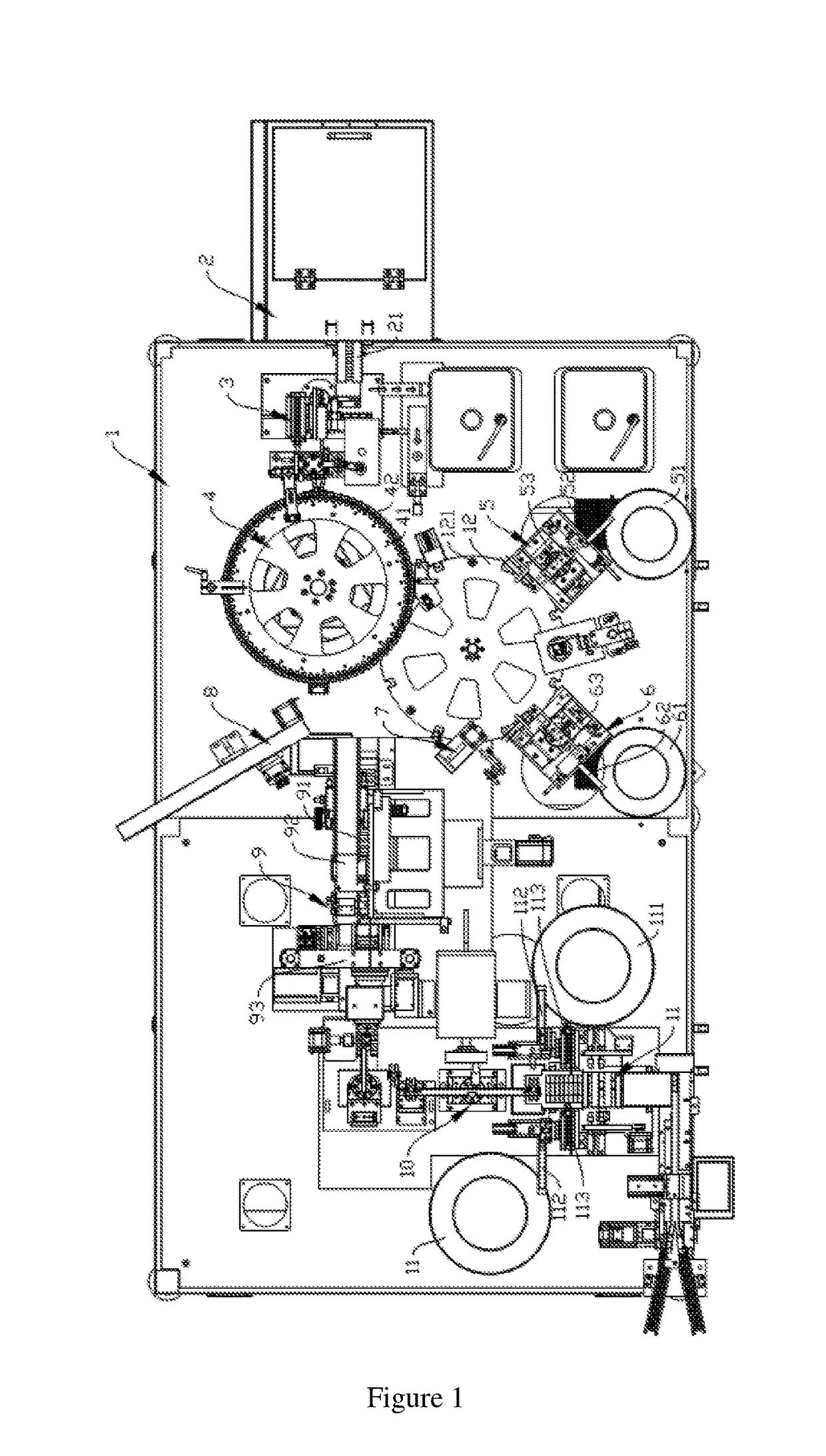

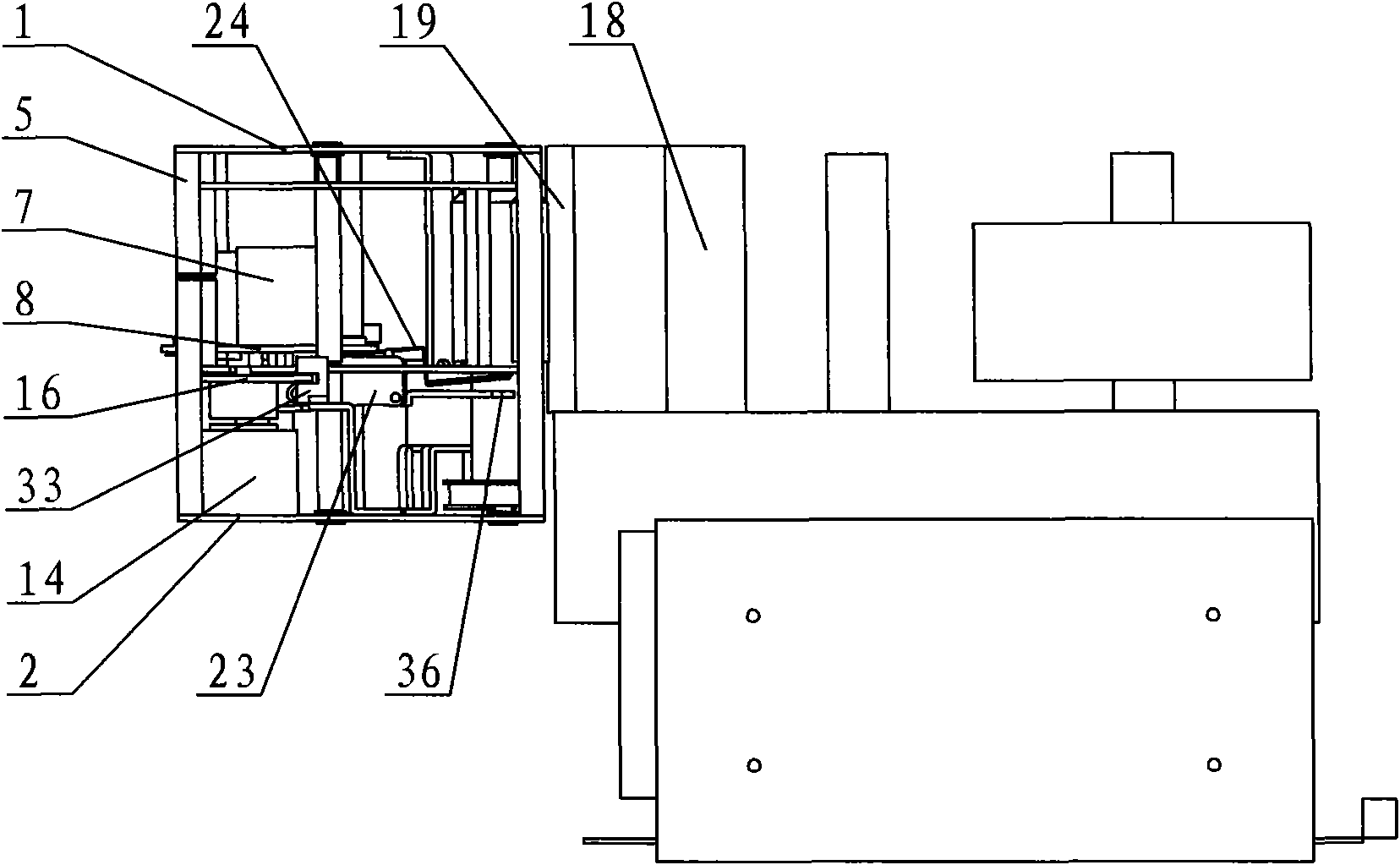

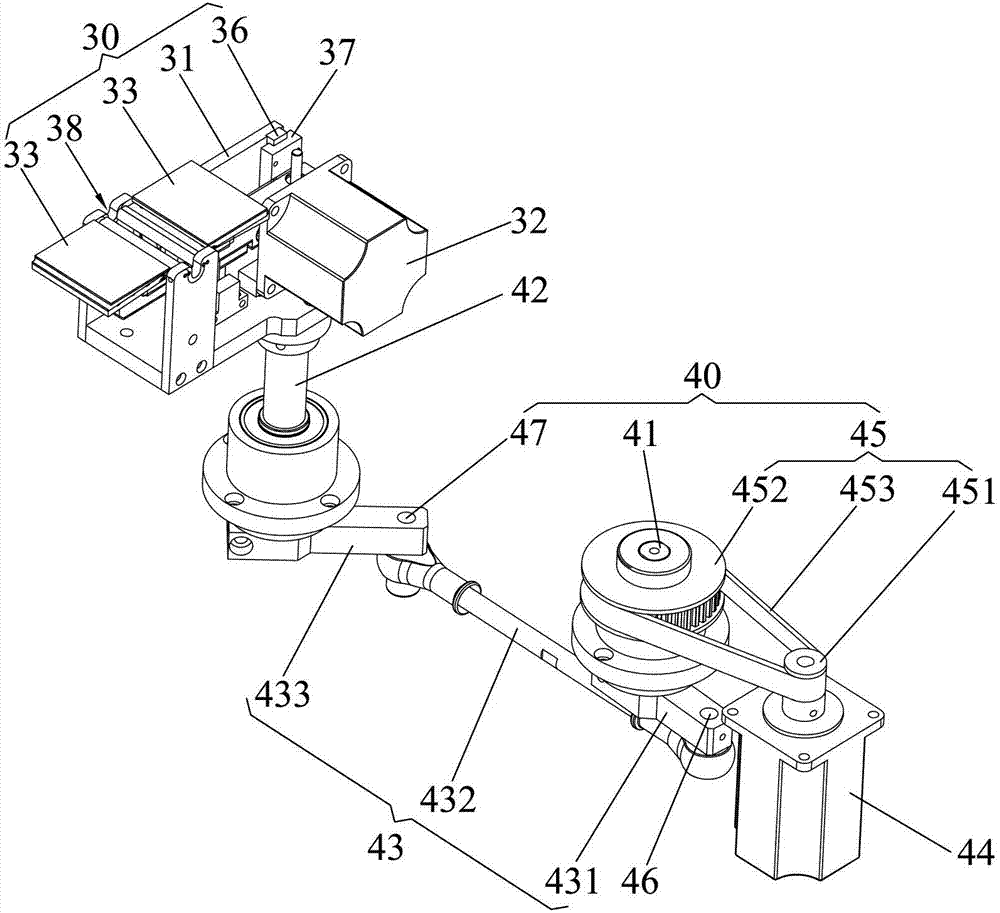

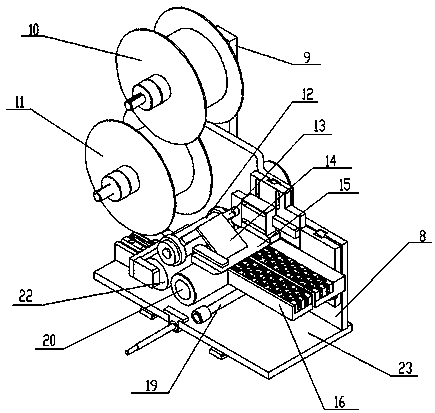

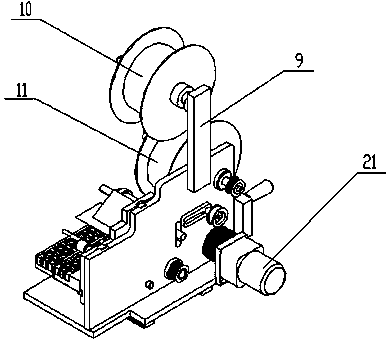

Electronic cigarette atomizer oiling and labeling device

ActiveUS20170196267A1Reduce laborImprove detection qualityAssembly machinesTobacco devicesElectrical resistance and conductanceElectronic cigarette

This disclosure provides oil filling and labeling apparatuses for atomizers of electronic cigarettes, which include a rack provided with a table board. A material pick-up operation position, an oil filling operation position, an assembling operation position, a labeling operation position and a pressing operation position for silicon rubber sleeve are provided on the table board. The oil filling and labeling apparatuses for the atomizers of the electronic cigarettes further include a material loading mechanism, an oil filling mechanism, a mechanism for mounting oil-sealing ring, a mechanism for mounting end cap, an electric resistance detection mechanism, a first material rotation mechanism, a labeling mechanism, a second material rotation mechanism and a mechanism for pressing silicon rubber sleeve. The atomizer of the electronic cigarette is successively conveyed for processing among such mechanisms.

Owner:ZHONGSHAN SHENGYUFENG TRADING CO LTD

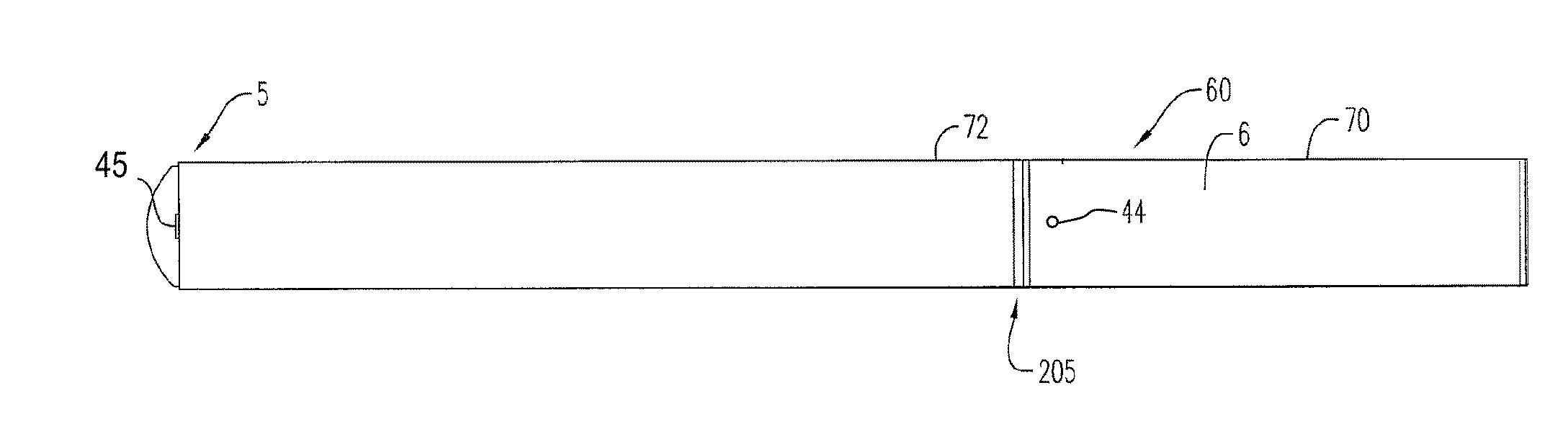

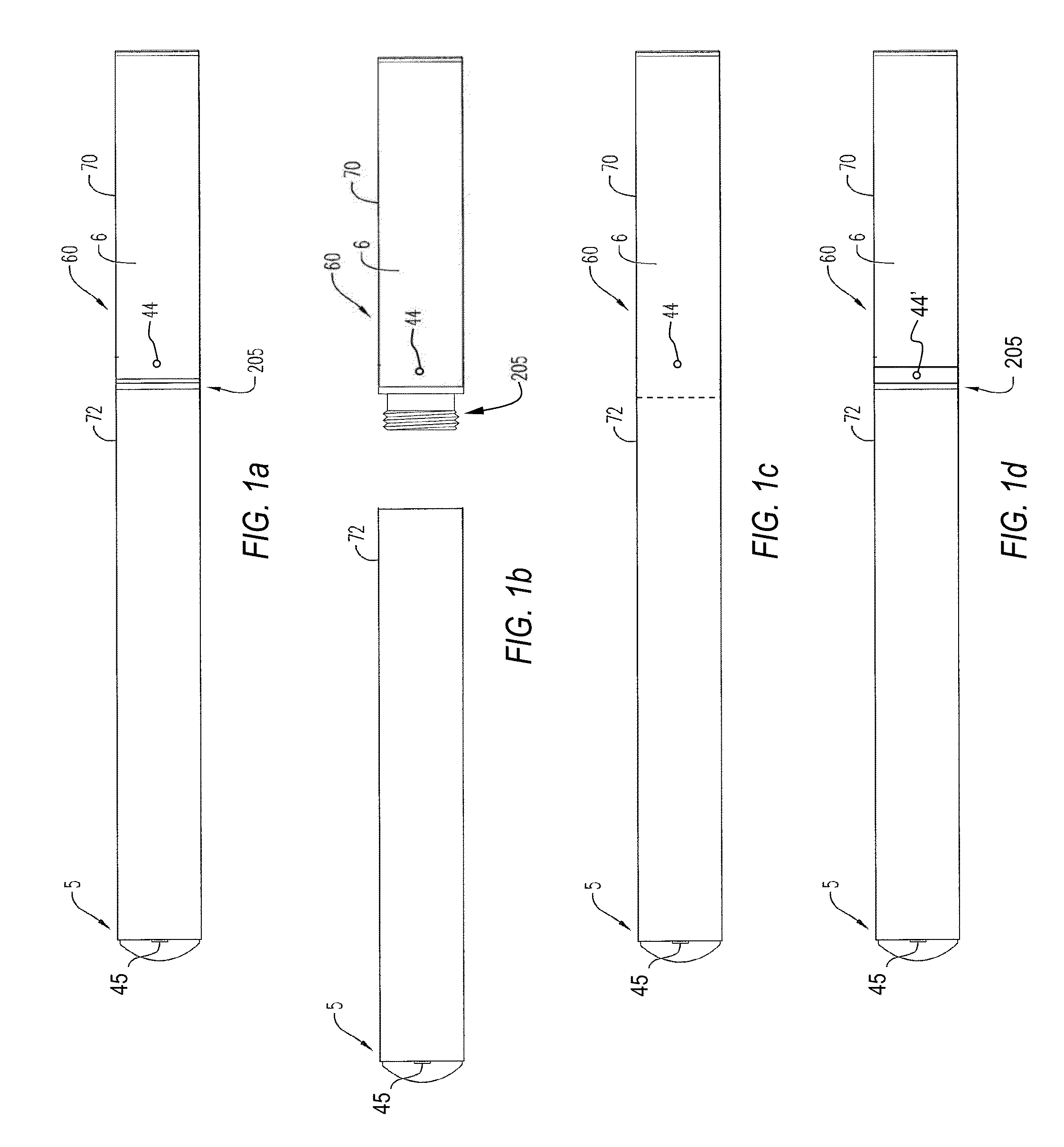

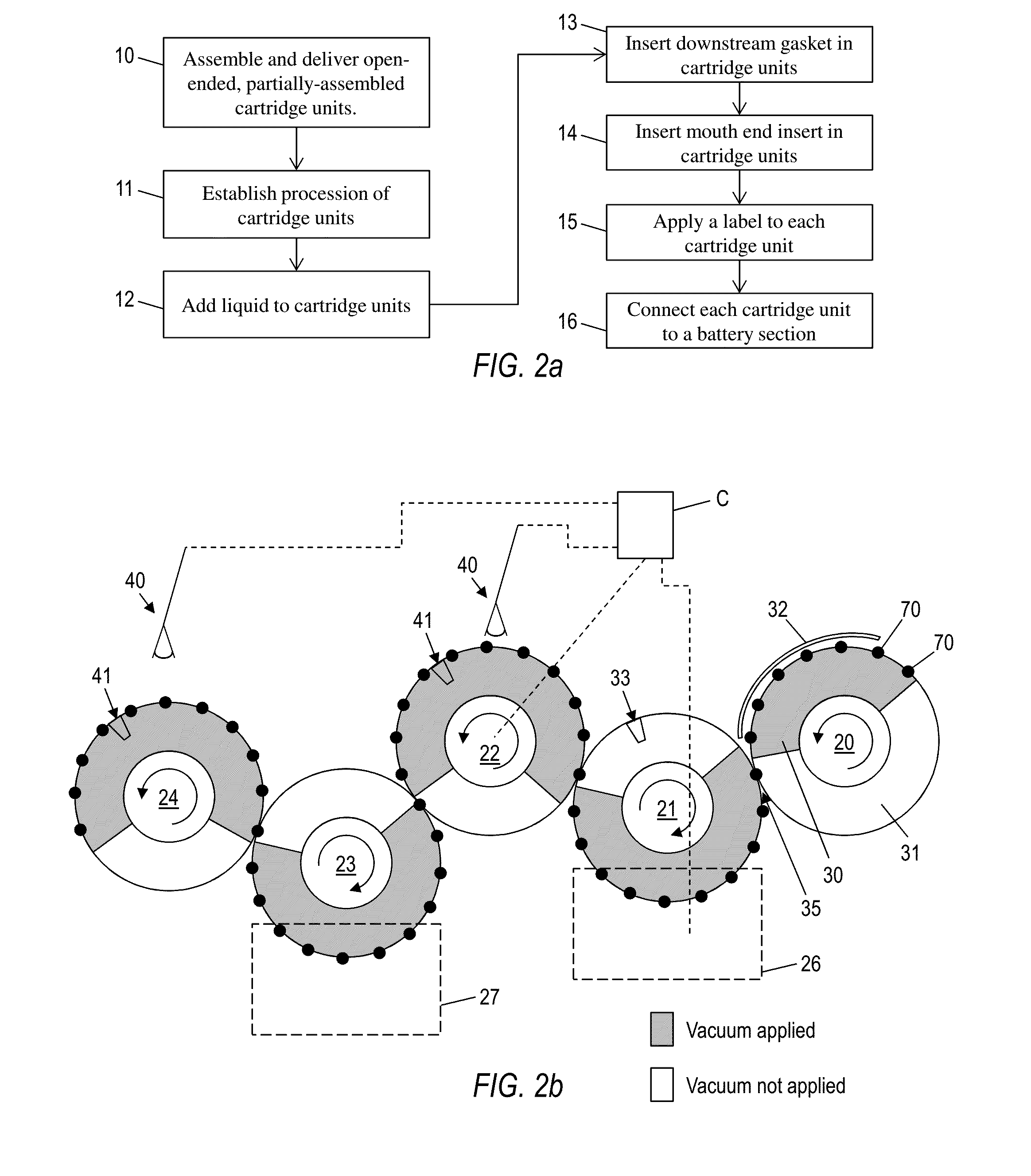

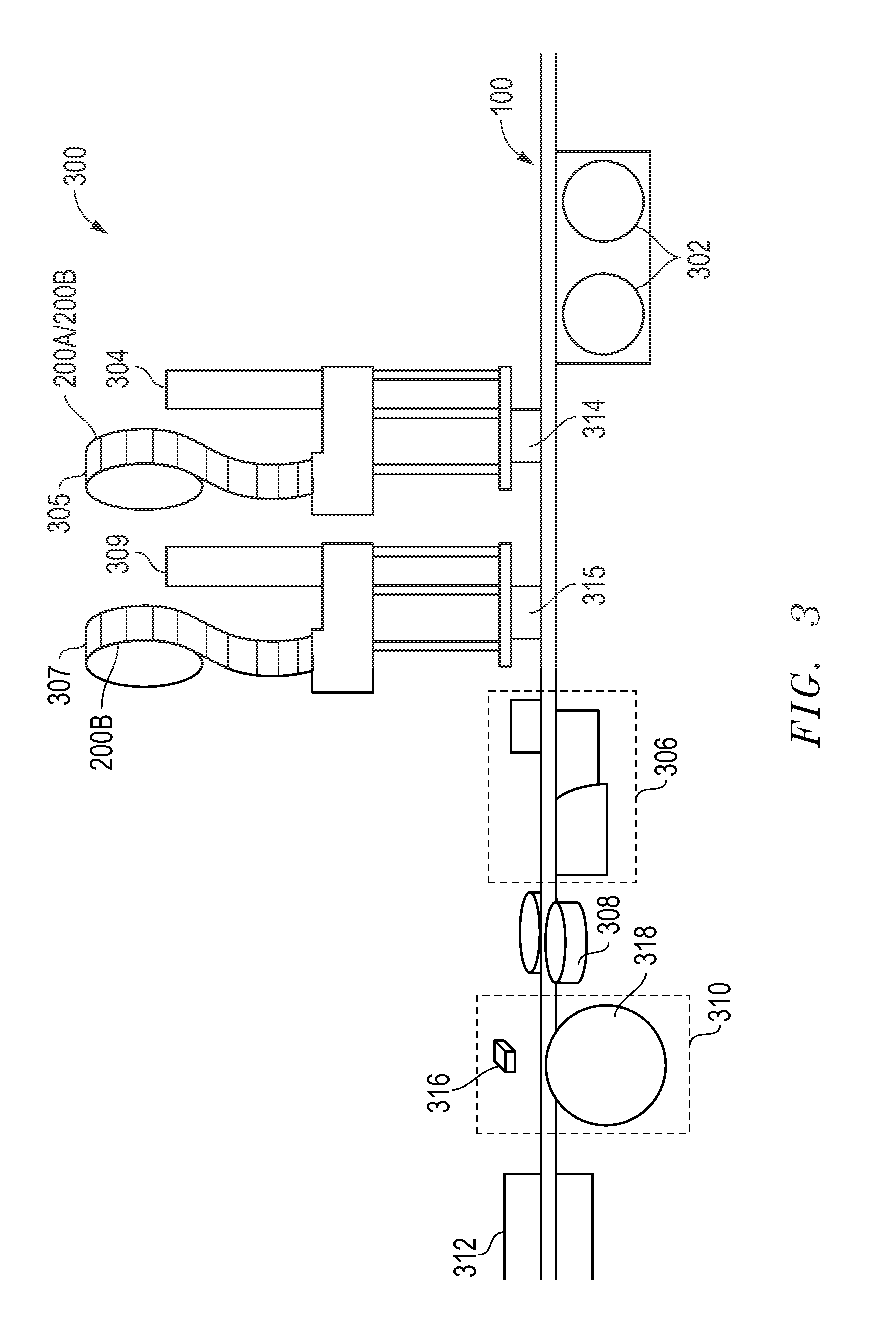

System and method for applying a label for the automated production of e-vapor devices

A system for use in manufacturing vapor-generating articles may include a rotatable drum that is configured to hold a plurality of the vapor-generating articles. The system may also include a tagging drum that is configured to tag a respective label to a housing of each of the vapor-generating articles. The system may also include a pressing roller that is configured to press a leading edge of the label against the housing after the tagging. The system may further include a rolling drum that is configured to roll the label around the housing after the pressing.

Owner:AKRIA CLIENT SERVICES LLC

Label printer

A label for applying to a support in a flag-type mode and a tape printer for printing the label to provide the correct size of printed and unprinted areas is described, wherein the label has a first area and a second area adjacent to the first area. The first area and the second area are arranged in use to provide a flag portion. The label further comprises a third area arranged on the other side of the second area to the first layer. The third area is sized to be wound around a periphery of the support.

Owner:DYMO (BVBA)

Method and apparatus for applying labels to cable or conduit

At least one guide roller is provided for guiding a moving cable or conduit. At least one tamping device comprising at least one tamping pad is provided for applying at least one label onto the moving cable or conduit. A guide shoe assembly comprising at least one guide shoe is provided for pressing the at least one label directly against at least one side of the moving cable or conduit. A method for applying labels is also provided. A method comprising guiding a cable or conduit to a labeling unit with a set of guide rollers, affixing a label to the cable or conduit with at least one tamping device, and pressing the label against at least one side of the cable or conduit using at least one guide shoe.

Owner:ENCORE WIRE CORP

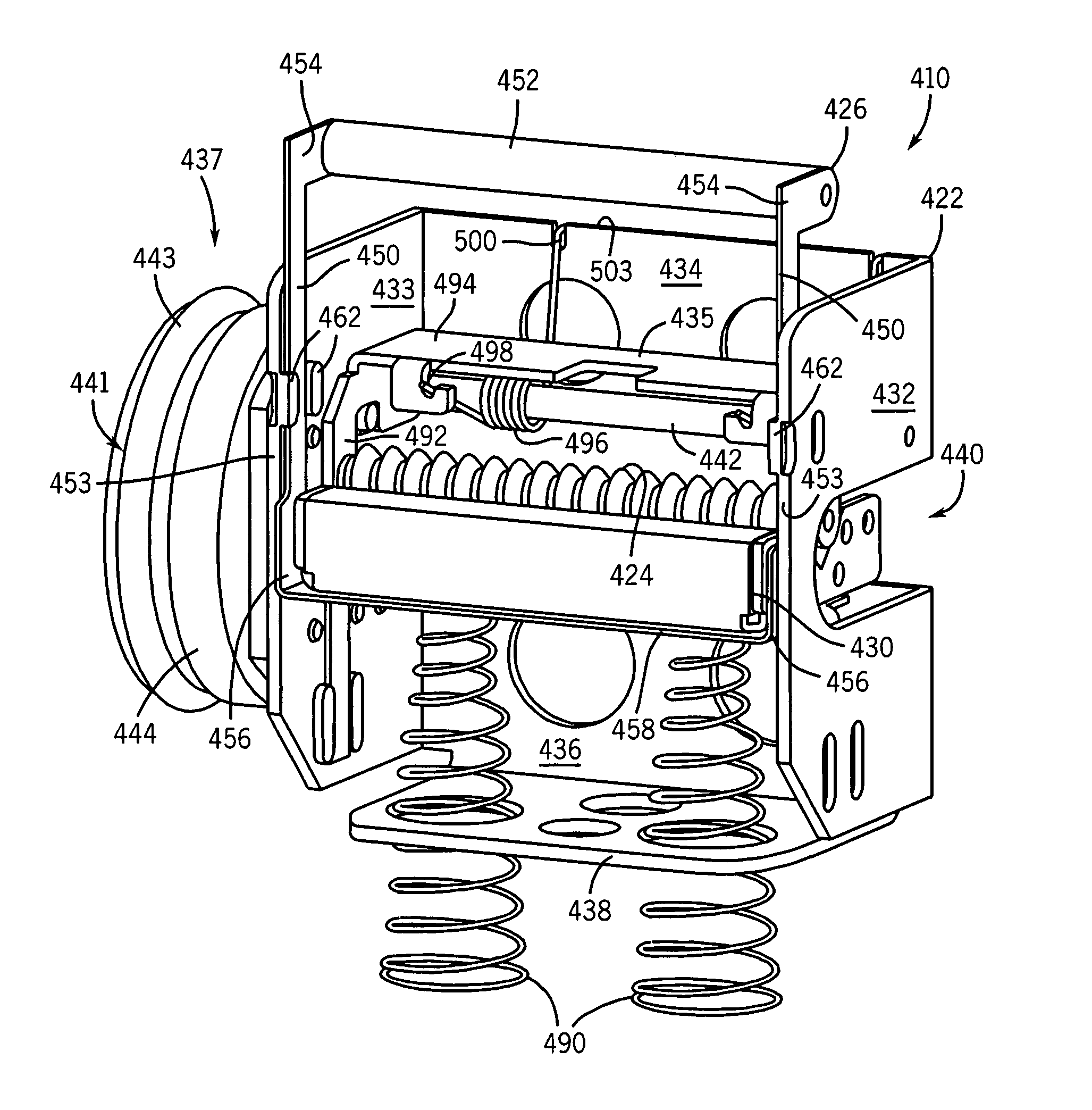

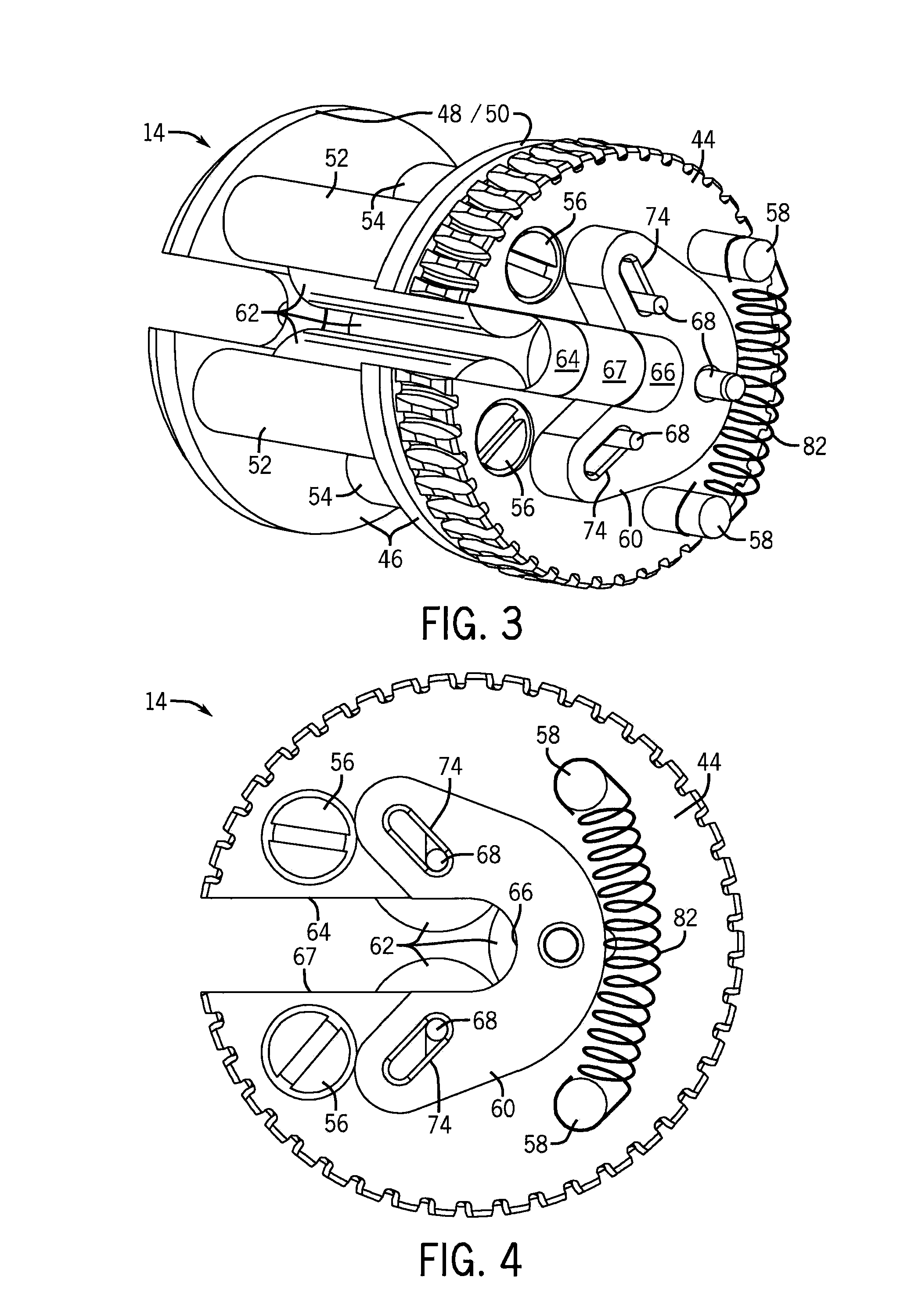

Label wrapper block assembly

ActiveUS7178572B2Mechanical working/deformationWrapper folding/bending apparatusEngineeringMechanical engineering

A label wrapper block assembly for mounting in a rotatably mounted wrapper frame in a label wrapper assembly includes a base having opposing ends joined by a top surface and a bottom surface. A channel extends between the ends in the top surface for receiving an object being wrapped by the label wrapper assembly. At least one biasing member is extendible into the channel for urging the label against the object received in the channel. In one embodiment, the at least one biasing member is a flexible material stretched across the base top surface.

Owner:BRADY WORLDWIDE INC

Tagger for Agricultural Baler

A tagger assembly has a tagger for affixing labels onto a lineal object binding a bale of agricultural crop material. The tagger having an input port for receiving the lineal object and an output port for evacuating the lineal object, and at least one retaining element for tensioning the lineal object, more particularly for tensioning the lineal object when it is raised from an initial position close to the bale to a raised position further away from the bale, for affixing a label.

Owner:BLUE LEAF I P INC

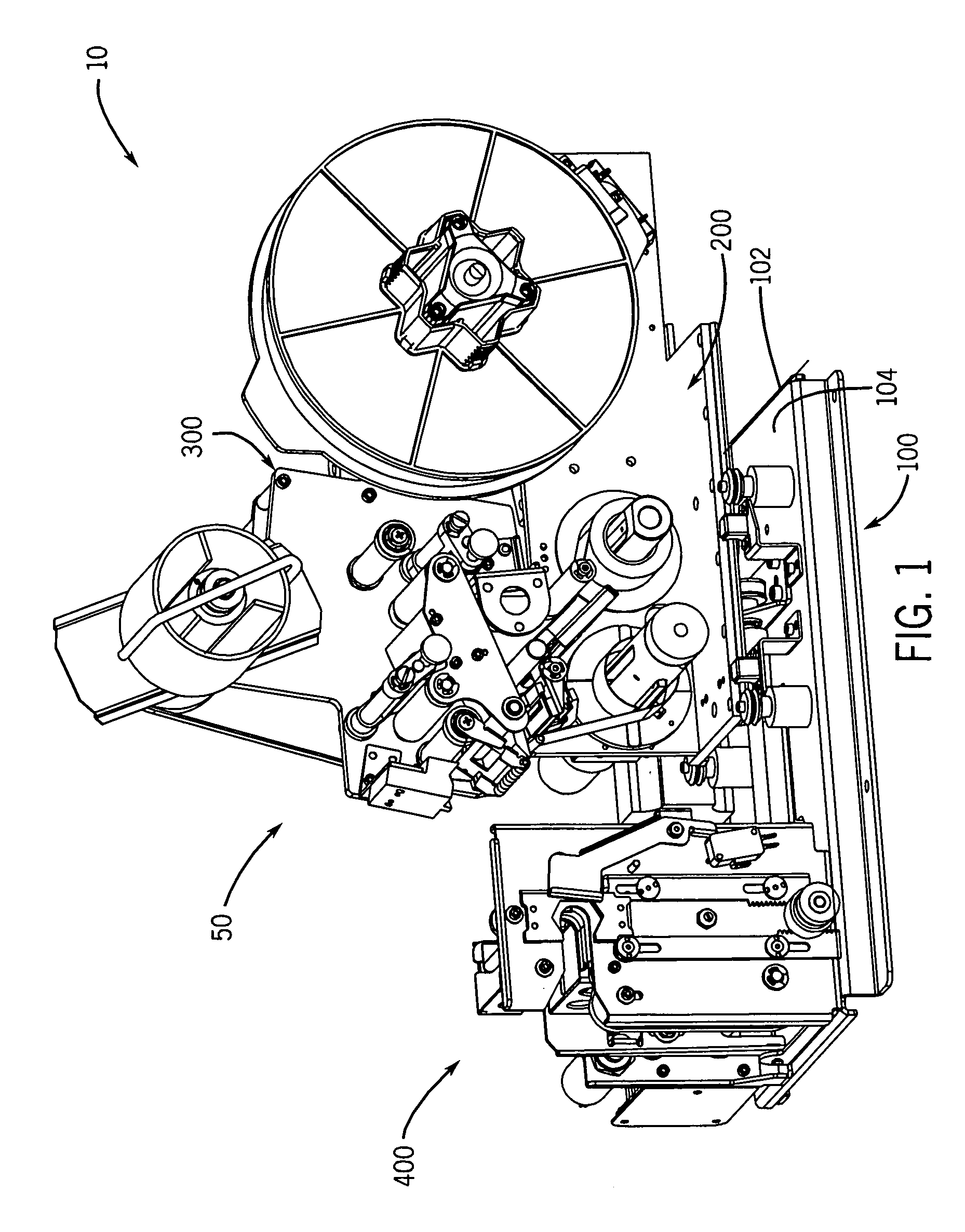

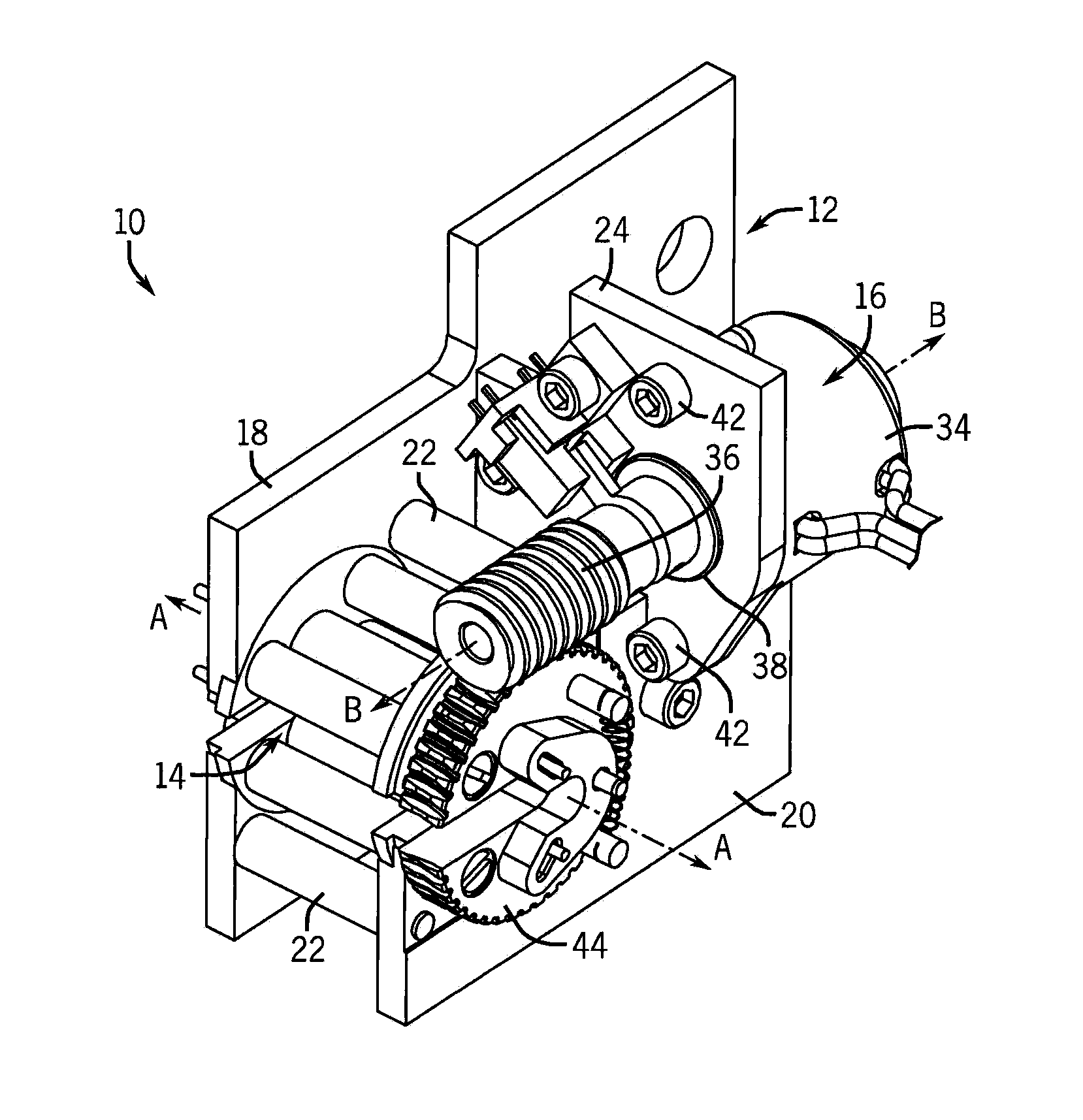

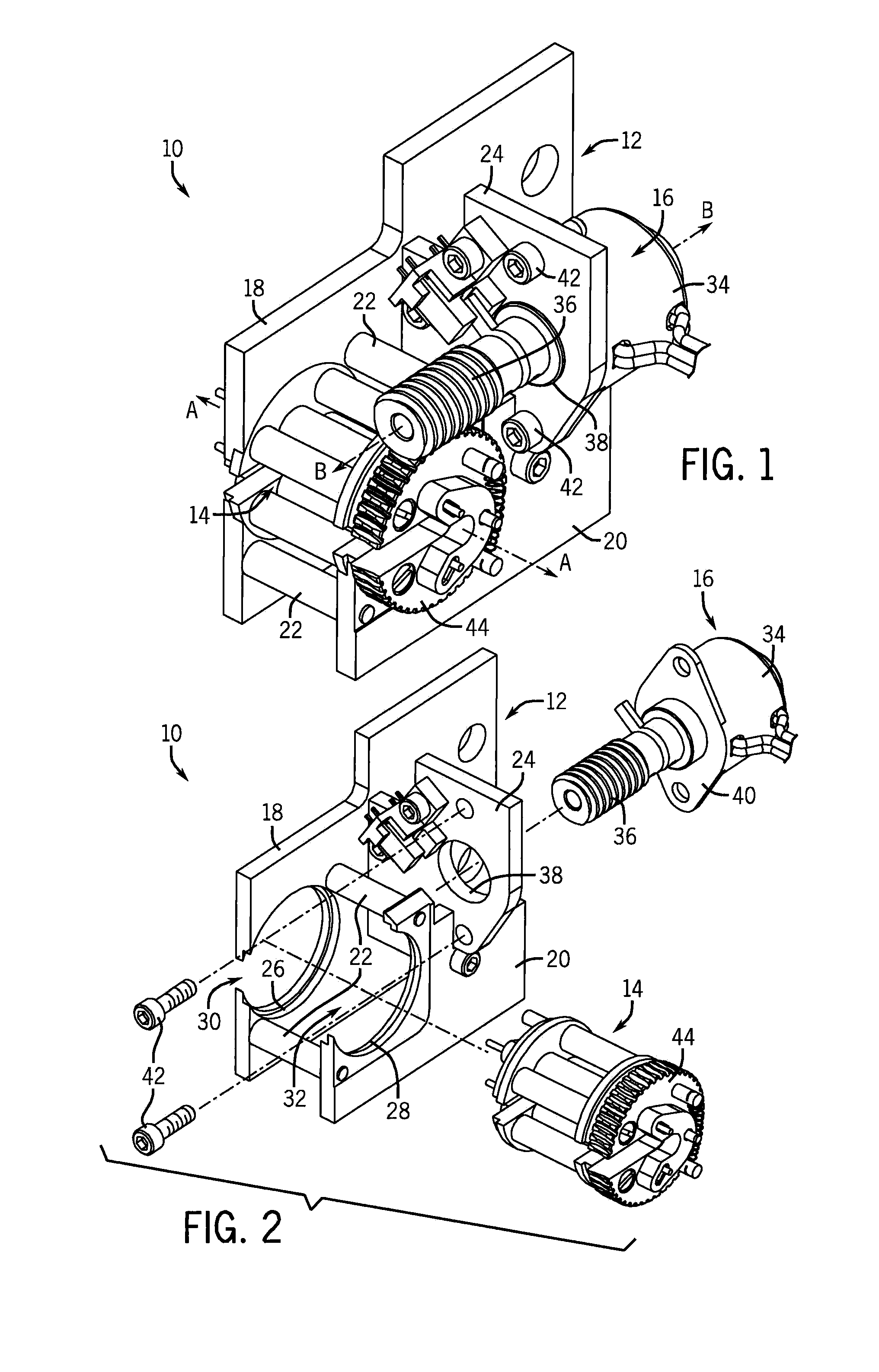

Label applicator

InactiveUS6875304B2Eliminate the problemLamination ancillary operationsPaper/cardboard articlesEngineeringPaper sheet

A label applicator that prints and applies a label onto an elongated object, such as a wire. The label applicator includes a base assembly having an upper surface. A printer is fixed to the base assembly for printing indicia on a label to form a printed label. A label wrapper is fixed to the base assembly adjacent to the printer for receiving the printed label and an object. In operation, the printer feeds the printed label into the label wrapper to form slack in the label to remove tension from the label prior to the label wrapper wrapping the label onto the object.

Owner:BRADY WORLDWIDE INC

Label applicator

ActiveUS7469736B2Minimal flaggingEasily kittedLaminationLamination apparatusCircular discElectric wire

An apparatus and method for wrapping adhesive backed labels around elongate articles, such as electrical wires including a rotatable puck assembly having an interrupted circumferential surface defining an opening for receiving an elongate object to be labeled and wing members for applying the label during rotation.

Owner:HELLERMANNTYTON CORP

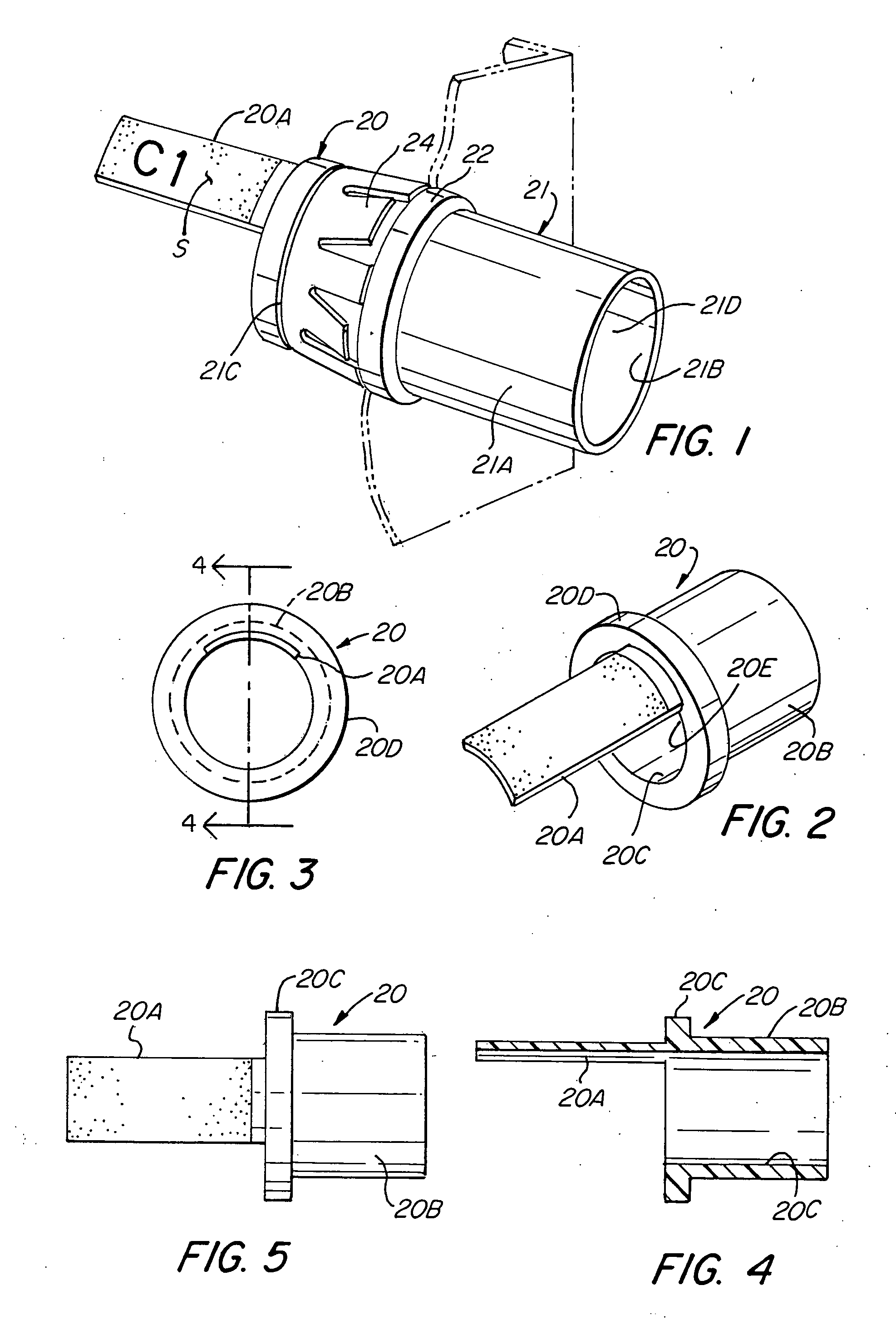

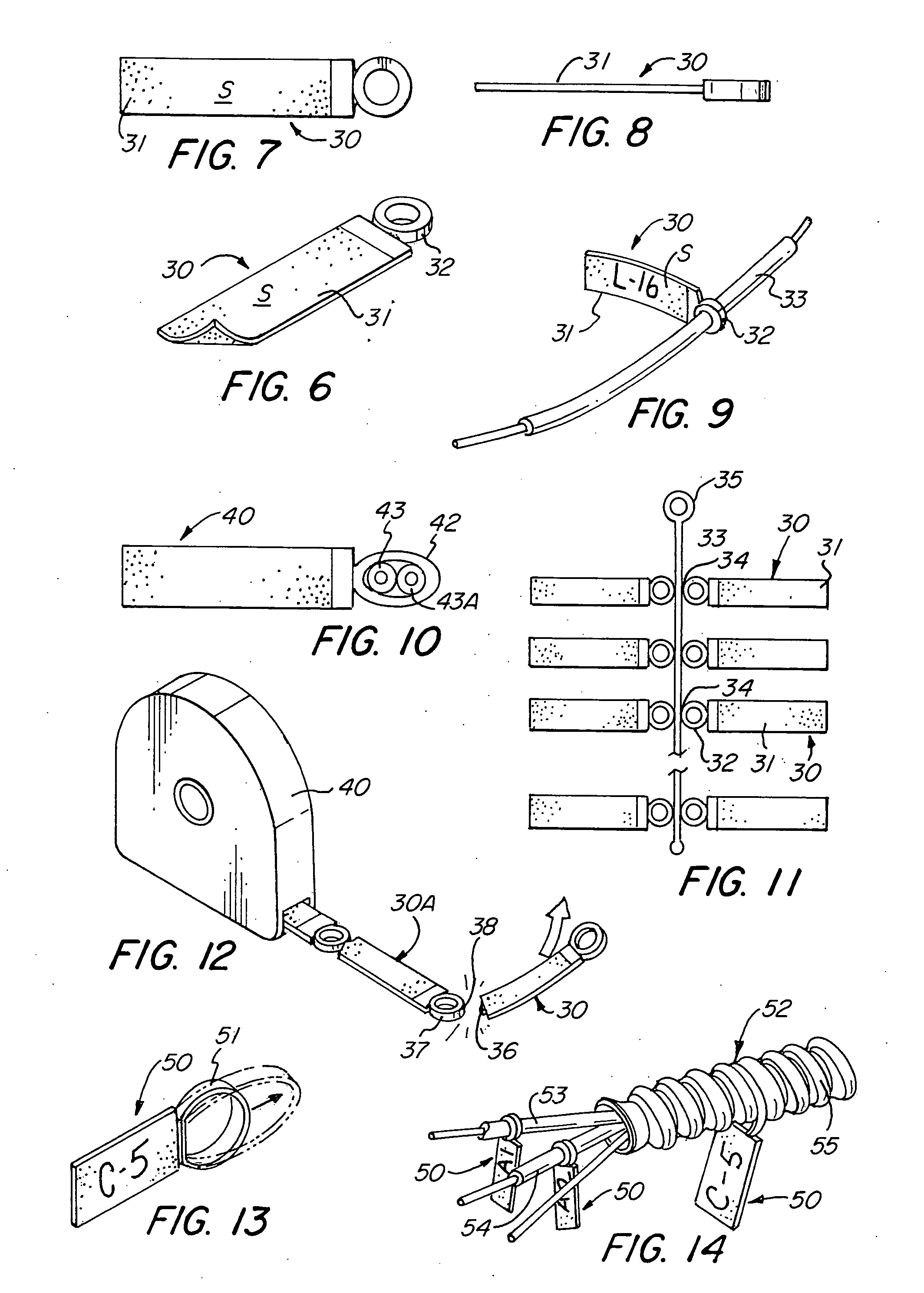

Wire/cable identification device

ActiveUS20090139743A1Improve distributionSimple structureStampsInsulated cablesElectricityIdentification device

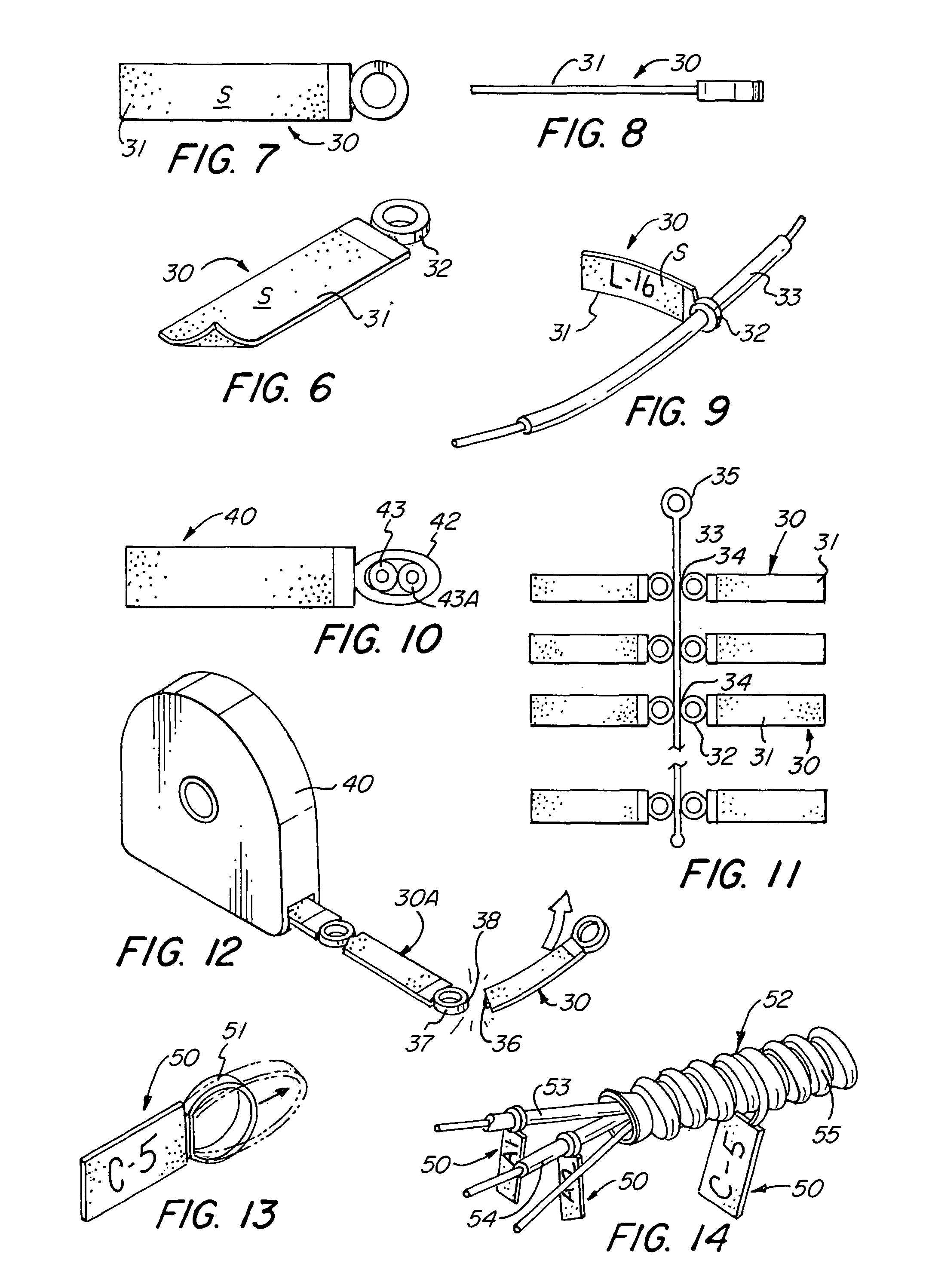

An electric wire identifier that includes an anti-short bushing in the form of an electrical insulating ring-like insert fitted onto the end of a metal or armored clad cable that defines the terminal end of the armored cable or into the end of an electrical connector that is generally inserted through a knock-out hole of an electric box or panel, and which bushing includes an integral extension or surface capable of retaining thereon suitable identifying indicia that is rendered visible throughout the lifetime of the electrical installation. In another form of the invention, the wire identifiers, in the form of a label or tag having a loop attachment that may be arranged in a tree or roll whereby the individual labels or tags can be readily dispensed as needed.

Owner:BRIDGEPORT FITTINGS LLC +2

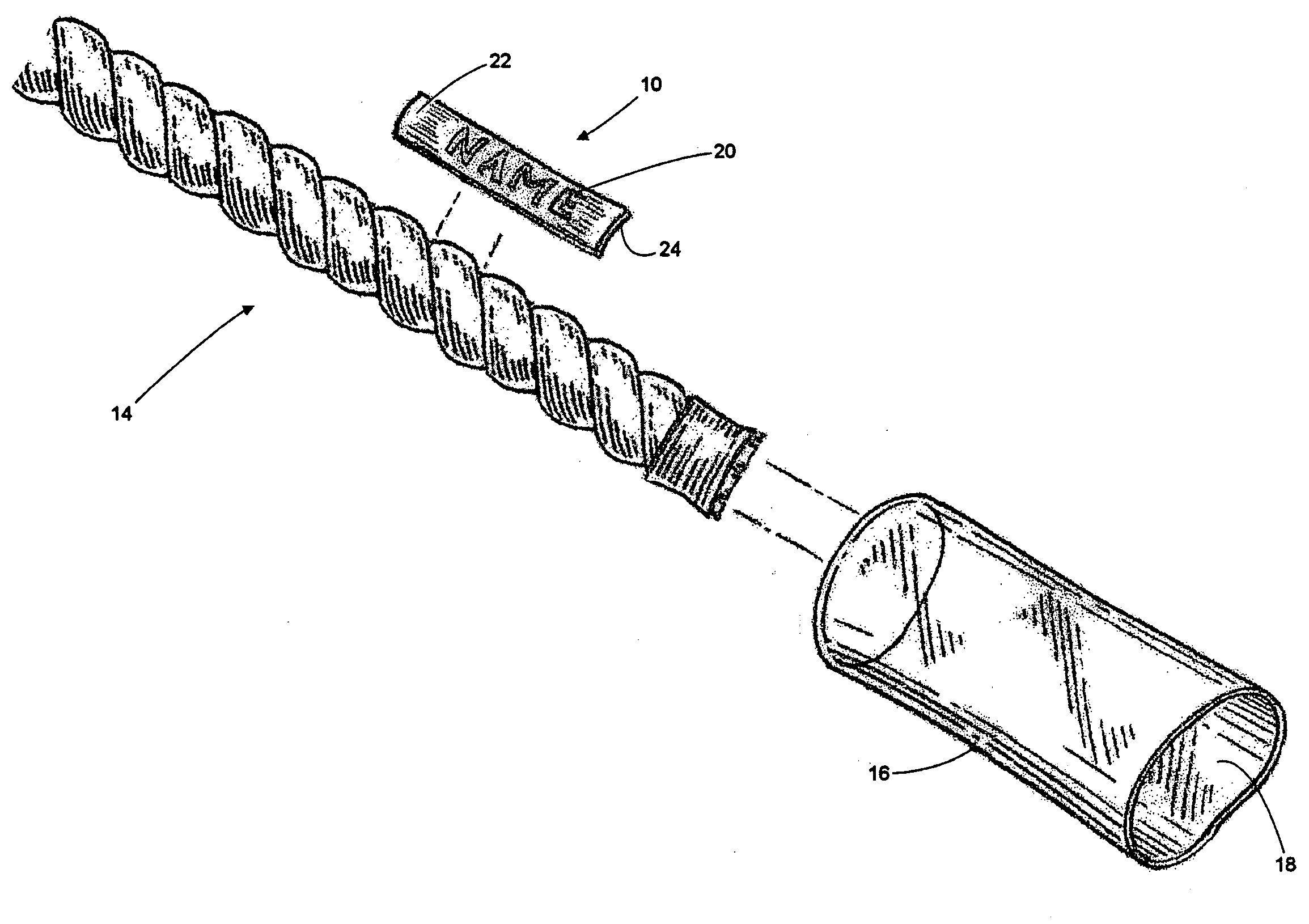

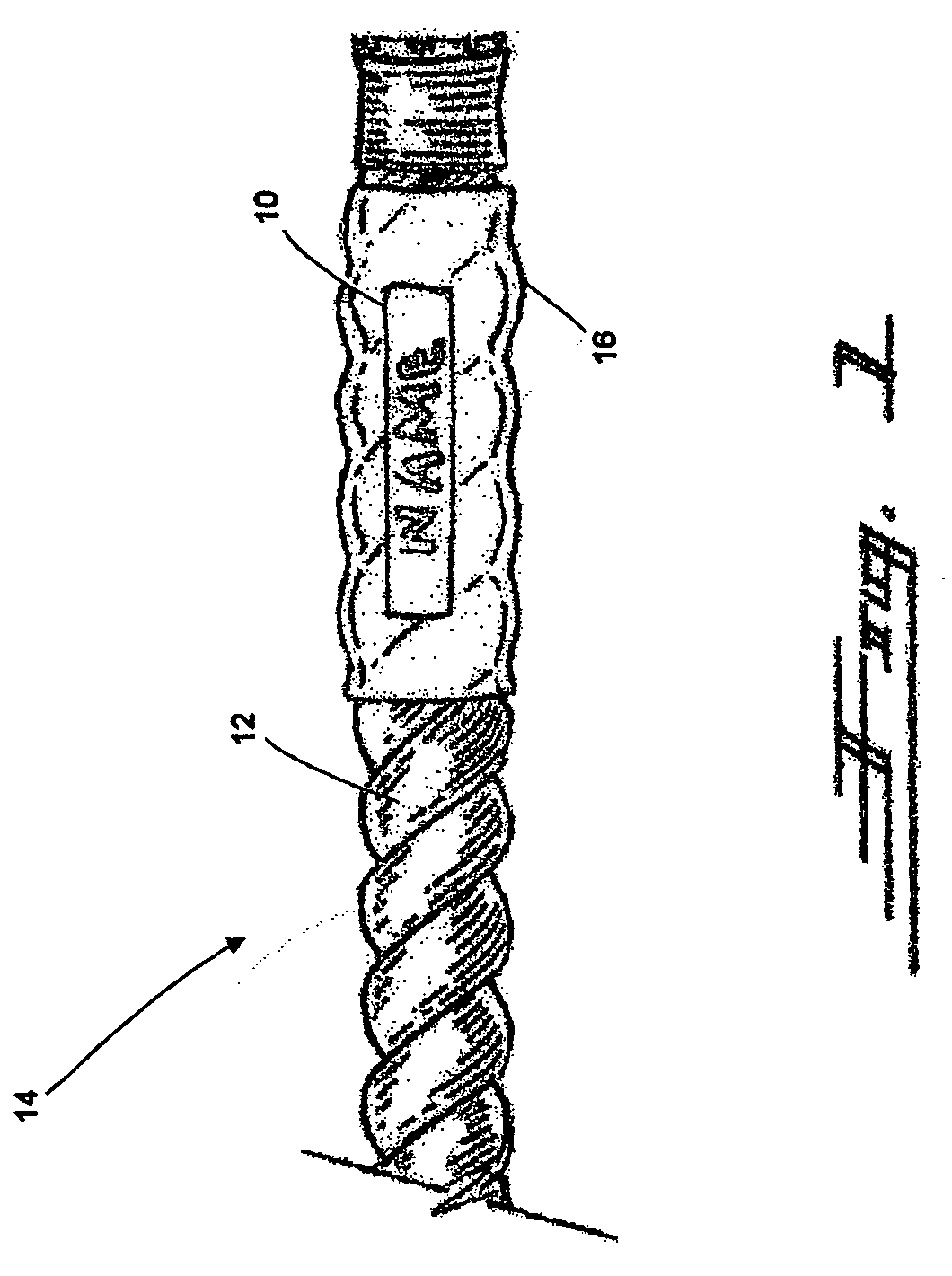

Shrink wrap labeling system and method

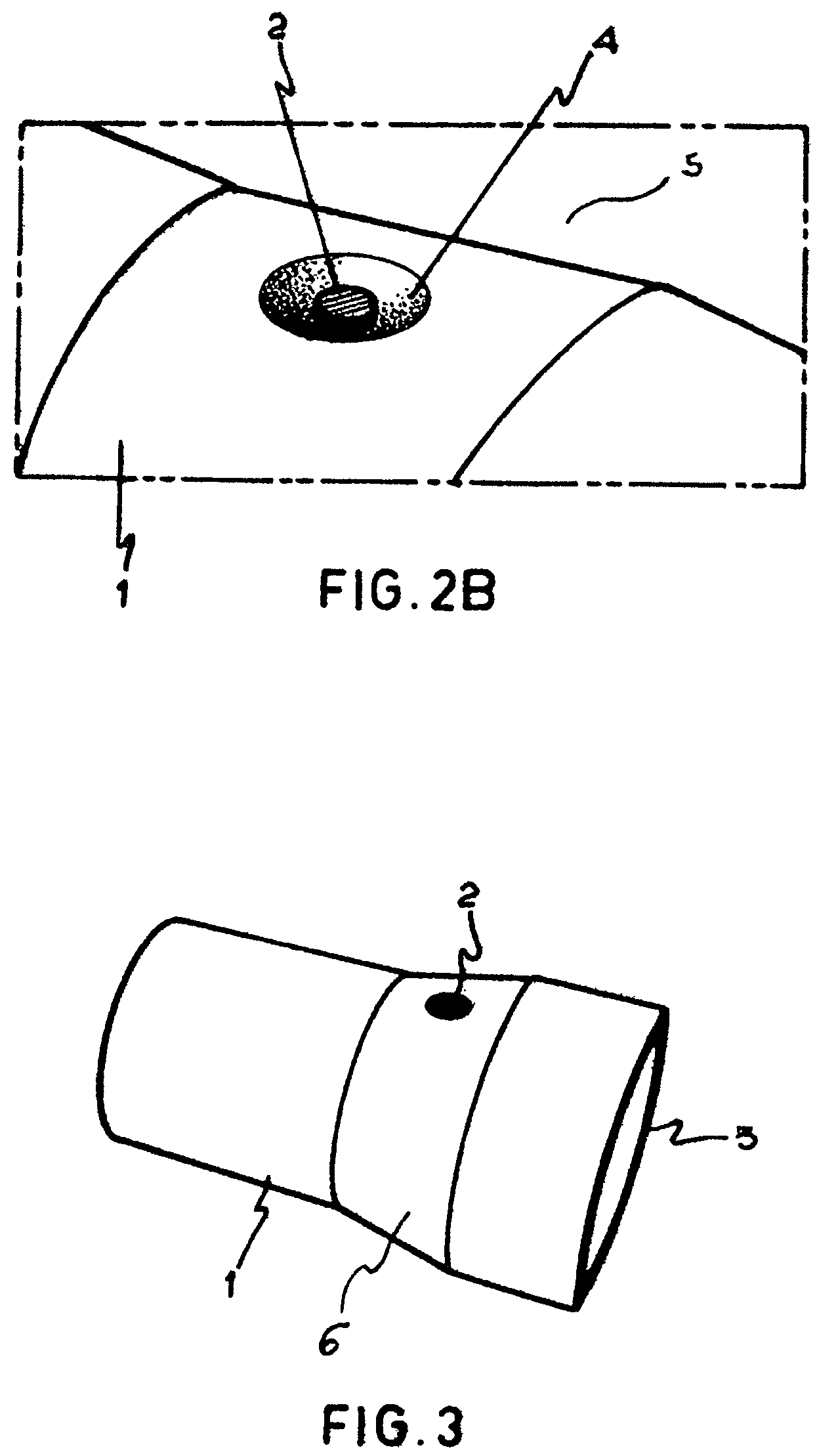

A method and kit are provided for labeling an object having a generally rounded outer surface, such as a cowboy lariat. The kit includes a label, substantially transparent heat-shrinkable tubing, and packaging suitable for storing, displaying, and distribution. Use of the invention is quick and efficient, providing a durable and easily recognizable label for imprinting an identifying mark thereon.

Owner:LOPEZ GEORGE A

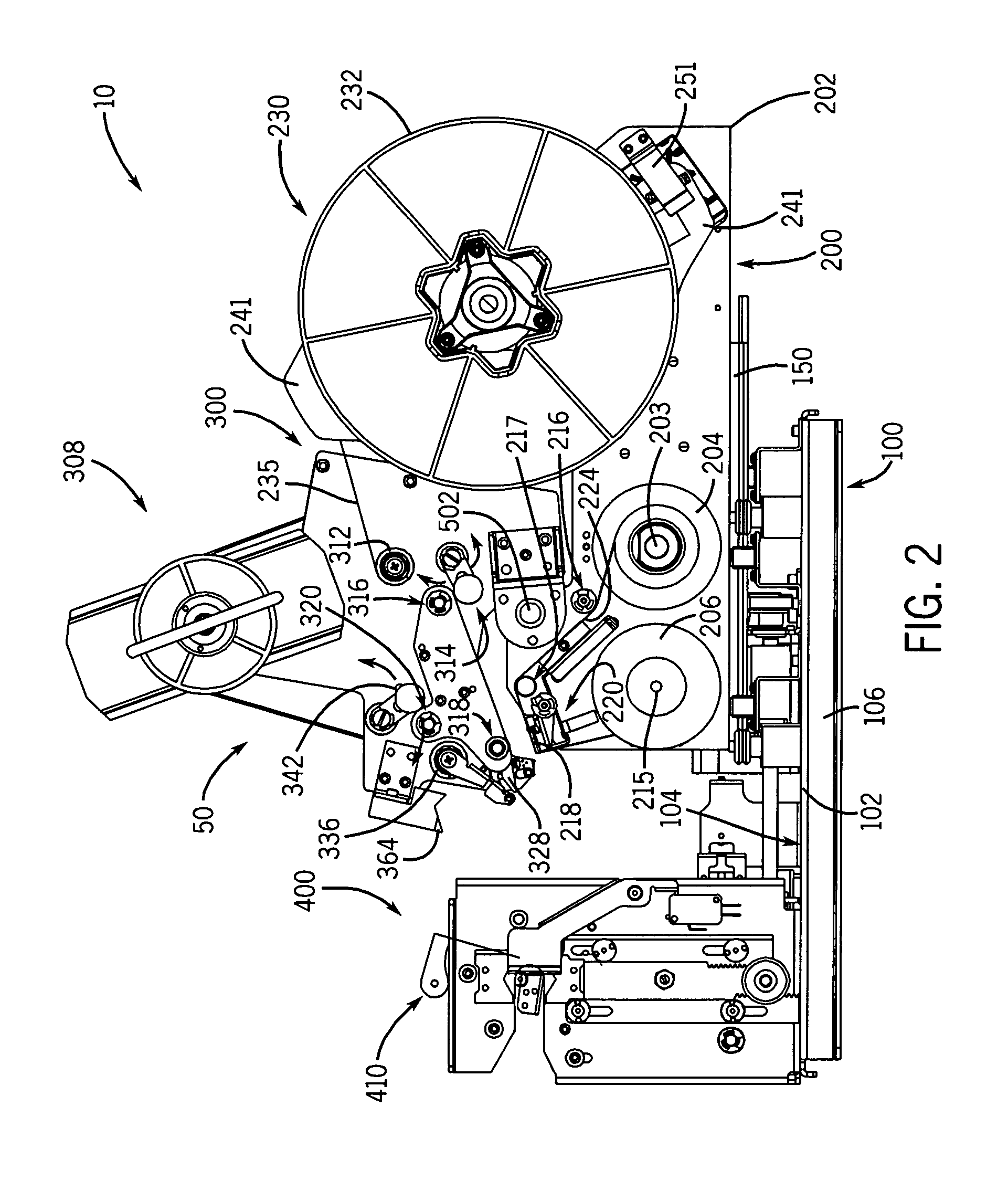

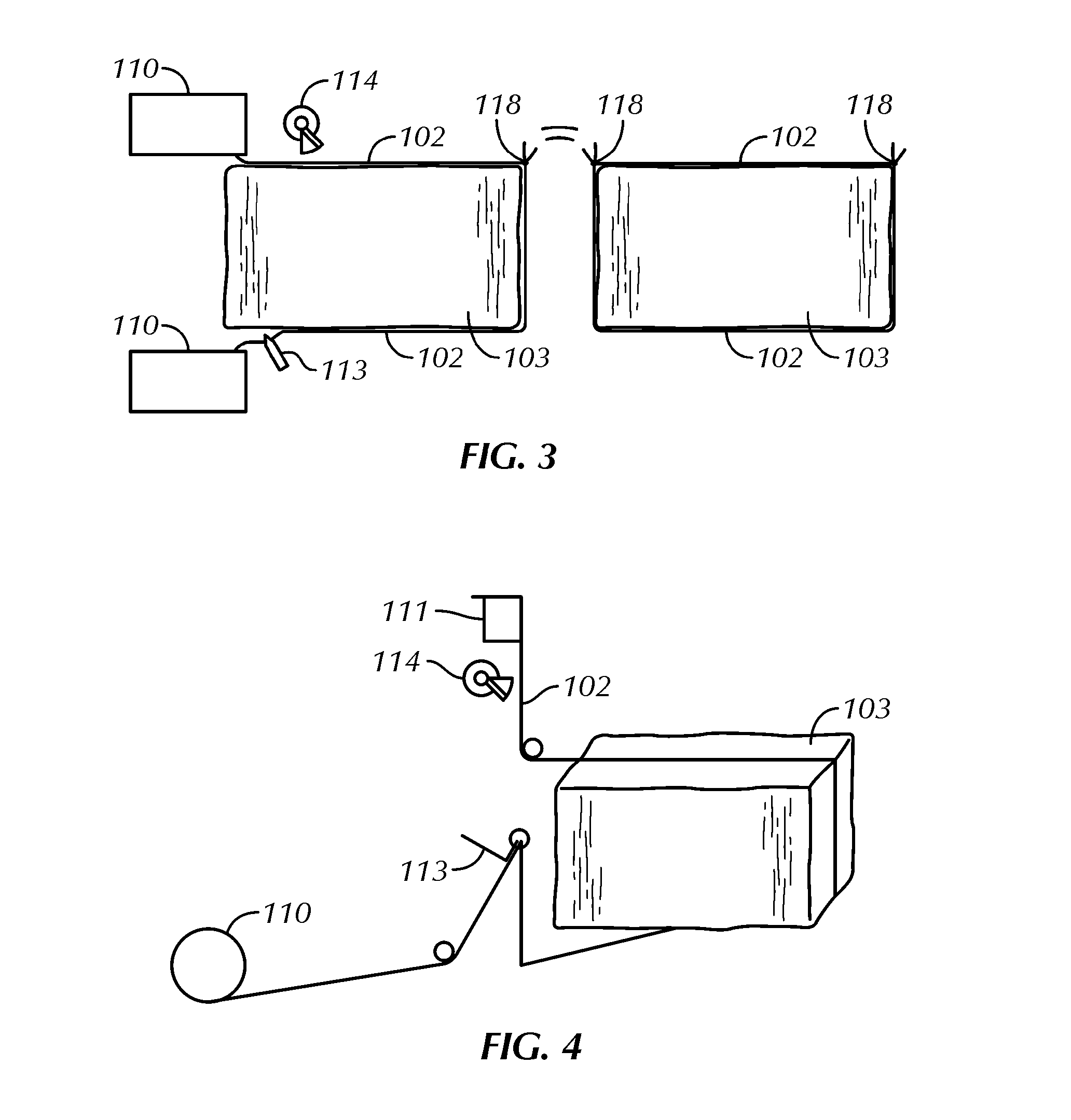

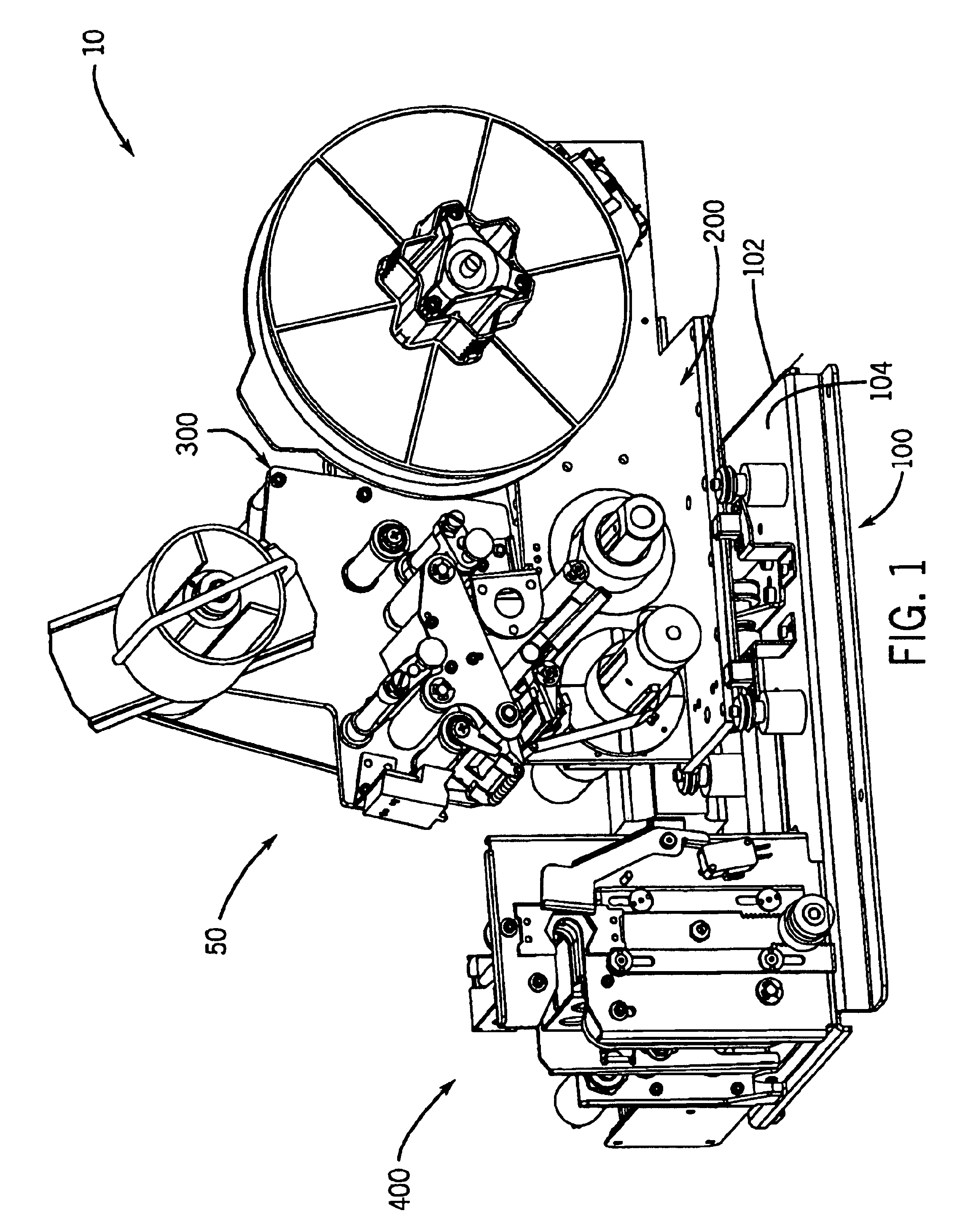

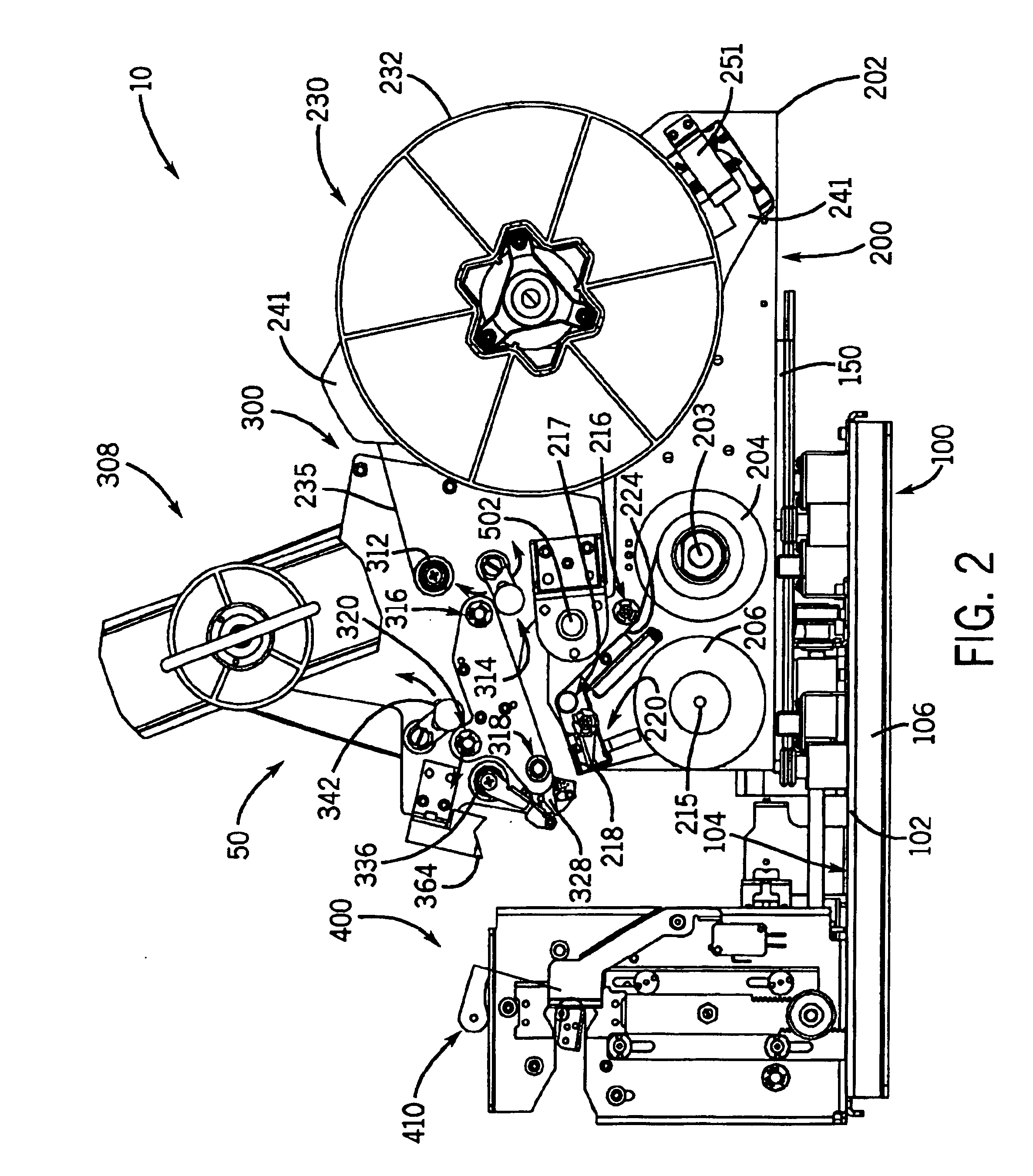

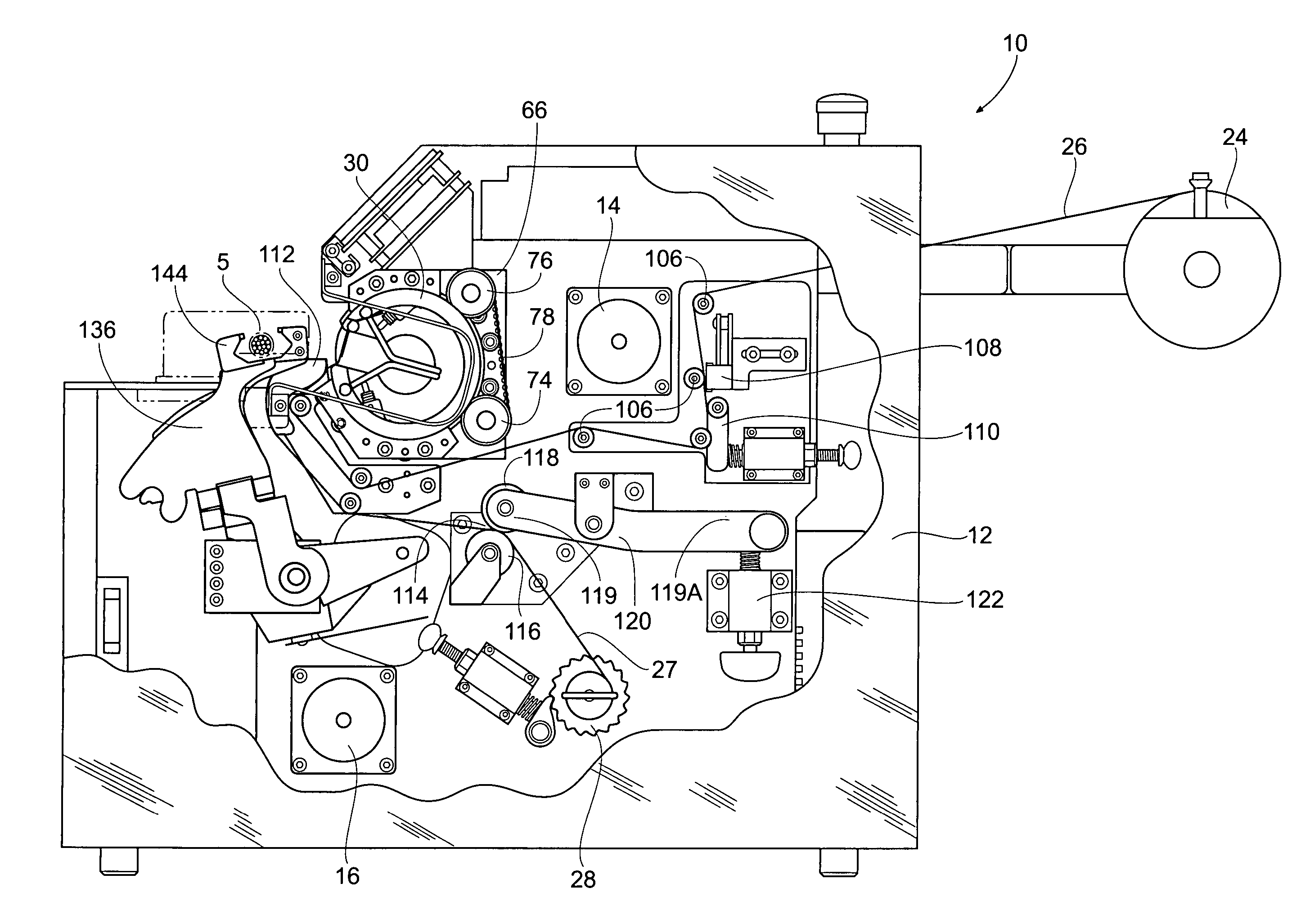

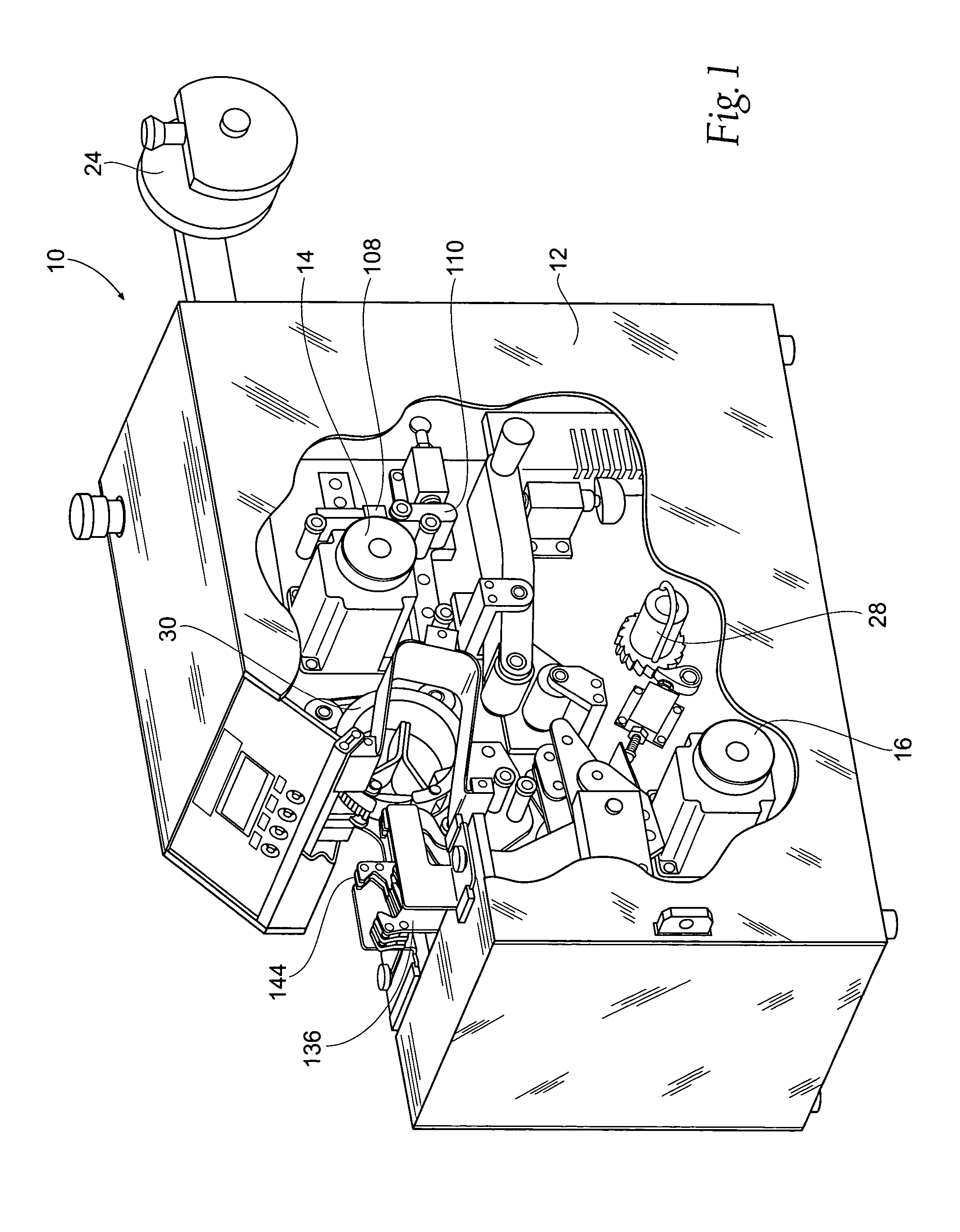

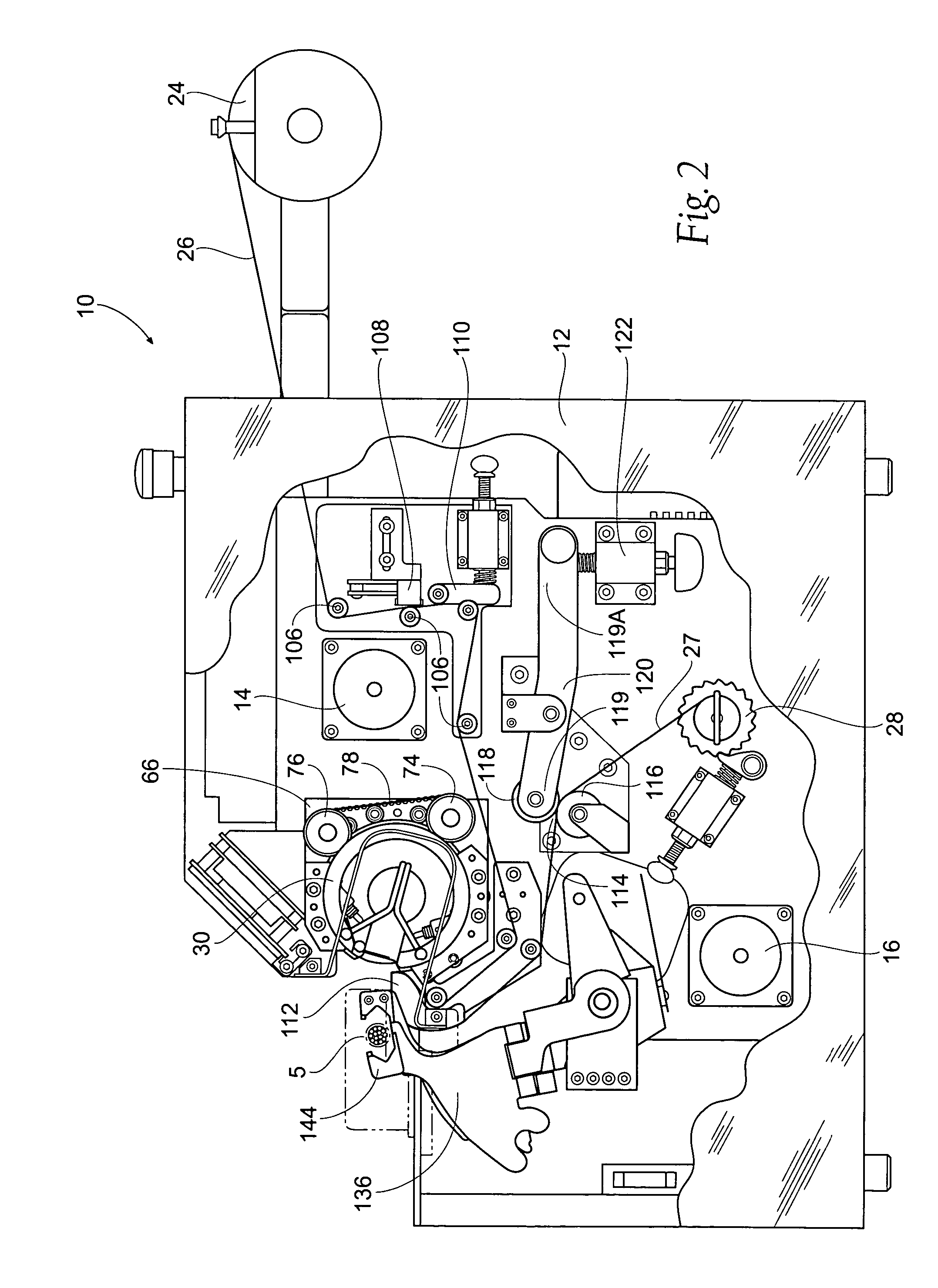

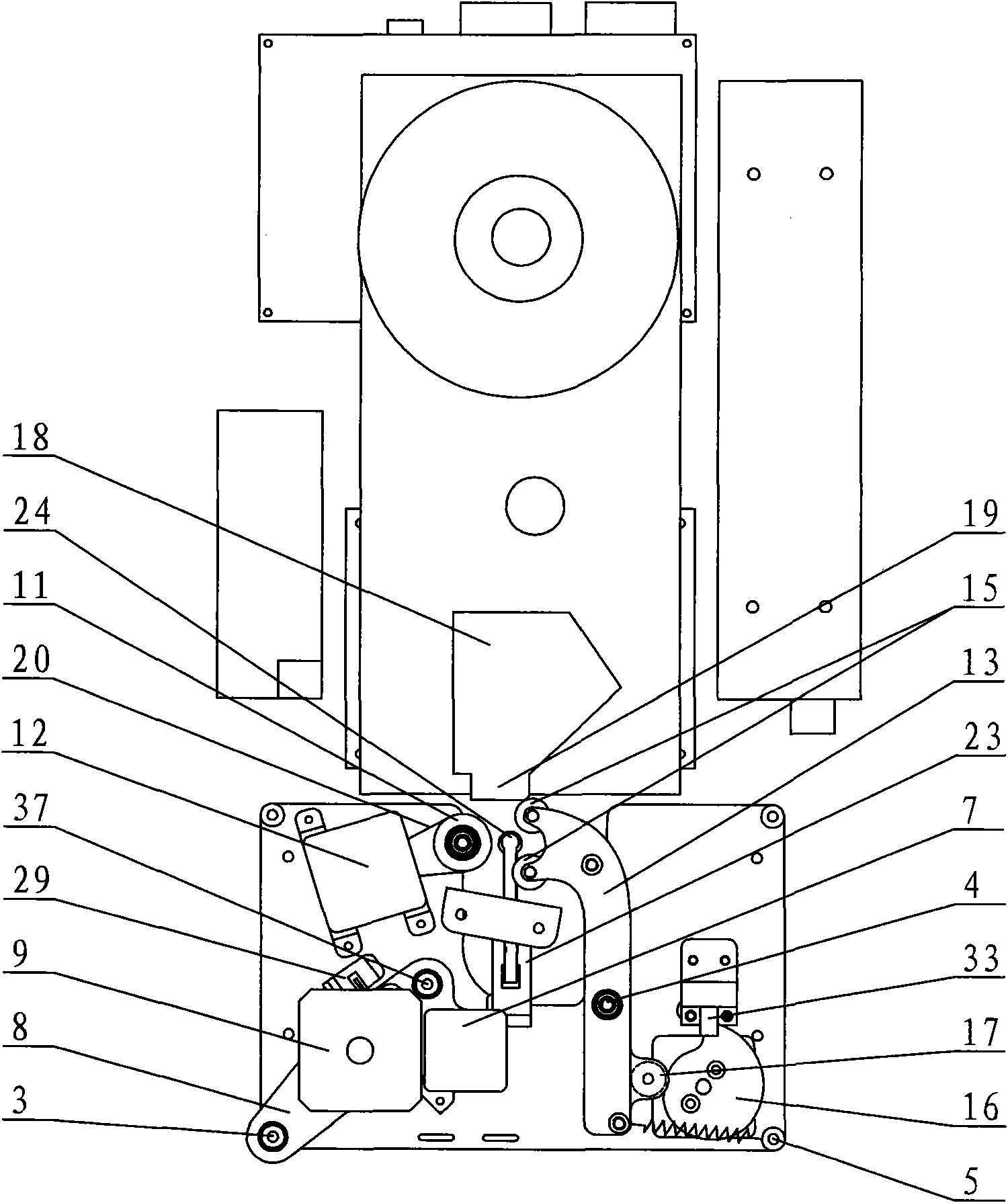

Coupon applicator and methods of applying coupon strips to grocery carts

An incentive-based grocery cart washing and disinfecting system including a consumer special-offer coupon applying apparatus, for use in a batch or continuous process comprising a housing having at least one pipe manifold with nozzles positioned therein to provide at least one treatment zone selected from pre-wash, wash, disinfecting, and rinse zones. In addition, blown air water-stripping / drying zones may be provided, with a heating source to assist drying. Following drying, a strip of specially adapted grocery coupons is optionally applied to the grocery cart handle, so that the coupons can be redeemed by customers during their subsequent shopping. The coupon strip comprises a leader portion and a coupon portion, and the leader can be wrapped and fixed around the grocery cart handle manually or by means of the automated machinery described. The system of the invention may be a fixed or mobile system, with the use preferably being on site at stores.

Owner:DM & BB

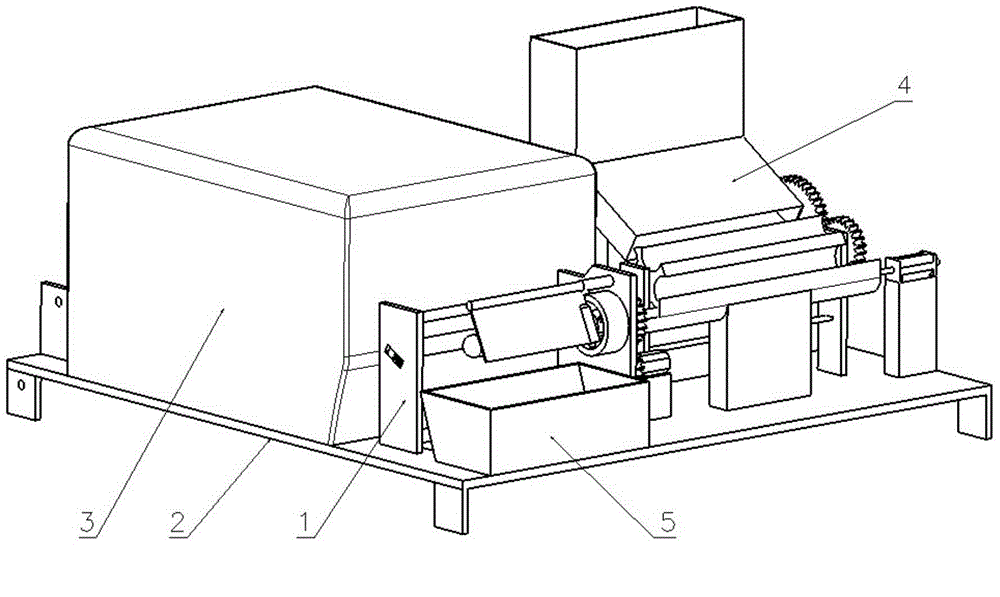

Test tube bar code gluing machine

ActiveCN101811586AEasy to readImprove pasting efficiencyManual label dispensersWithdrawing sample devicesEngineeringTest tube

The invention provides a test tube bar code gluing machine, relates to a machine for gluing a label on a test tube, and aims to provide a test tube bar code gluing machine with simple structure, tidy gluing and high efficiency. The test tube bar code gluing machine comprises a frame and an execution part, wherein the execution part is arranged on the frame, and comprises a test tube clamping device, a test tube supporting device, a test tube rotating device and a bar code printing and gluing device; the test tube clamping device, the test tube supporting device, the test tube rotating device and the bar code printing and gluing device comprise a corresponding power part respectively; the power part drives the execution part to execute the following actions: a, the test tube supporting device executes or cancels axial support to the test tube, and adjusts the height of the test tube; b, the test tube clamping device executes or cancels clamping to the test tube; c, the test tube rotating device drives the test tube to circumferentially rotate; and d, the bar code printing and gluing device glues the bar code on the wall of the test tube.

Owner:SHANGHAI JINYU LUOBO ELECTRONICS TECH

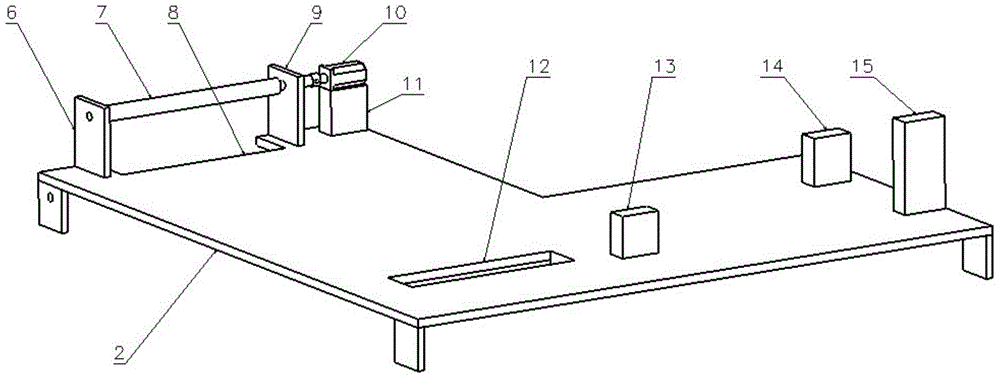

Test tube labeling machine with capabilities of automatic feeding and blanking

InactiveCN104691880ARealize automatic feeding processRealize blankingLabelling machinesLabelling elongated objectsDrive motorEngineering

The invention belongs to the field of labeling, relates to a test tube labeling machine with the capabilities of automatic feeding and blanking and aims at solving the problem of low efficiency of a labeling machine in the prior art. The test tube labeling machine mainly comprises a labeling mechanism, a bottom plate, a feeding mechanism and a blanking cabin, wherein the labeling mechanism consists of a turntable mechanism, a label pressing mechanism, a rotation mechanism and a rack assembly; the turntable mechanism consists of a turntable, a gear ring, a turntable driving gear, a turntable driving motor and a driving motor support seat; the feeding mechanism consists of a plate pushing mechanism, a rotary wheel mechanism and a feeding cabin mechanism which are fixed to the bottom plate sequentially. According to the test tube labeling machine, automatic feeding and blanking of a test tube can be realized, the labeling efficiency can be improved, test tubes with different diameters can be clamped, the test tubes stored in a feeding cabin can successfully enter the rotary wheel mechanism without the blockage phenomenon by adopting a cam mechanism, and the test tubes in a feeding cabin can singly and orderly enter a U-shaped groove for labeling by adopting the rotary wheel mechanism, the structure is simple, the debugging is convenient, the cost is low and the operation is convenient.

Owner:JILIN UNIV

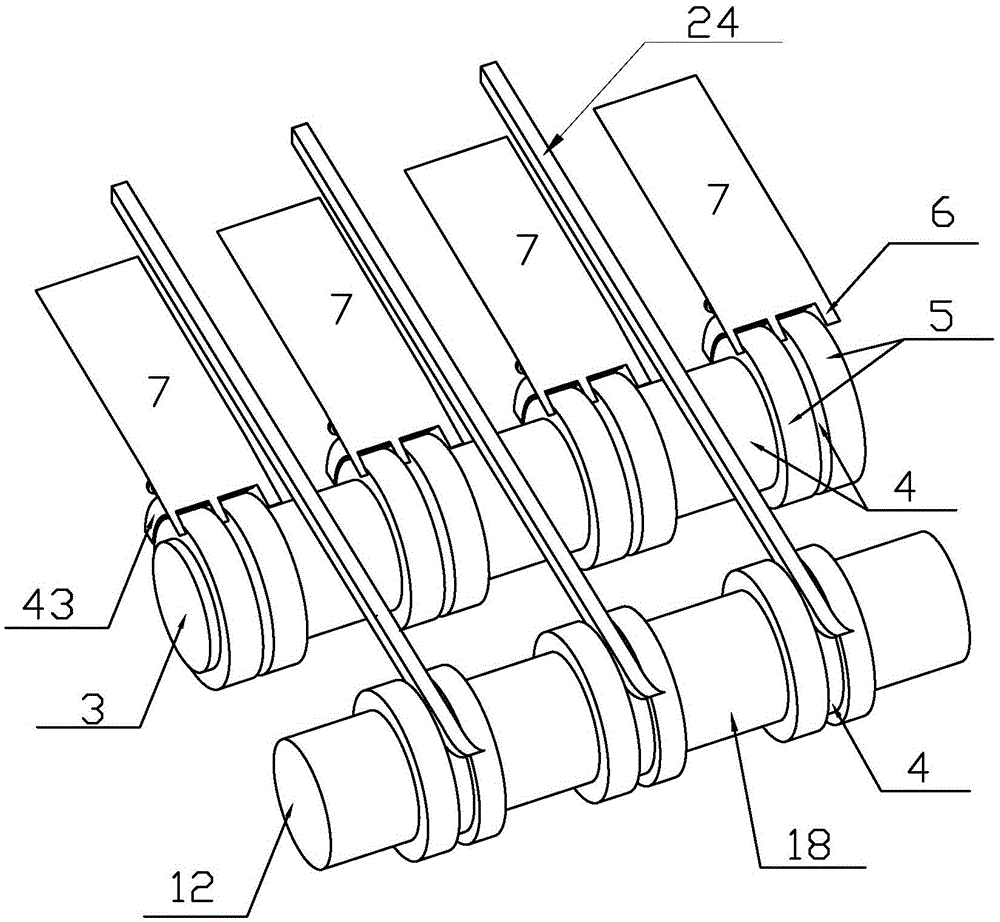

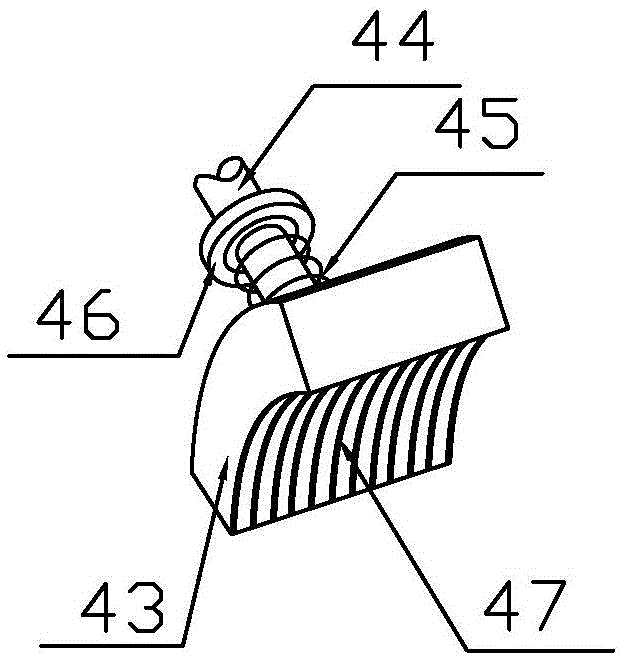

Equipment for sticking paint prevention paster to chopsticks and dedicated paster belt

ActiveCN102700788AImprove processing efficiencyIncrease productivityFilm/foil adhesivesLabelling machinesEngineeringAutomation

The invention belongs to the technical field of chopstick processing and discloses equipment for sticking paint prevention paster to chopsticks. The equipment mainly comprises a chopstick hopper, a chopstick delivery mechanism, a paster delivery mechanism, a rotary sticking mechanism, a power system for driving action components, and a receiving box. According to the invention, the delivery mechanisms delivers to-be-processed chopsticks and the paster automatically, a set of rubbing and rolling mechanism imitating manual rubbing and rolling actions is arranged, and the paster is stuck to the chopsticks through the reverse translational motions of an upper rubbing plate and a lower rubbing plate in the rubbing and rolling mechanism. Therefore, the automation in sticking the paint prevention paster to the chopsticks is realized. Besides, manpower and labor cost are effectively saved while the chopstick processing efficiency is greatly improved, and the equipment has direct promoter action and practical significance to the improvement on the chopstick production efficiency and the advancement of the chopstick processing technology.

Owner:ZHEJIANG SHUANGQIANG BAMBOO & WOOD CO LTD

Cylindrical material labeling machine and labeling method

InactiveCN104085575AHigh speedLow costLabelling machinesLabelling elongated objectsRolling paperGear wheel

The invention relates to a cylindrical material labeling machine and labeling method. A piece of cylindrical product packaging paper is pasted manually in a rolling manner, and the cost is high. The cylindrical material labeling machine comprises a rack, a paper feeding device, a gumming mechanism and a roll paper pasting mechanism, wherein the gumming mechanism comprises a hot melt glue groove and a gumming roller; the gumming roller is provided with multiple ring grooves to be divided into multiple annular gumming surfaces, paper pressing bulges are arranged above the gumming roller, and the two ends of the gumming roller are respectively provided with a lifting device; an upper fixed roller and a lower fixed roller are linked in the same direction by a meshing gear so as to form a paper pulling roller group, a paper drum group is composed of the upper fixed roller, an upper moving roller and a lower moving roller, the paper feeding device comprises a movable paper absorbing mechanism and a conveying chain mechanism, and the conveying chain mechanism is arranged on the upper stream of the gumming roller. The invention also relates to the cylindrical material labeling method. The cylindrical material labeling machine and method provided by the invention have the advantages that the speed is high, the cost is low, a pasted label is smooth and firm and the glue dosage is low, and can be used for pasting labels of party cannon, fireworks or other paper materials, plastics and metal materials.

Owner:王丽娜

Wire cable labelling machine

ActiveCN103395527AFully automatedImprove labeling qualityLabelling machinesLabelling elongated objectsEngineeringSelf locking

The invention provides a wire cable labelling machine. The wire cable labelling machine comprises a rack, an adhesive sticker conveying device, a bonding device, a wire cable conveying device and a self-locking type swinging device, wherein the wire cable conveying device is installed on the rack and used for conveying wire cables to the bonding device; the self-locking type swinging device comprises a first pivot shaft, a second pivot shaft, a first linkage element, a second linkage element, a third linkage element and a first driver; the first pivot shaft and the second pivot shaft are pivoted on the rack, one end of the first linkage element is installed on the first pivot shaft, the other end of the first linkage element is pivoted with one end of the second linkage element, the other end of the second linkage element is pivoted with one end of the third linkage element, the other end of the third linkage element is installed on the second pivot shaft, the first linkage element, the second linkage element, the third linkage element and the rack form a first crank rocker mechanism, the first linkage element, the second linkage element and the third linkage element correspondingly serve as a first crank, a first connection and a first rocker in the first crank rocker mechanism; the first driver is arranged on the rack and used for driving the first pivot shaft to rotate; the bonding device is installed on the second pivot shaft. The wire cable labelling machine provided by the invention is capable of improving labelling quality and efficiency for wire cables.

Owner:SHENGLAN TECH CO LTD

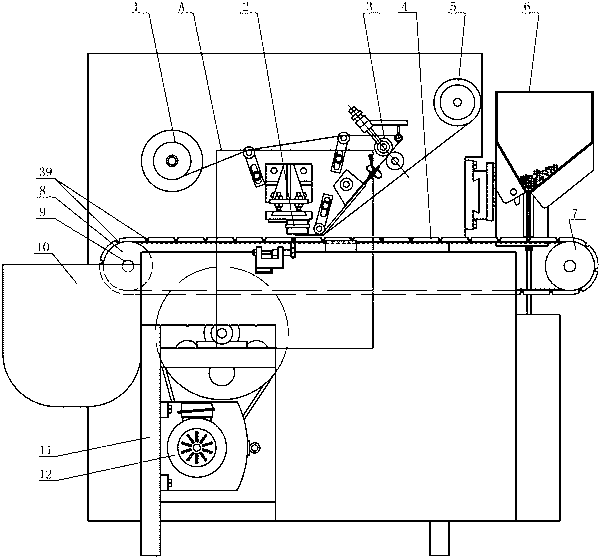

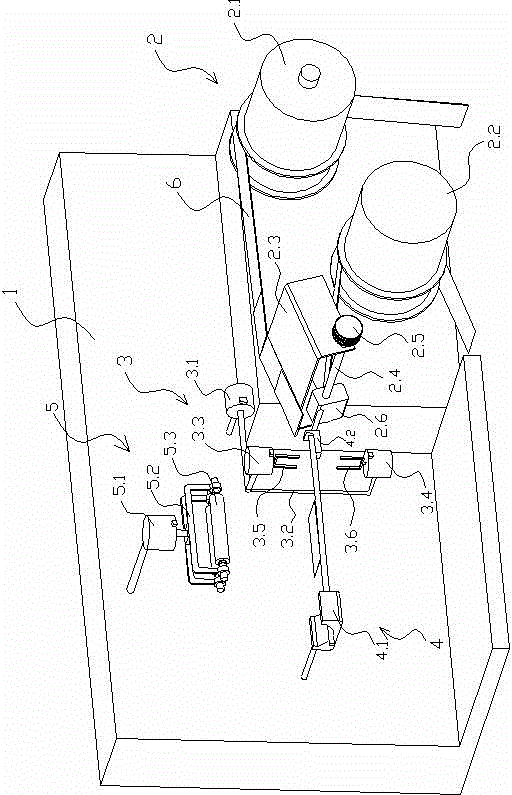

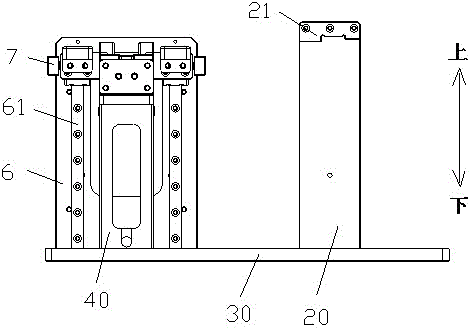

Automatic electric cable labeler and labeling method thereof

ActiveCN102717943AHigh speedSimple structureLabelling machinesLabelling elongated objectsEngineeringTransfer mechanism

The invention relates to an automatic electric cable labeler and a labeling method thereof. The labeler comprises a rack (1), a labeling feeding mechanism (2), a clamping and transferring mechanism (3), an electric cable supporting mechanism (4) and a compressing mechanism (5) are mounted on the rack (1), the labeling feeding mechanism (2) comprises an unwinding roller (2.1), a winding roller (2.2) and an adjusting plate (2.3), the adjusting plate (2.3) is hinged on the rack (1), the clamping and transferring mechanism (3) comprises a horizontally arranged transverse moving air cylinder (3.1), a piston rod of the transverse moving air cylinder (3.1) is provided with a vertical rod (3.2), an upper end and a lower end of the transverse moving air cylinder (3.1) are provided with an upper air cylinder (3.3) and a lower air cylinder (3.4) respectively, and piston rods of the upper air cylinder (3.3) and the lower air cylinder (3.4) are provided with an upper press block (3.5) and a lower press block (3.6) respectively. The automatic electric cable labeler is high in labeling efficiency, simple in structure and low in manufacturing cost.

Owner:JIANGYIN AKCOME SCI & TECH

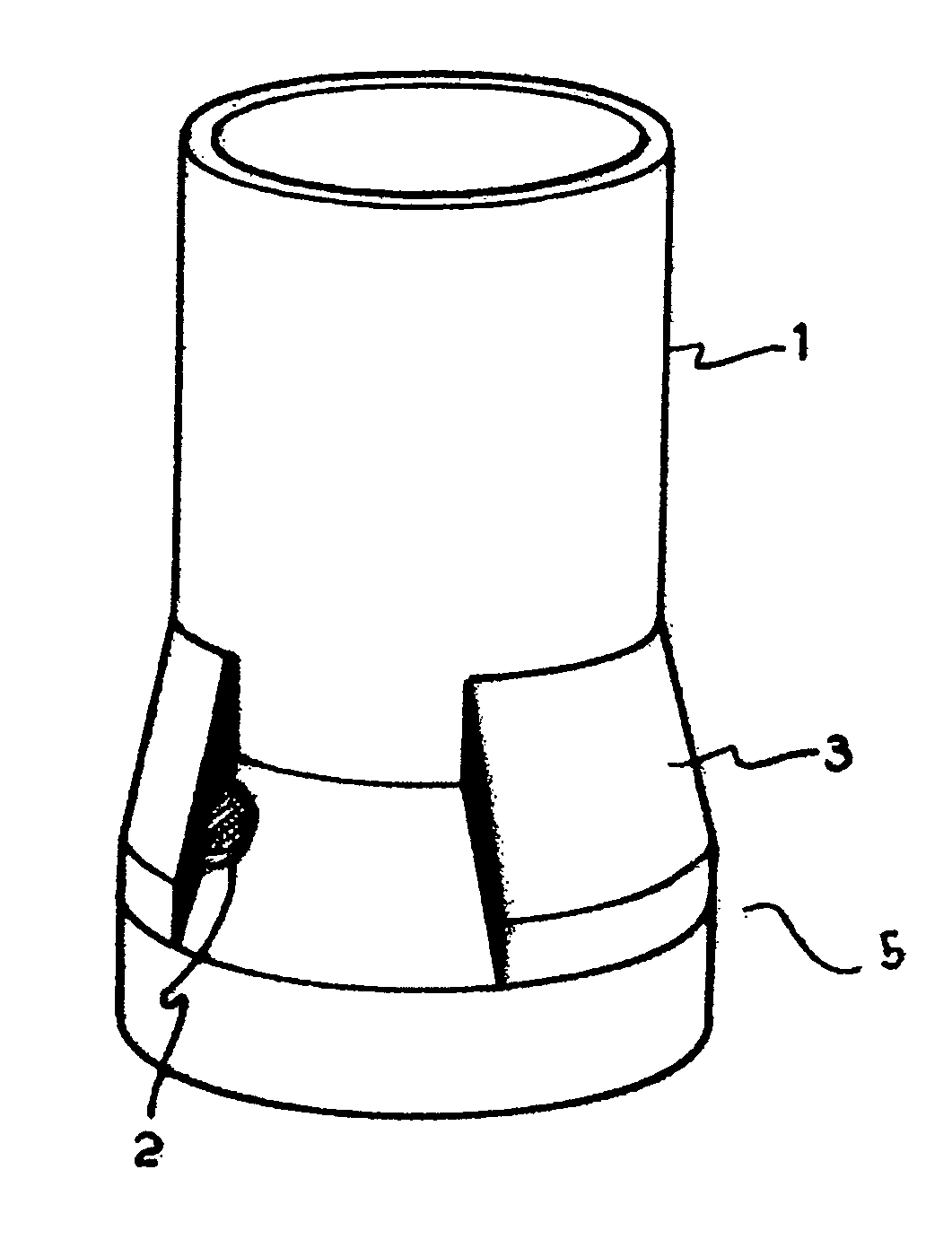

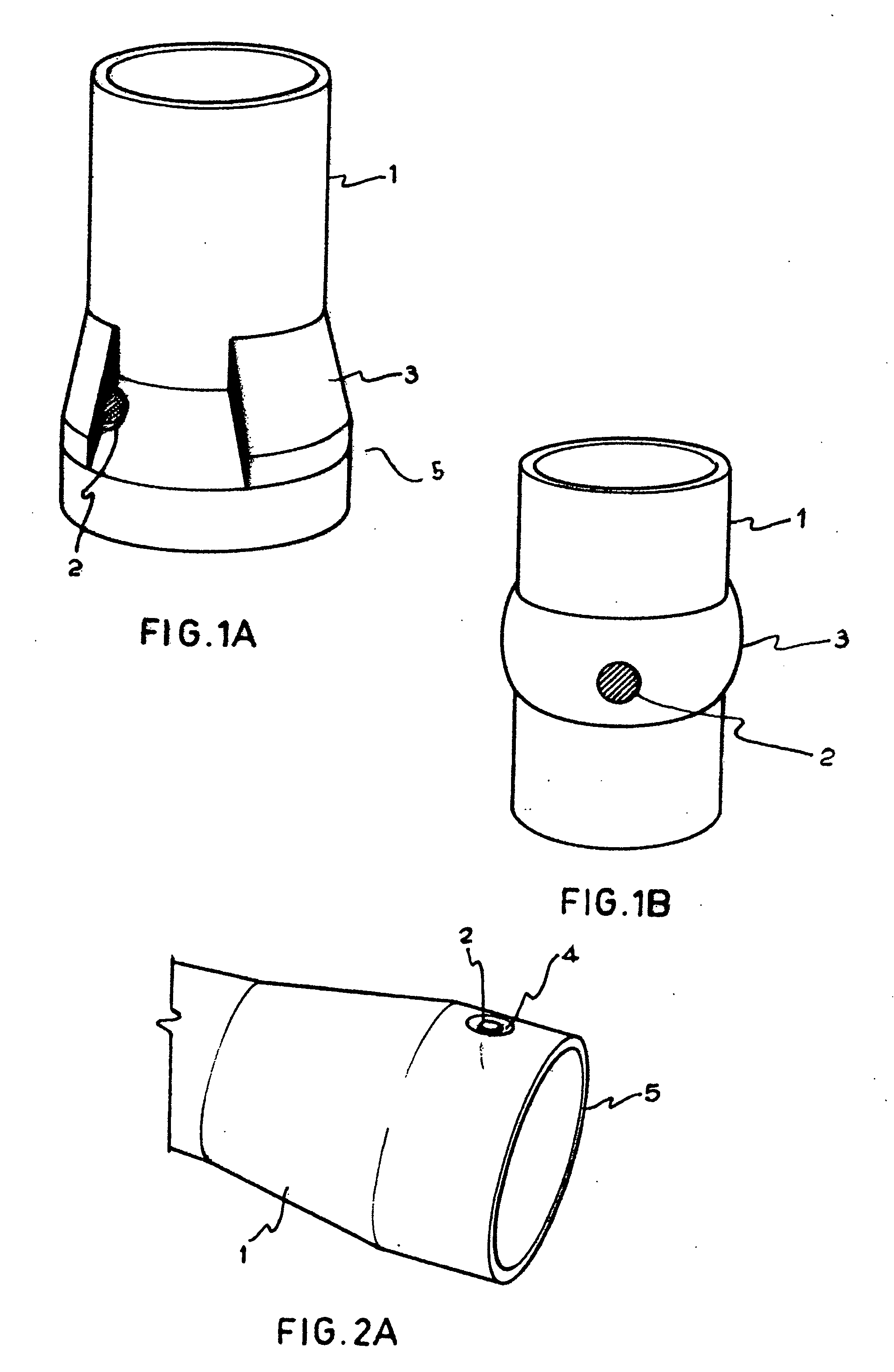

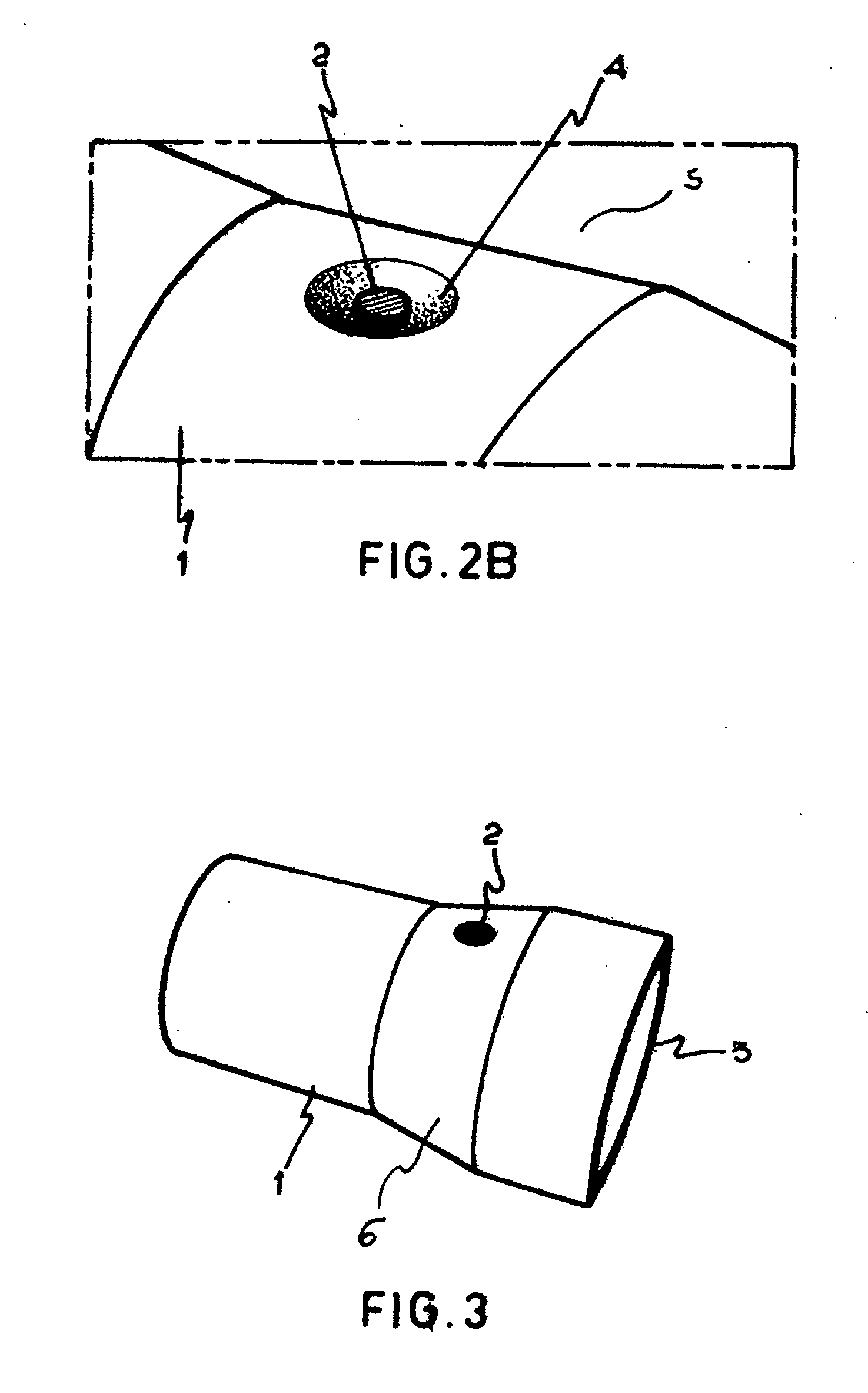

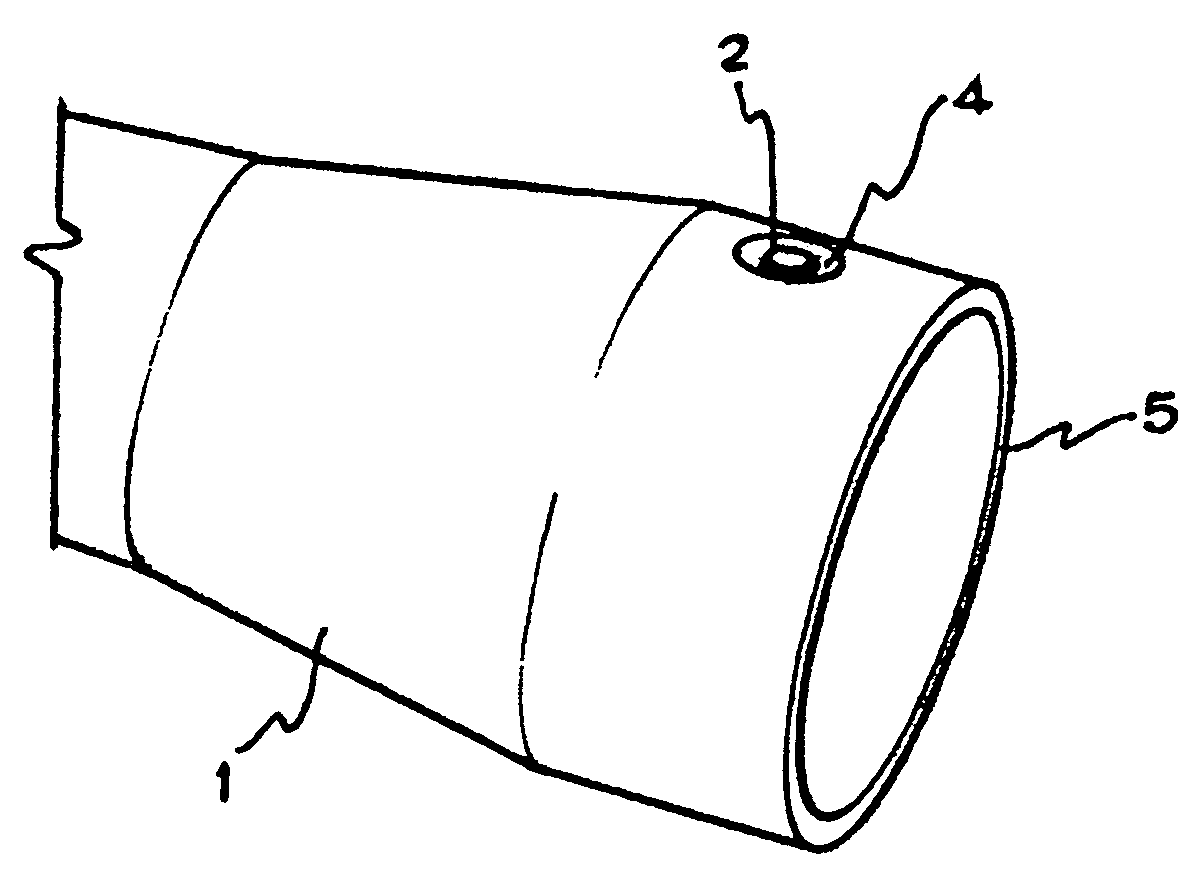

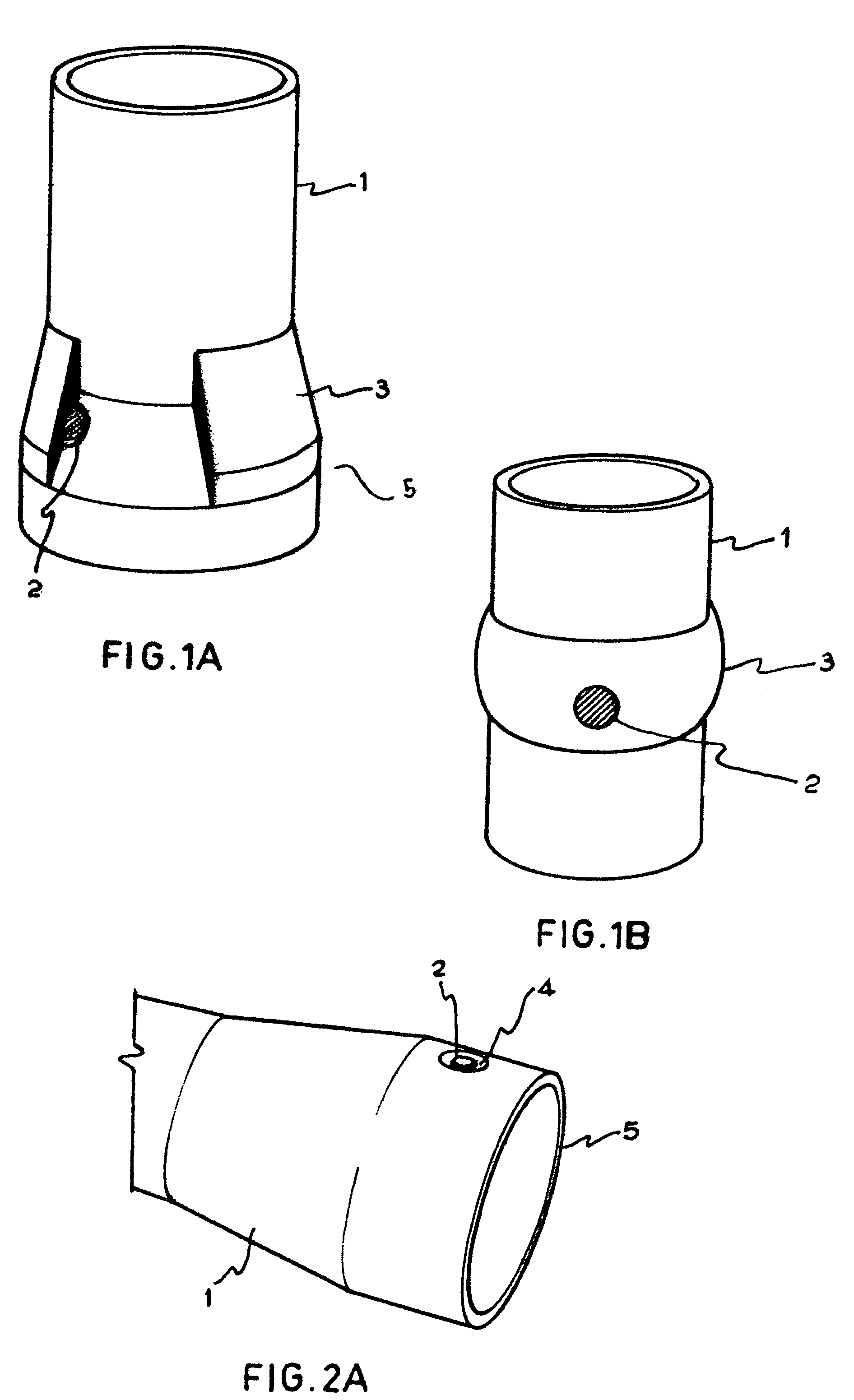

Metal tube assembly and radio frequency identification (RFID) tag

InactiveUS20070018825A1Inhibition effectSmall separationRecord carriers used with machinesBurglar alarm by hand-portable articles removalEngineeringMillimeter

Owner:SIDERCA SAIC

Electronic cigarette atomizer oiling and labeling device

ActiveUS9956656B2Improve assembly accuracyImprove detection qualityAssembly machinesLiquid materialElectronic cigaretteSilicone rubber

This disclosure provides oil filling and labeling apparatuses for atomizers of electronic cigarettes, which include a rack provided with a table board. A material pick-up operation position, an oil filling operation position, an assembling operation position, a labeling operation position and a pressing operation position for silicon rubber sleeve are provided on the table board. The oil filling and labeling apparatuses for the atomizers of the electronic cigarettes further include a material loading mechanism, an oil filling mechanism, a mechanism for mounting oil-sealing ring, a mechanism for mounting end cap, an electric resistance detection mechanism, a first material rotation mechanism, a labeling mechanism, a second material rotation mechanism and a mechanism for pressing silicon rubber sleeve. The atomizer of the electronic cigarette is successively conveyed for processing among such mechanisms.

Owner:ZHONGSHAN SHENGYUFENG TRADING CO LTD

Round wire rod label sticking jig and application method thereof

InactiveCN106275669APrecise positioningAvoid pasting deviation and other problemsLabelling machinesLabelling elongated objectsWire rodEngineering

The invention provides a round wire rod label sticking jig and an application method thereof. The round wire rod label sticking jig comprises a positioning assembly and a sticking assembly; the positioning assembly is used for positioning a label and comprises two positioning seats which are mutually symmetric; a gap through which a round wire rod passes is formed between the two positioning seats; the sticking assembly is arranged below the positioning assembly and comprises two pressing wheels which are arranged adjacently and are used for tightly pressing and sticking the label. By setting the positioning assembly for positioning the label, the label is accurately positioned, and problems of deviated label sticking and the like are avoided; after the label is put onto the two positioning seats, the gap is just located in the middle of the label and the round wire rod passes through the gap, so that the middle part of the label is stuck on the round wire rod; the label is extruded from the middle, so that the label is firmly stick, quality defects including bumps, bubbles, warping and the like are not caused and the sticking quality of the label is improved; furthermore, the sticking efficiency is also greatly improved and the production cost is reduced.

Owner:GEER TECH CO LTD

Metal tube assembly and radio frequency identification (RFID) tag

InactiveUS7557716B2Inhibition effectSmall separationRecord carriers used with machinesBurglar alarm by hand-portable articles removalRadio frequencyMetal

Owner:SIDERCA SAIC

Wire/cable identification device

ActiveUS7745740B2Improve distributionSimple structureStampsInsulated cablesElectricityIdentification device

An electric wire identifier that includes an anti-short bushing in the form of an electrical insulating ring-like insert fitted onto the end of a metal or armored clad cable that defines the terminal end of the armored cable or into the end of an electrical connector that is generally inserted through a knock-out hole of an electric box or panel, and which bushing includes an integral extension or surface capable of retaining thereon suitable identifying indicia that is rendered visible throughout the lifetime of the electrical installation. In another form of the invention, the wire identifiers, in the form of a label or tag having a loop attachment that may be arranged in a tree or roll whereby the individual labels or tags can be readily dispensed as needed.

Owner:BRIDGEPORT FITTINGS LLC +2

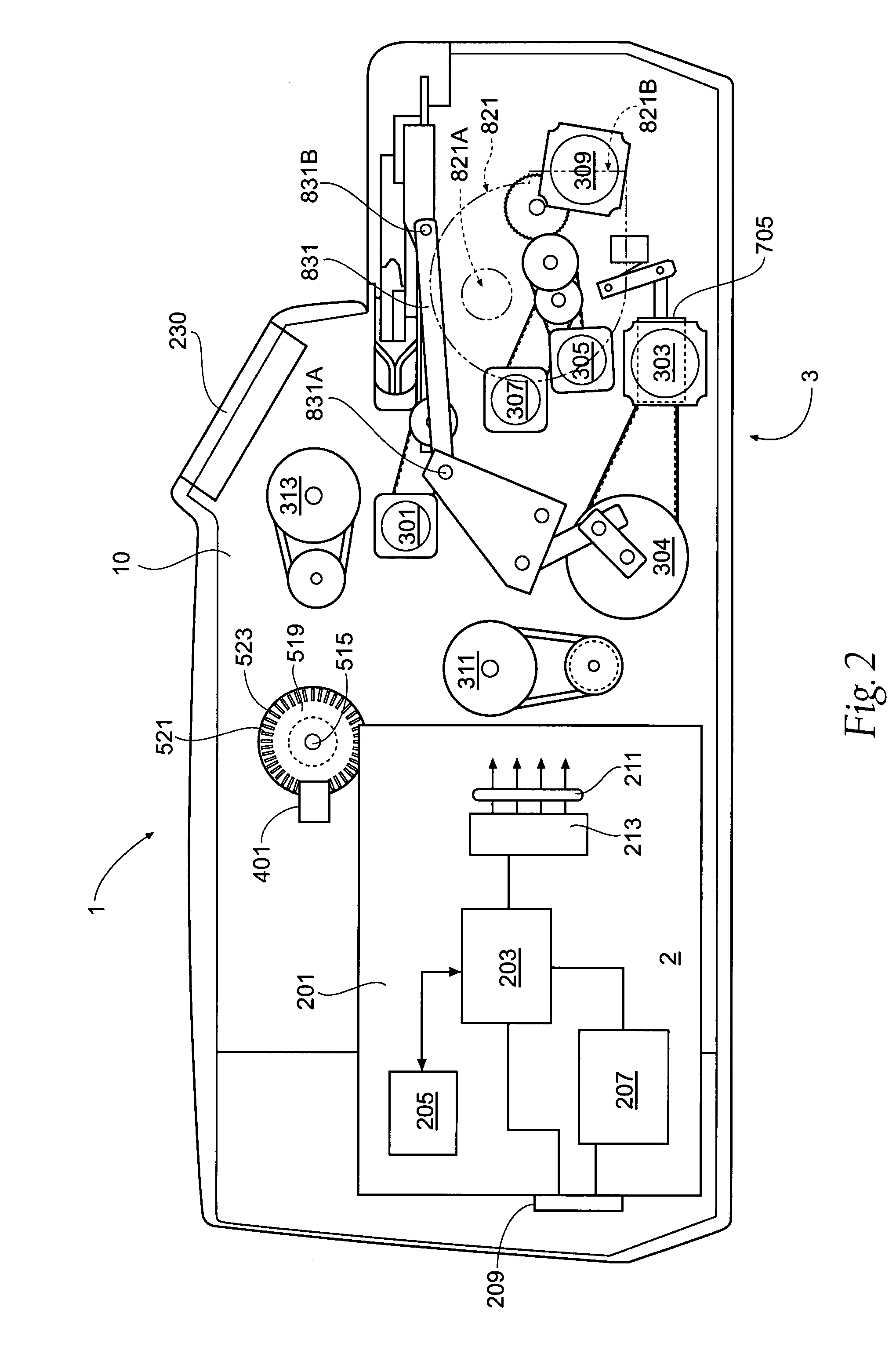

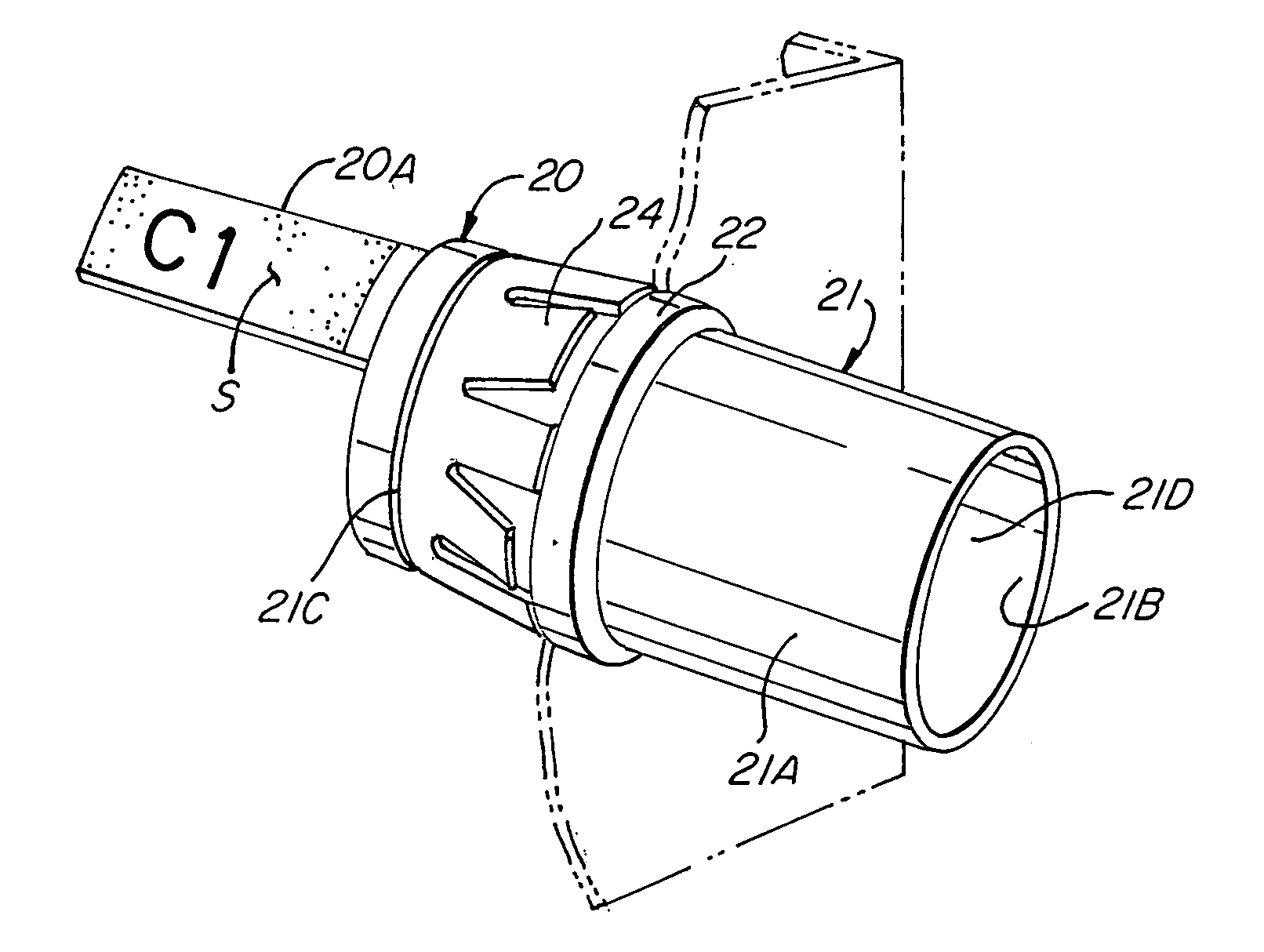

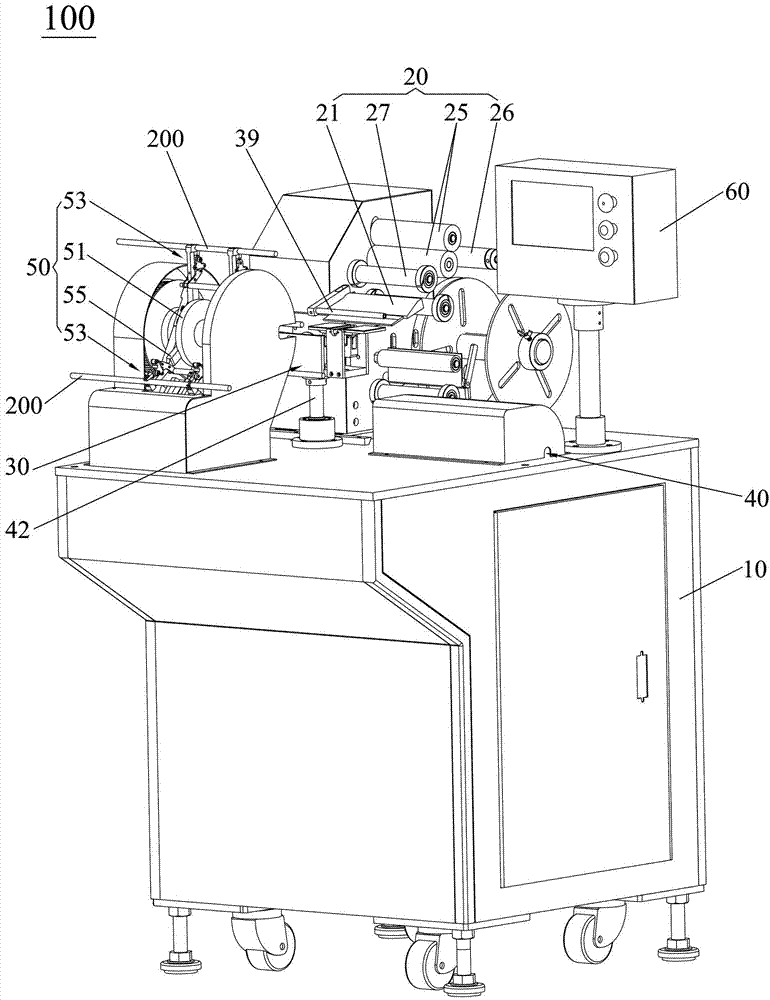

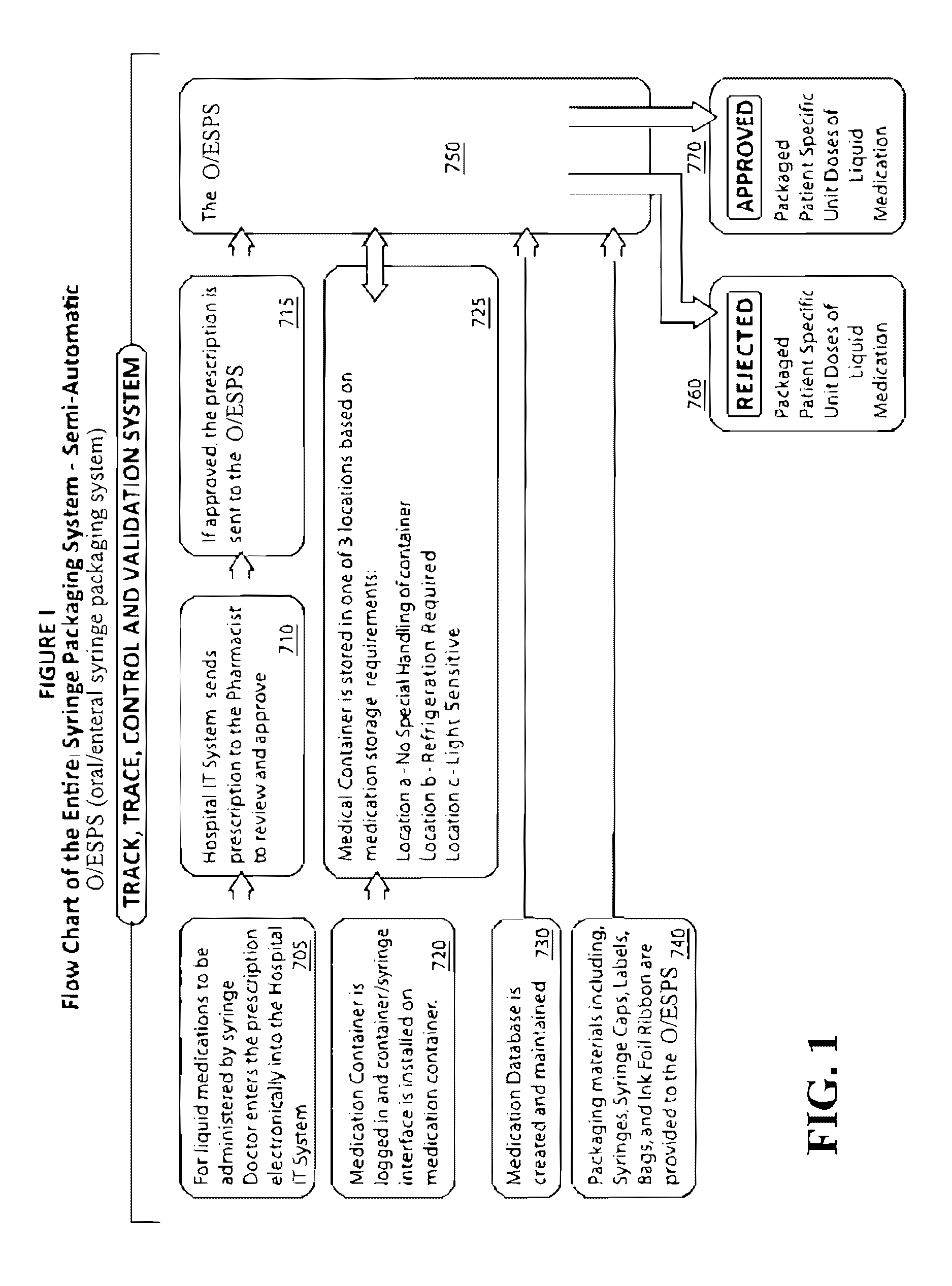

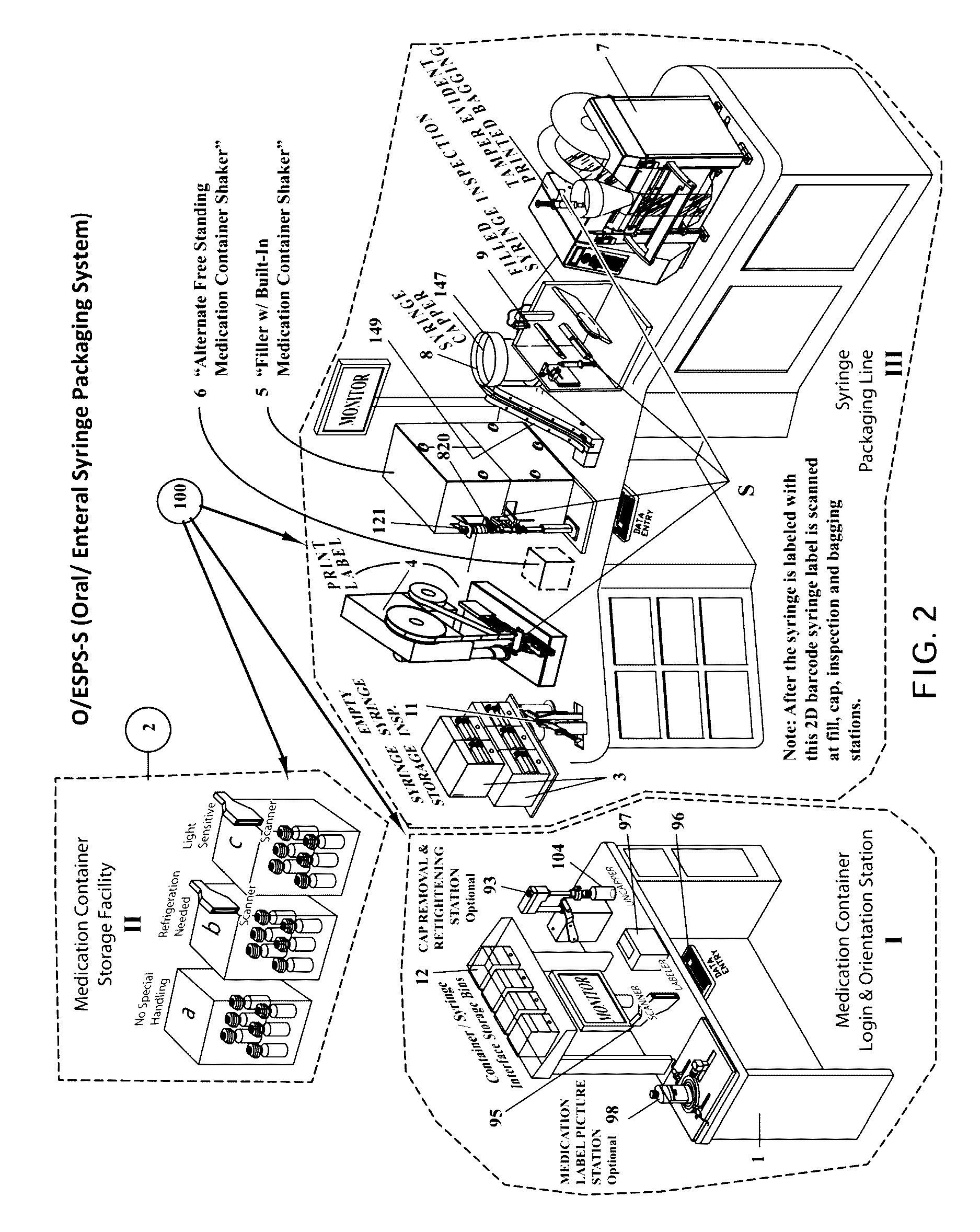

Syringe filling and packaging system for hospital pharmacies

A semi-automated system (100) suitable for use in a hospital setting for filling patient-specific liquid medication prescriptions from bulk medicine containers (104) into oral / enteral syringes (S) for administration on a just-in-time basis. The system enables hospital pharmacists to simplify and streamline their task, increasing the number of prescriptions that can be filled in a day, improving patient safety and care by minimizing medication errors and the consequences that ensue.

Owner:NATIONAL INSTRUMENTS

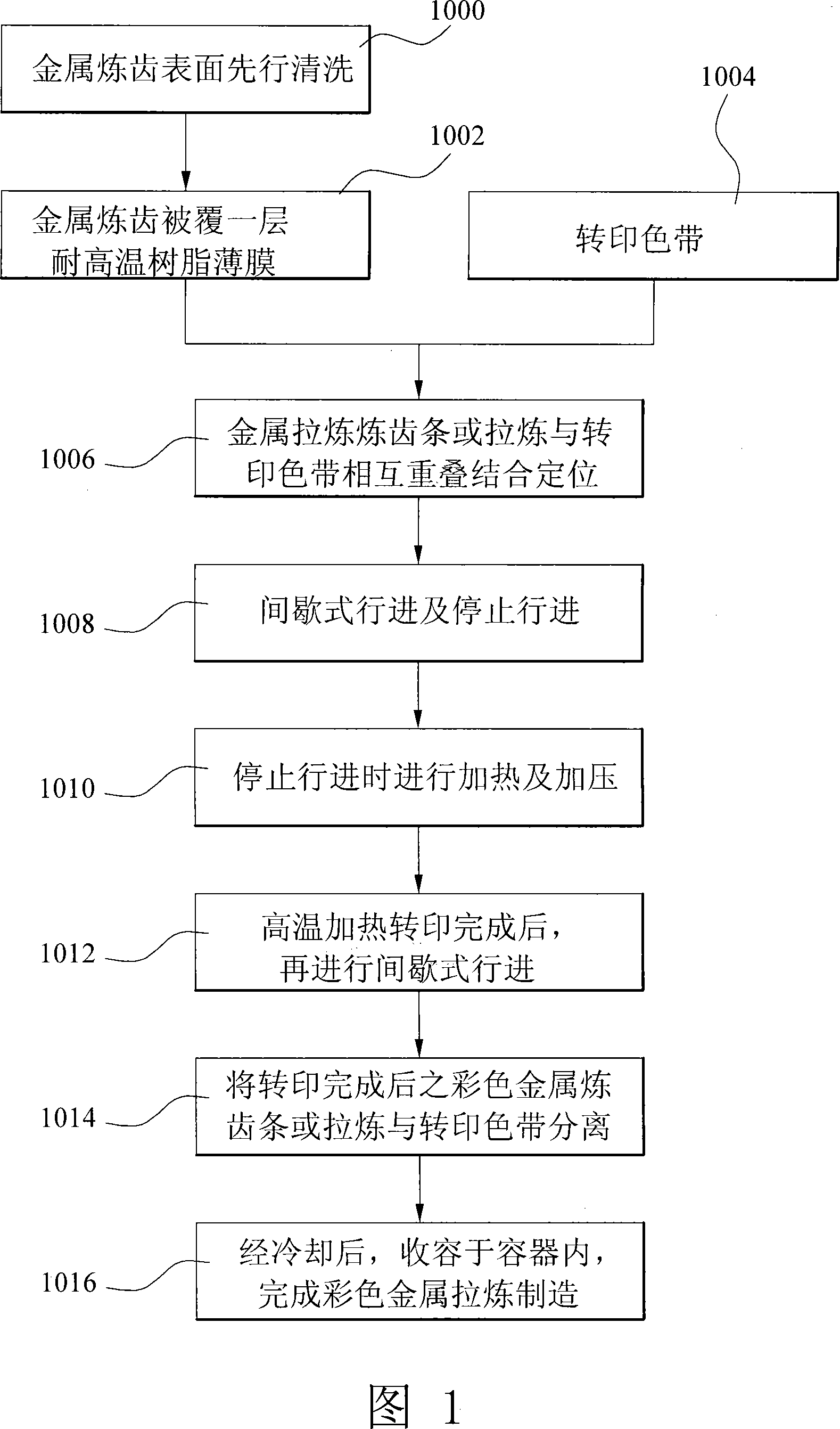

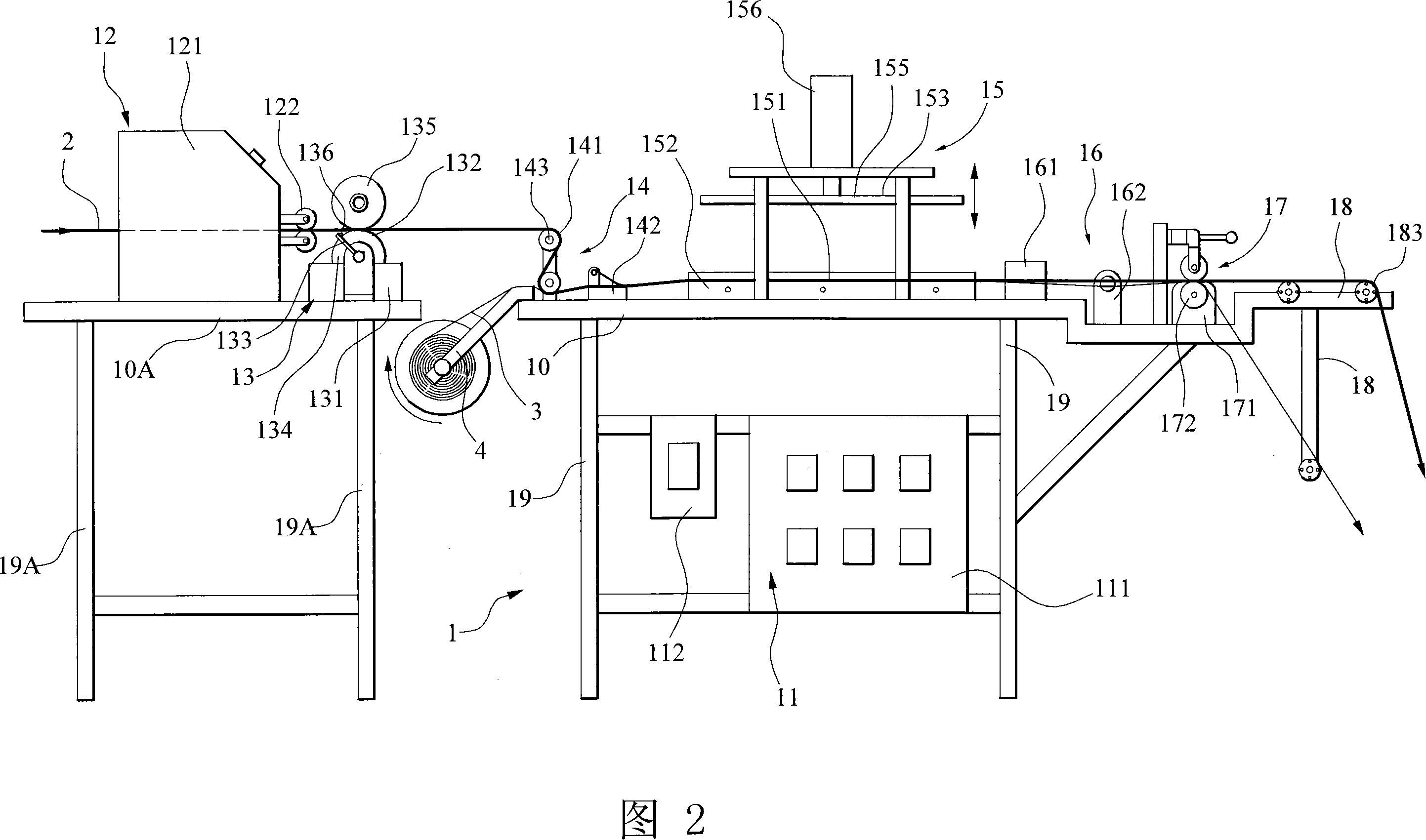

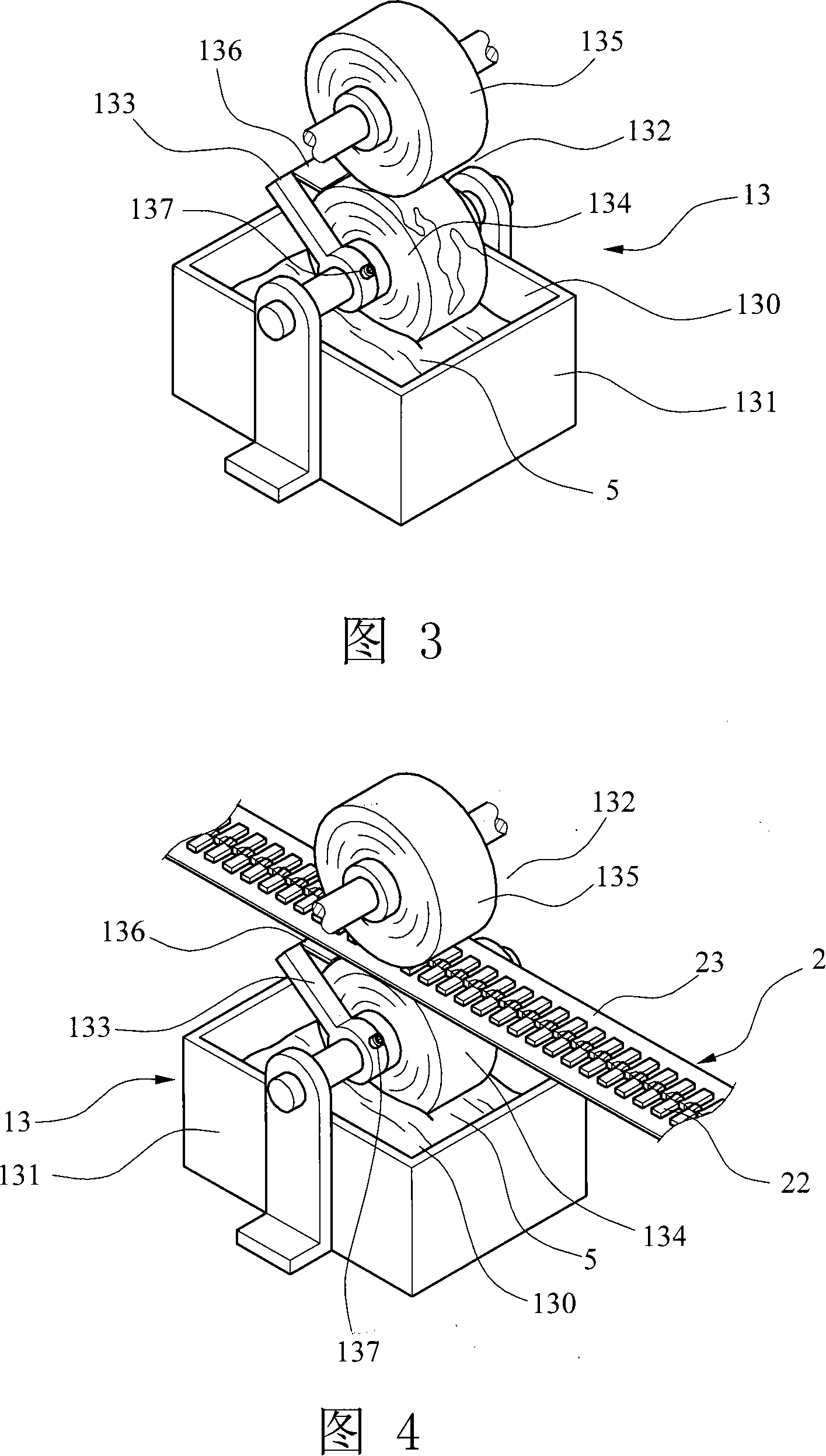

Method of manufacturing color metal zipper and apparatus therefor

InactiveCN101125508AImprove efficiencyImprove yieldSlide fastenersDecorative surface effectsMetallurgyDead time control

Method and apparatus of manufacturing color metal zipper are disclosed. The method includes washing half-finished metal zipper; overlaying a thin film on the upper surface of half-finished metal zipper; feeding color transfer paper; overlaying the half-finished metal zipper on the color transfer paper and positioning same; intermittently advancing the overlaid half-finished metal zipper and the color transfer paper; heating and pressing the overlaid half-finished metal zipper and the color transfer paper in an interval when the advancing stops for uniformly transferring color of the color transfer paper to a portion of the half-finished metal zipper; intermittently advancing the half-finished metal zipper and the color transfer paper again; separating the finished color metal zipper from the color transfer paper while intermittently advancing; and cooling and storing the finished color metal zipper and color transfer paper.

Owner:IRIS ZIPPER

Full-automatic battery label sticking machine

ActiveCN103448969AShorten the action cycleIncrease productivityLabelling machinesLabelling elongated objectsNumerical controlDisplay device

The invention provides a full-automatic battery label sticking machine. The full-automatic battery label sticking machine comprises a rack, as well as a label and backing paper separating device, a label settling device, a battery picking device, a battery longitudinal moving device and a battery putting back device which are positioned on the rack; the label sticking machine is also connected with a numerical control display device. The full-automatic battery label sticking machine provided by the invention has the beneficial effects that a battery and a label are positioned accurately; the label sticking time is shortened by adopting a dual-suction-disc structure; multi-point positioning can be achieved by adopting an electric cylinder; the full-automatic battery label sticking machine is convenient to regulate and improves the product yield, a battery turnover device is saved, the integral structure is greatly simplified, and multiple purposes with one machine are realized.

Owner:滁州润度智能科技有限公司

Wrapper assembly

ActiveUS8783318B2Reduce component countMore compactPackaging cigaretteWrapper folding/bending apparatusEngineeringMechanical engineering

Owner:BRADY WORLDWIDE INC

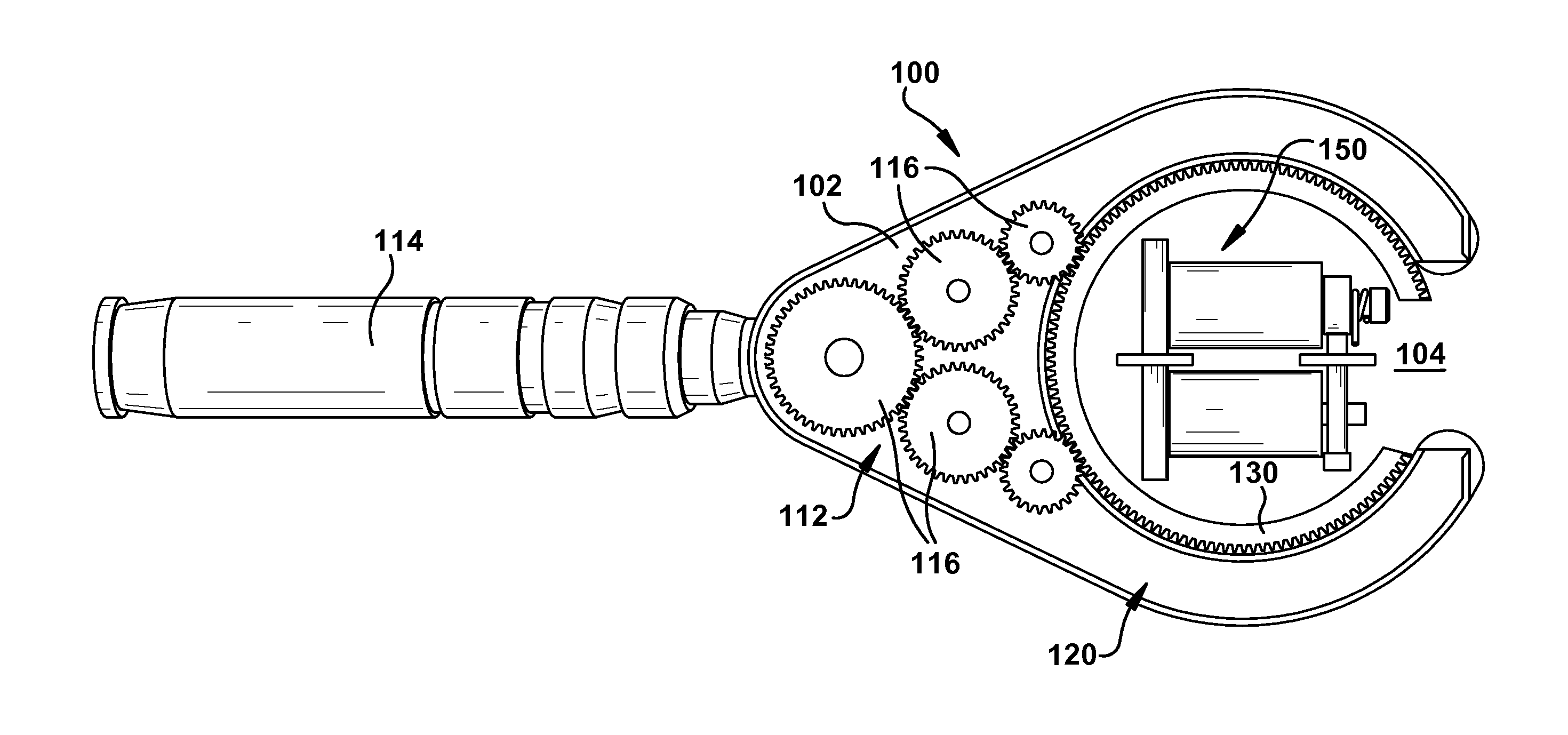

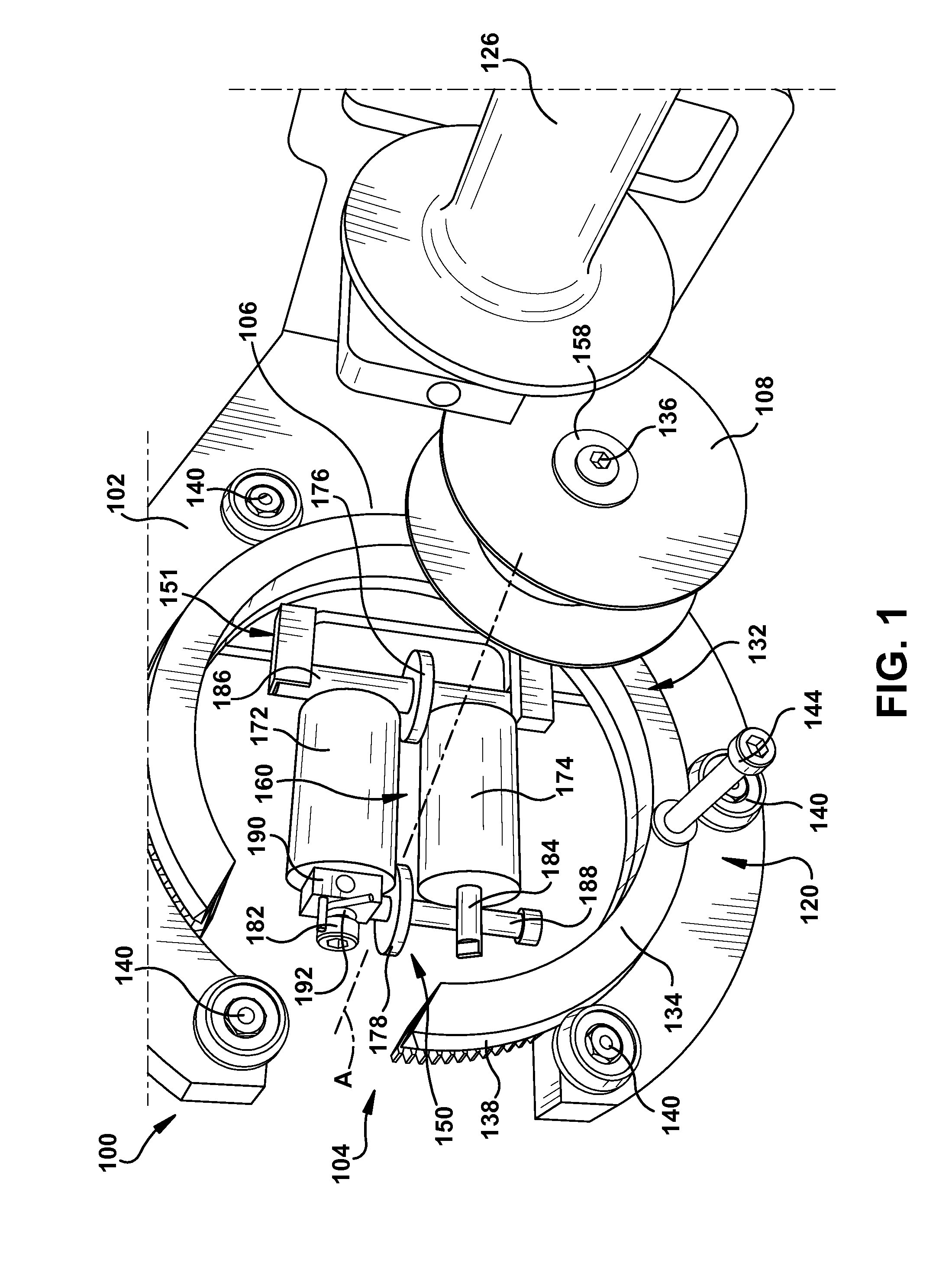

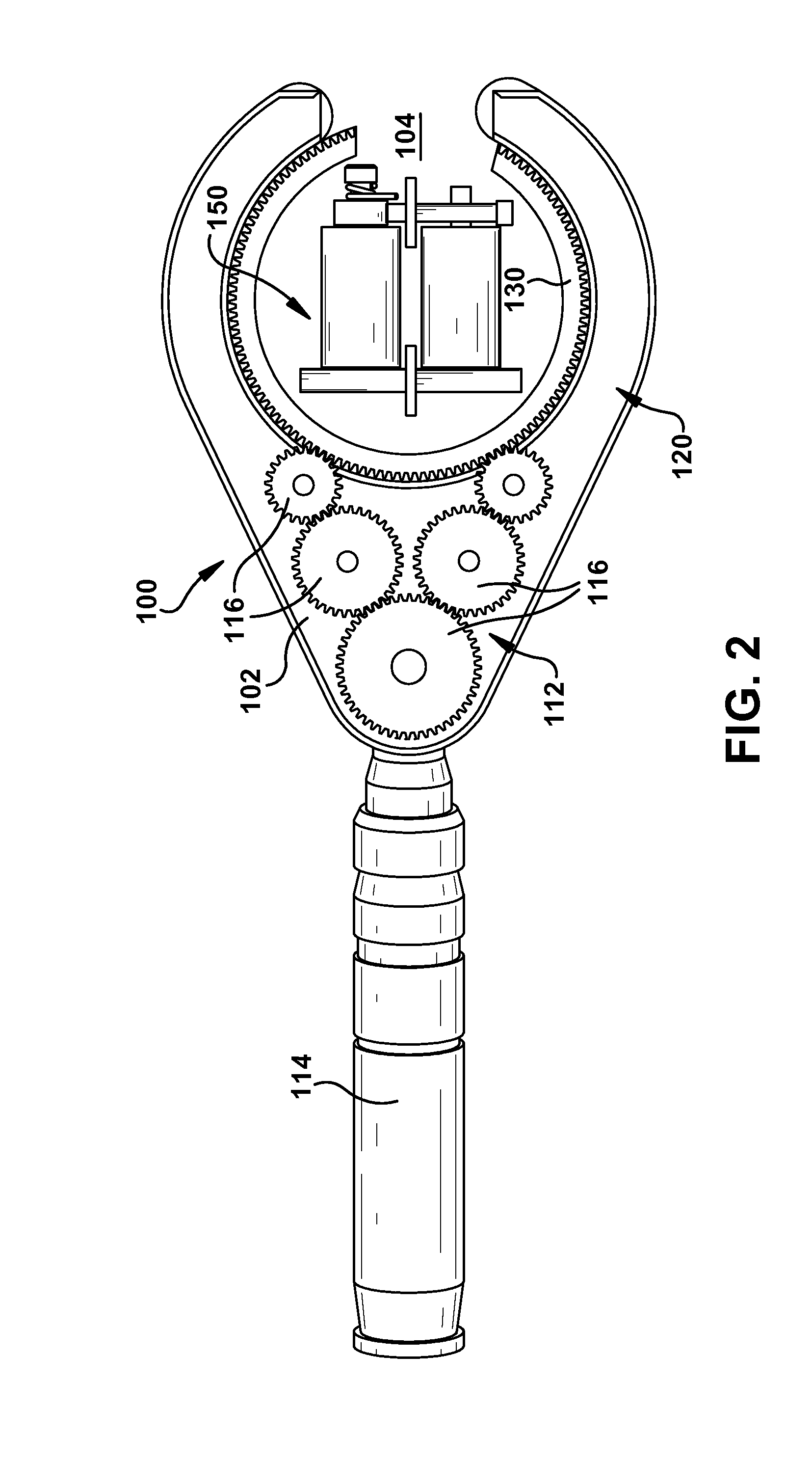

Hand-carried taping machine with non-powered guide system

A hand-carried taping machine for taping an elongated object is disclosed. The machine includes a powered gear set operably coupled to a body and powered by a drive system. An applicator head includes a substantially C-shaped gear in meshing engagement with the powered gear set such that the substantially C-shaped gear rotates about an application axis under control of the drive system, and a tape reel mount for rotatably mounting a reel of tape on the substantially C-shaped gear for rotation about the application axis and application of the tape to the elongated object. A non-powered guide system operably couples to the body for guiding the applicator head along the elongated object with transient engagement with the elongated object such that the elongated object is maintained in a vicinity of the reel of tape.

Owner:GENERAL ELECTRIC CO

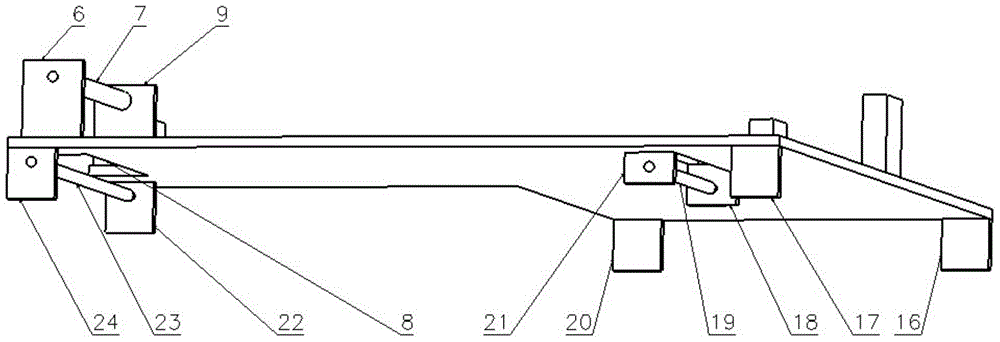

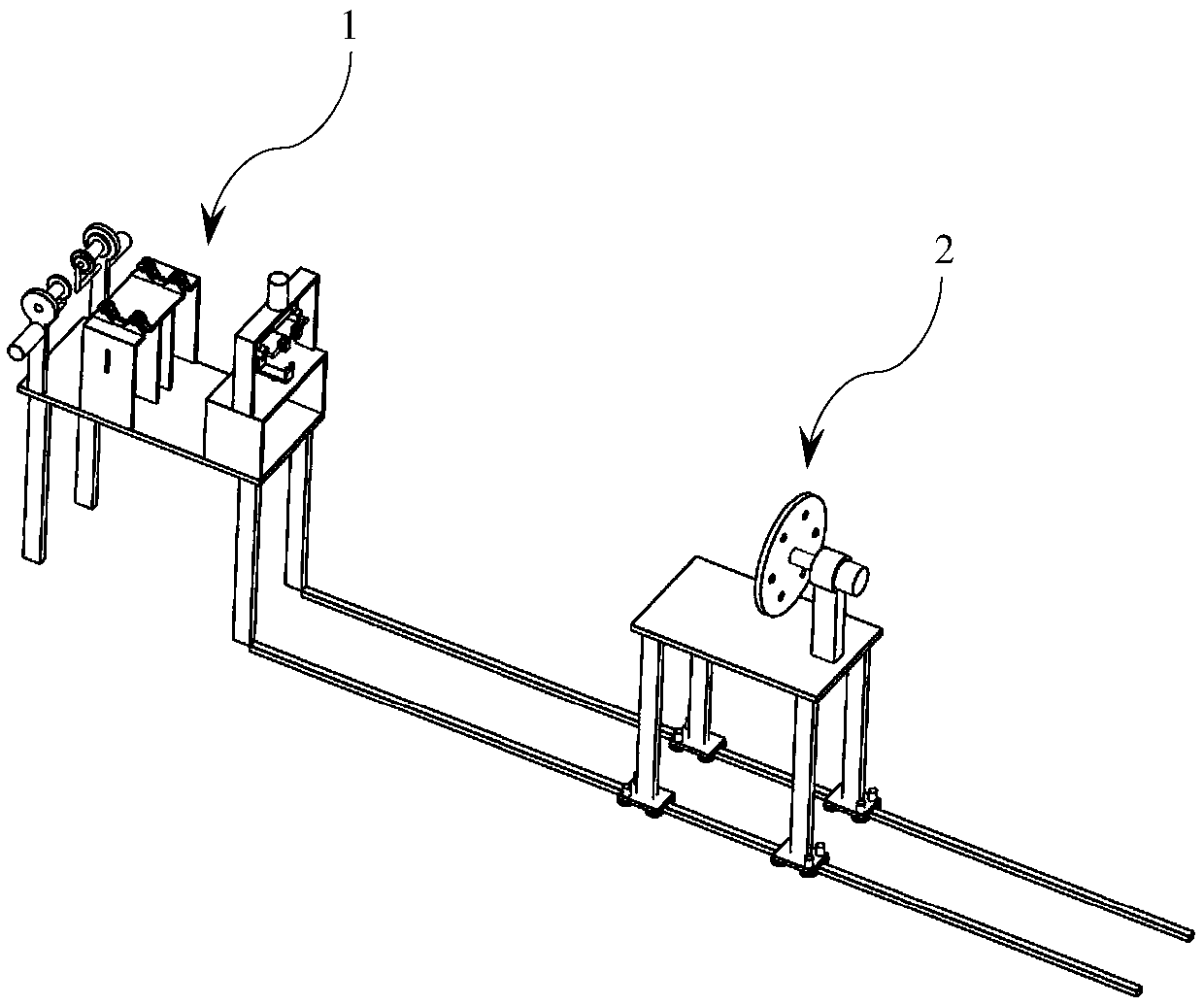

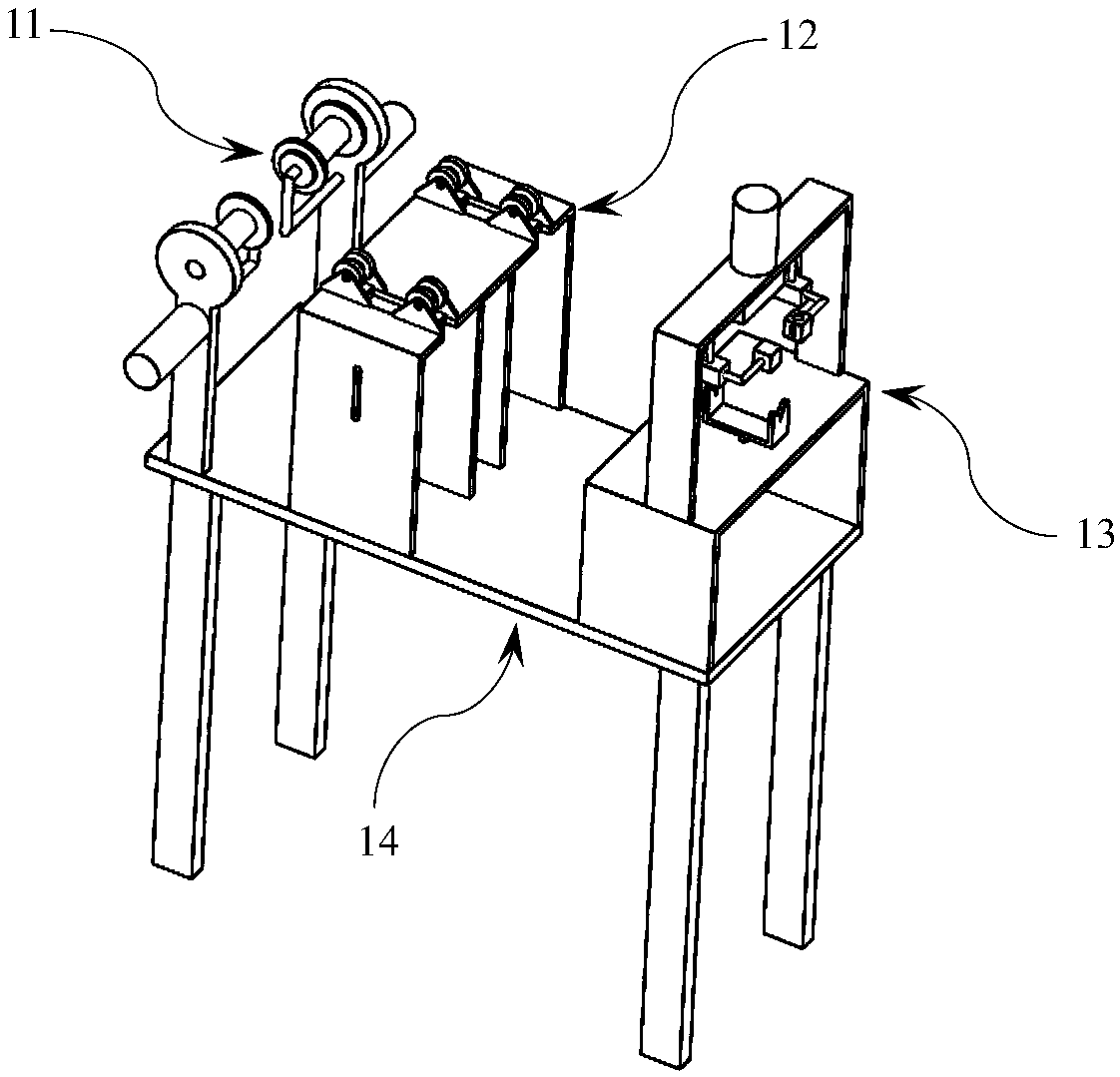

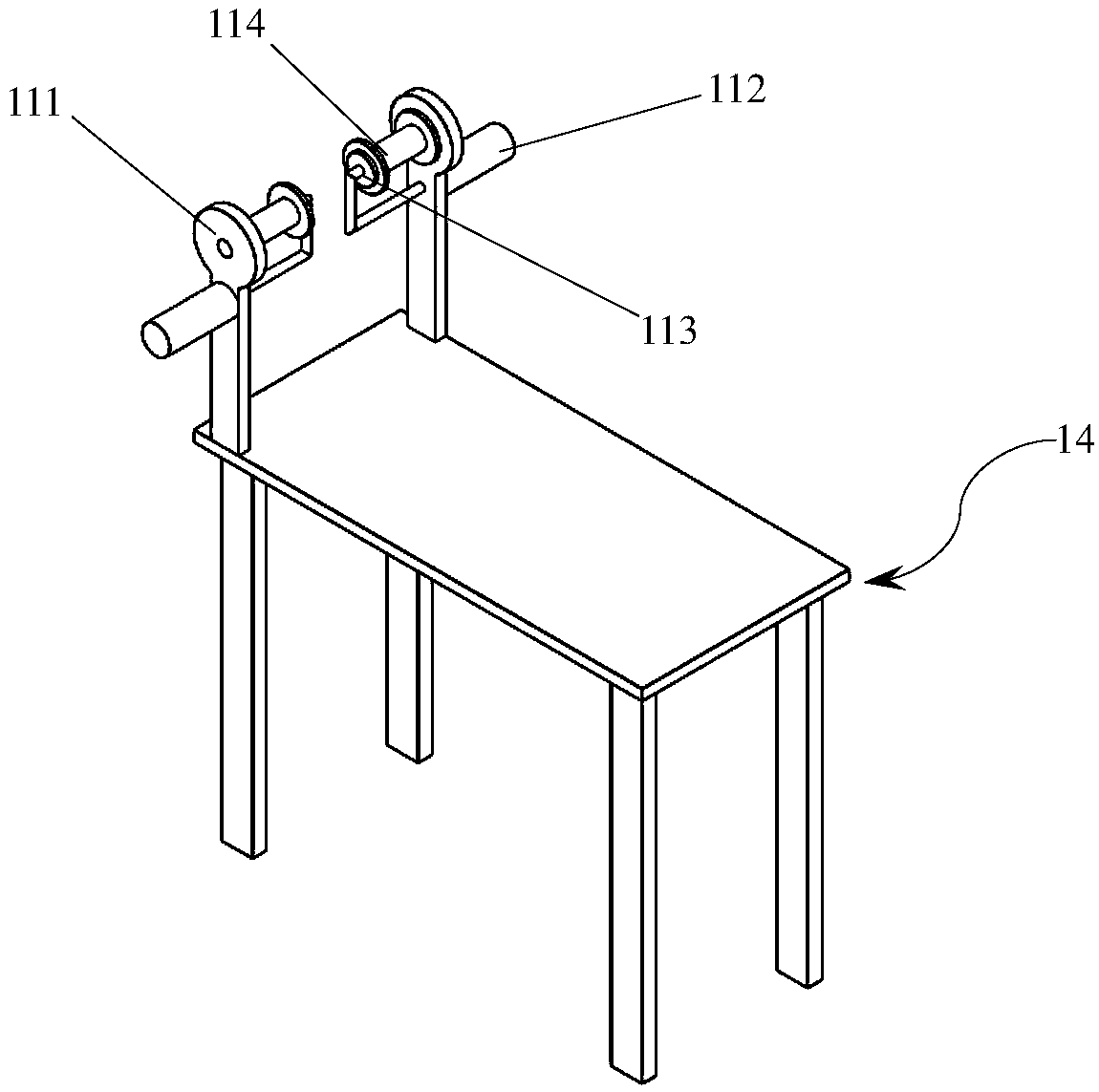

Semi-automatic wire twisting device for equal length parallel twisting of electric heating wires

PendingCN109570405AAvoid Manual LabelingImprove automationLabelling elongated objectsSemi automaticSystem controller

The invention discloses a semi-automatic wire twisting device for equal length parallel twisting of electric heating wires, which comprises a head wire releasing unit, a tail wire twisting unit and asystem controller. The head wire releasing unit is used for automatic retraction, automatic tensioning and automatic labeling after wire releasing of electric heating wires, and comprises an automaticwire releasing mechanism, an adaptive tensioning mechanism, an automatic labeling mechanism and a first bench. The automatic wire releasing mechanism, the adaptive tensioning mechanism and the automatic labeling mechanism are sequentially installed on a table surface of a table frame. The tail wire twisting unit arranged in parallel with the head wire releasing unit is used for automatic mutual-twisting, self-twisting prevention and length automatic adjustment of the electric heating wires. The system controller is connected with the head wire releasing unit and the tail wire twisting unit, and is used for controlling the head wire releasing unit and the tail wire twisting unit to complete automatic retraction, automatic tensioning, automatic labeling after automatic parallel twisting, automatic mutual twisting, self-twisting prevention and automatic length adjustment of the electric heating wires.

Owner:NANJING COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com