Cylindrical material labeling machine and labeling method

A technology for labeling machines and articles, applied in the directions of labeling machines, labeling, labels, etc., can solve the problems of low efficiency, high labeling cost, poor quality, etc., and achieve smooth labeling, low glue consumption, and fast speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

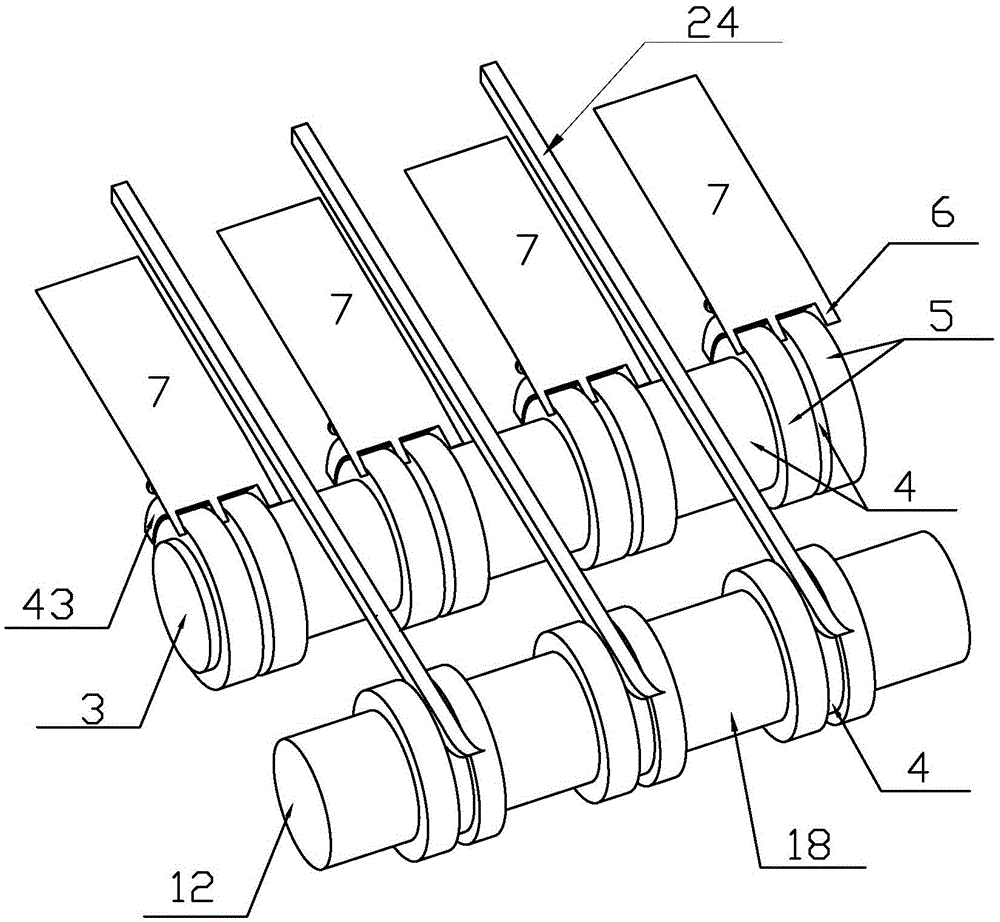

[0028] Implementation mode one: if figure 1 , 2 As shown, the cylindrical article labeling machine includes a frame 1, a paper feeding device, a gluing mechanism and a roll paper sticking mechanism, and the three are arranged on the frame in sequence, and it is characterized in that: the gluing mechanism includes hot melt adhesive Groove 2 and gluing roller 3, electric heating mechanism (not shown) is attached on this hot-melt adhesive trough 2, has a plurality of annular grooves 4 on the described gluing roller 3, and gluing roller 3 is divided into many A ring-shaped gluing surface 5.

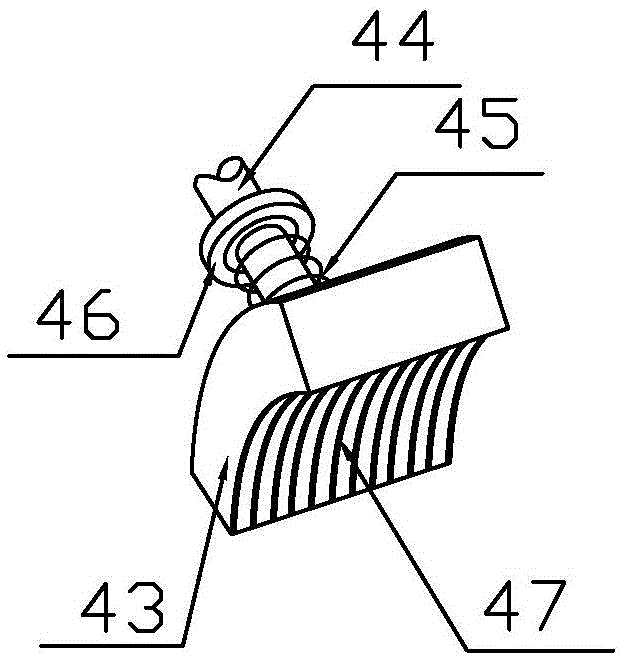

[0029] A paper-pressing protrusion 6 is arranged above the glue-applying roller 3 , and the above-mentioned paper-pressing protrusion 6 corresponds to the annular groove 4 on the glue-applying roller 3 one by one, and partially extends into the annular groove 4 . A reed 7 is arranged above the gluing roller 3 , and the front end of the reed 7 points to the gluing surface on the gluing rolle...

Embodiment approach 2

[0036] Implementation mode two: if Figure 4 As shown, a storage bin 34 is provided above the frame 1, an upper protrusion 35 is provided on the upstream side of the slider at both ends of the upper moving roller 13, and a discharge roller 36 is arranged between the two upper protrusions 35. A baffle plate 37 is provided at the lower opening of the storage bin 34 on the opposite side; a finished product drag box 38 with casters is provided below the frame. Other structures are as described in Embodiment 1. With such a design, after the upper moving roller retreats, the discharge roller in the storage bin can be released and entered into the winding paper roller group.

[0037] The method for labeling cylindrical articles using the cylindrical article labeling machine described in Embodiment 2 comprises the following steps:

[0038] (1). Preparation and paper feeding: place a paper holder 39 upstream of the frame 1, place stacked labels 40 on the paper holder 39, make the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com