Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Improve labeling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

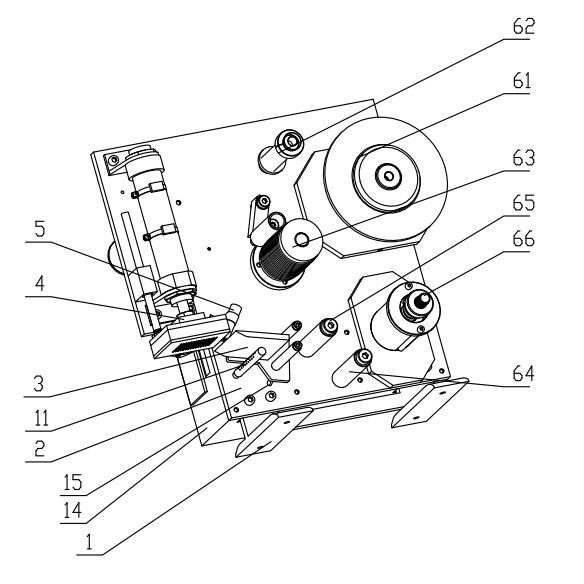

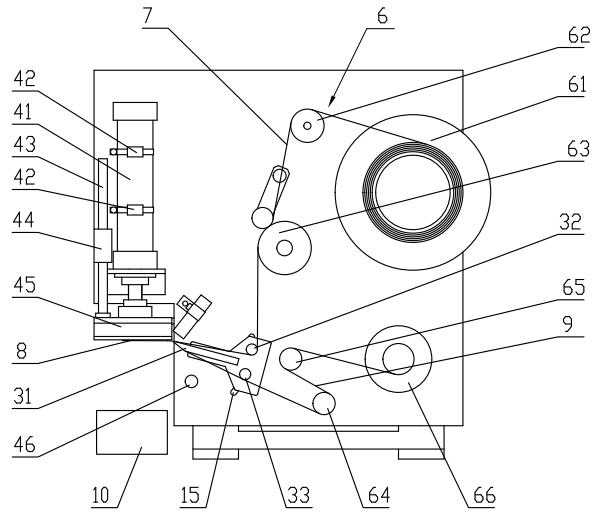

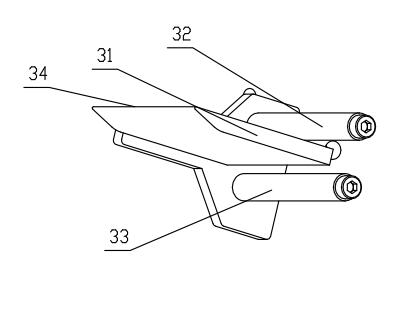

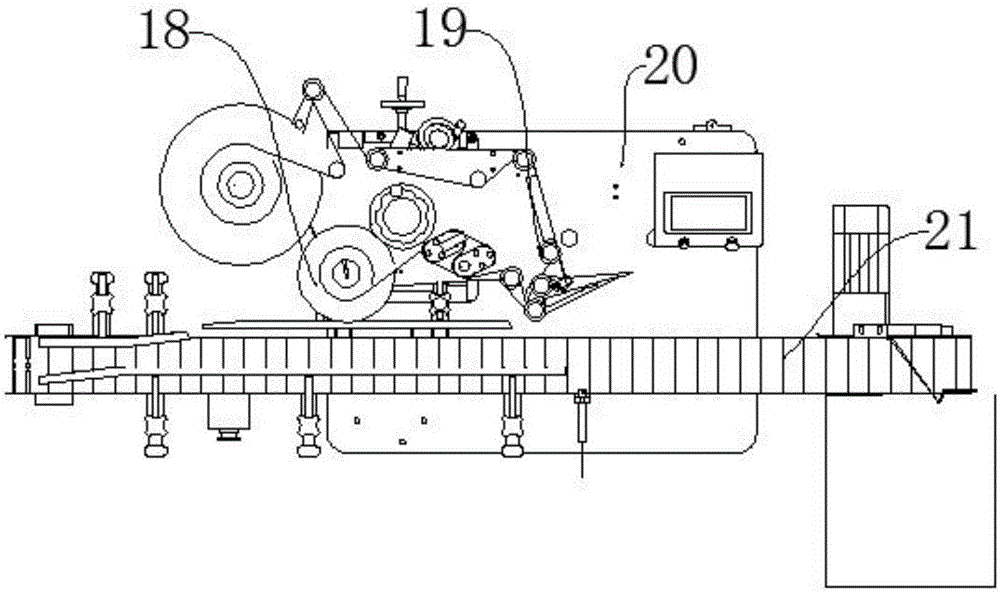

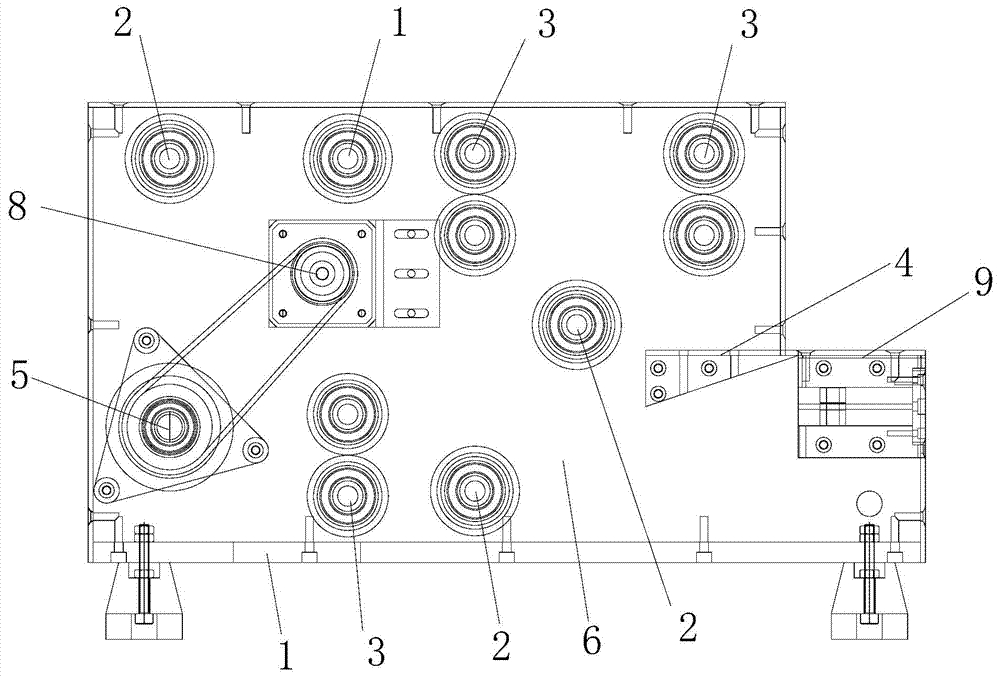

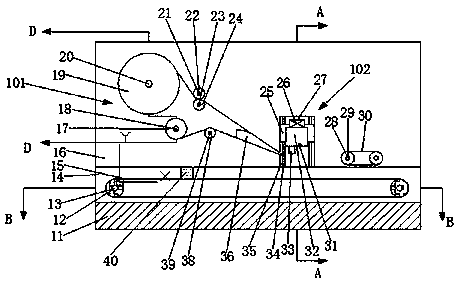

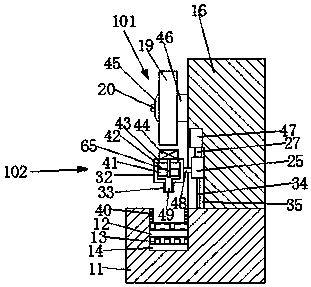

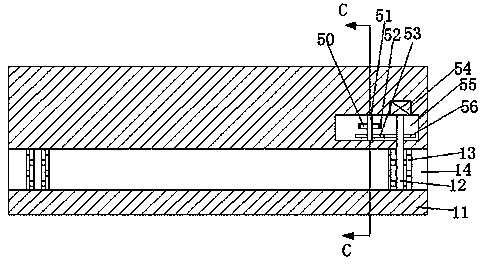

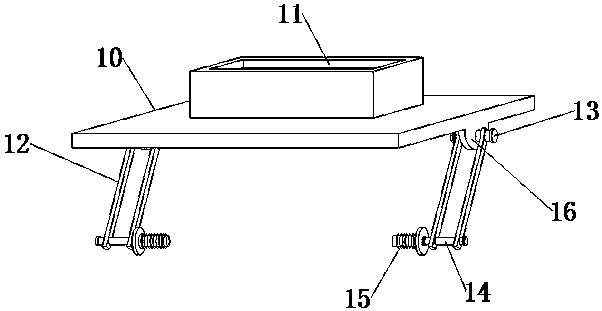

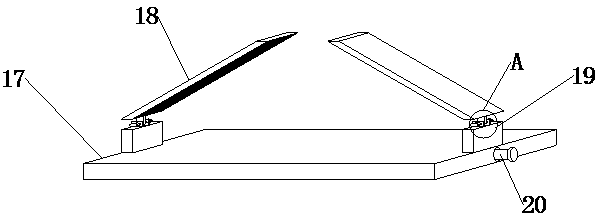

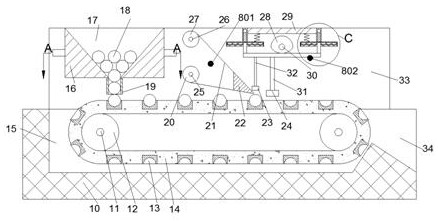

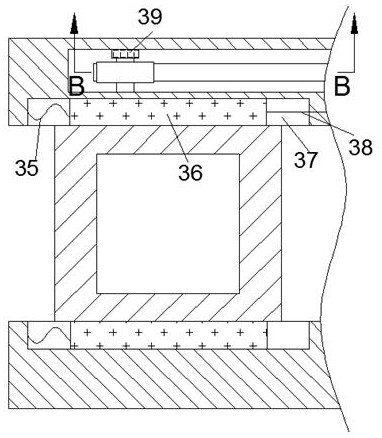

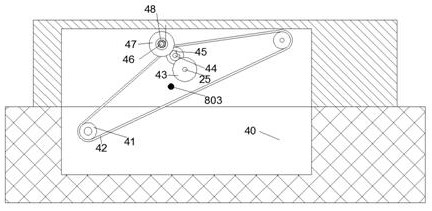

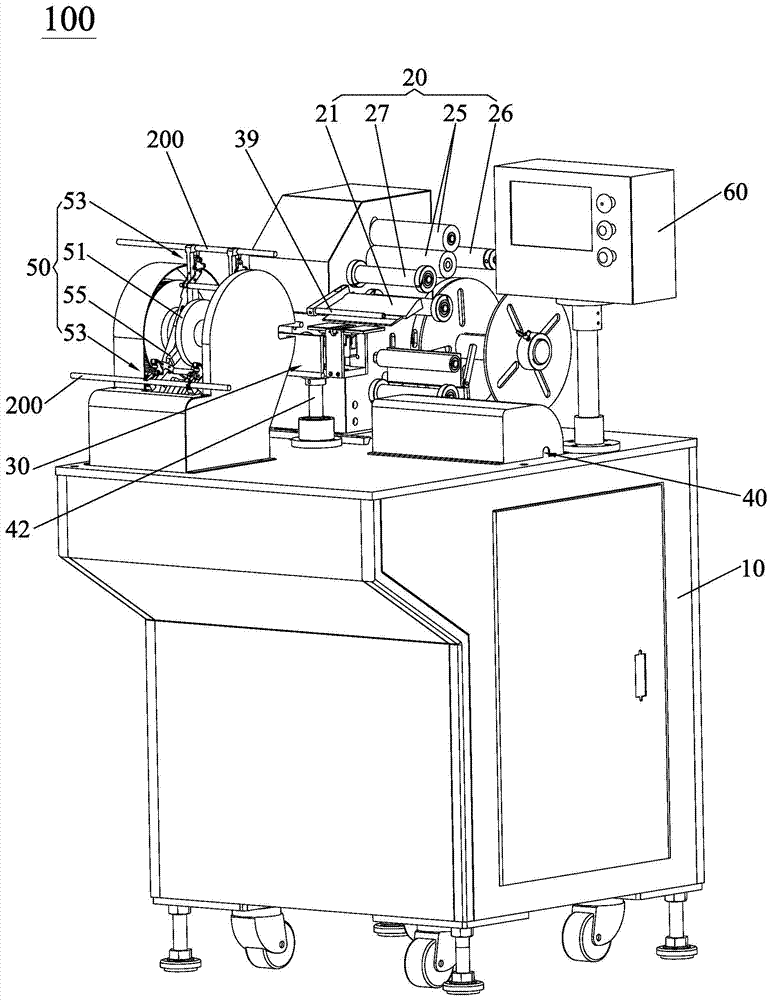

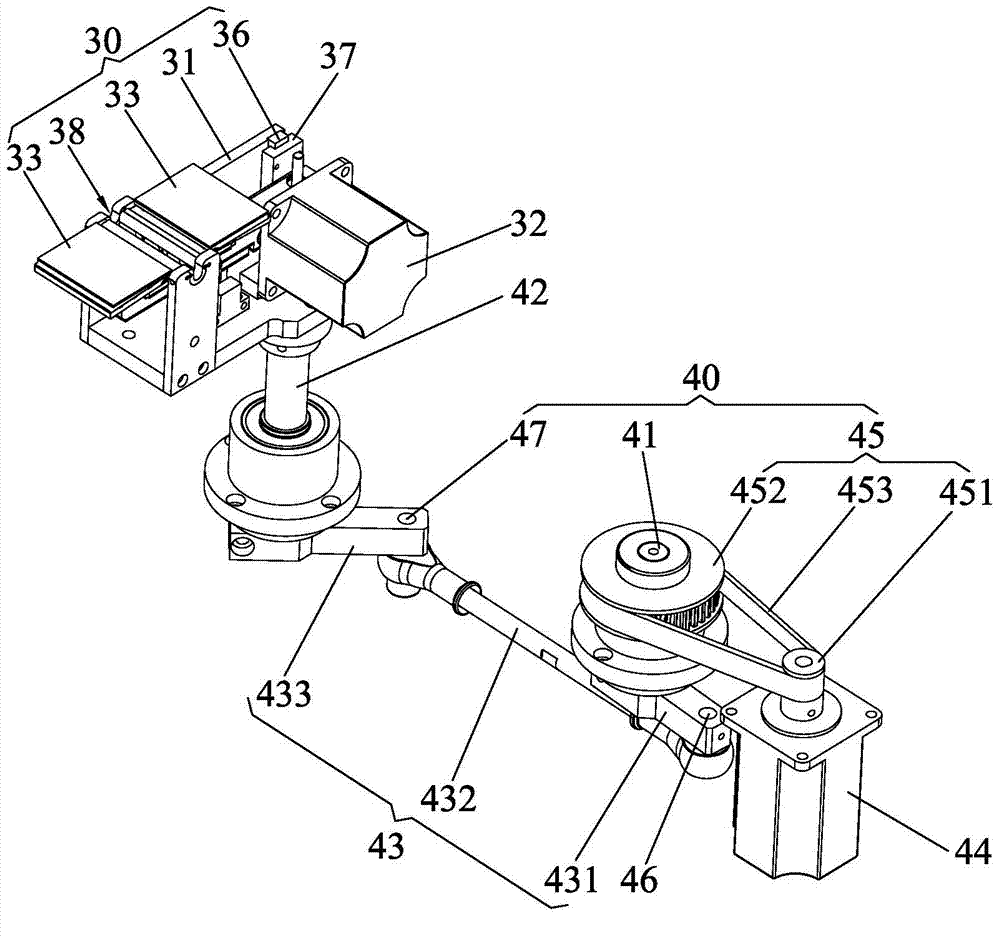

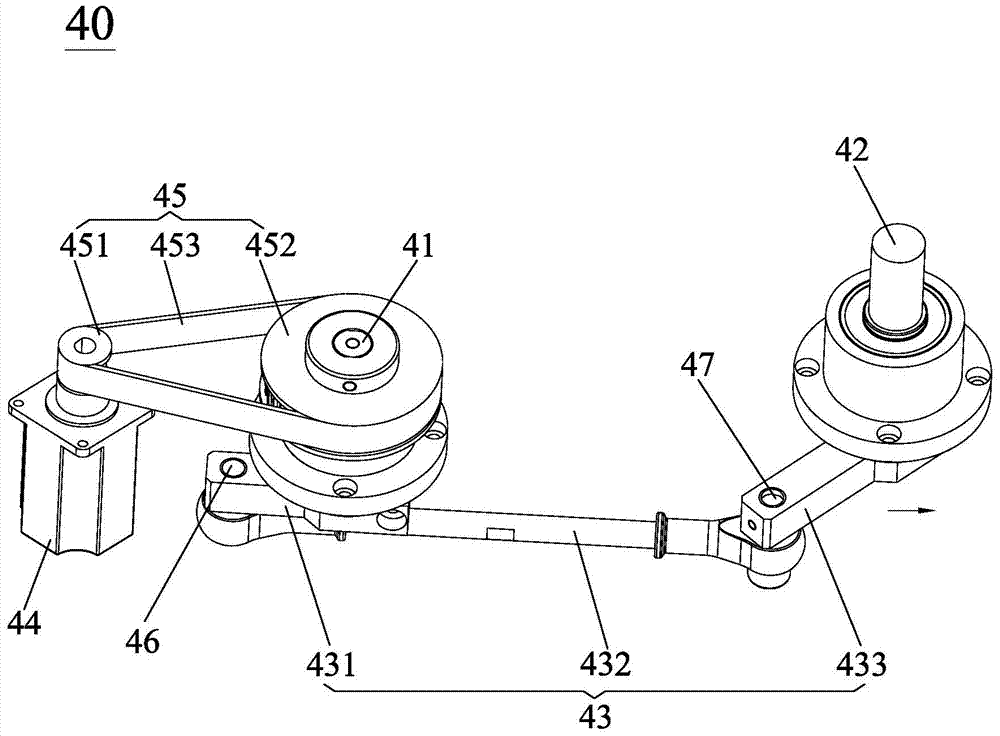

Automatic tag removing and labeling machine

InactiveCN102642649AImprove labeling efficiencyGood labeling qualityLabelling machinesLabelling machineDrive motor

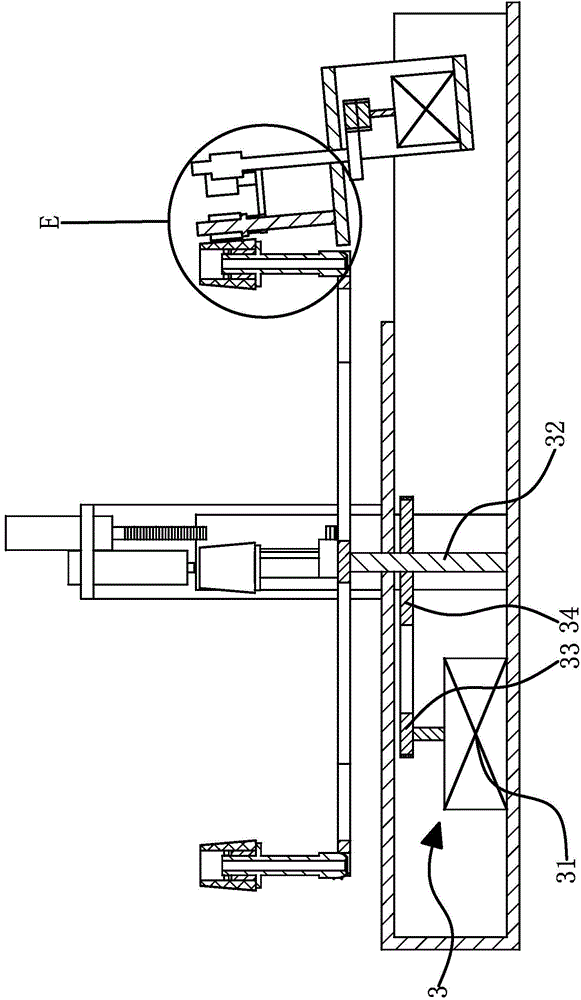

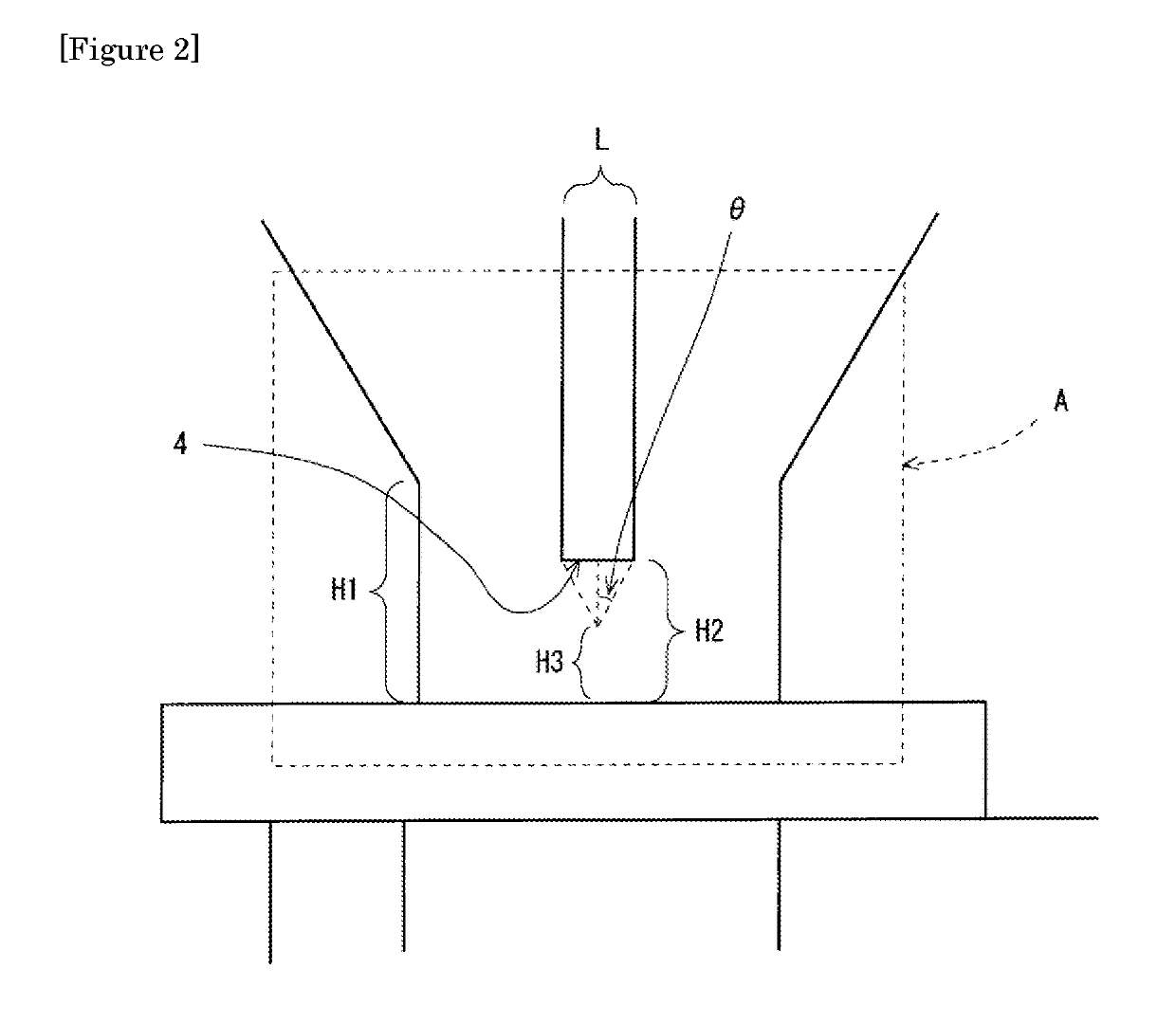

The invention discloses an automatic tag removing and labeling machine, a tag removing device, a tag labeling device and a tag band conveying device are arranged on an installation panel, a tag labeling cylinder of the tag labeling device is arranged vertically on one side of the installation panel, and a tag labeling head is fixed on a piston rod of the tag labeling cylinder; a tag removing plate of the tag removing device inclines upwards and is fixedly arranged on the installation panel, and a photoelectric control switch is arranged on the upper portion of a tag removing cutter edge; a gas blowing pipe is arranged on the lower portion of the tag removing device, and a gas blowing hole faces toward the bottom of the tag labeling head; and a traction roll of the tag band conveying device is driven by a driving motor to rotate, and a rolling tension wheel is connected with the driving motor through a synchronous belt. The automatic tag removing and labeling machine ingeniously utilizes blowing to bear removed tags, transfers the removed tags, attaches the removed tags to the tag labeling head by using vacuum, adopts pneumatic pressure to label and achieves automatic cycling operation by utilizing a magnetic switch and the photoelectric control switch. The labeling efficiency is high, labeling quality is good, and the machine is suitable for highly automatic assembly line work.

Owner:JIANGNAN UNIV

Tag noise correction based crowd-sourced tagging data quality improvement method

InactiveCN105426826AImprove labeling qualityVersatilityCharacter and pattern recognitionData setIntegration algorithm

The invention relates to a tag noise correction based crowd-sourced tagging data quality improvement method. The method comprises the following steps: running a tag integration algorithm in an initial crowd-sourced tagging data set to form a data set after tag integration, and estimating tagger quality and integrated tag quality information of samples in the process; performing multi-round K-fold cross validation by utilizing the data set after tag integration, and constructing a high-quality data set; determining a tag noise set in combination with the tagger quality and the tag quality of the samples by utilizing a prediction probability of a class tag of each sample in the multi-round K-fold cross validation process; and training a classification model by utilizing the high-quality data set generated in the multi-round K-fold cross validation process, and performing prediction and replacement on the class tag of each sample in the tag noise data set by using the model. With the tag noise correction method, the quantity of potential noise tag samples in the data set after original tag integration is reduced, so that the data quality is improved.

Owner:张静

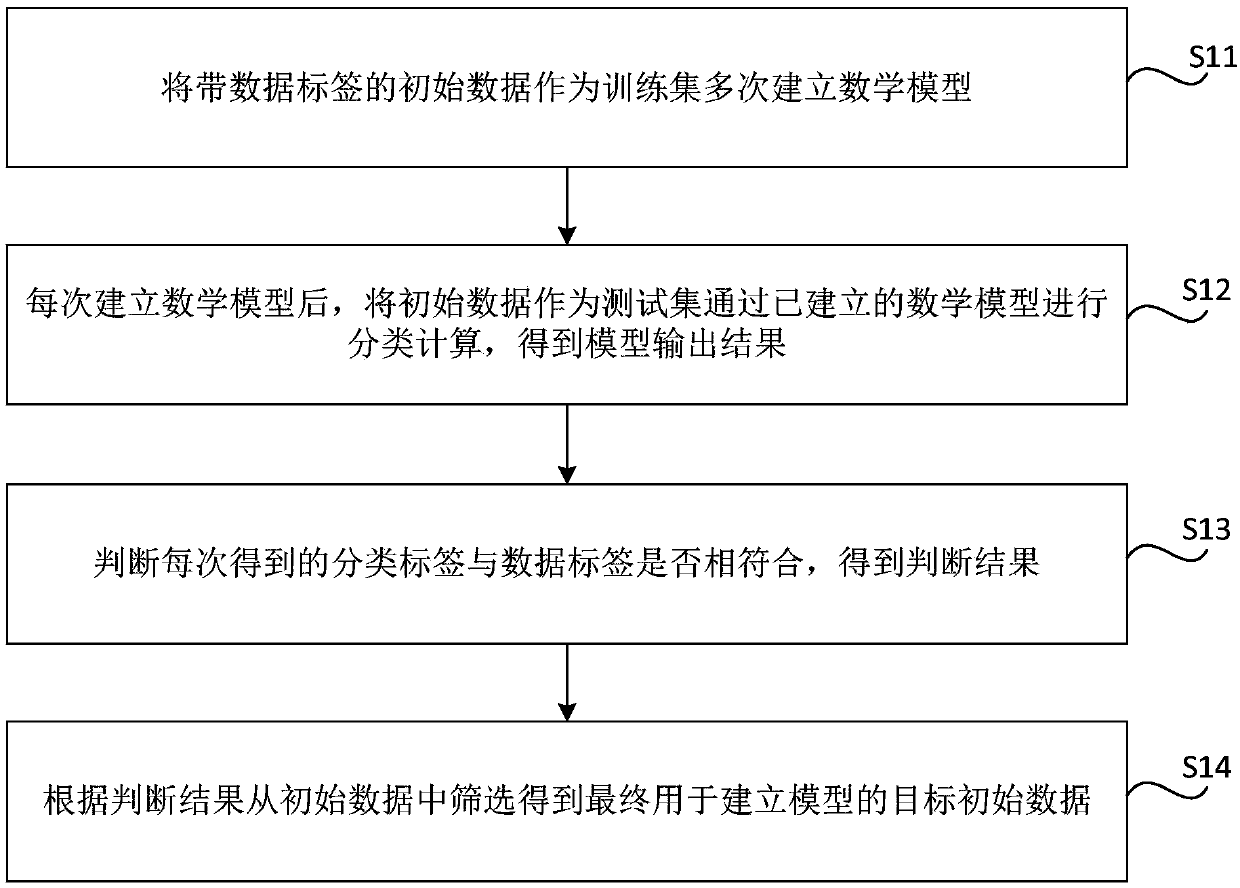

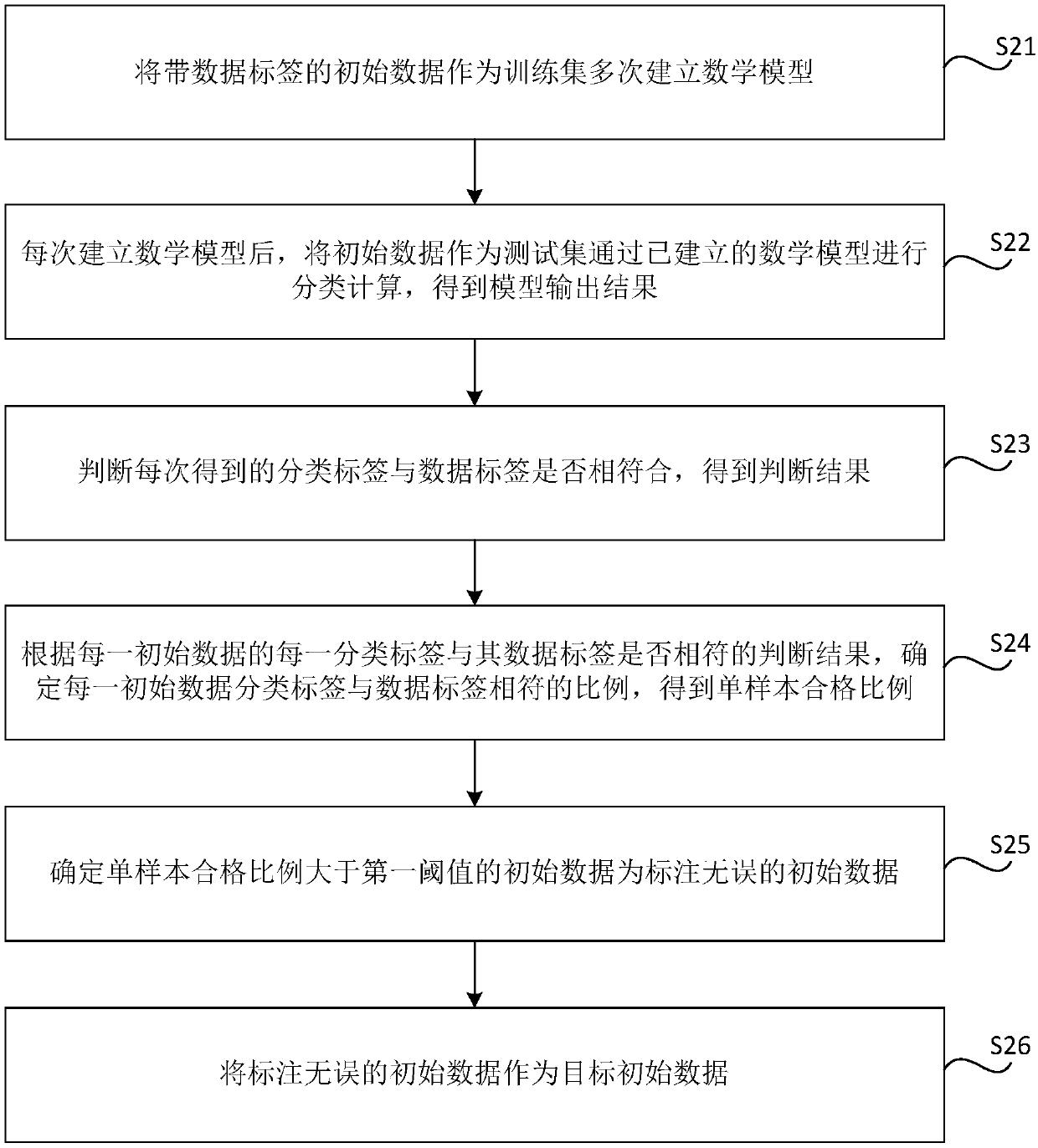

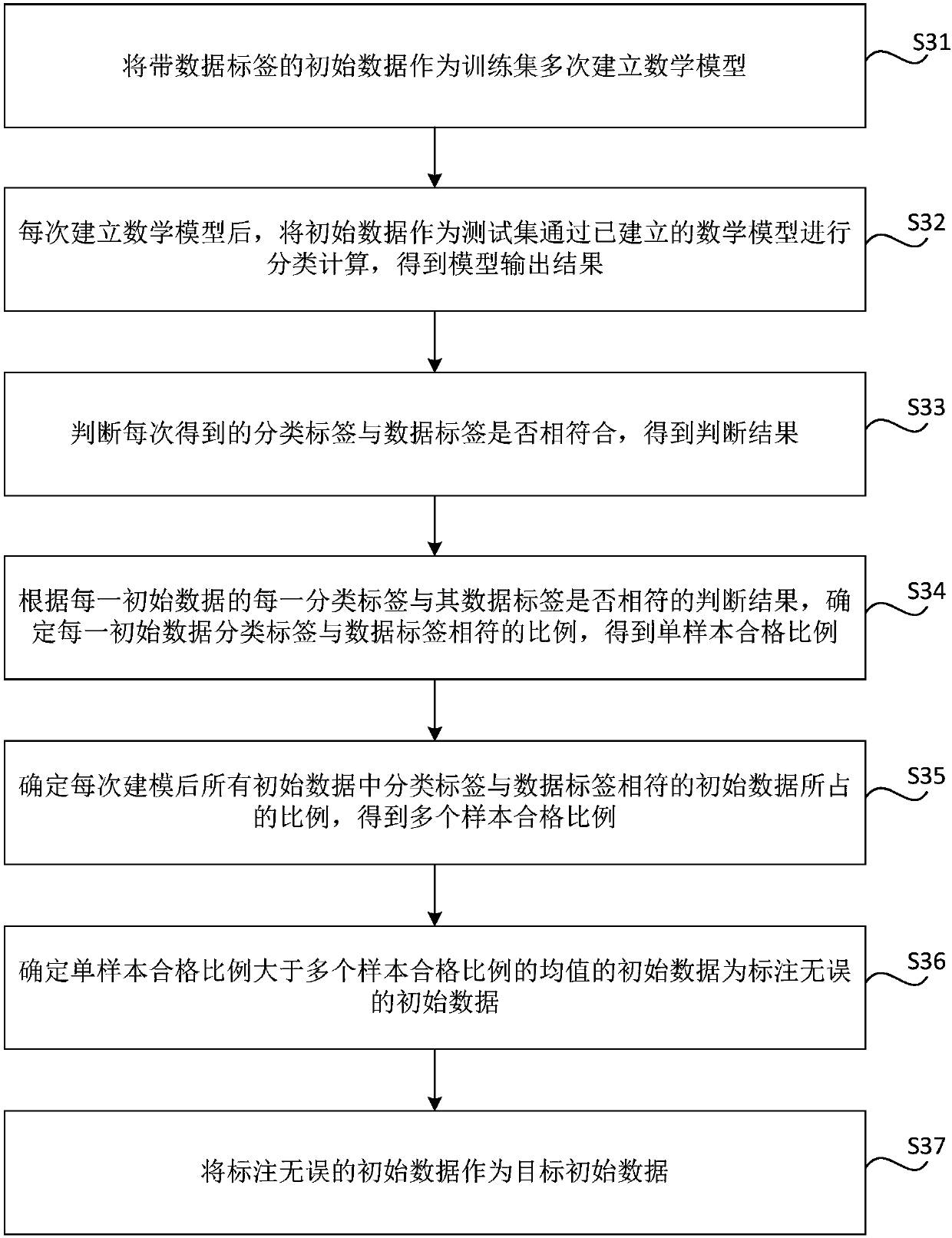

Modeling data selection method and apparatus, storage medium and electronic device

InactiveCN108171335AImprove labeling qualityImprove accuracyCharacter and pattern recognitionMachine learningData selectionMathematical model

The invention relates to a modeling data selection method and apparatus, a storage medium and an electronic device, and aims to solve the problem of low classification model accuracy caused by inaccurate modeling data selection in the prior art. The method comprises the steps of building a mathematic model for multiple times by taking initial data with data tags as a training set; after the mathematic model is built each time, performing classification calculation through the built mathematic model by taking the initial data as a test set to obtain a model output result, wherein the model output result comprises classification tags of the initial data; judging whether the classification tags obtained each time are consistent with the data tags or not, thereby obtaining a judgment result; and according to the judgment result, screening out target initial data finally used for building the model from the initial data.

Owner:NEUSOFT CORP

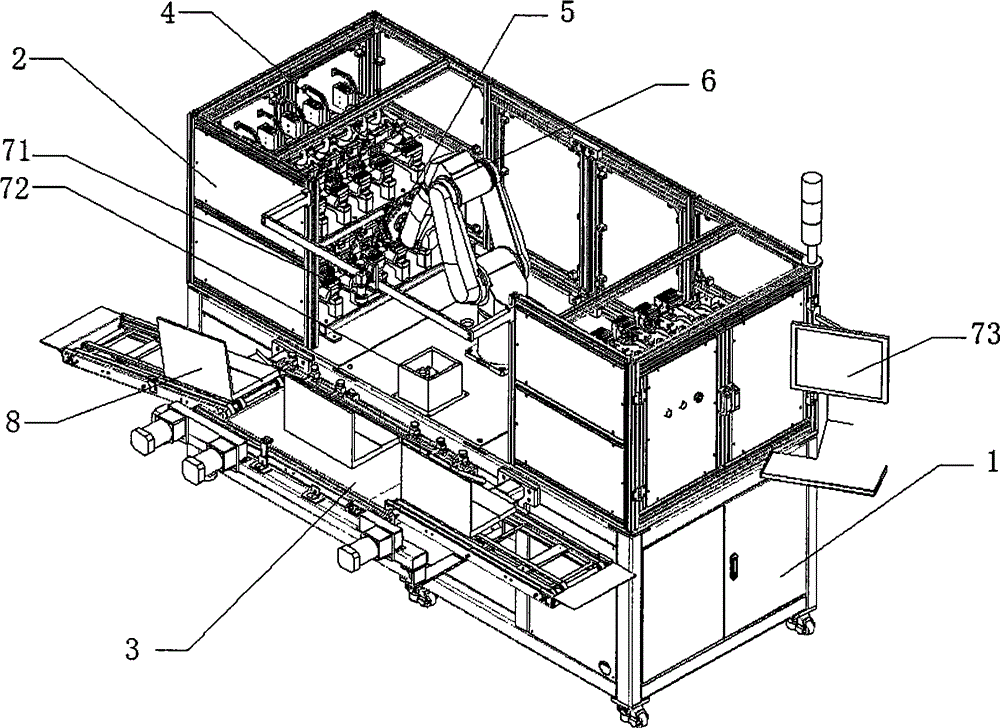

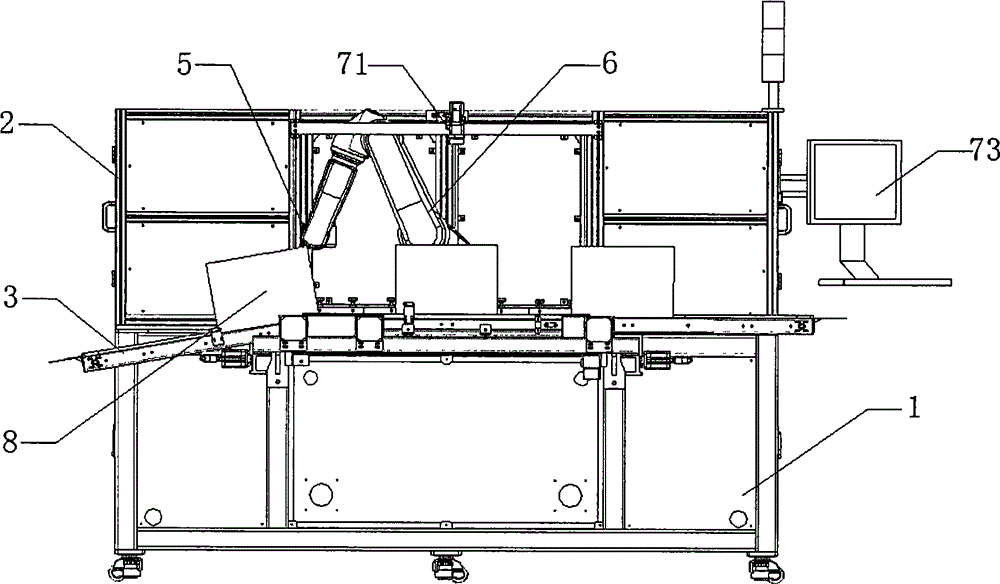

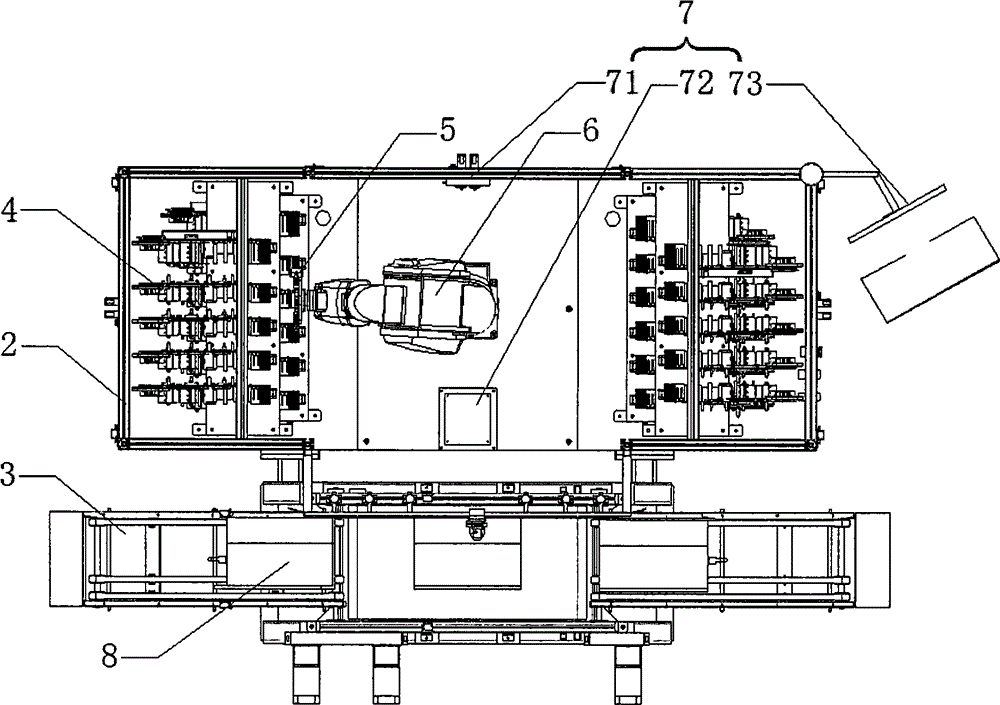

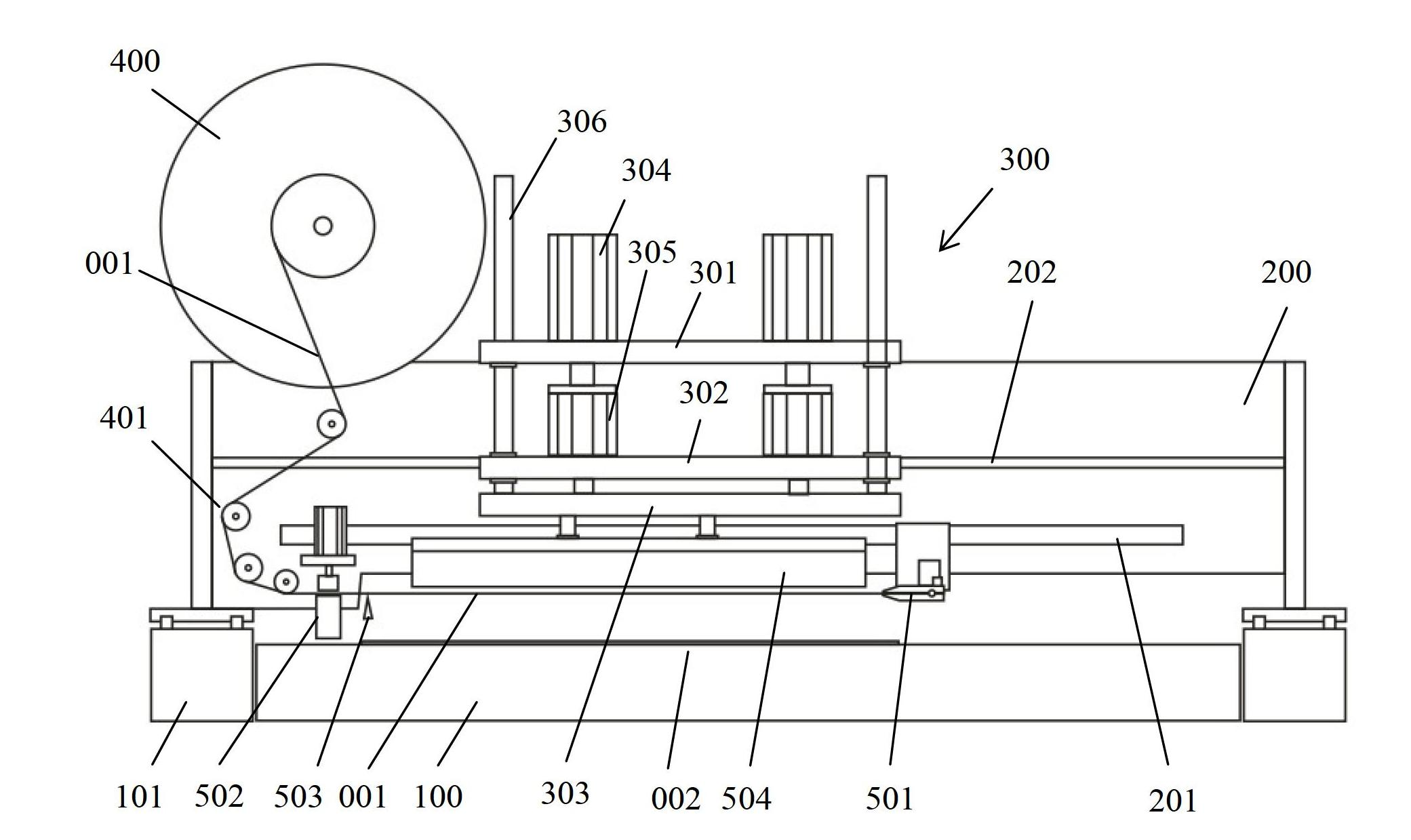

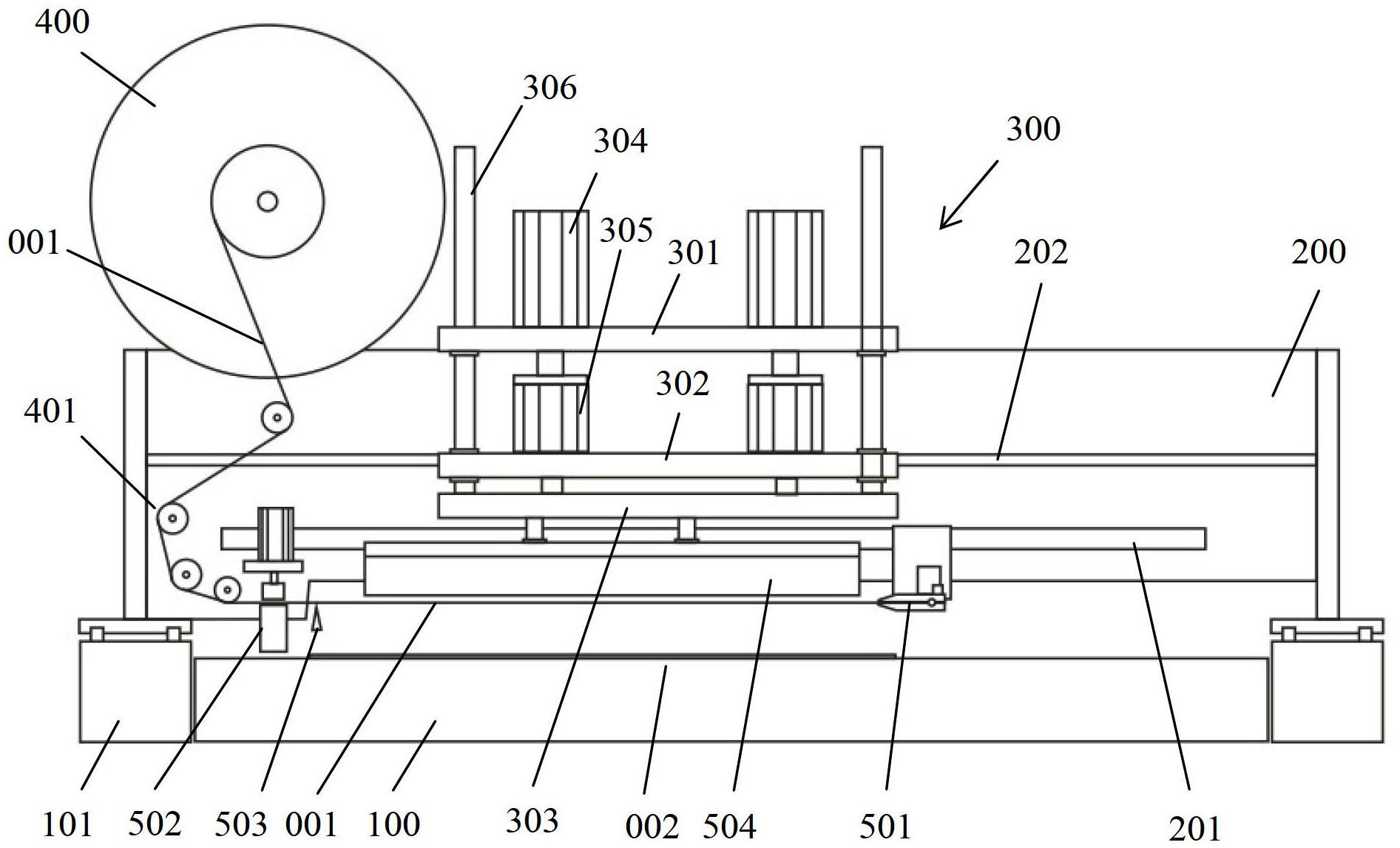

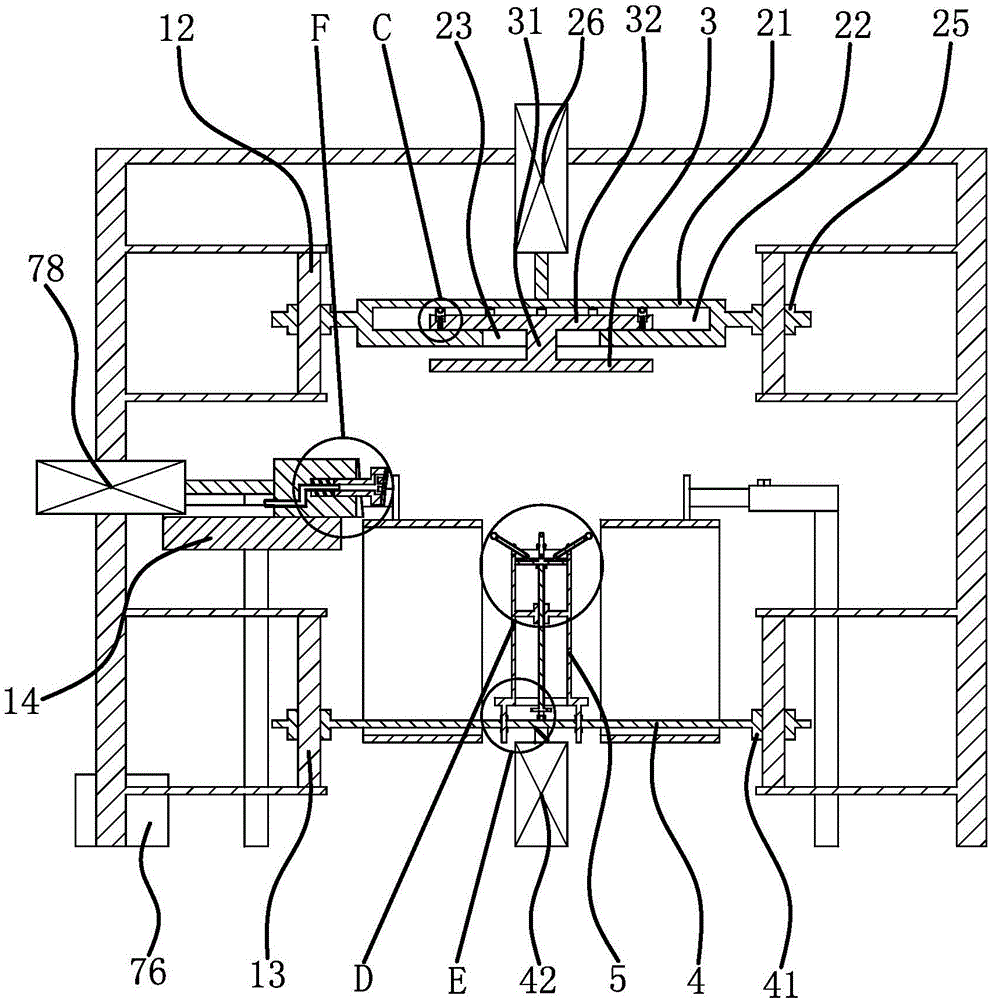

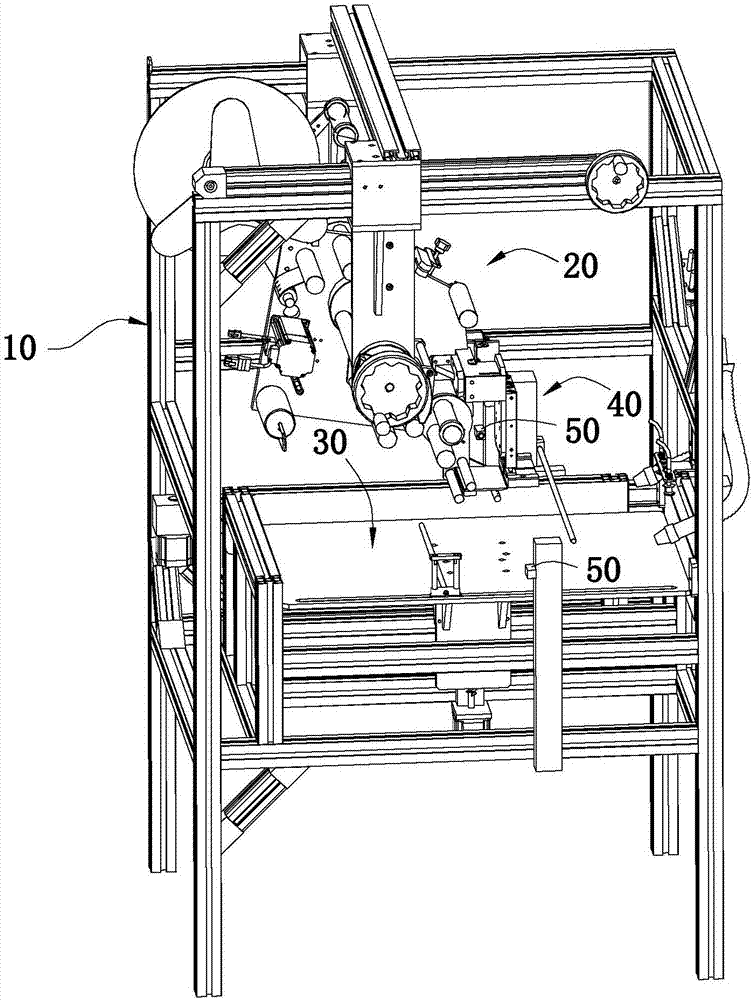

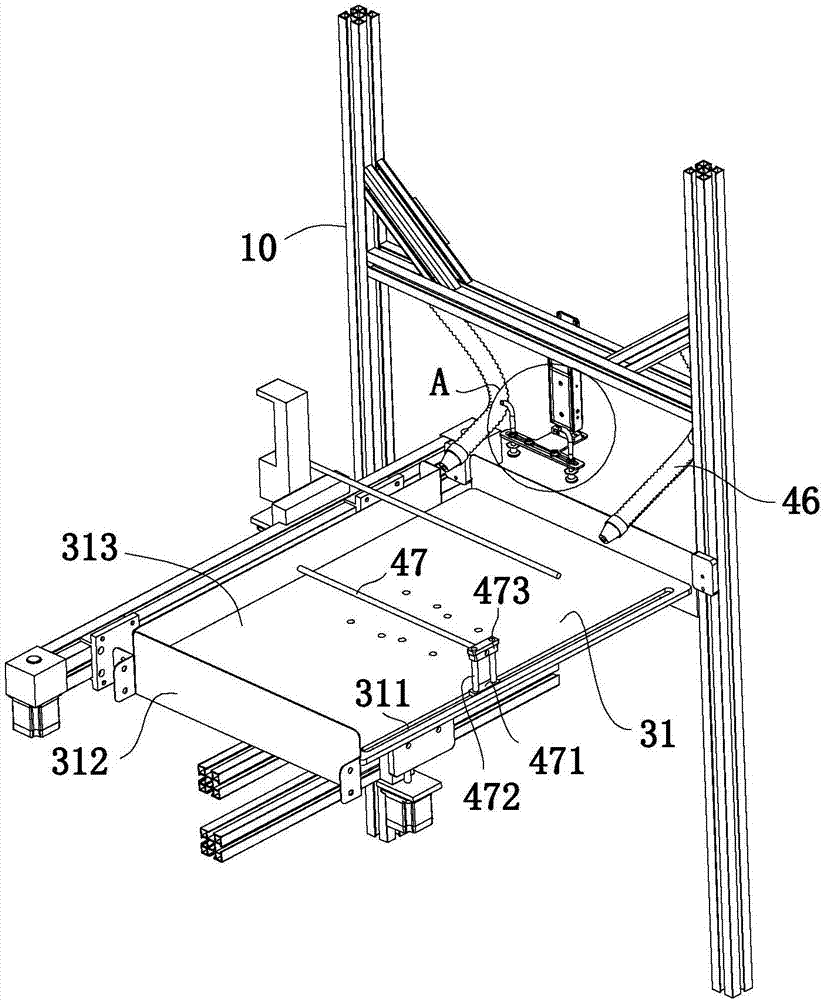

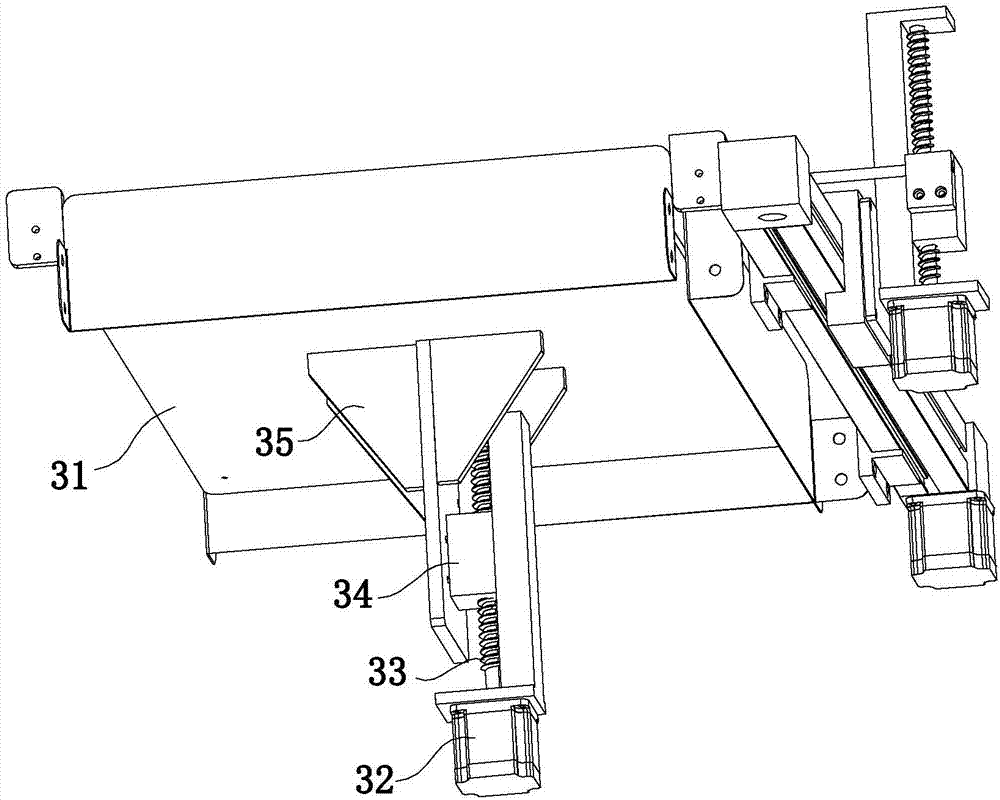

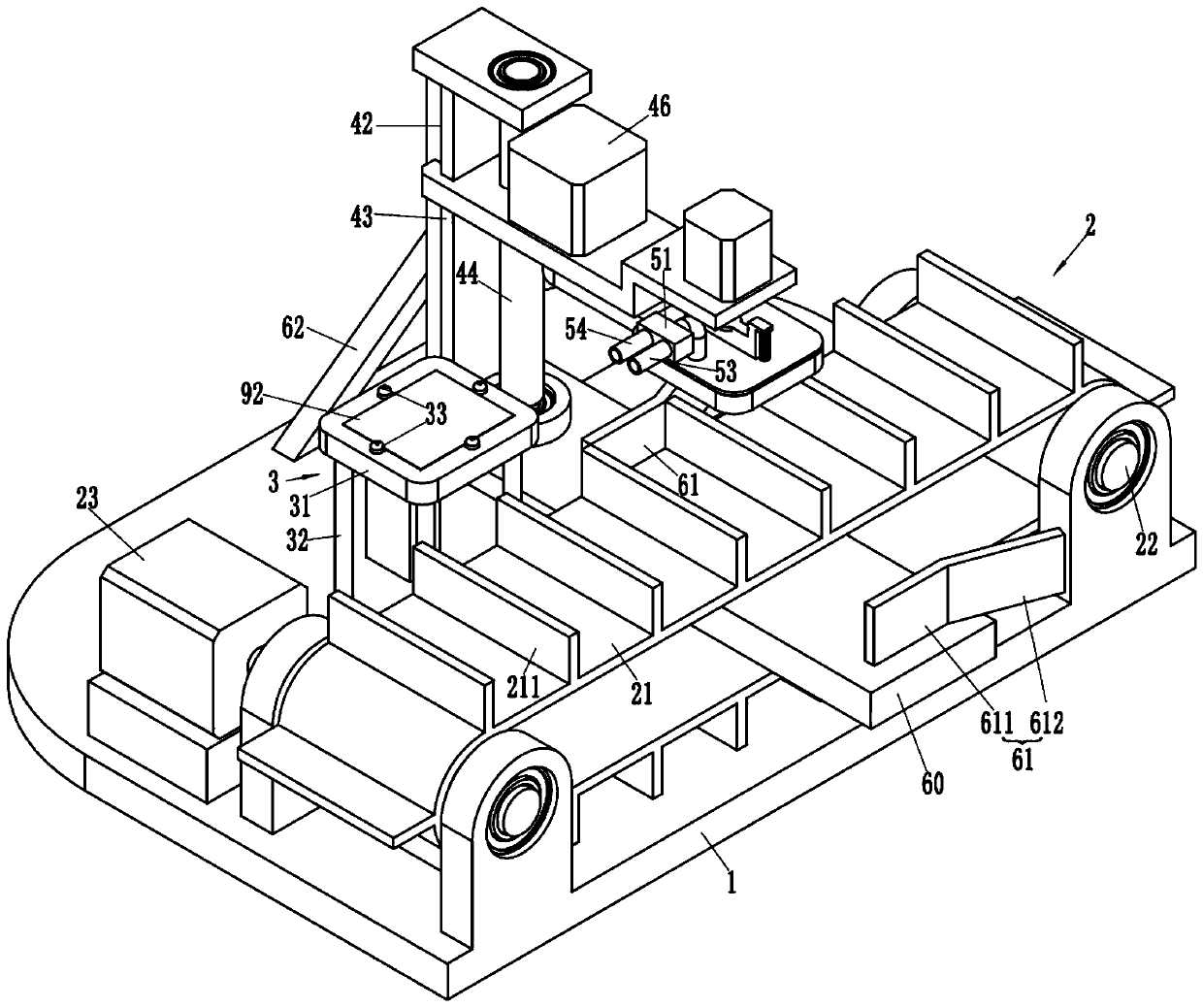

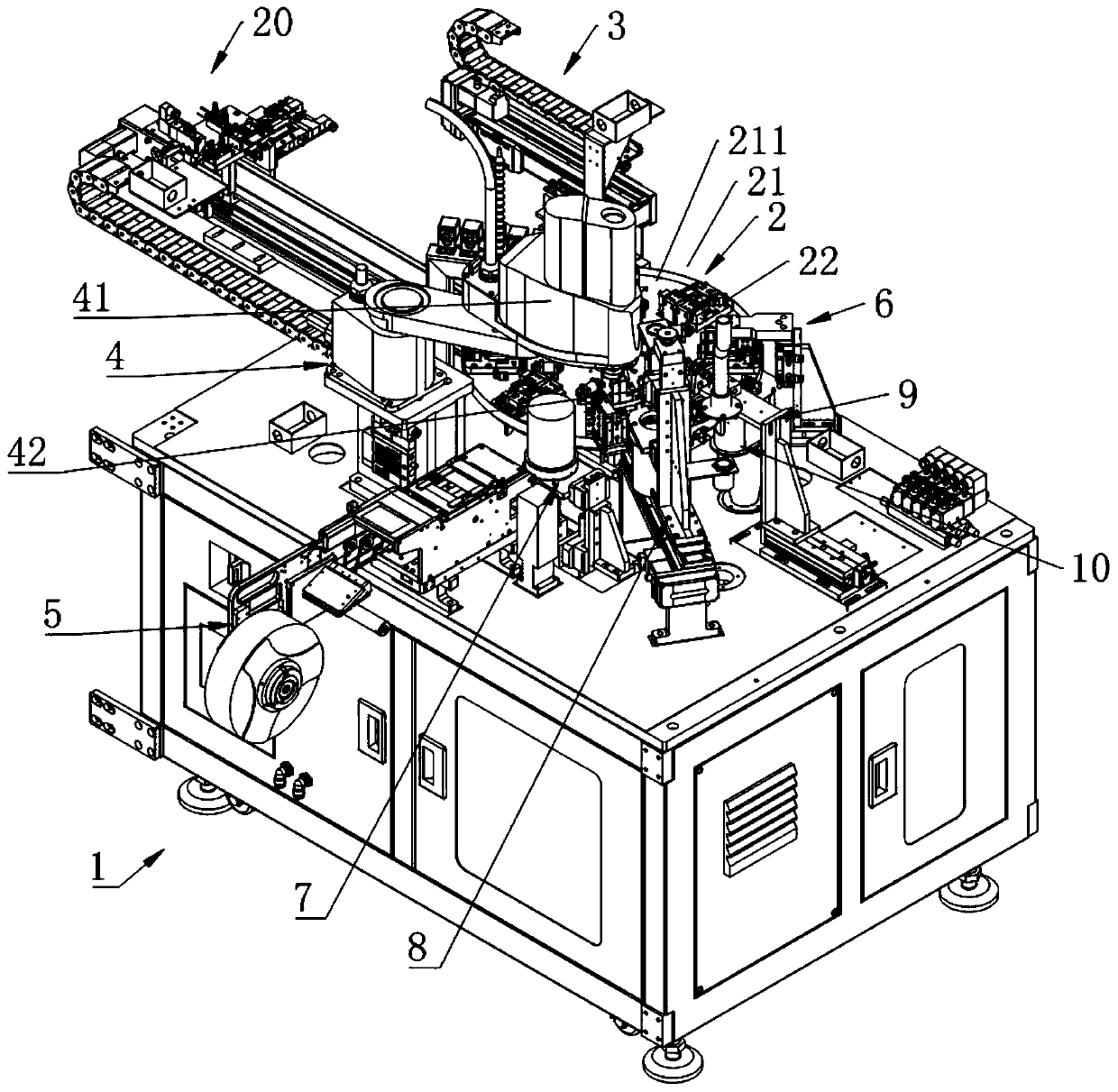

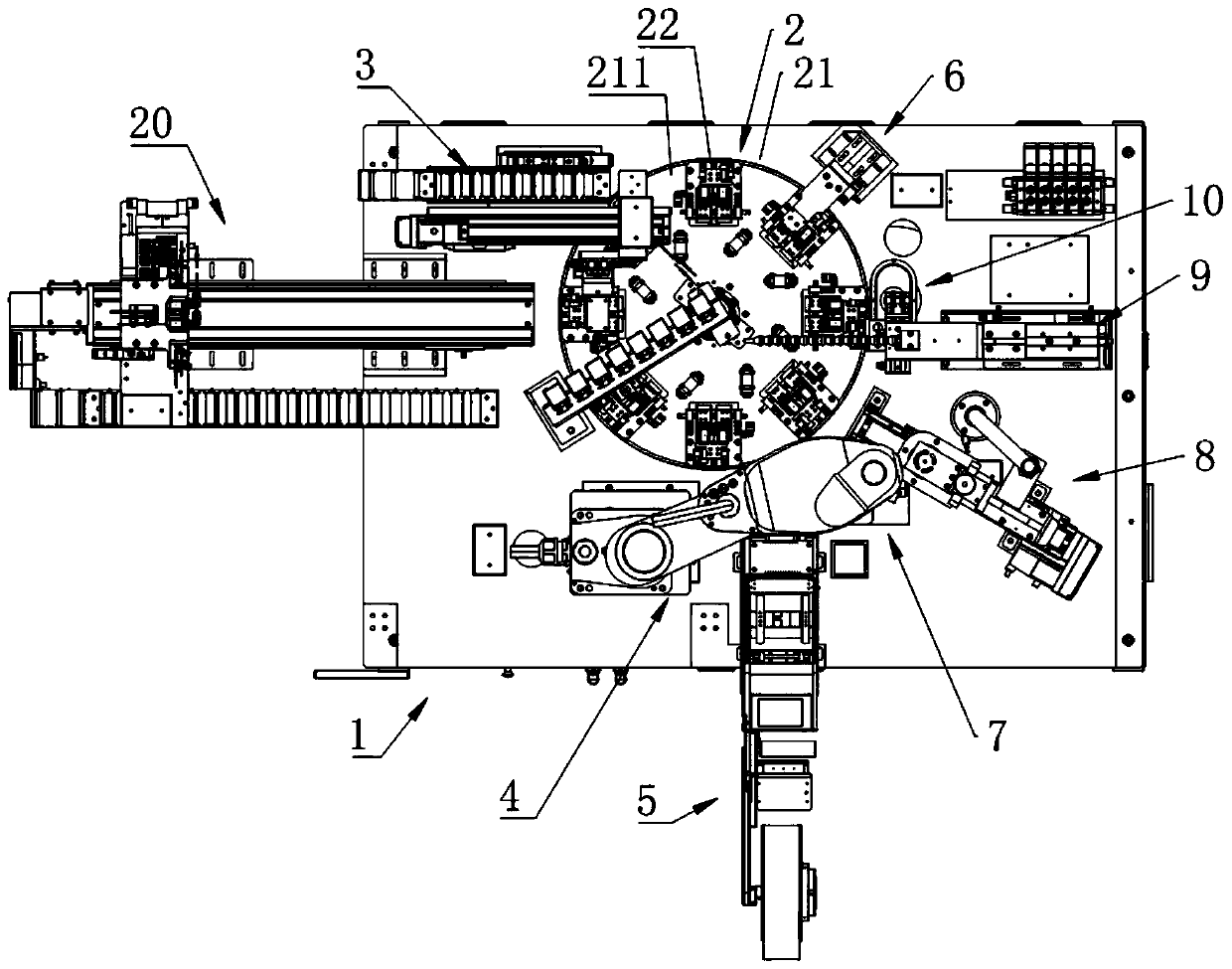

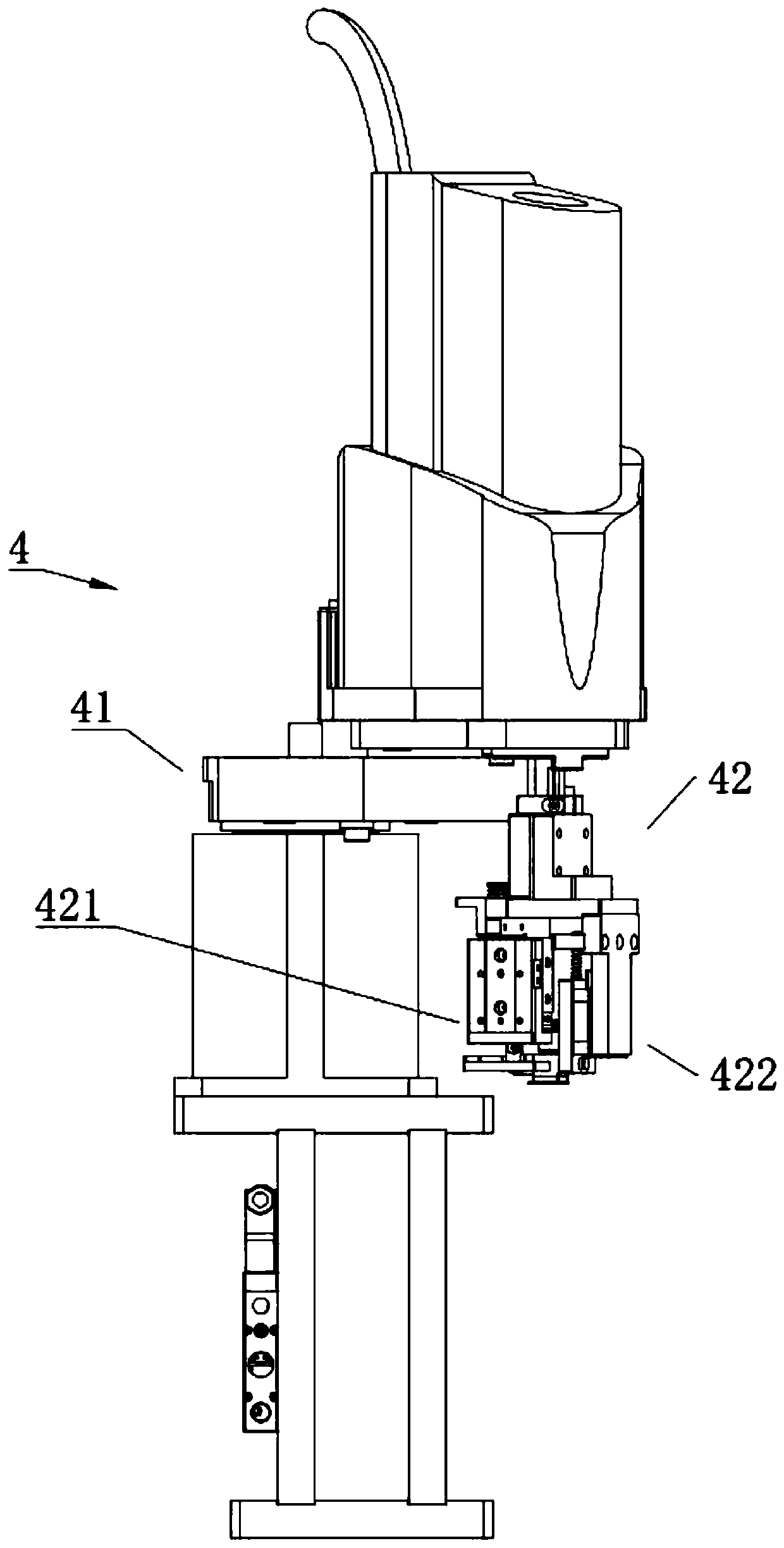

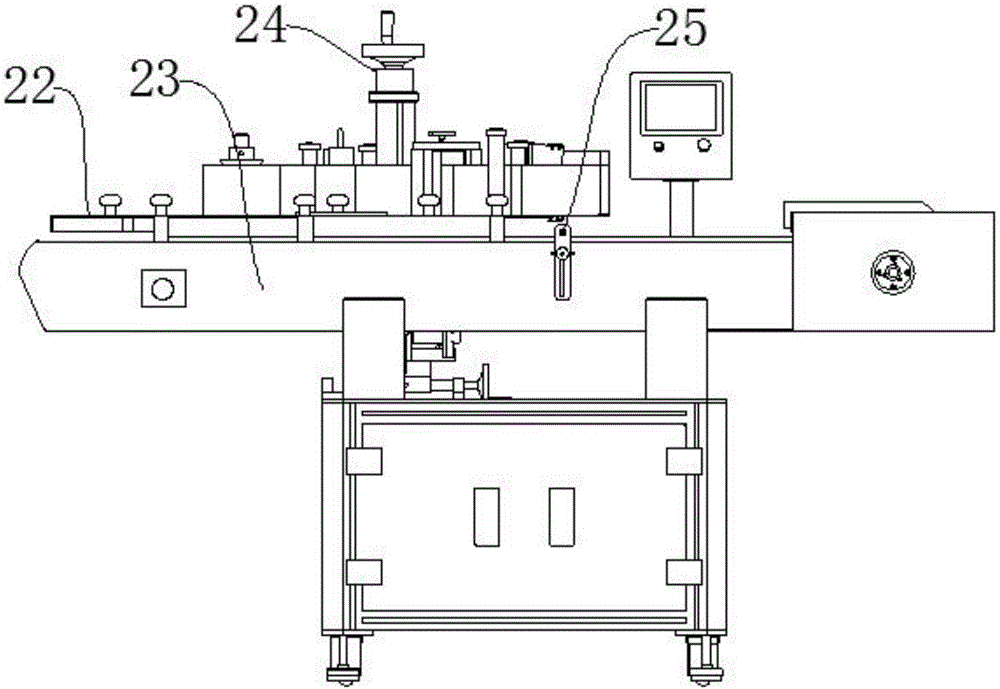

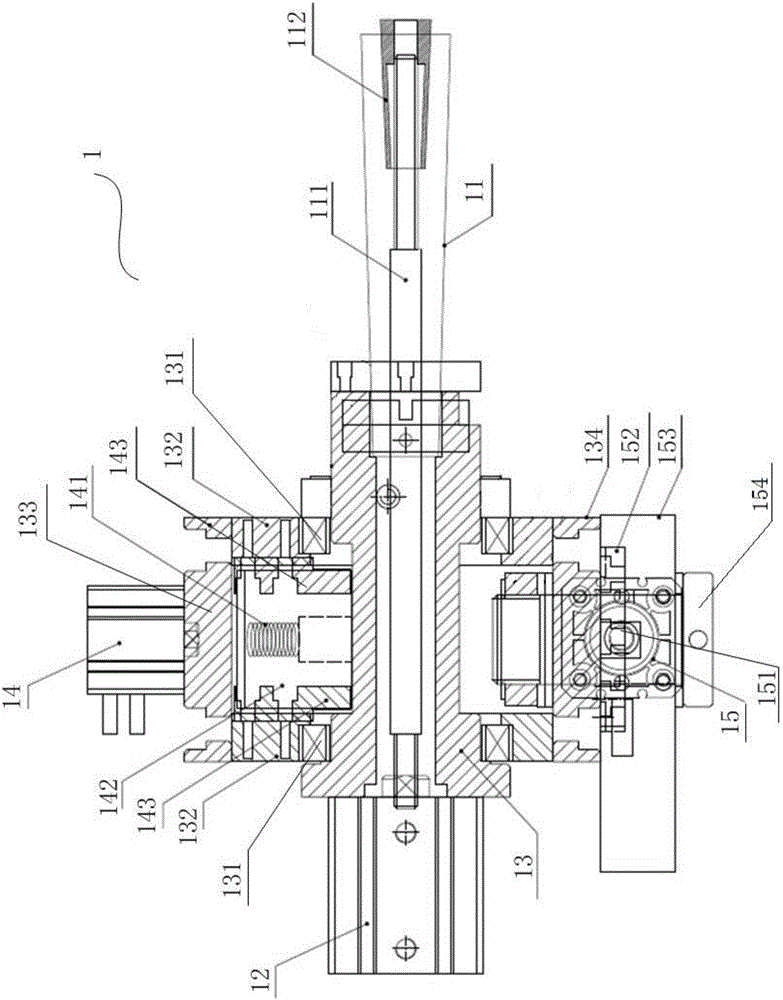

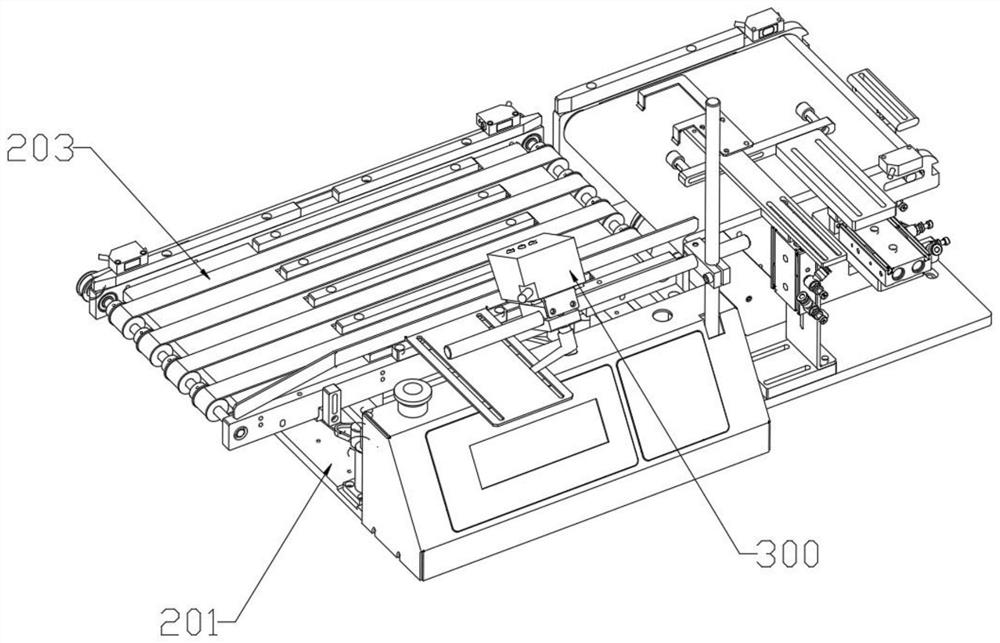

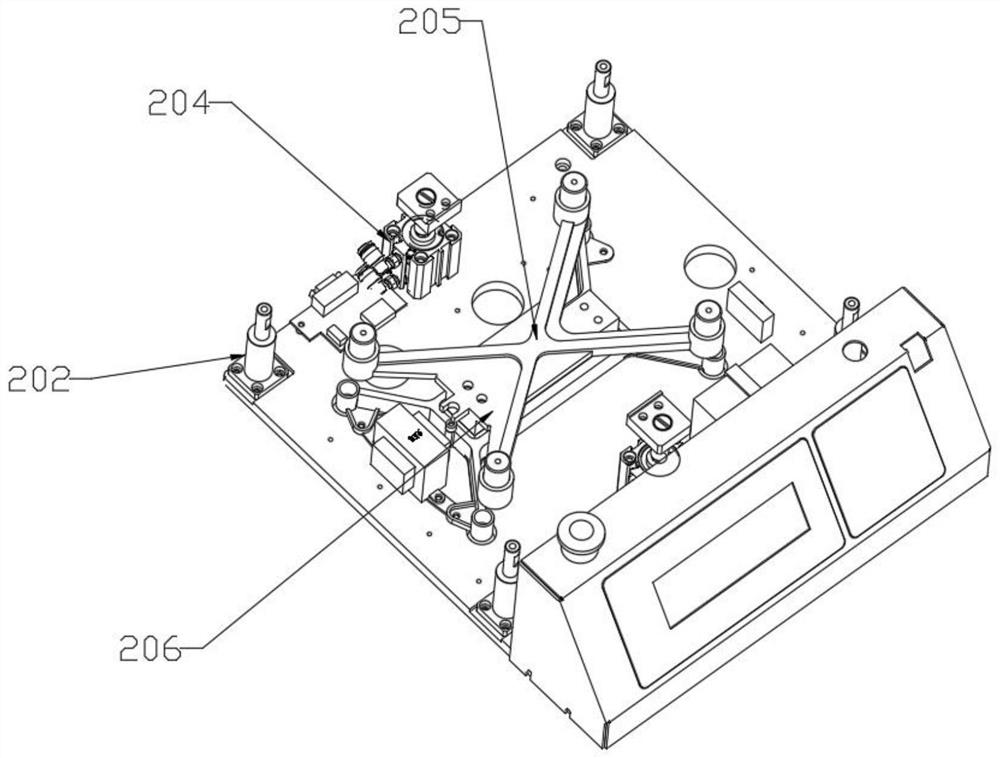

Automatic labeling machine of six-axis mechanical arm

InactiveCN104443616AHigh speed pick and placePrecise positioningLabelling machinesHigh rateEngineering

The invention discloses an automatic labeling machine of a six-axis mechanical arm. The automatic labeling machine of the six-axis mechanical arm comprises a labeling machine body, an upper rack set, a three-section belt line, a positioning system, a label peeling machine set, a label sucking set and a six-axis mechanical arm, wherein the upper rack set is fixedly mounted on the labeling machine body; the three-section belt line is arranged on the side edge of the labeling machine body; the label peeling machine set is mounted on the upper rack set; the six-axis mechanical arm is fixedly mounted on the labeling machine body; the label sucking set sleeves the six-axis mechanical arm. The automatic labeling machine of the six-axis mechanical arm has the characteristics that labels are taken and arranged at high rate and are precisely positioned; the manual labeling error rate is reduced; the labeling quality is improved; a pentagonal suction disc rotates and sucks a plurality of labels; a plurality of labels can be simultaneously pasted to notebook computers.

Owner:ANHUI HONGSHI AUTOMATION EQUIP CO LTD

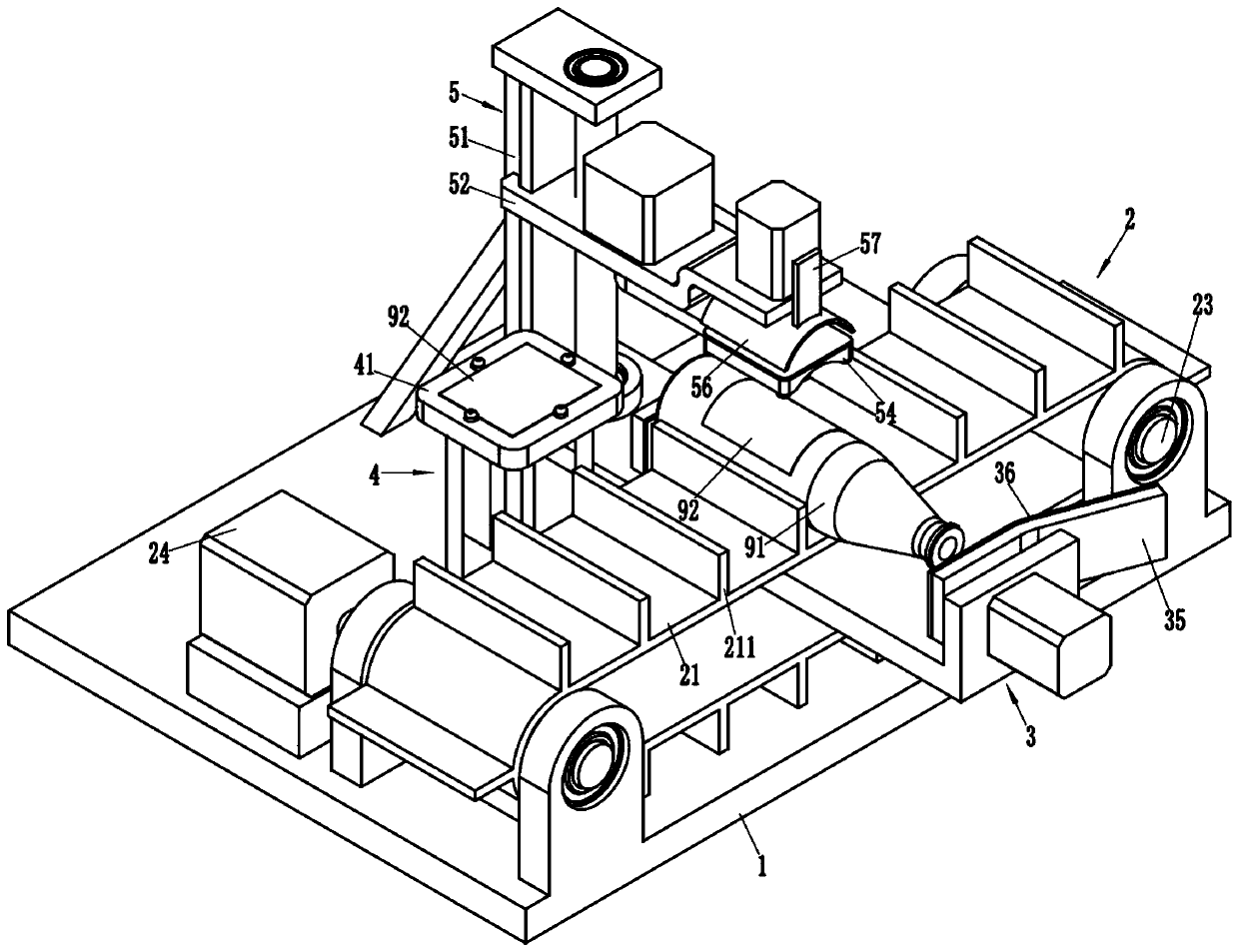

Automatic wine bottle labeling equipment

InactiveCN111532531AAutomatic transferAutomated paste workLabelling short rigid containersLabelling machinesWine bottleProcess engineering

The invention discloses automatic wine bottle labeling equipment which comprises a rack. A wine bottle conveying mechanism, a wine bottle locating mechanism, a label containing table and a labeling mechanism are arranged on the rack. By means of the automatic wine bottle labeling equipment, the work of label transfer and label pasting can be automatically achieved, and the labeling work efficiencyand the labeling quality are improved.

Owner:台州市知味堂餐饮企业管理咨询有限公司

Improved labelling machine for plastic cups

ActiveCN104803059ASpecifications in orderHigh degree of automationLabelling short rigid containersEngineeringMechanical equipment

The invention provides a labeling machine of a plastic cup, and belongs to the technical field of mechanical equipment, and solves the problem that the conventional plastic cup labeling machine is low in efficiency. The labeling machine of the plastic cup comprises a working table, wherein a working disc is connected with the working table; the working table is internally provided with a first driving mechanism; the working disc is connected with a plurality of positioning rods; a positioning mechanism is arranged between the working disc and the positioning rod; a positioning block is connected with the positioning rod; the working table is provided with a labeling base; a first rotating rod and a second rotating rod are connected with the labeling base; the working table is internally provided with a second driving mechanism; the labeling base is further fixedly connected with a fixing rod; the fixing rod is sleeved with a label pressing block; a tension mechanism is further arranged on the labeling base; an adjusting mechanism, a tightening piece mechanism, a turning mechanism and a jacking mechanism are arranged between the labeling base and the working table. The labeling machine of the plastic cup is capable of adhering a label to the outer side wall of the plastic cup, is high in working efficiency, and is applicable to plastics of different sizes.

Owner:NANTONG FULEHUA MACHINERY CO LTD

Automatic labeling equipment

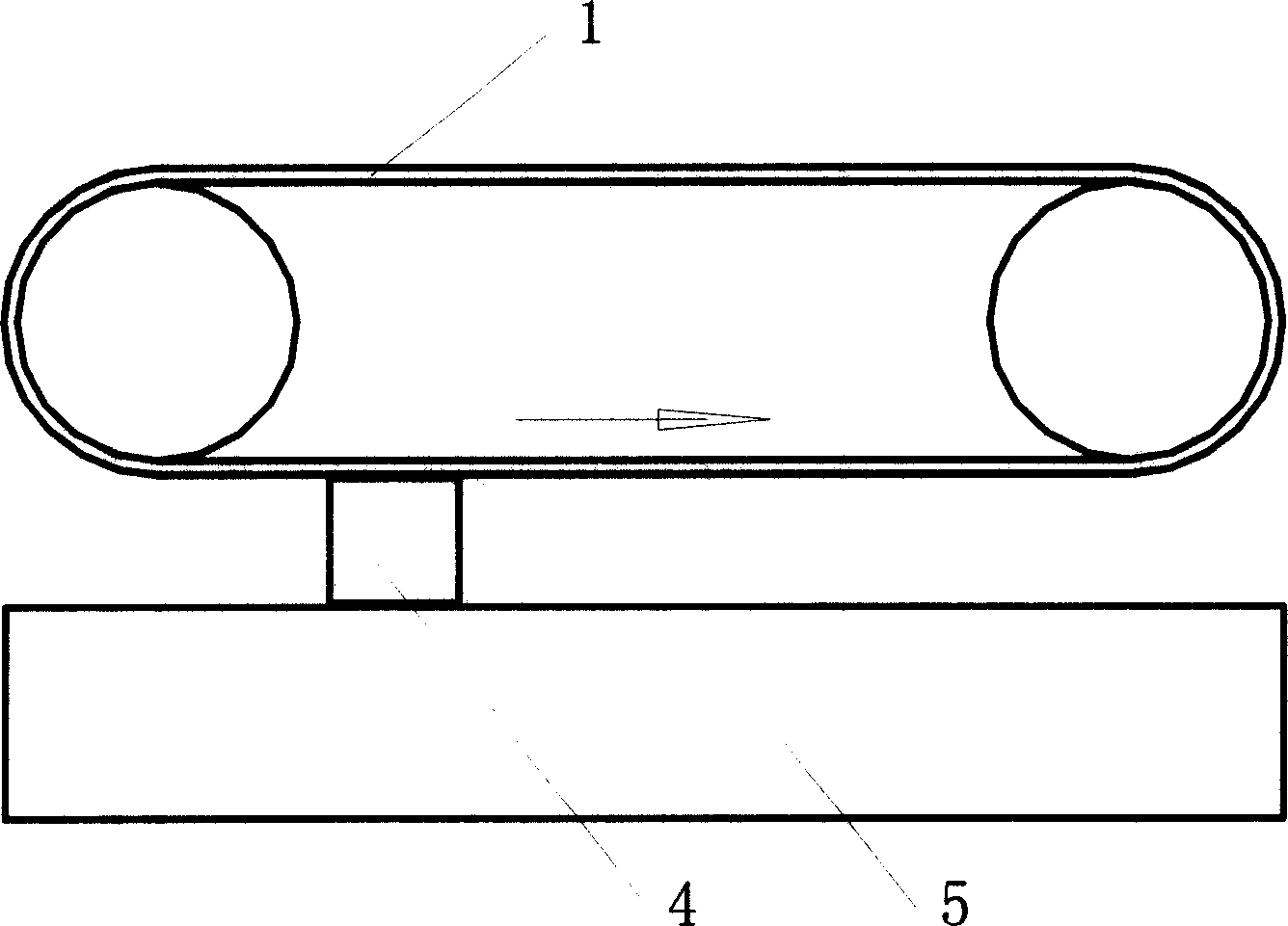

InactiveCN102658988AImprove labeling efficiencyImprove labeling qualityWebs handlingAutomatic test equipmentFixed frame

The invention discloses automatic labeling equipment which comprises a bottom paper platform and a transverse supporting beam arranged above the bottom paper platform, wherein a fixed frame is arranged on the transverse supporting beam; a vertical pneumatic driving component is arranged on the fixed frame; a bar-shaped suction plate is arranged on the vertical pneumatic driving component and driven by the vertical pneumatic driving component to move up and down in a reciprocating manner; a transverse first sliding rail is arranged at the lower part of the transverse supporting beam; a first chuck which is driven to move along the first sliding rail in a reciprocating manner is arranged in the first sliding rail; a winding drum is arranged above the side end of the transverse supporting beam; a second chuck is arranged below the winding drum and corresponds to the first sliding rail; and a cutter is arranged in front of the second chuck. The automatic labeling equipment can automatically paste a label on bottom paper, so that the labeling efficiency is improved, and the labeling quality is improved.

Owner:SHANGHAI MAXIM GARMENT ACCESSORIES

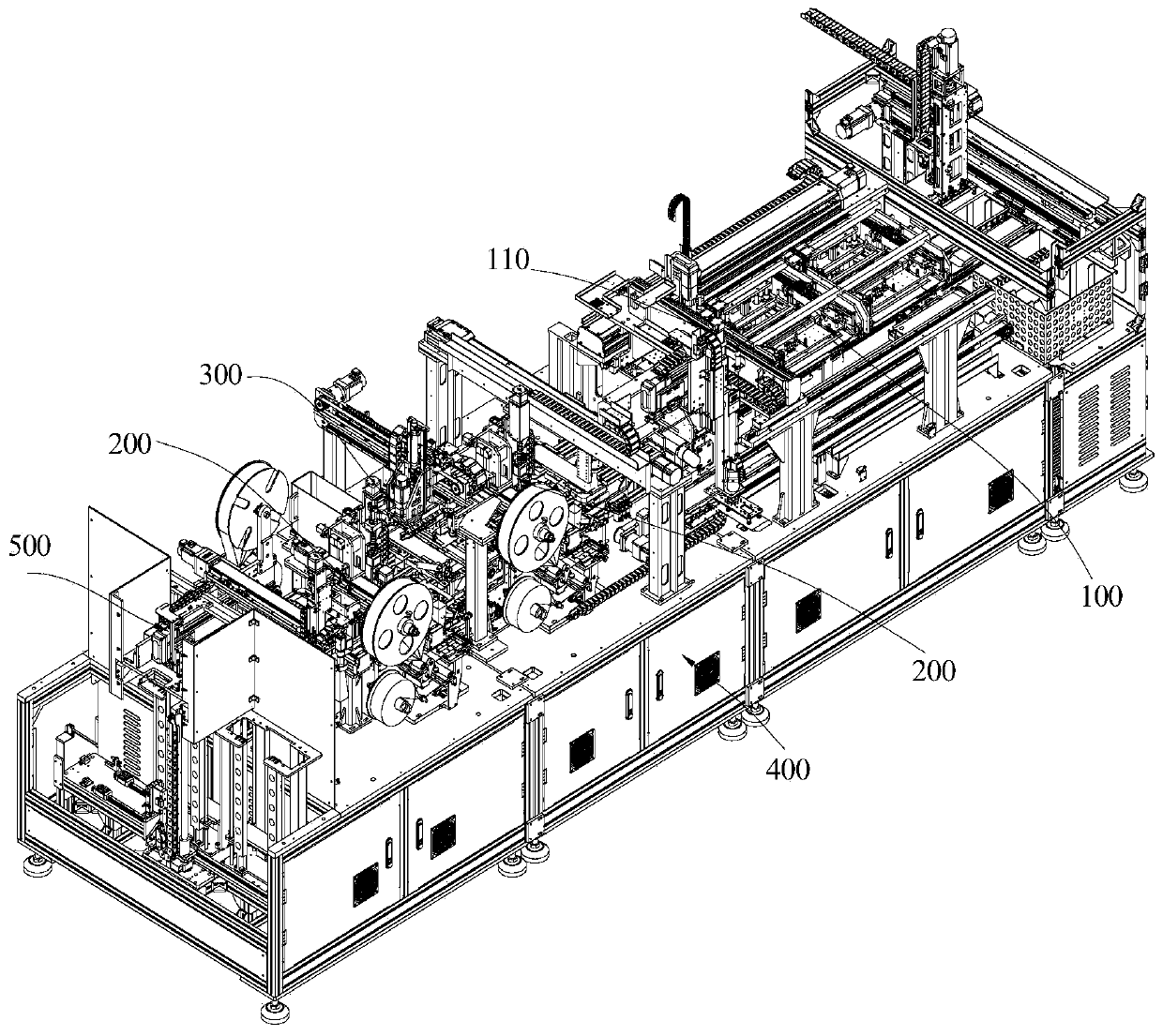

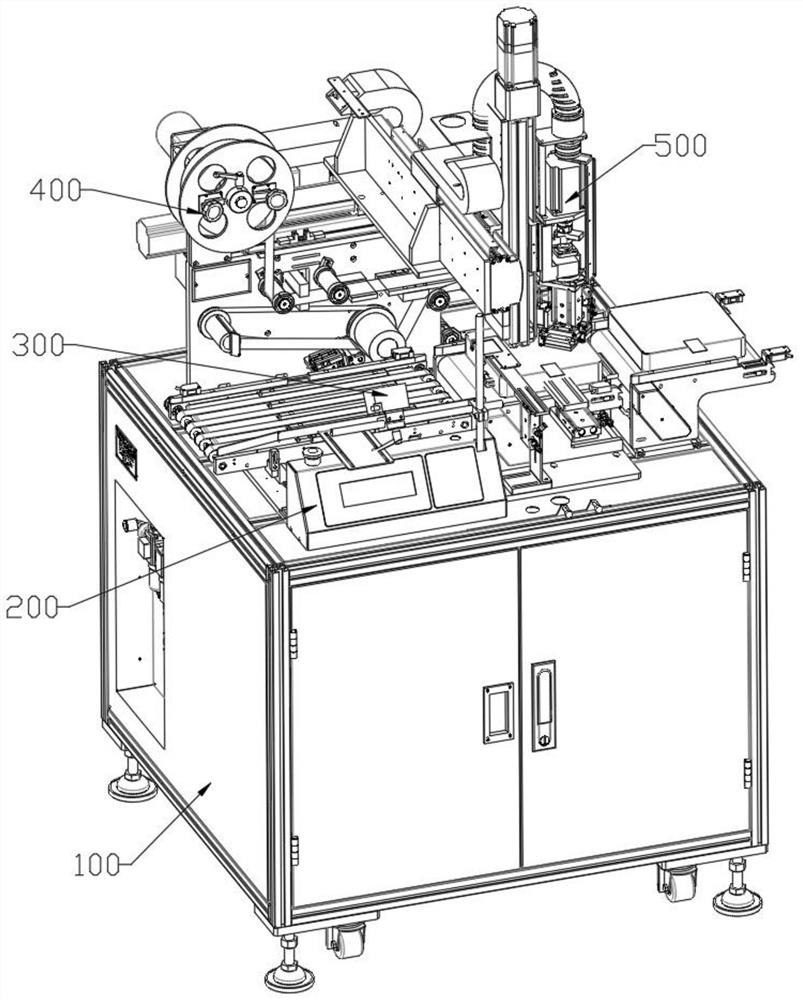

Automatic production line for paper box labeling and folding

ActiveCN111038809AHigh degree of automationReduce human interventionLabelling machinesProduction lineRobot hand

The invention discloses an automatic production line for paper box labeling and folding. The automatic production line comprises a machine body, wherein a labeling mechanism comprises a first workbench, a second workbench, a first workpiece transferring mechanism and a labeling mechanical arm; the first workbench is provided with a positioning assembly; the second workbench is provided with a label pressing mechanism; the label pressing mechanism comprises a label pressing roller, a first drive assembly and a second drive assembly; the label pressing roller is arranged above the second workbench; a box folding mechanism comprises a workpiece carrying plate assembly, a guide assembly and a second workpiece transferring mechanism; the workpiece carrying plate assembly comprises a workpiece carrying plate, a workpiece carrying plate drive mechanism and an overturning mechanism; the workpiece carrying plate is provided with a workpiece jig used for fixing a workpiece and used for driving the workpiece carrying plate to move to a forming station; the overturning mechanism is used for driving the workpiece to overturn after the workpiece carrying plate moves to the forming station; and the guide assembly is used for guiding the overturning mechanism to overturn after the workpiece carrying plate moves to the forming station. By means of the automatic production line, labeling and boxfolding can be automatically completed, and the production efficiency is improved.

Owner:ZHUHAI BOJAY ELECTRONICS

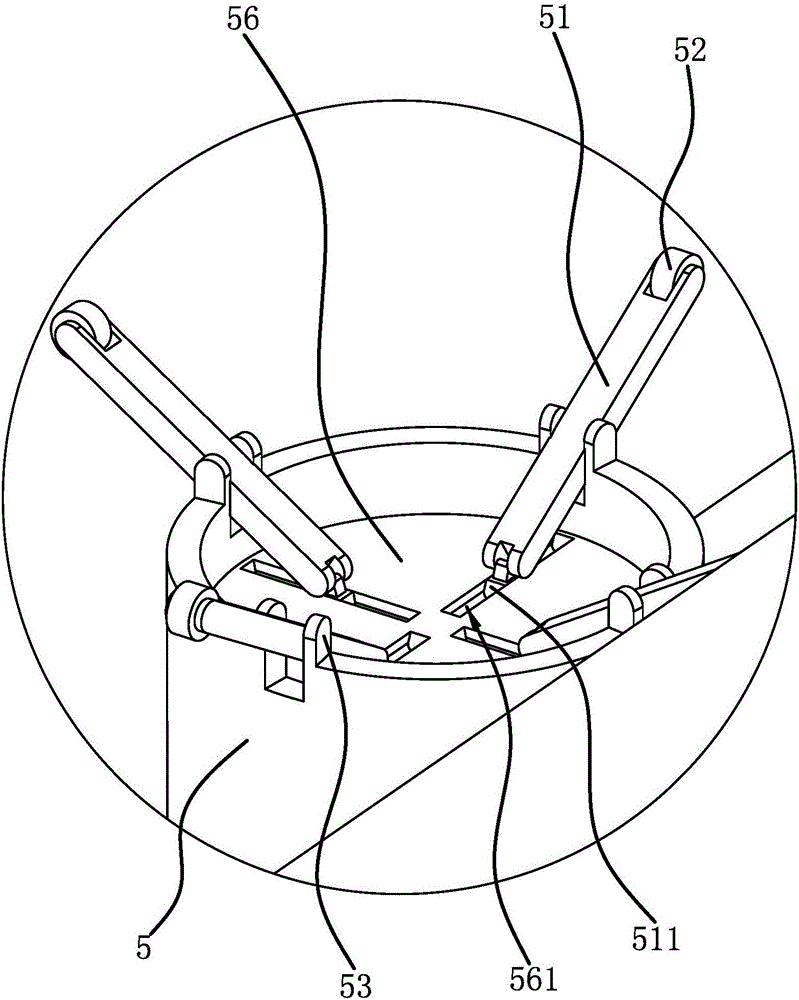

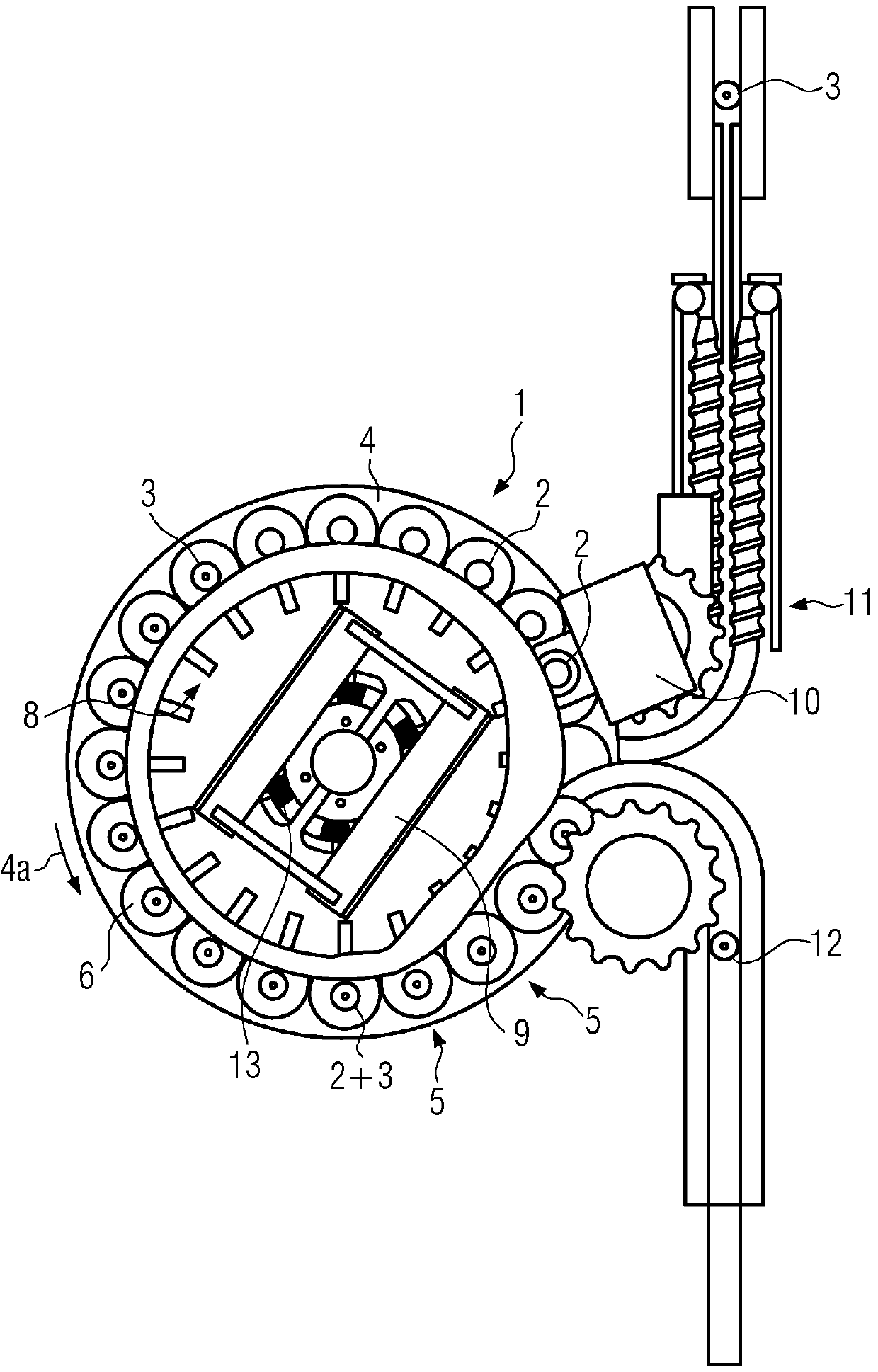

Labeling mechanism of round bowl production line

ActiveCN106829106APrecise positioningImprove labeling qualityLabelling machinesLabelling short rigid containersProduction lineConveyor belt

The invention provides a labeling mechanism of a round bowl production line and belongs to the technical field of machining equipment, aiming at solving the problem that an outer wall of an existing round bowl is difficulty labeled. According to the labeling mechanism of the round bowl production line, the round bowl production line comprises a rack; the rack is provided with two conveyor belts; the labeling mechanism comprises a hoisting frame and a hoisting plate; the hoisting frame and the hoisting plate are in sliding connection onto the rack; the hoisting frame is connected with a pressing disc; the hoisting plate is vertically connected with a supporting pipe; a plurality of positioning rods are hinged to the upper end of the supporting pipe; positioning wheels are hinged to the outer ends of the positioning rods; the rack is provided with an upper driving air cylinder and a lower driving air cylinder; the rack is in sliding connection with an abutting seat; the abutting seat is connected with a sticking seat; the sticking seat is provided with an adsorption mechanism; positioning shafts are arranged at parts, located at two sides of the abutting seat, of the rack. The labeling mechanism of the round bowl production line can be used for automatically labeling an outer side wall of a round bowl, and the labeling quality and the labeling efficiency are relatively high.

Owner:深圳市格仕乐科技有限公司

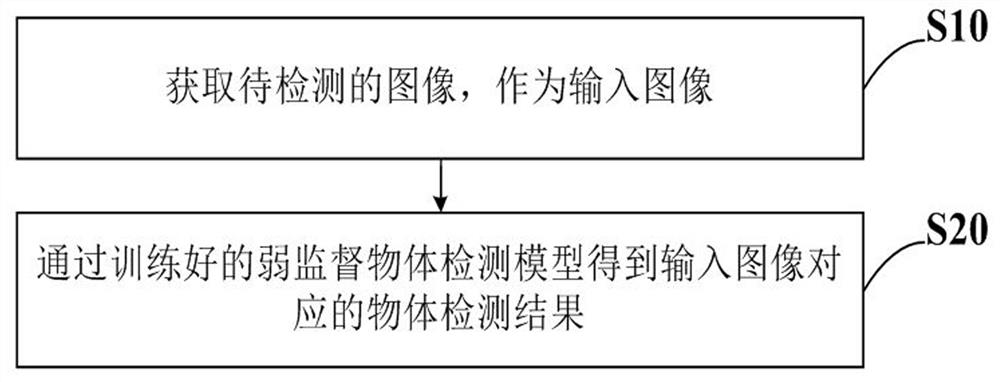

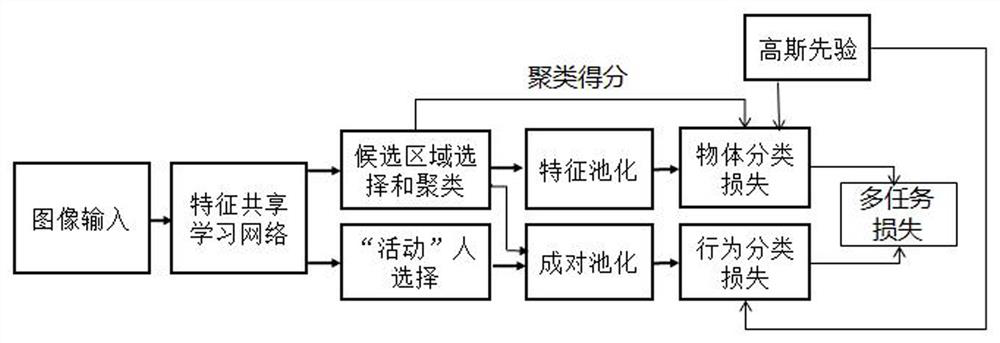

Object detection method based on human-object interaction weak supervision label

ActiveCN111931703AHigh precisionImprove labeling qualityCharacter and pattern recognitionNeural architecturesEngineeringImage pair

The invention belongs to the field of computer vision and robot vision, particularly relates to an object detection method based on a human-object interaction weak supervision label, and aims at solving the problems that an existing weak supervision object detection method is low in model convergence speed and poor in detection precision. The method comprises the following steps: acquiring a to-be-detected image as an input image; obtaining an object detection result corresponding to the input image through a trained weak supervision object detection model, wherein the weak supervision objectdetection model is constructed based on a deep convolutional neural network. According to the invention, the precision of weak supervision object detection is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Full-automatic plastic bag labeller

PendingCN107954043AImprove labeling efficiencyImprove labeling qualityLabelling deformable materialsLabelling machinesReciprocating motionEngineering

Disclosed is a full-automatic plastic bag labeller. The full-automatic plastic bag labeller comprises a machine frame, a labelling mechanism, a stacking mechanism and a turnover mechanism, wherein thelabelling mechanism, the stacking mechanism and the turnover mechanism are arranged on the machine frame. The stacking mechanism comprises a stacking platform. The labelling mechanism is located above the stacking platform, and comprises a label covering assembly. The label covering assembly comprises at least one label covering air cylinder, wherein the stroke of each label covering air cylinderis perpendicular to the stacking platform. The turnover mechanism comprises a lifting air cylinder, at least one vacuum suction device, a press rod and a poking rod, wherein the lifting air cylinderis fixed to one side of the machine frame, the stroke of the lifting air cylinder is perpendicular to the stacking platform, the vacuum suction devices are driven by the lifting air cylinder to ascendand descend, the press rod can be attached to the stacking platform, and the poking rod can get close to / keep away from one side of the press rod to conduct reciprocating movement. Due to the fact that the turnover mechanism is arranged to conduct paging labelling operation on plastic bags placed on the stacking platform so as to replace an existing conveying type labelling mode, the full-automatic plastic bag labeller is suitable for labelling operation of large-sized plastic bags or ultra-thin plastic bags, and the labelling efficiency is substantially improved.

Owner:宁波聚思智能科技有限公司

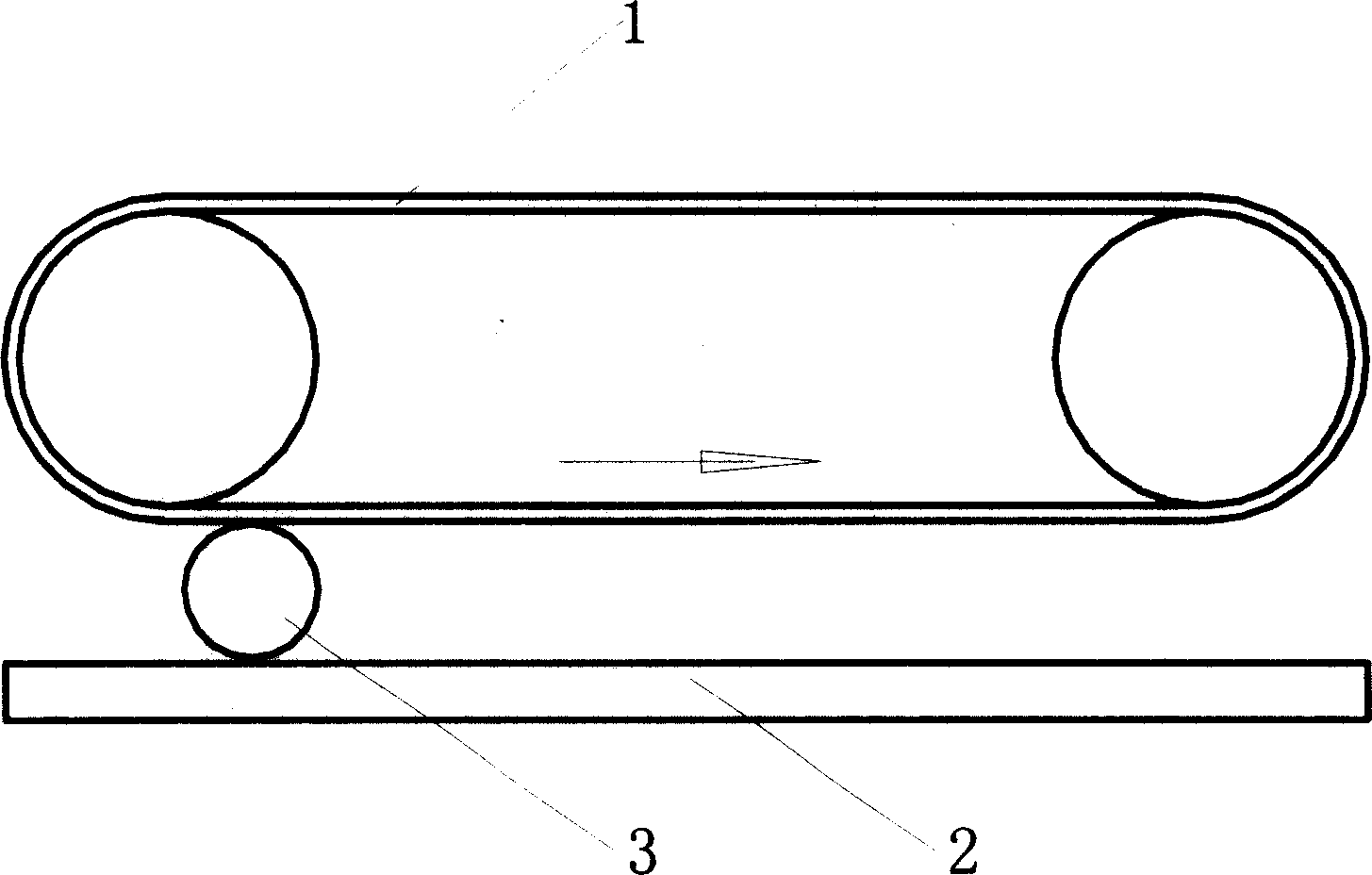

Roller wheel mark rubbing device for mark sticking machine

The roller label rubbing device for label sticking machine includes one relatively large roller and one push plate opposite to the roller. The roller has outer surface of soft material, the push plate is soft elastic deformable body, and there is some interval left between the push plate and the roller for the square bottle to enter. The push plate is suspended elastic belt of rectangular strip, and there is vacuum belt guiding mechanism in the bottle inlet. The present invention can complete label sticking job on four sides of square bottle with one single label sticking head, and has simple structure, reliable operation, high label sticking quality and long service life.

Owner:张春林

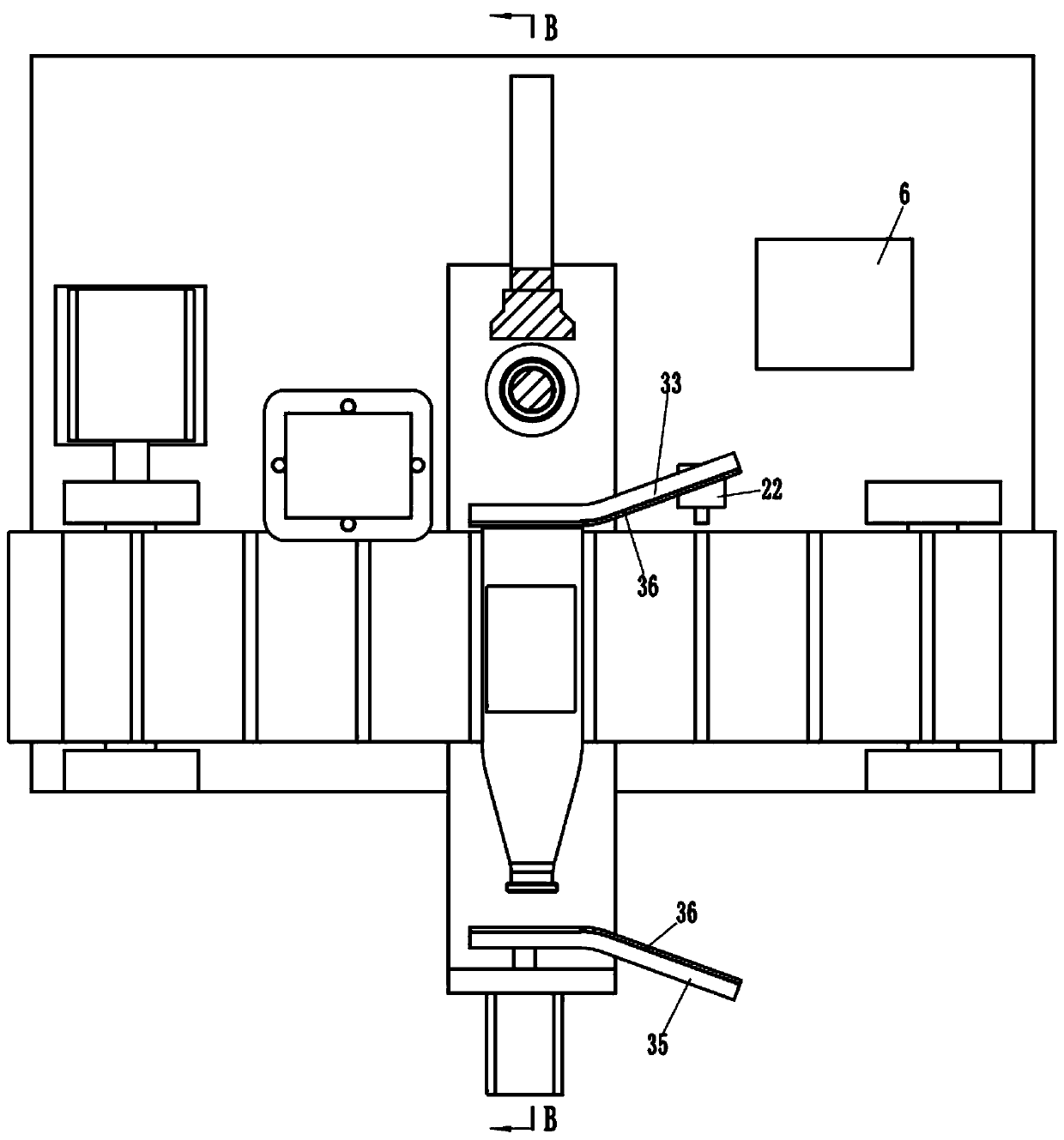

Automatic wine bottle labeling equipment

InactiveCN111532530AAutomatic transferAutomated paste workLabelling short rigid containersLabelling machinesSuction forceWine bottle

The invention discloses automatic wine bottle labeling equipment which comprises a rack. A wine bottle conveying mechanism, a label placing table and a labeling mechanism are arranged on the rack, thewine bottle conveying mechanism comprises a conveying belt, a limiting plate is arranged on the conveying belt, a sensor is arranged on the limiting plate, the labeling mechanism comprises a liftingrotatable label transferring disc, the label transferring disc adsorbs labels through vacuum suction force, and the labels are pasted through high-pressure gas. According to the equipment, label transfer and label pasting work can be automatically realized, and labeling work efficiency and labeling quality are improved.

Owner:台州市知味堂餐饮企业管理咨询有限公司

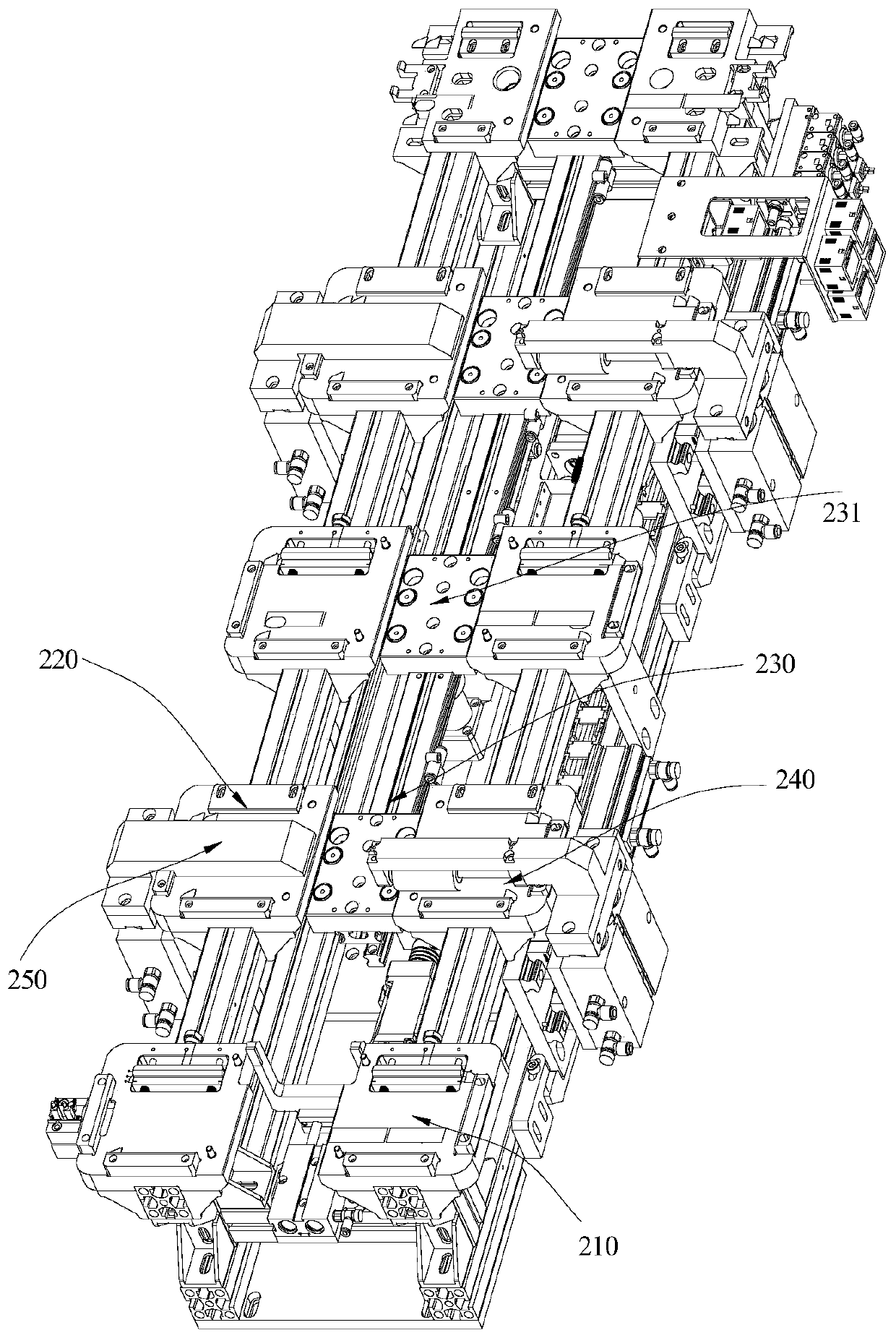

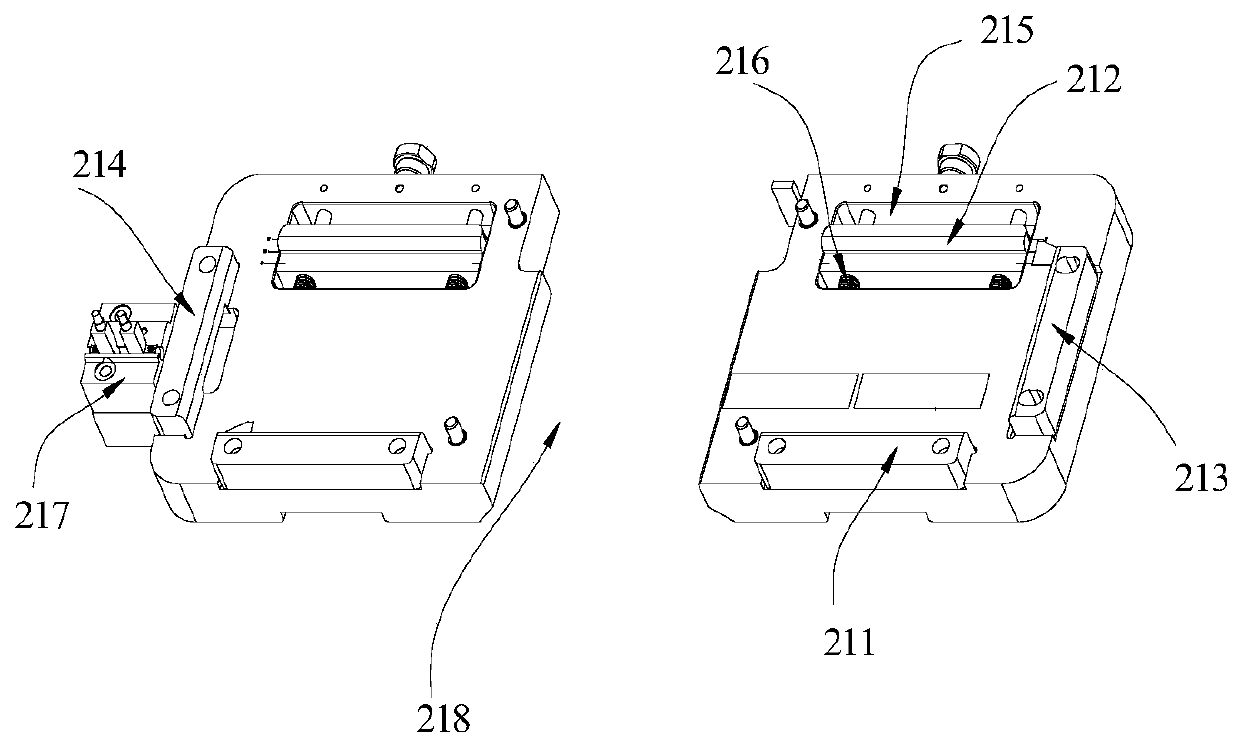

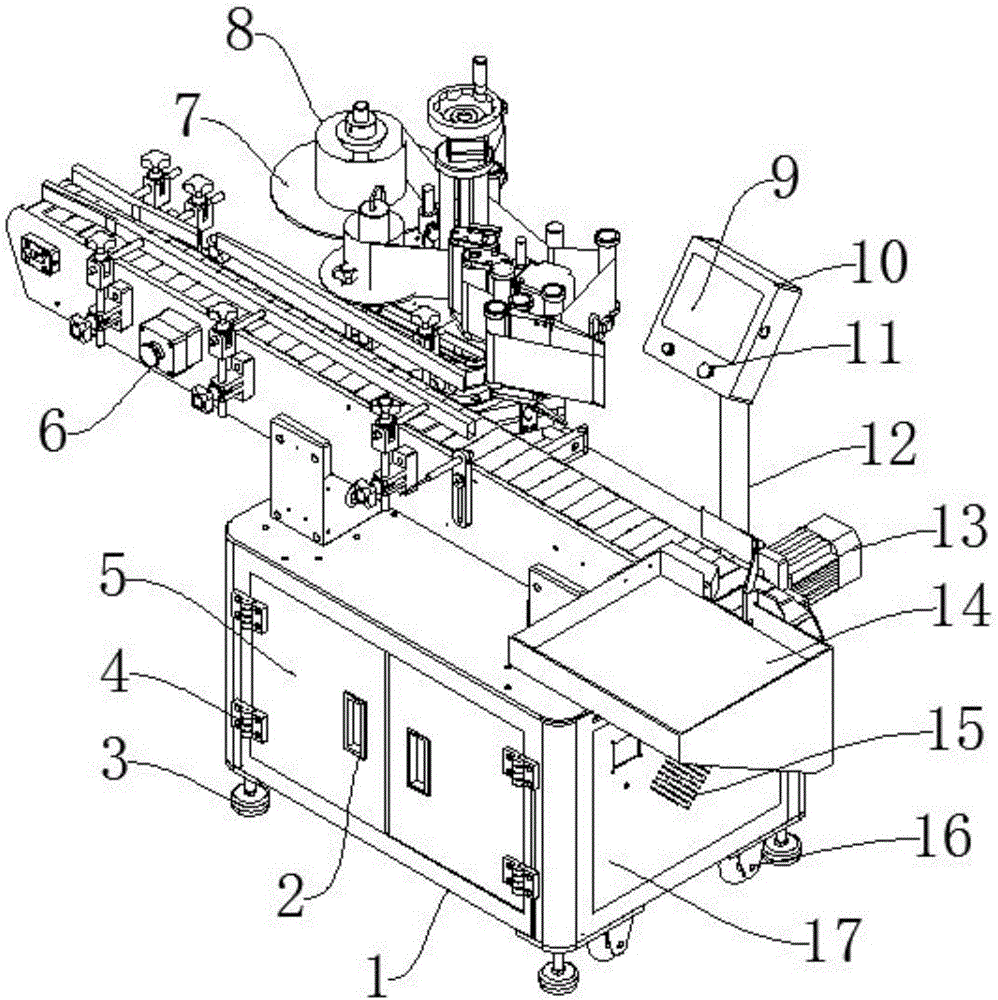

Automatic labeling machine and labeling method

InactiveCN111252326AImprove accuracyGuaranteed labeling qualityLabelling machinesProcess engineeringMechanical engineering

The invention discloses an automatic labeling machine. The automatic labeling machine comprises a machine frame, a carrier rotary table device, a feeding device and a labeling device, wherein the carrier rotary table device, the feeding device and the labeling device are arranged on the machine frame; the feeding device and the labeling device are sequentially arranged in the rotation direction ofthe carrier rotary table device; the feeding device is used for feeding of products and label pieces; the carrier rotary table device is used for conveying the fed products to pass the labeling device; and the labeling device receives the fed label pieces and pasts the label pieces onto the products, and the pasted label pieces are rolled. The invention further discloses a labeling method. The label pieces are pasted onto the products through the labeling device at first, then, a rolling reinforcing mode is adopted, thus, the label pieces are fastened onto the products, and the product labeling quality is ensured.

Owner:HUIZHOU DESAY AUTOMATION TECH

Intelligent plastic bottle quality certificate sticking device for plastic production

InactiveCN105819047AImprove labeling qualityImprove labeling efficiencyLabelling short rigid containersLabelling machinesSmart controlEngineering

The invention discloses an intelligent plastic bottle qualification certificate sticking device for plastic production, which comprises an electric cabinet, a labeler, a conveying platform, and an intelligent controller. A base is arranged under the electrical cabinet, and wheels are installed under the base. Support feet are installed under the base, a ventilation window is provided on one side of the electrical cabinet, a hinge is provided on the electrical cabinet, a cabinet door is installed on the electrical cabinet, a handle is provided on the cabinet door, and a handle is provided on the electrical cabinet. A top plate is arranged on the side, and a wire pipe is installed on the top board, the intelligent controller is installed on the wire pipe, a display screen is arranged on the intelligent controller, and control buttons are installed on the intelligent controller. The delivery platform is installed on the top plate, and a photoelectric sensor is installed on one side of the delivery platform. The beneficial effect is that the present invention can intelligently adjust the labeling pressure while pasting the certificate of conformity, thereby improving the labeling quality and labeling efficiency.

Owner:郑雪松

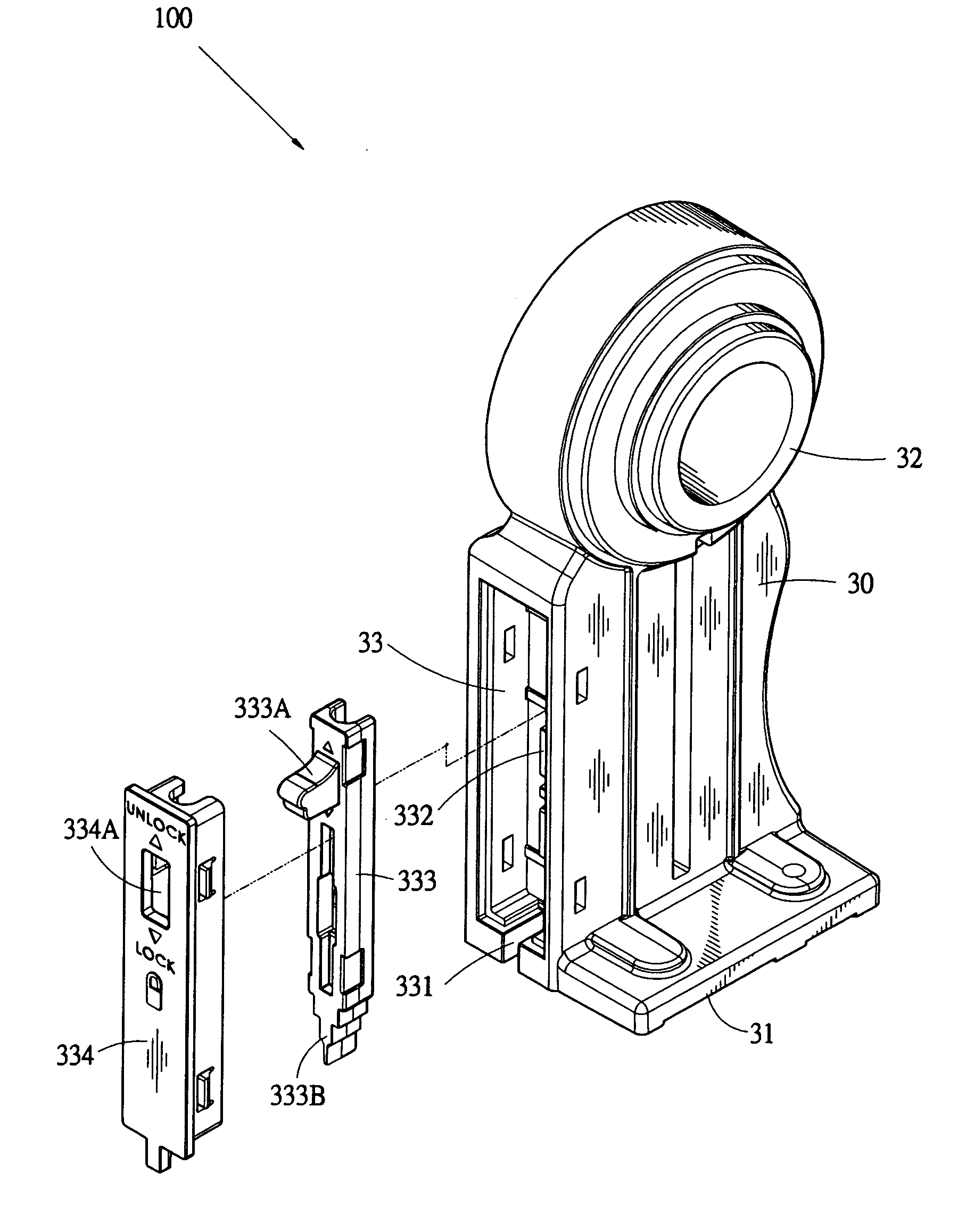

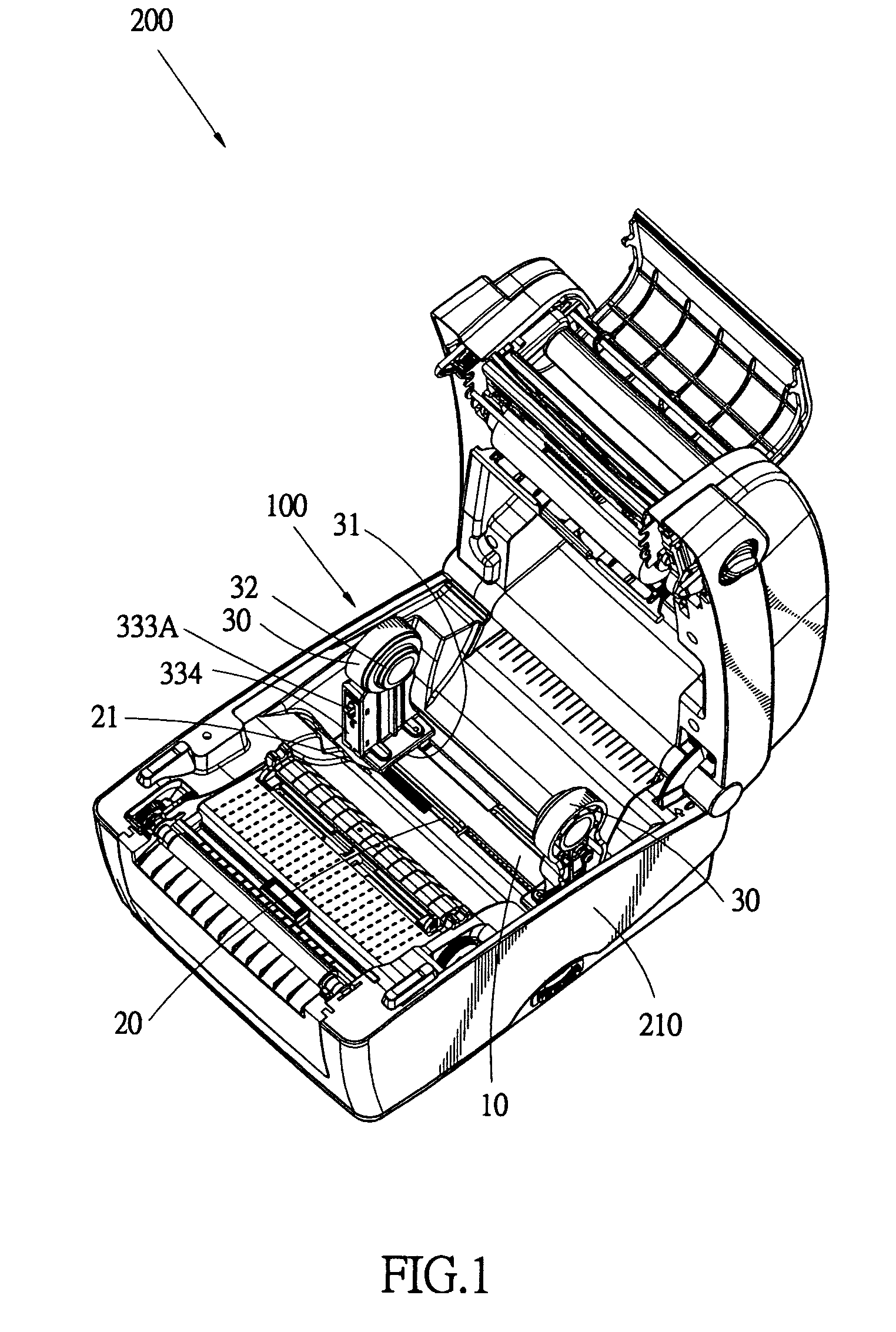

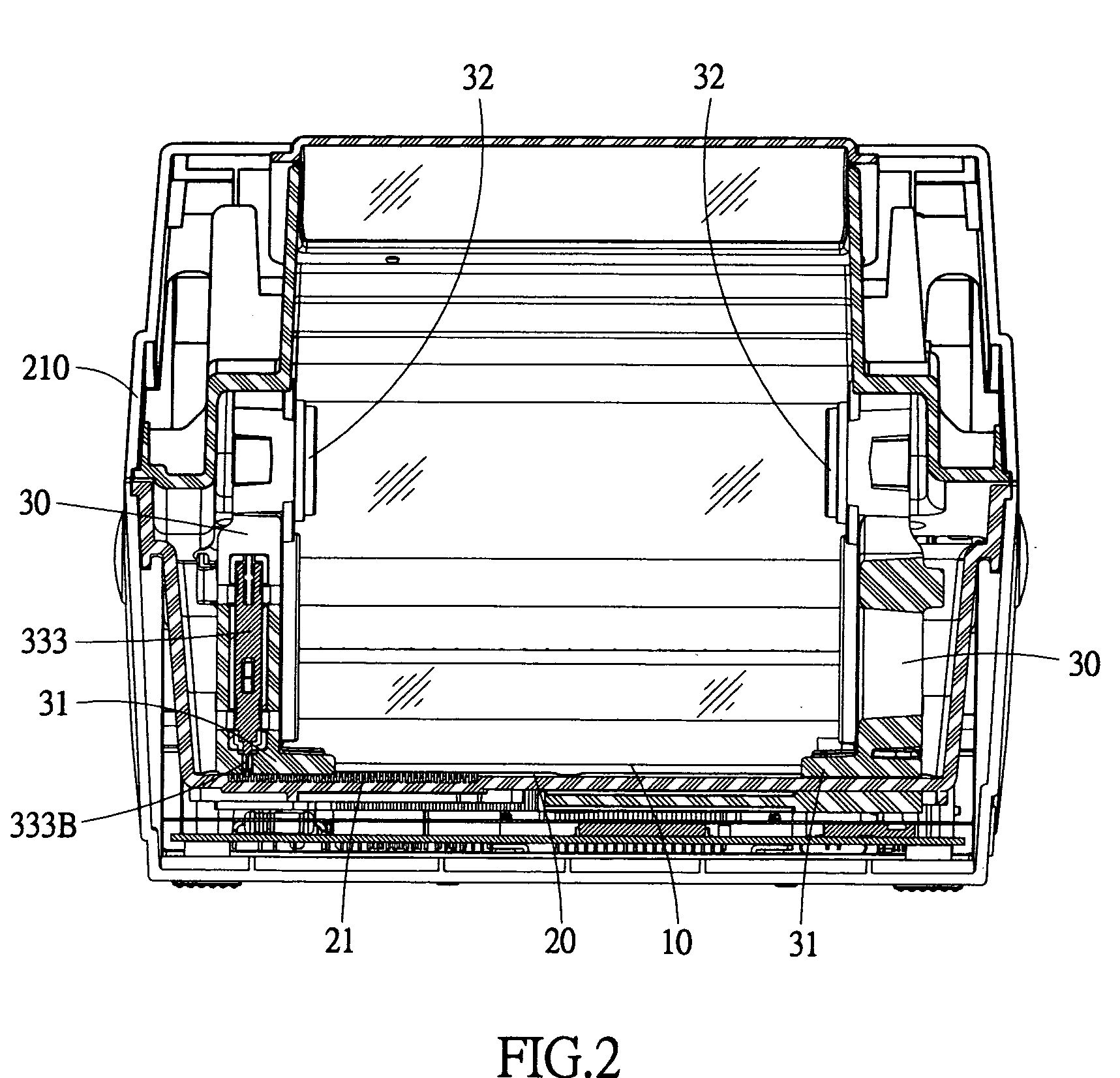

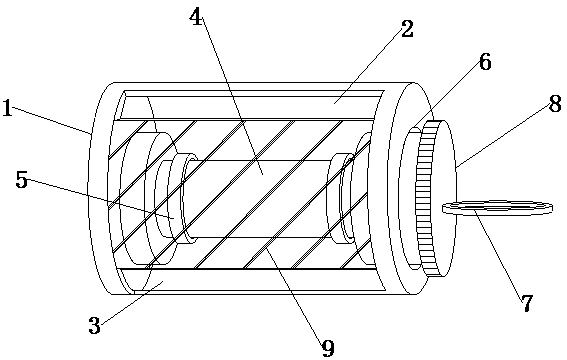

Label roll positioning device of barcode printer

ActiveUS8182163B2Improve labeling qualityOther printing apparatusWebs handlingBarcodeMechanical engineering

A label roll positioning device is provided for a barcode printer and includes at least one slide rail, at least one positioning rail, and at least one pair of roll retainers. The slide rail and the positioning rail are arranged in a parallel manner inside a housing of the barcode printer. The positioning rail forms teeth on a surface thereof. At least one of the roll retainers has a bottom forming a mounting portion that is slidably fit and mounted to the slide rail for being slidable along the slide rail. The roll retainers are spaced to receive a roll of label therebetween in a securely held manner. The roll retainer is provided therein at least one positioning plug having an end forming a locking section. The positioning plug can be downward driven to have the locking section downward projecting out of the roll retainer, and the positioning plug can be upward driven to have the locking section back into concealment inside the roll retainer. Thus, with the roll of label received between the roll retainers, the positioning plug is downward driven and the locking section engages the teeth of the positioning rail to effect positioning and fixing for securely holding the roll of label between the roll retainers. A positioning device with movable and adjustable locking engagement can be realized.

Owner:TSC AUTO TECH

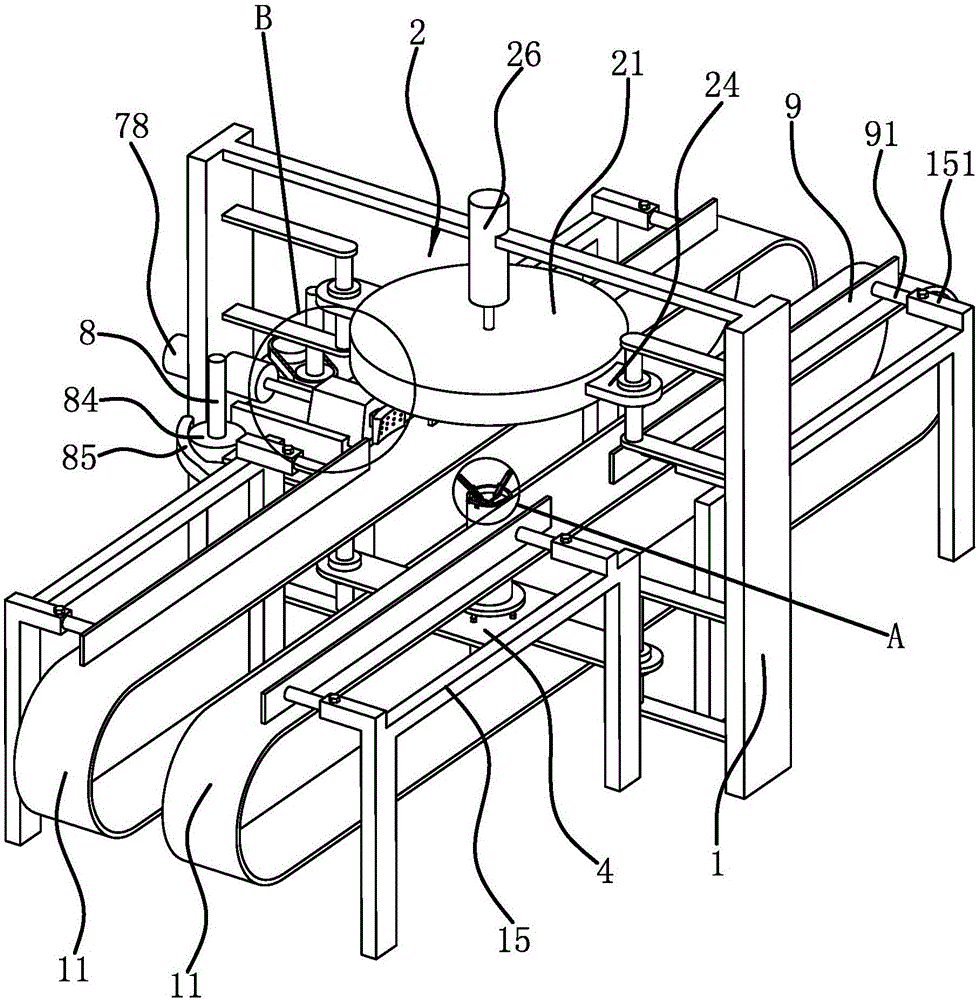

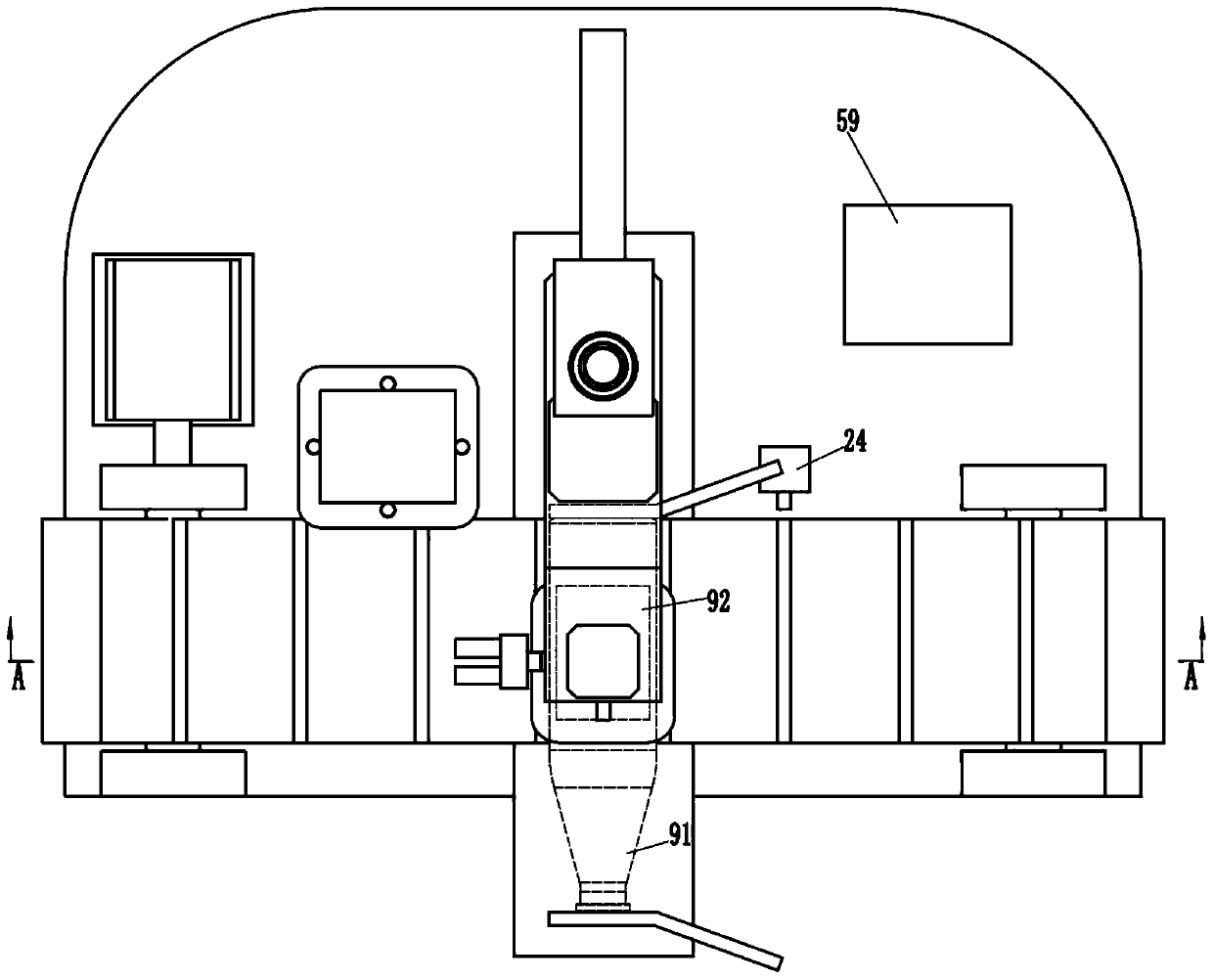

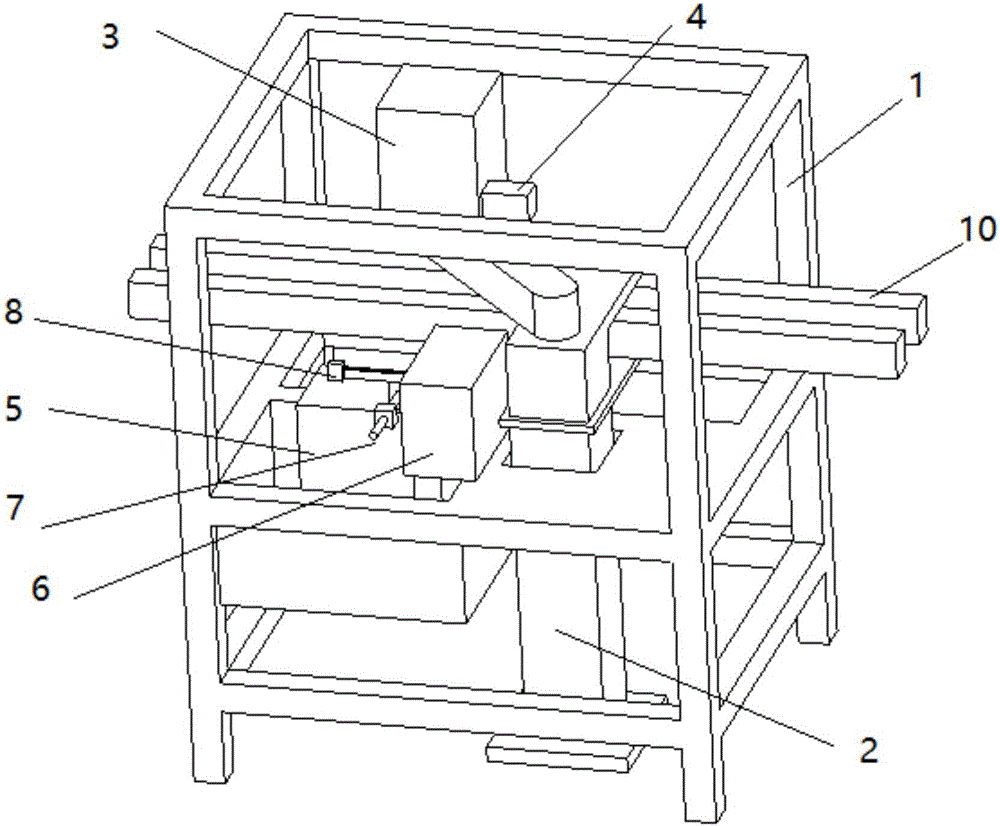

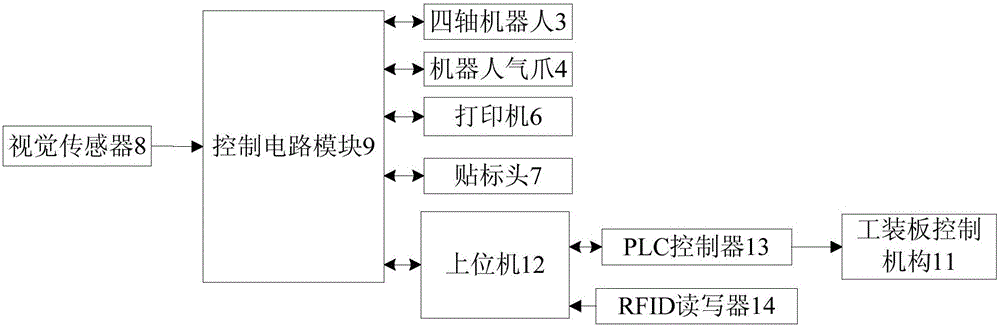

Electric energy meter robot labeling device with intelligent vision detecting function

ActiveCN105866724ASimple structureFlexible structureManufacture of electrical instrumentsElectricityVision sensor

The invention discloses an electric energy meter robot labeling device with an intelligent vision detecting function. The electric energy meter robot labeling device comprises the components of a frame, a robot base, a four-axis robot, a robot air claw, a transfer table, a printer, a labeling head vision sensor and a control circuit module. The frame and the robot base are fixed on ground. The four-axis robot is mounted on the robot base. The robot air claw is mounted on the four-axis robot. The transfer table is mounted on the frame. The printer is mounted on the frame. A labeling head is mounted on the printer and moves in the horizontal direction. A vision sensor is mounted on the printer and right faces the transfer table. The input end of the control circuit module is connected with the output end of the vision sensor. The data output end of the control circuit module is electrically connected with the four-axis robot, the robot air claw, the printer and the labeling head. The electric energy meter robot labeling device has advantages of compact structure, high flexibility, high stability, low fault rate, high labeling quality and high reliability. Furthermore the electric energy meter robot labeling device can effectively settle problems such as label content detection.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +1

Roll of white heat-shrinkable polyester-based film

PendingUS20190210262A1Improve shrinkageGood shrinkage finish propertyFlat articlesPolyesterPolymer science

The invention provides a roll of a white heat-shrinkable polyester-based film containing titanium oxide which can suppress occurrence of a processing trouble of a label or the like cut out from the roll, even when widening the roll. The roll of the white heat-shrinkable polyester-based film satisfies the following requirements: (1) the length of the film is 1,000-20,000 m and the width of the film is 400-10,000 mm, (2) the heat-shrinkage ratio in a main shrinkage direction is 50-85%, (3,4) the difference between the maximum and minimum heat-shrinkage ratio in the main shrinkage direction is 0-3% among samples which are sampled in each of the width and longitudinal directions of the film, and (5,6) the difference between the maximum and minimum apparent specific gravity is 0-0.01 g / cm3 among samples which are sampled in each of the width and longitudinal directions of the film.

Owner:TOYO TOYOBO CO LTD

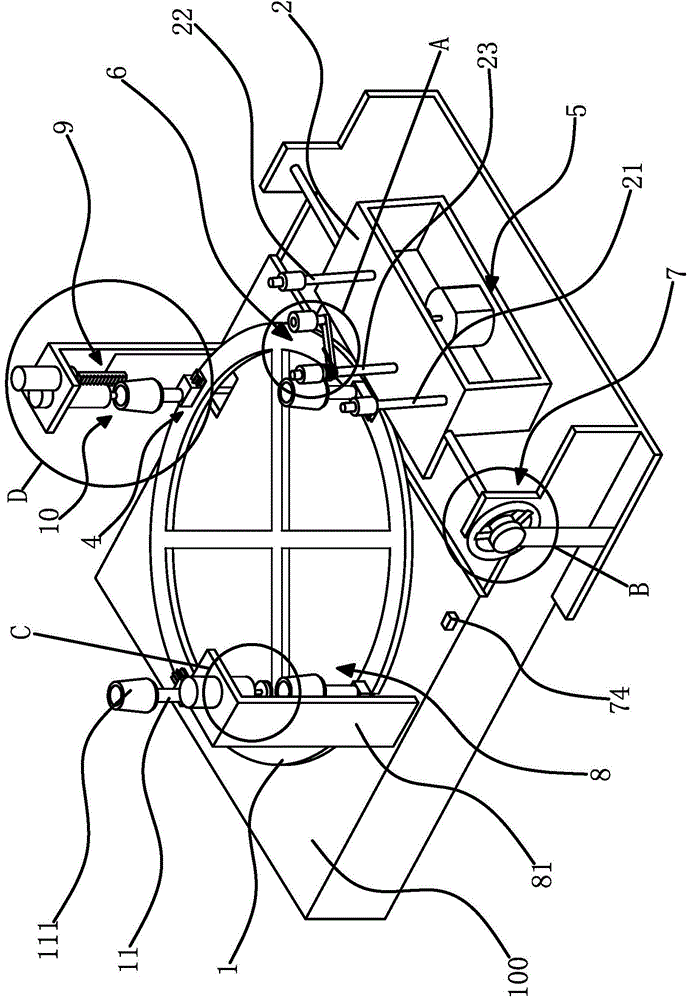

Labeling machine

ActiveCN105015870AEasy to pasteReduce human wasteLabelling machinesLabelling elongated objectsVehicle frameControl manner

The invention discloses a labeling machine used for labeling a vehicle frame. The labeling machine comprises a vehicle frame fixing device. The vehicle frame fixing device comprises a tensioning device box which is clamped to the vehicle frame through tension. The tensioning device box is connected with a first driving device driving the tensioning device box to open or close. The tensioning device box is fixedly connected to a main rotating shaft arranged in the X-axis direction. The main rotating shaft can rotate around the X-axis and the Y-axis respectively. The main rotating shaft is provided with a first braking device used for stopping the main rotating shaft from rotating around the X-axis and a second braking device used for stopping the main rotating shaft from rotating around the Y-axis. The first driving device, the first braking device and the second braking device are connected with a manual electromagnetic valve in a controlled manner. The labeling machine achieves mechanical fixing of the vehicle frame and can rotate in different directions, and thus a label can be conveniently pasted; labor waste is reduced, and labor intensity is relieved; and labeling quality is improved.

Owner:江苏资福智能装备有限公司

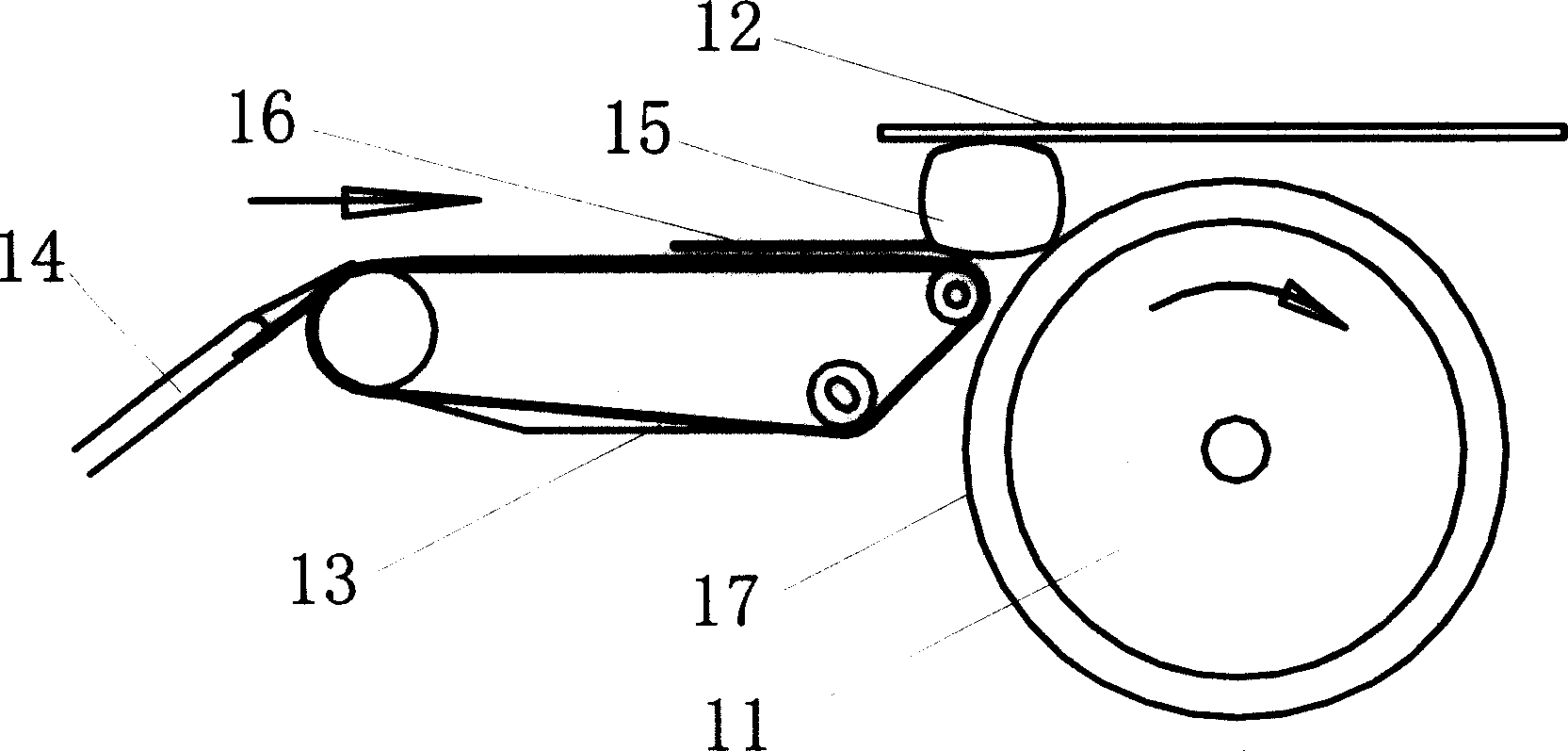

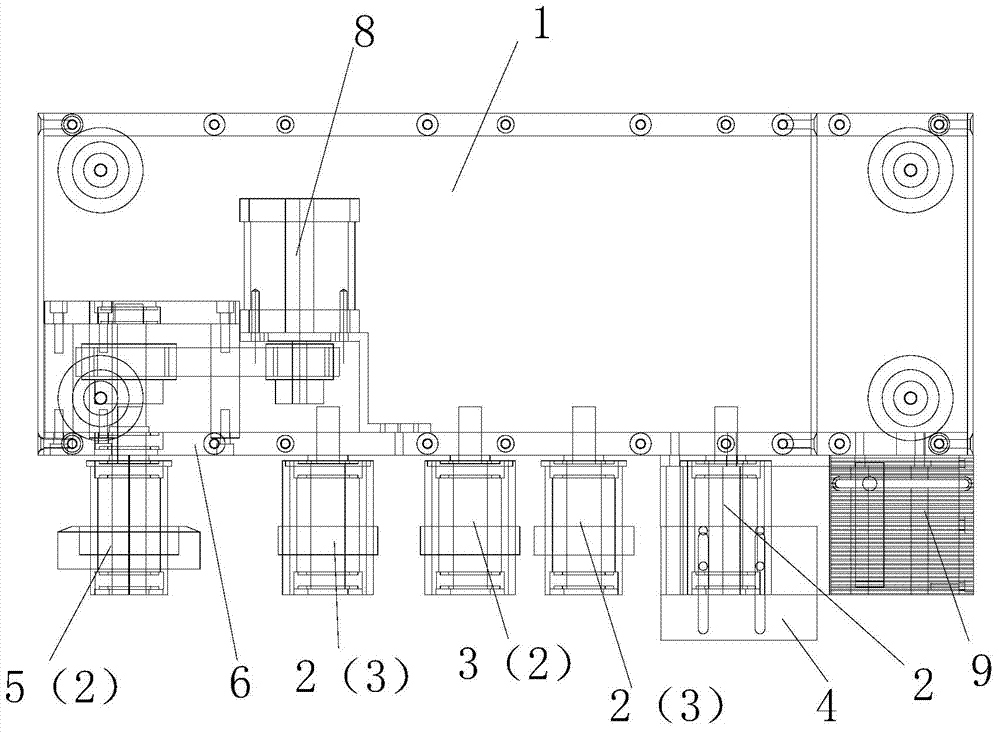

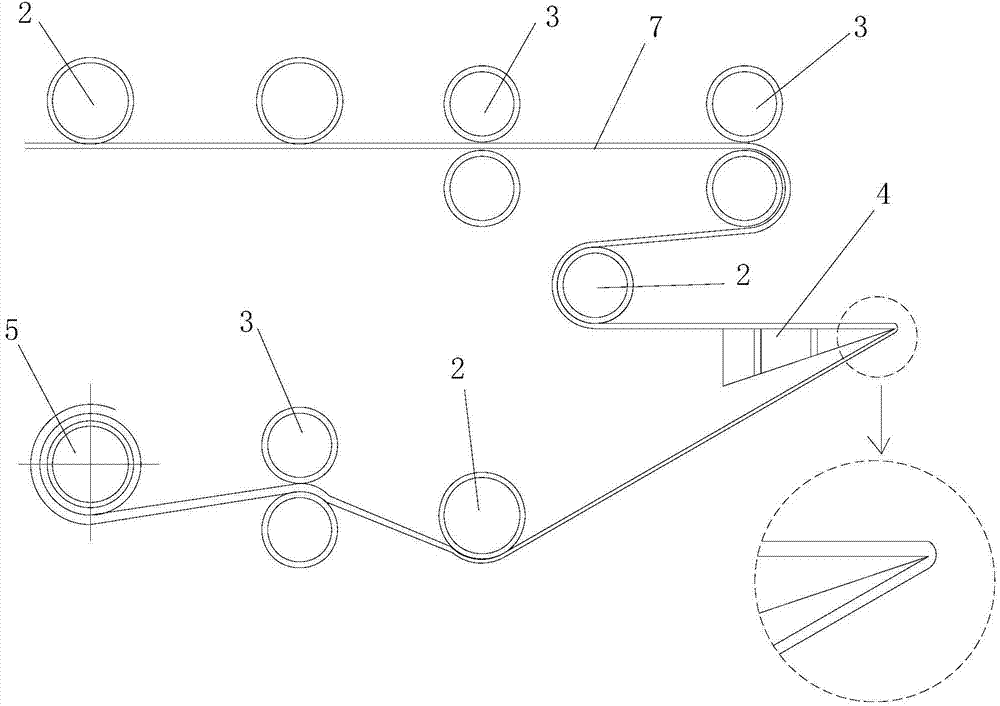

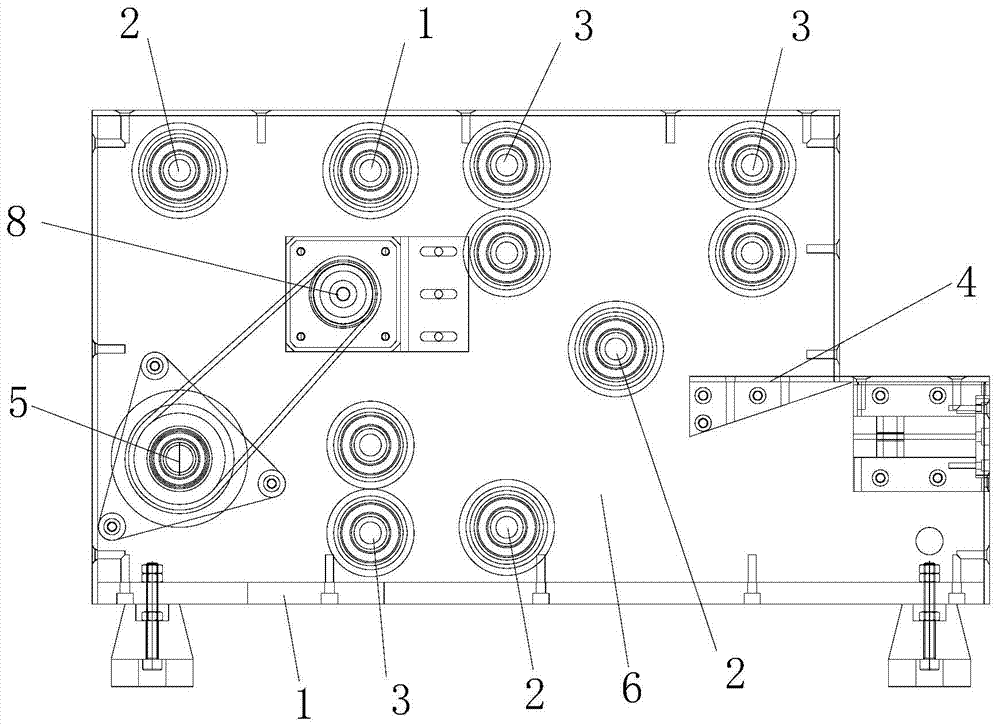

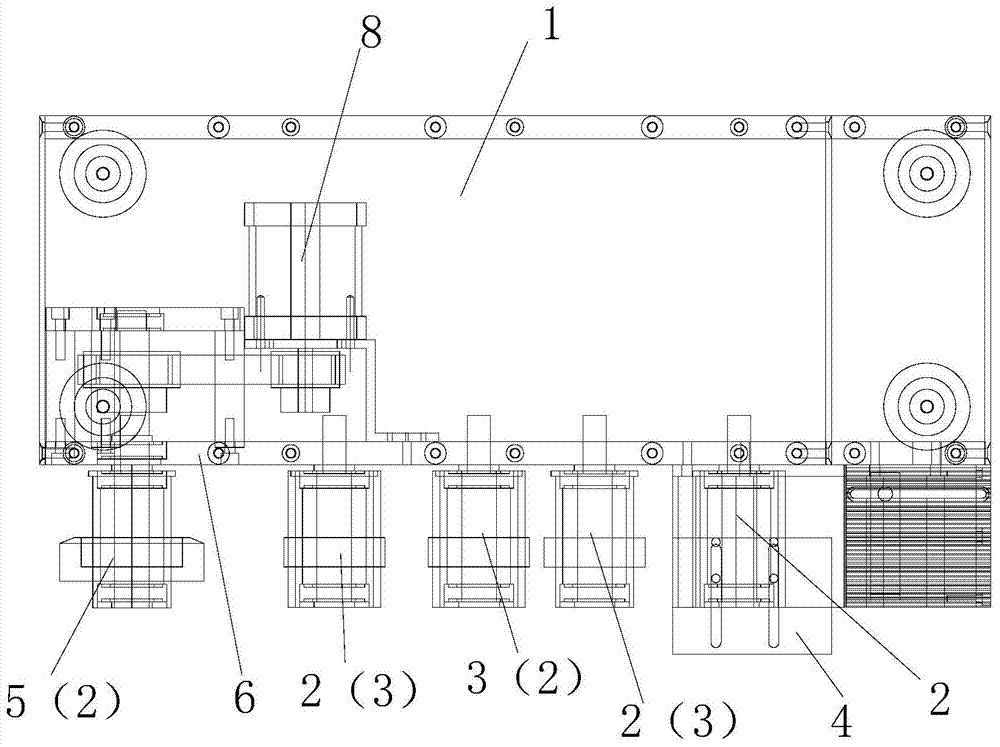

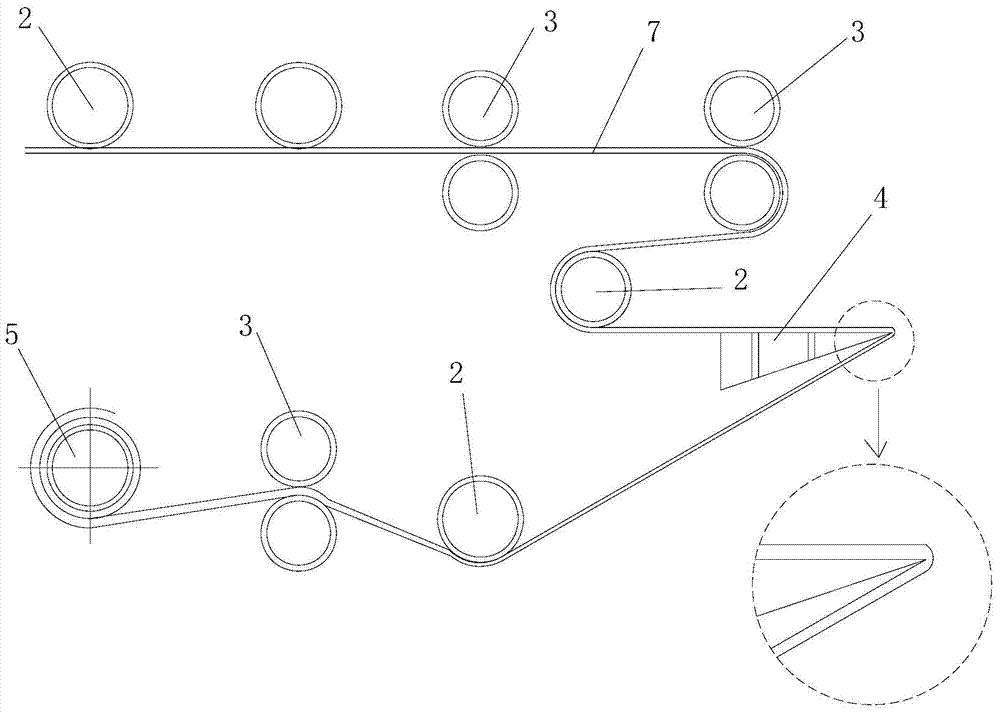

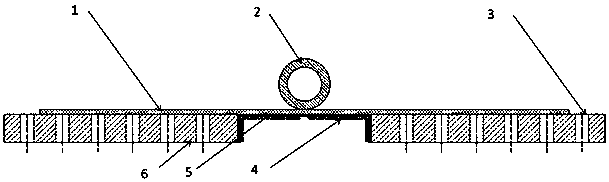

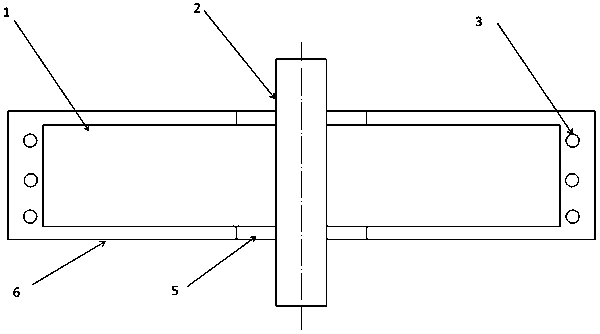

Automatic label separator

InactiveCN104494983ASimple structureReduce volumeLabelling machinesRight trianglePulp and paper industry

The invention provides an automatic label separator. The automatic label separator comprises a bracket, material belt pressing wheels, guide roller sets, a label separation plate and a material belt recycling roll, wherein a fixed plate is arranged on the bracket; the plurality of material belt pressing wheels are arranged on the fixed plate at intervals; the plurality of guide roller sets are arranged on the fixed plate at intervals; the label separation plate is arranged at the end part of one side of the fixed plate; the vertical section of the label separation plate is in a right triangle shape; the material belt recycling roll is arranged at the end part of the other side of the fixed plate, relative to the label separation plate; and a vacuum label suction device is further arranged at the front end of the label separation plate. By virtue of the automatic label separator, the stripping speed between a label and a label belt is greatly increased and the stripping effect is guaranteed, so that the labeling efficiency and quality of the adhesive sticker labeling machine are improved.

Owner:苏州格林电子设备有限公司

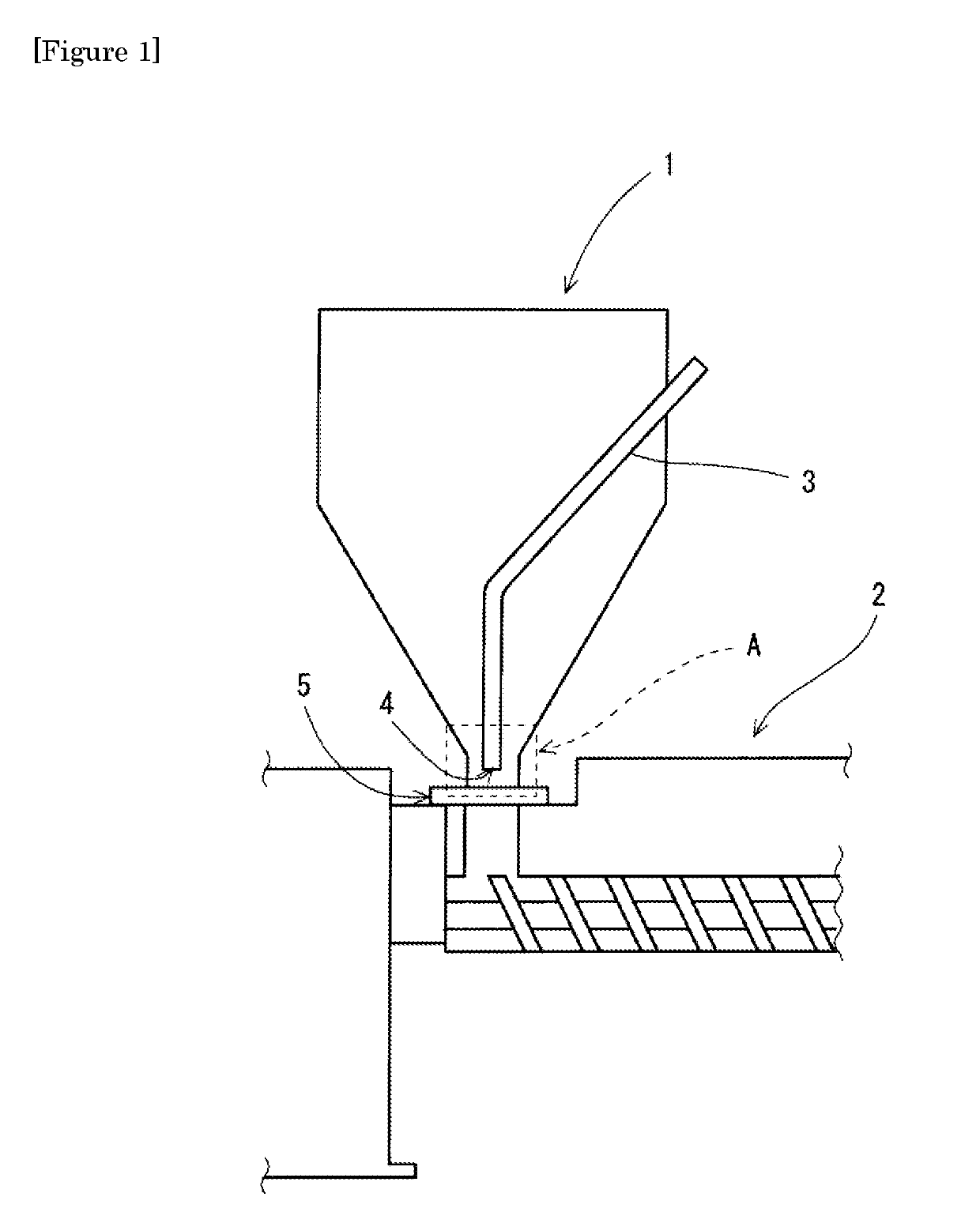

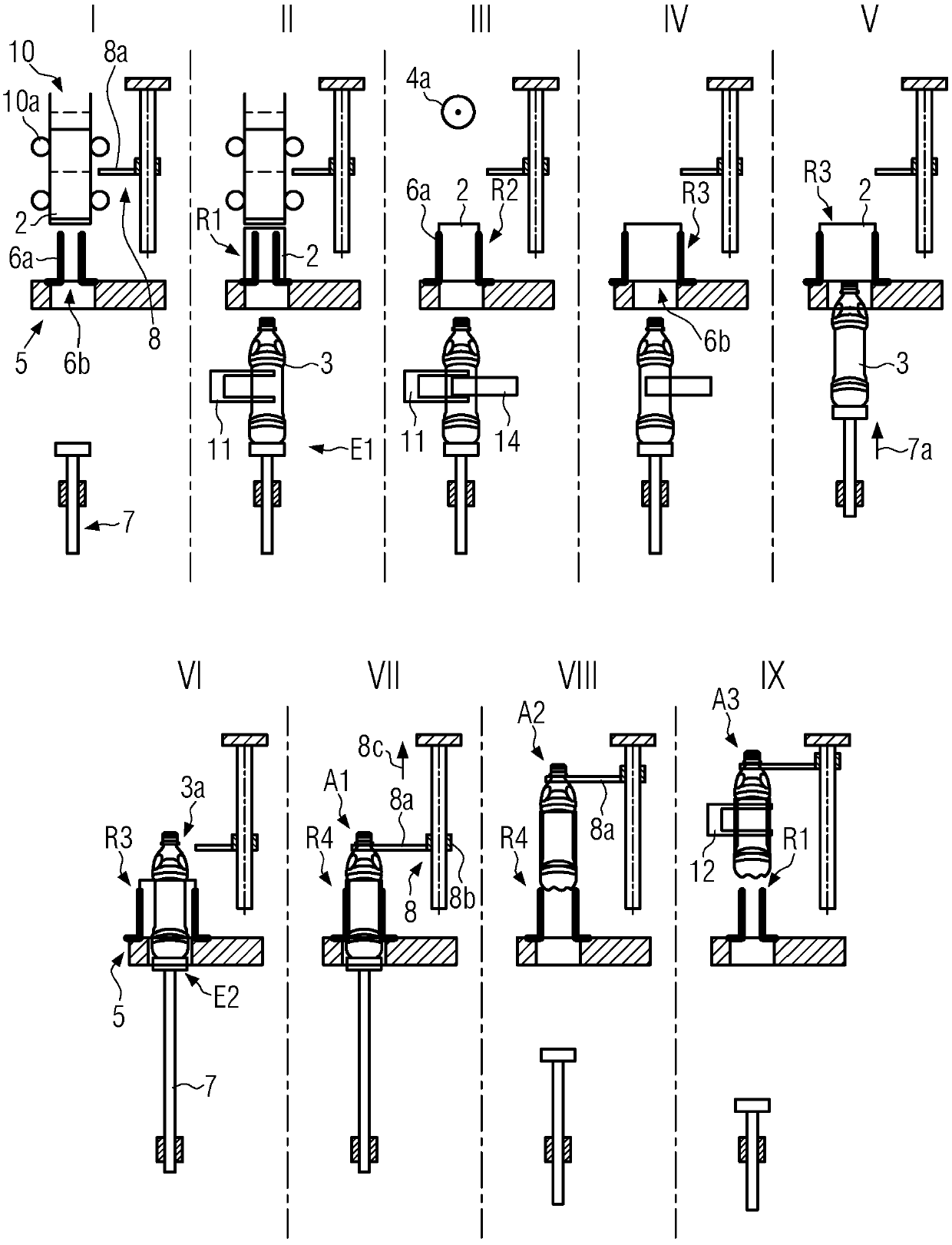

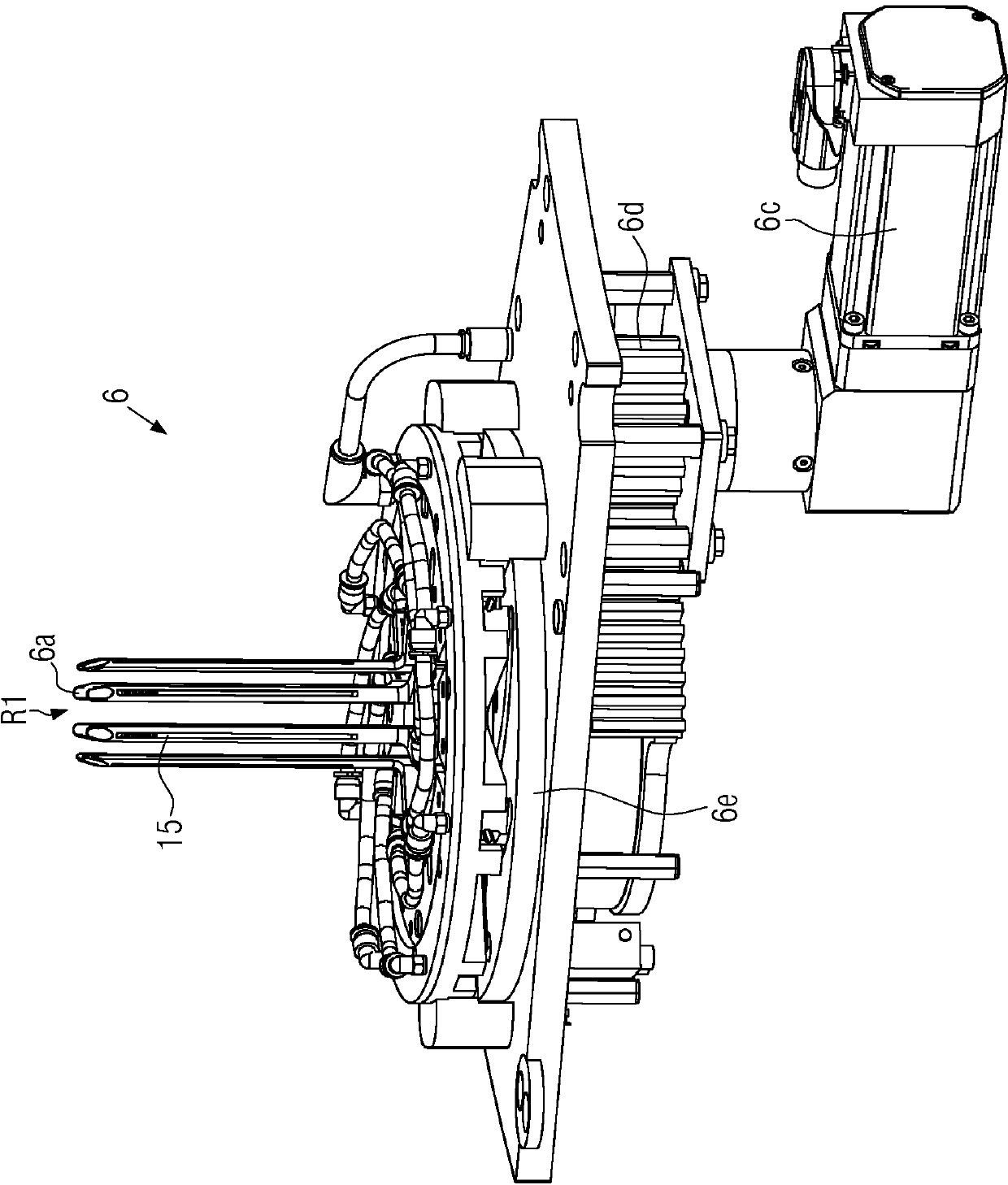

Method and device for labelling containers with stretch sleeves

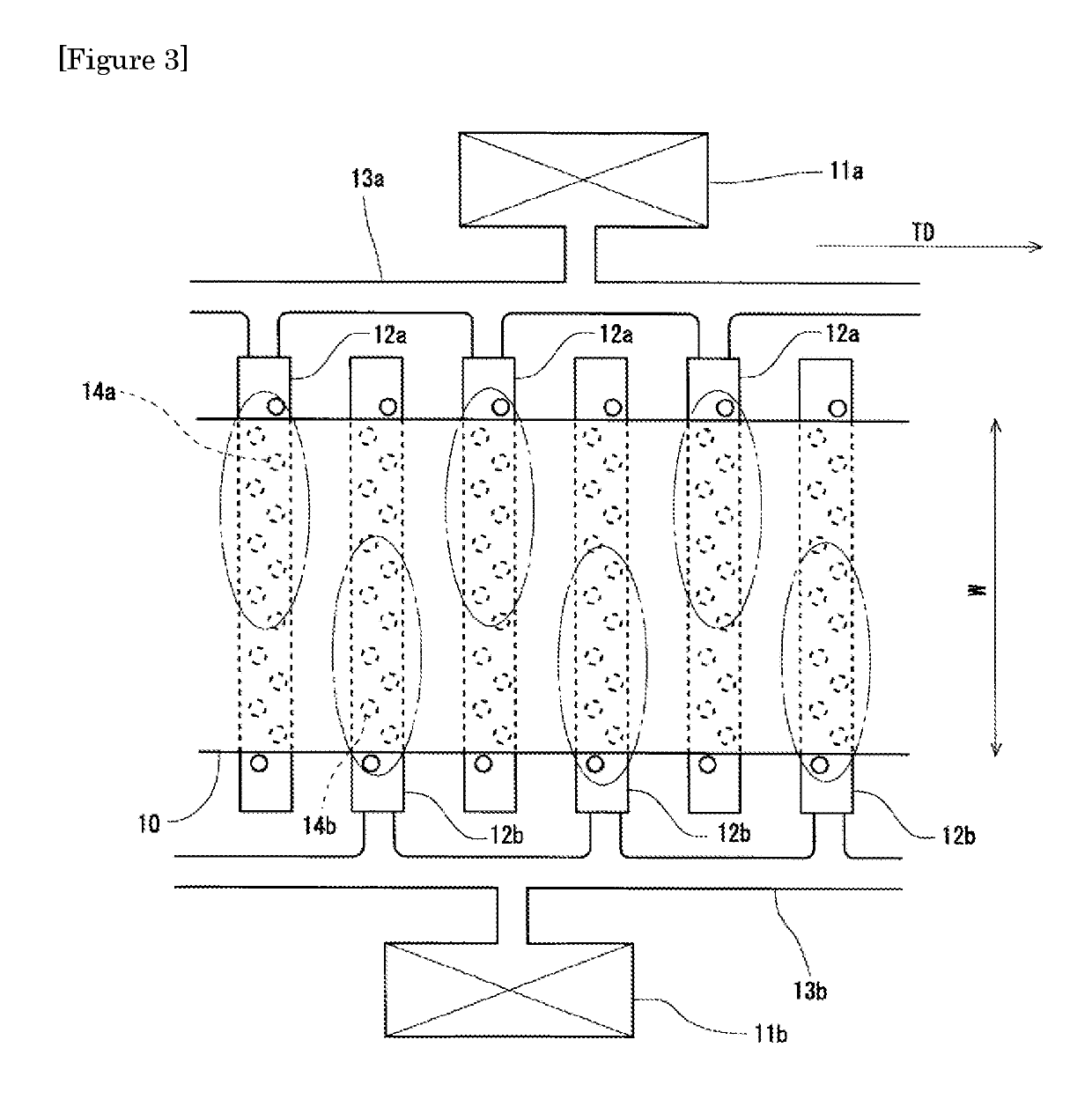

ActiveCN103129788AGood reproducibilityEasy to set upLabelling short rigid containersAir bearingElectric drive

A method and a device for labelling containers with stretch sleeves are provided. The invention relates to the method and the device for labelling the containers with the stretch sleeves. The device can adjust different support speed when supporting the label sleeves and / or adjust different lifting speed when the labelled containers are pulled out from a support unit. Damage of the label sleeves and inaccurate positioning of the label sleeves on the containers can be avoided. Generation of a compression air bearing between the label sleeves and the support unit can flexibly adapt by means of electric drive control in order to improve labeling quality.

Owner:KRONES AG

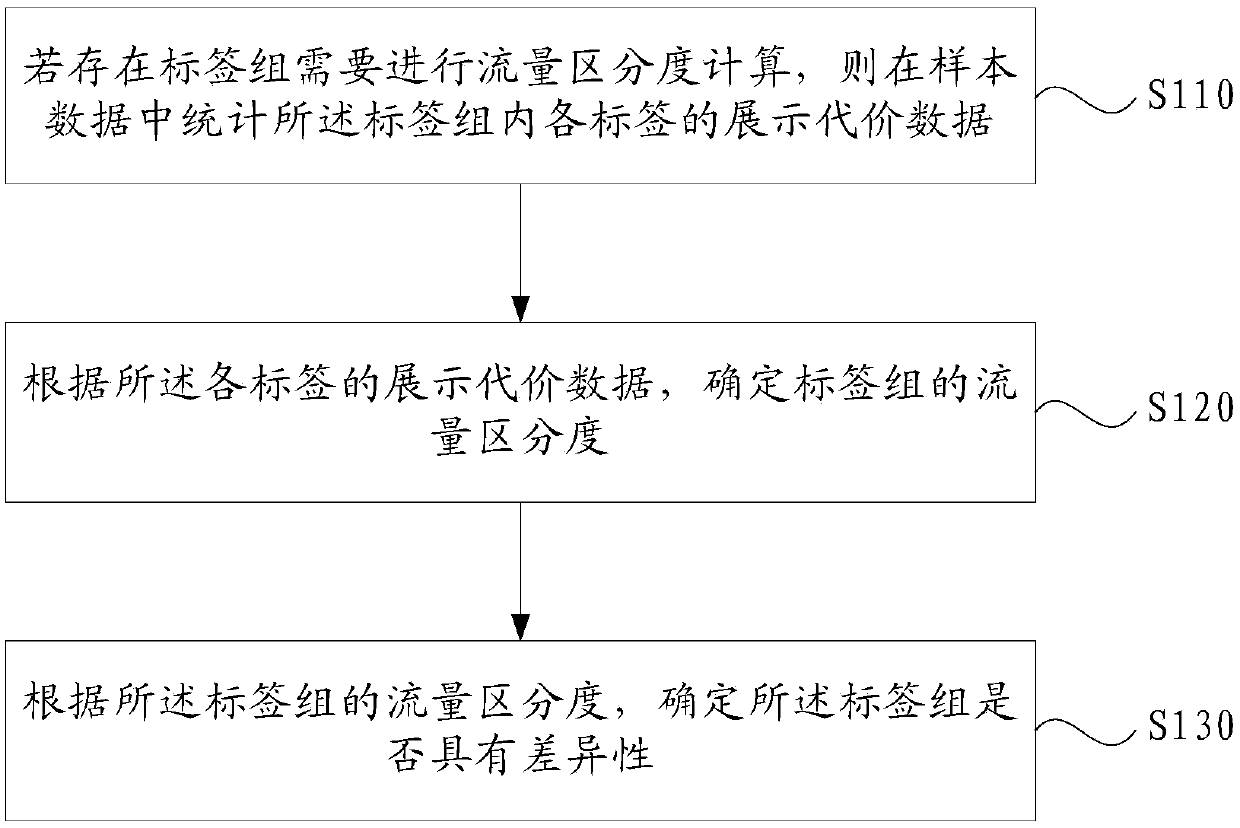

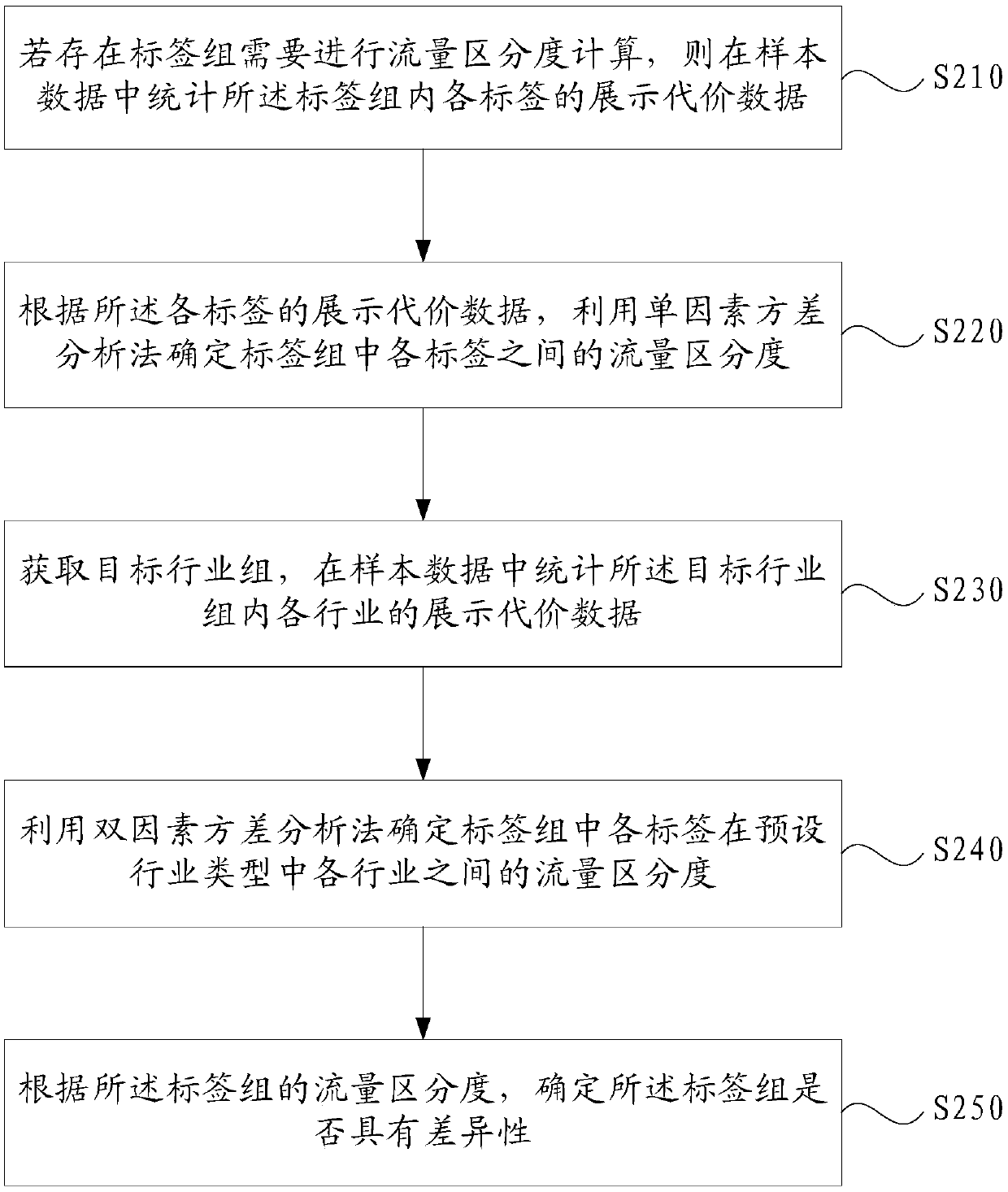

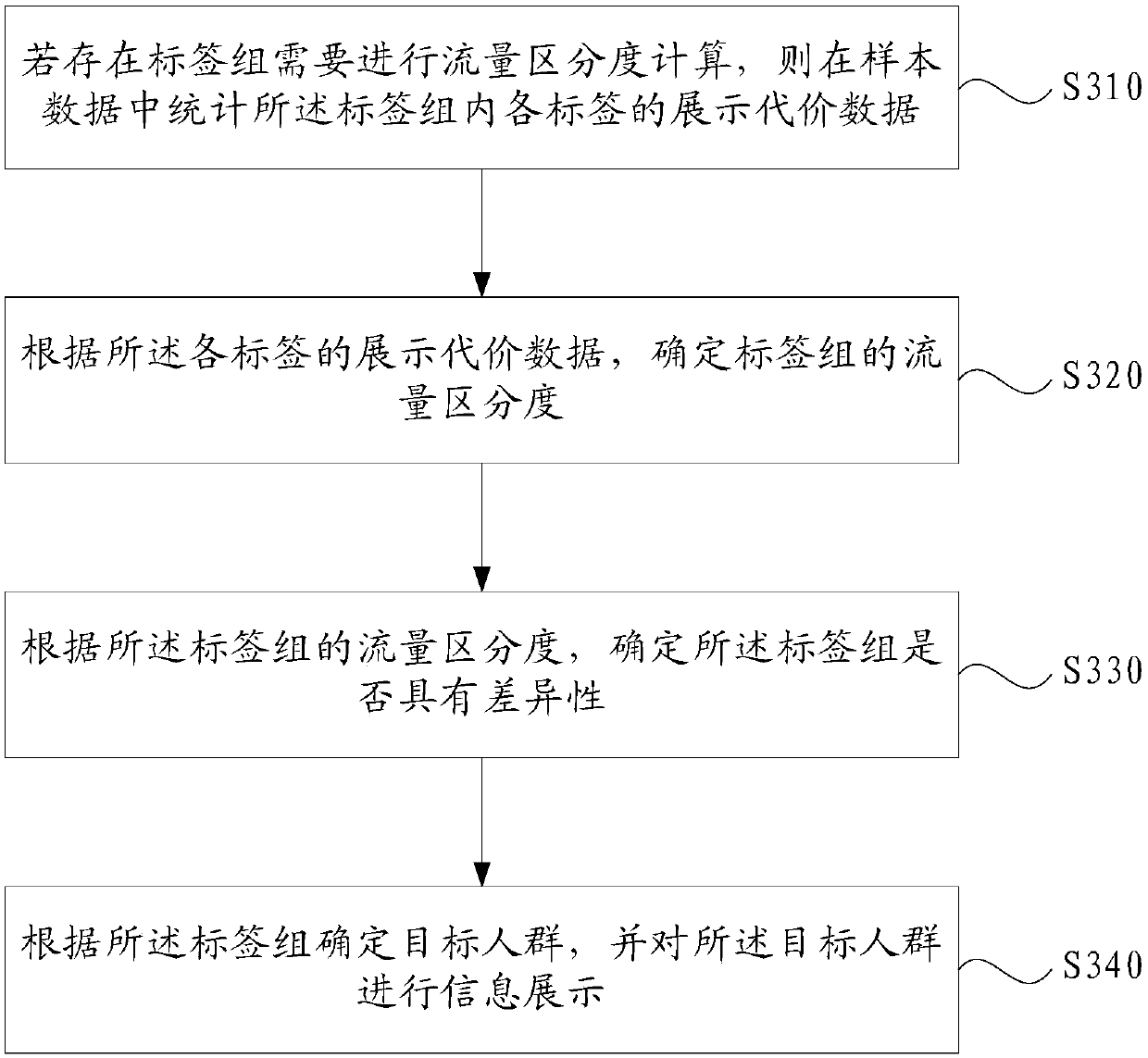

Label group difference determination method and device, electronic equipment and readable medium

PendingCN111143346AImprove the effectEvaluation scienceVisual data miningStructured data browsingLabel qualityEngineering

The embodiment of the invention discloses a label group difference determination method and device, electronic equipment and a readable medium. The method comprises the following steps: if a label group needs to be subjected to flow discrimination calculation, counting display cost data of each label in the label group in sample data; according to the display cost data of each label, determining aflow discrimination degree of a label group; and determining whether the label groups have difference or not according to the flow discrimination of the label groups. By adopting the technical schemeprovided by the invention, the label can be evaluated more scientifically, so that the effect of improving the quality of the label is achieved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Label separating device of labeling machine

The invention discloses a label separating device of a labeling machine. The label separating device comprises a support, a plurality of material strap compression rollers, a plurality of guide roller groups, a label separating plate and a material strap recycling roll, wherein the support is provided with a fixed plate; the plurality of material strap compression rollers are arranged on the fixed plate at intervals; the plurality of guide roller groups are arranged on the fixed plate at intervals; the label separating plate is arranged on the end part at one side of the fixed plate; the longitudinal cross section of the label separating plate is a right triangle; the material strap recycling roll is arranged on the end part at the other side of the fixed plate opposite to the label separating plate. The label separating device is simple and compact in structure, and is small in size; a saltation corner is arranged at the conveying direction of a label trap at the front end of the label separation plate for label separation, so that labels and label straps are separated, the stripping speed of the labels and the label straps is improved greatly, and the stripping effect is ensured, thereby improving the labeling efficiency and quality of a non-dry sticker labeling machine.

Owner:苏州格林电子设备有限公司

Automatic labeling device with sucker

InactiveCN110712822AWill not miss the markAccurate labelingLabelling machinesCircular discStructural engineering

The invention provides an automatic labeling device with a sucker. The automatic labeling device comprises a machine body; a conveying cavity with an opening facing upwards is formed in the upper endin the machine body in a horizontal penetrating manner; rotatable conveying shafts symmetrically arranged left and right are arranged between the front wall and the rear wall of the conveying cavity;conveying rollers are fixedly arranged on the outer circumferential surfaces of the conveying shafts; a first conveyor belt is arranged between the conveying rollers on two sides in a winding manner;a fixed block is fixedly arranged on the upper end surface of the machine body and on the rear side of the conveying cavity; a paper feeding device is arranged at the left end of the front end surfaceof the fixed block, and comprises a rotatable first rotating shaft arranged at the upper left end of the front end surface of the fixed block; a rotating disk is fixedly arranged at the rear end of the outer circumferential surface of the first rotating shaft; and a label paper roll is arranged on the outer circumferential surface of the first rotating shaft and on the front side of the rotatingdisk. A label is adsorbed by the sucker, when a sensor senses a product, the label is stuck on the product, and at last, the label is flattened by the conveyor belt on the rollers, label leaking and warping are avoided, labeling is accurate, and the labeling quality is improved.

Owner:WUHAN SAIENJI DAILY NECESSITIES CO LTD

Self-adhesive label labeling machine for bottles

InactiveCN112478356ANot easy to dropNo manual operationLabelling machinesLabelling short rigid containersAdhesiveEngineering

The invention discloses a self-adhesive label labeling machine for bottles. The self-adhesive label labeling machine comprises a base, wherein a first space is formed in the upper surface of the base,a discharge space used for discharging the bottles is formed in the right side of the first space; first rotating shafts which are symmetrical in the left and right positions are rotatably connectedto the front surface of the discharge space; a first belt pulley is fixedly connected to each first rotating shaft; a first belt is connected between the first belt pulleys in a belt manner; limitinggrooves which are evenly distributed at equal intervals are fixedly formed in the outer side surface of the first belt. The function of automatically adding the bottles is achieved through a vibratingfixing block and a feeding space, then labels are stripped through a triangular block, finally, the labels are compacted and automatically discharged through extrusion actions of a soft cushions, thelabeling operation of the bottles is completed, and manual operation is basically not needed in the whole process, so that the self-adhesive label labeling machine is very convenient to use, and highin labeling efficiency; and the labels can be tightly attached to the bottles and are not prone to falling off, so that the labeling quality is good, and the labeling machine is worthy of popularization.

Owner:南京智多鑫商贸有限公司

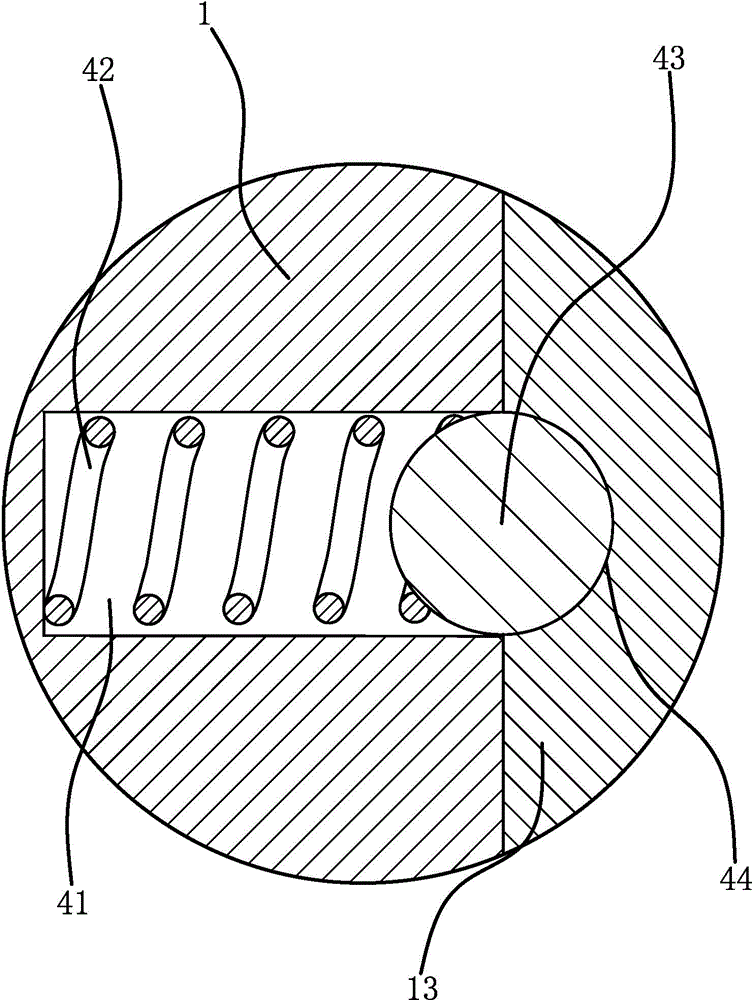

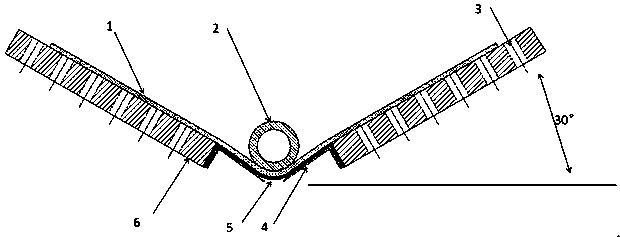

Adaptive label merging device for labeling machine

InactiveCN109573227AWide range of applicationsImprove work efficiency and labeling qualityAffixing tagsLabelling machineSelf adaptive

The invention relates to an adaptive label merging device for a labeling machine, and belongs to the technical field of folded labeling. According to the adaptive label merging device for the labelingmachine, labeling objects with different pipe diameters can be subjected to folded pasting of labels, and the working efficiency and the labeling quality of the folded labeling machine can be significantly improved. According to the technical scheme, the adaptive label merging device for the labeling machine is used in the folded labeling machine, two label-merging suction plates are symmetrically arranged on the two sides of a folded axis, a plurality of air holes are formed in the label-merging suction plates in a penetrating mode, the two label-merging suction plates are flexibly connectedthough wrapping leather, the wrapping leather is in an inverted-U shape, two L-shaped elastic pressing strips are symmetrically fixed to the inner wall of the wrapping leather along the two sides ofthe folded axis, the long edges of the L-shaped elastic pressing strips serve the compressing ends and are used for attaching the wrapping leather and the labels on the wrapping leather to the circumferences of the labeling objects in a fastened mode in the labeling process.

Owner:北京速阔智能科技有限公司

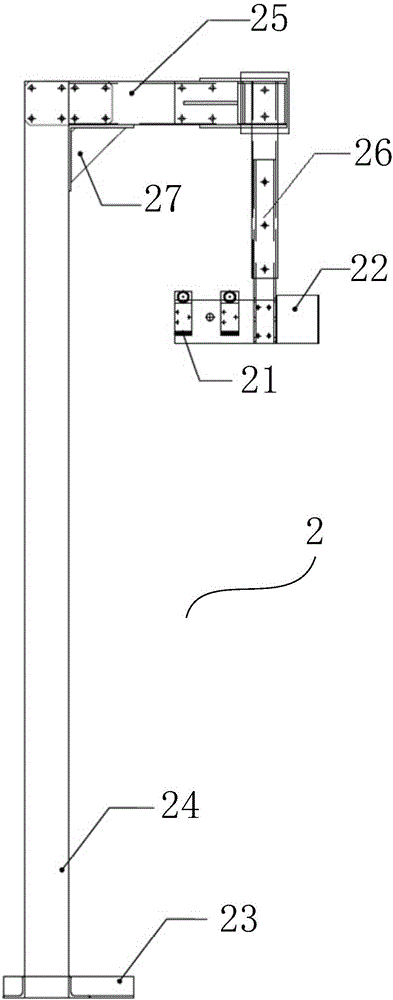

Wire cable labelling machine

ActiveCN103395527BFully automatedImprove labeling qualityLabelling machinesLabelling elongated objectsSelf lockingLabelling machine

Owner:SHENGLAN TECH CO LTD

Automatic weighing, code scanning and labeling equipment

PendingCN112572940AImprove efficiencyImprove work efficiencySortingWeighing auxillary devicesProcess engineeringMechanical engineering

The invention discloses automatic weighing, code scanning and labeling equipment. The equipment comprises a rack, and a weighing mechanism, a code scanning mechanism, a label stripping mechanism, a labeling mechanism and a runner mechanism which are all arranged on the rack. The weighing mechanism comprises a weighing device and a weighing conveying belt arranged above the weighing device. The code scanning mechanism is arranged beside the weighing mechanism and is used for scanning codes of boxes with qualified weights and uploading information; the label stripping mechanism is arranged beside the weighing mechanism and is used for separating labels in a label material belt; the labeling mechanism comprises a moving module, a labeling assembly arranged on the moving module, and a protection assembly arranged between the moving module and the labeling assembly, and is used for pasting a label separated from the label stripping mechanism on a box; and the automatic weighing, code scanning and labeling device can automatically perform weighing, code scanning and labeling, and has the advantages of high working efficiency and high accuracy compared with a conventional manual manner.

Owner:东莞长城开发科技有限公司

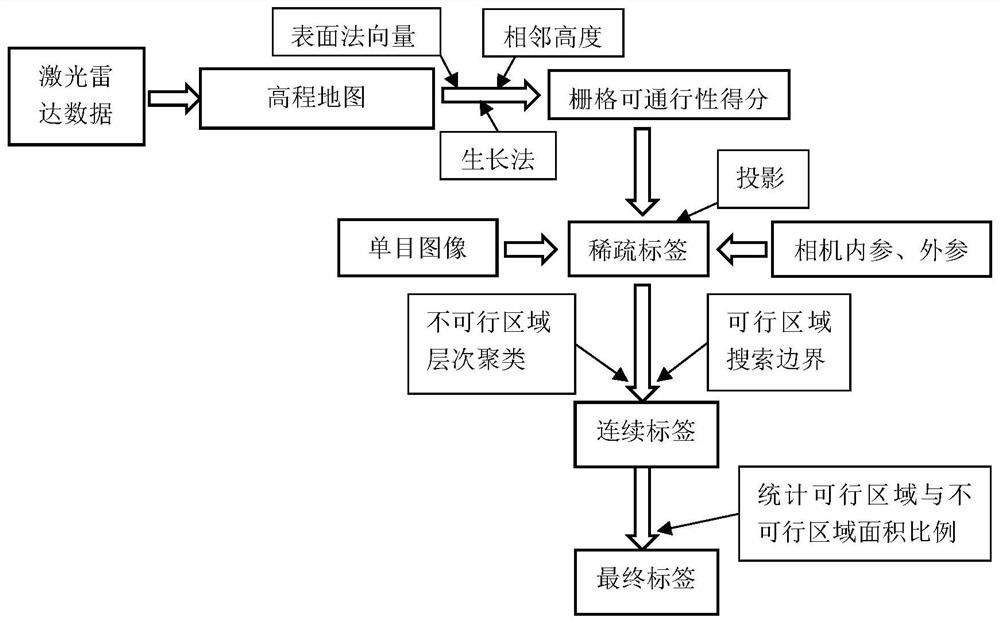

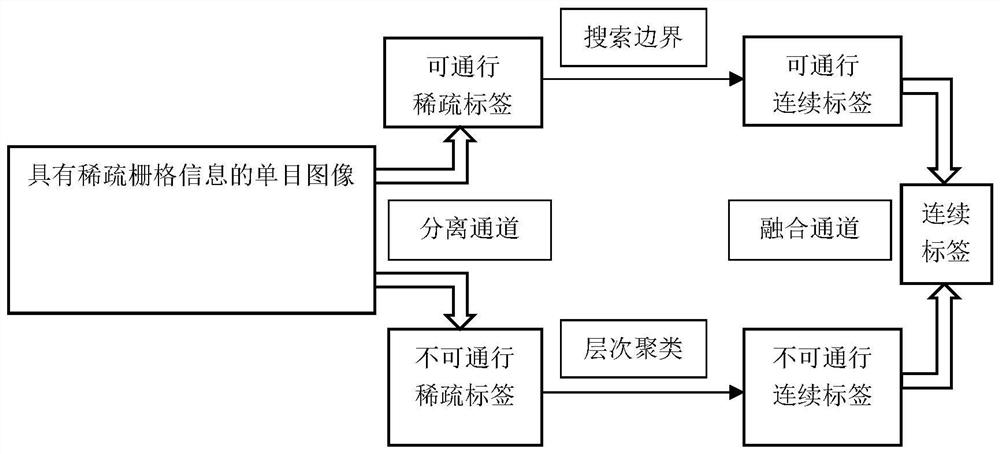

Method for generating feasible region label based on laser radar

ActiveCN113222025ALow costImprove qualityImage enhancementImage analysisElevation mapSearch algorithm

The invention discloses a method for generating a feasible area label based on a laser radar. The method comprises the steps: obtaining laser radar data of a robot and a monocular camera image, constructing an elevation map according to the current laser radar data, calculating the trafficability score of each grid according to the height information of each grid on the elevation map, and mapping the passability score of each grid on the elevation map to the image according to the external and internal parameter matrixes of the monocular camera, obtaining continuous passable and impassable region labels by combining clustering and search algorithms in machine learning, and obtaining high-quality labels through an automatic screening framework. The method can be suitable for many public data sets without labels, a huge-scale data set with labels is generated, the cost of network training is greatly reduced, fusion use of sensors and combined use of multiple methods are achieved, the advantages of all the methods are brought into full play in the algorithm, and therefore the effects of improving the label quality and reducing the label cost are achieved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com