Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

251results about "Labelling deformable materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-transfer label well-suited for labeling fabrics and methods of making and using the same

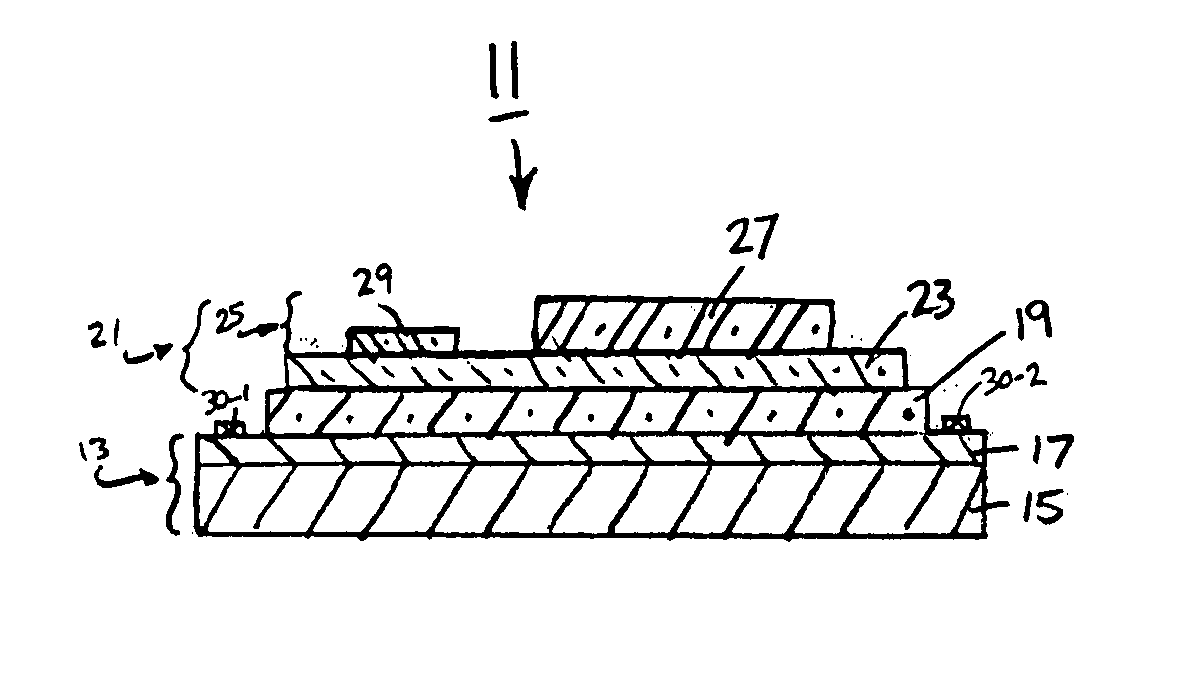

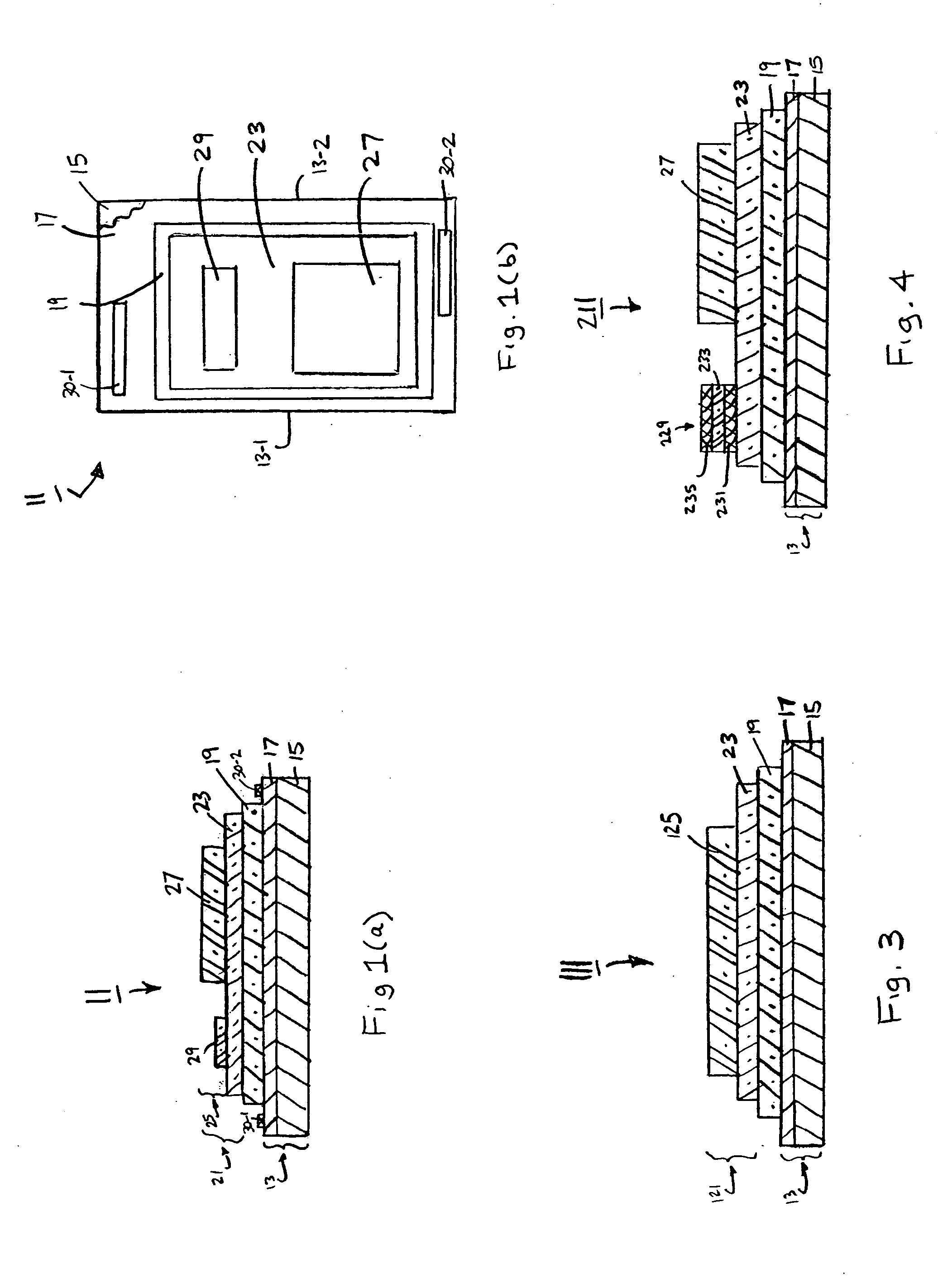

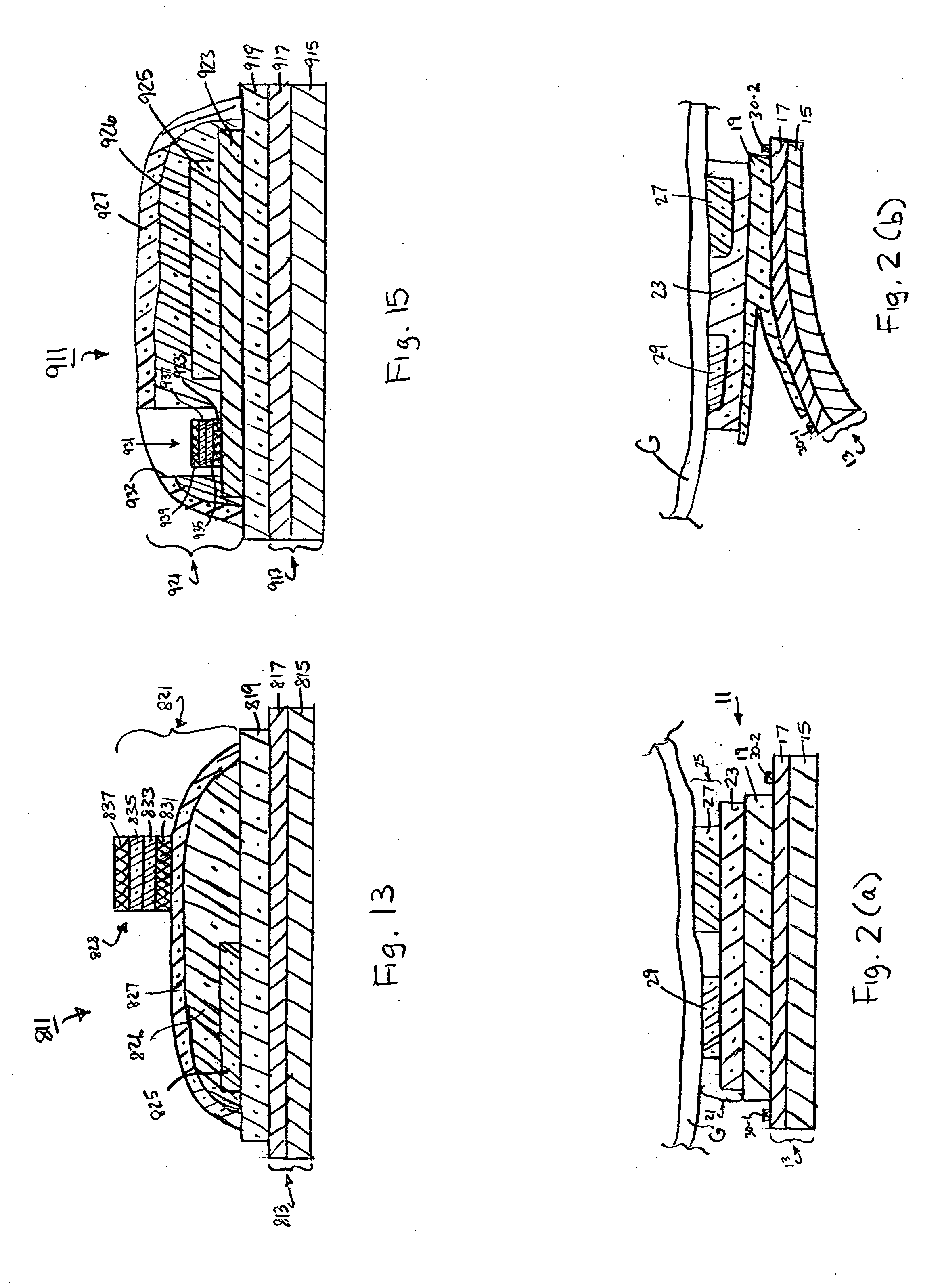

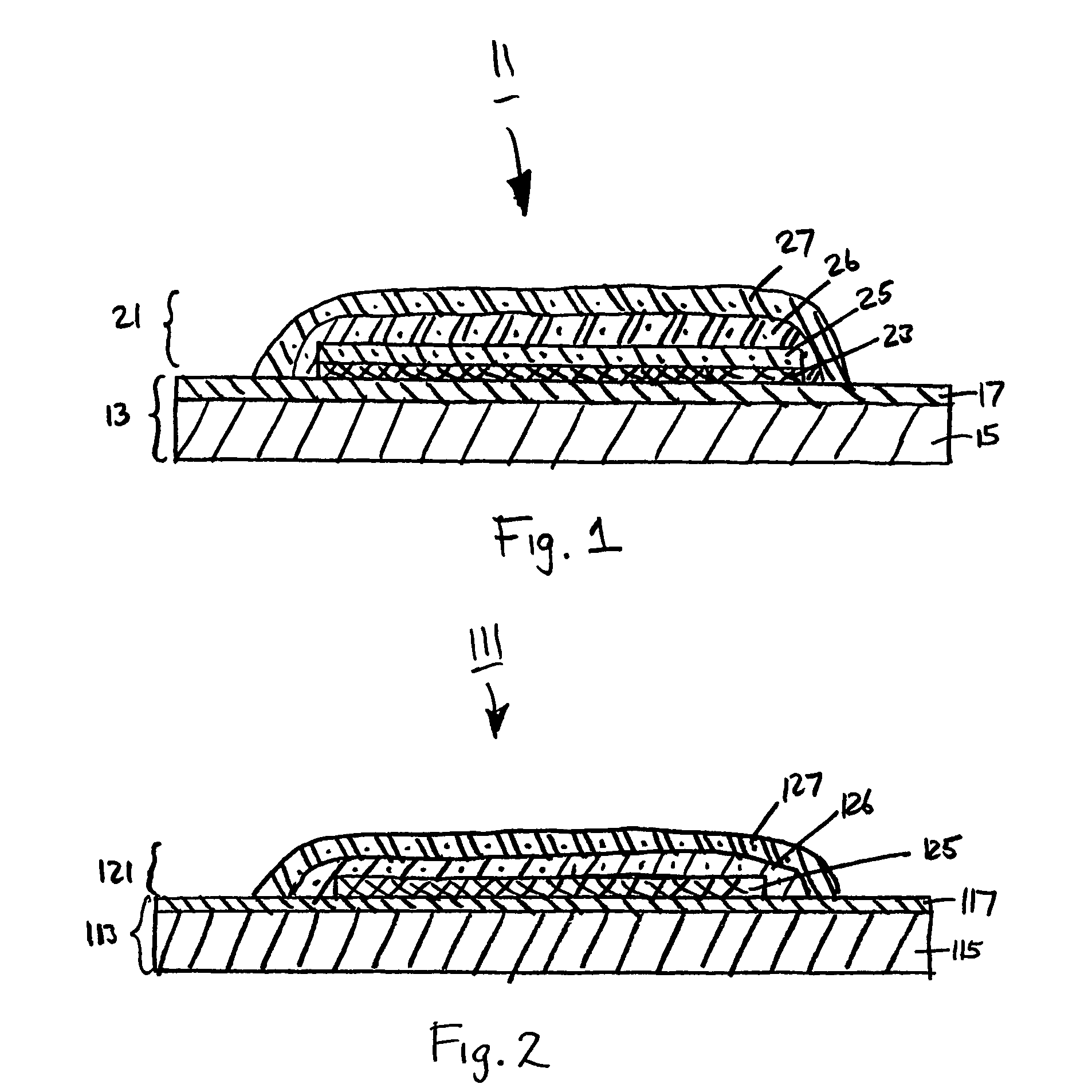

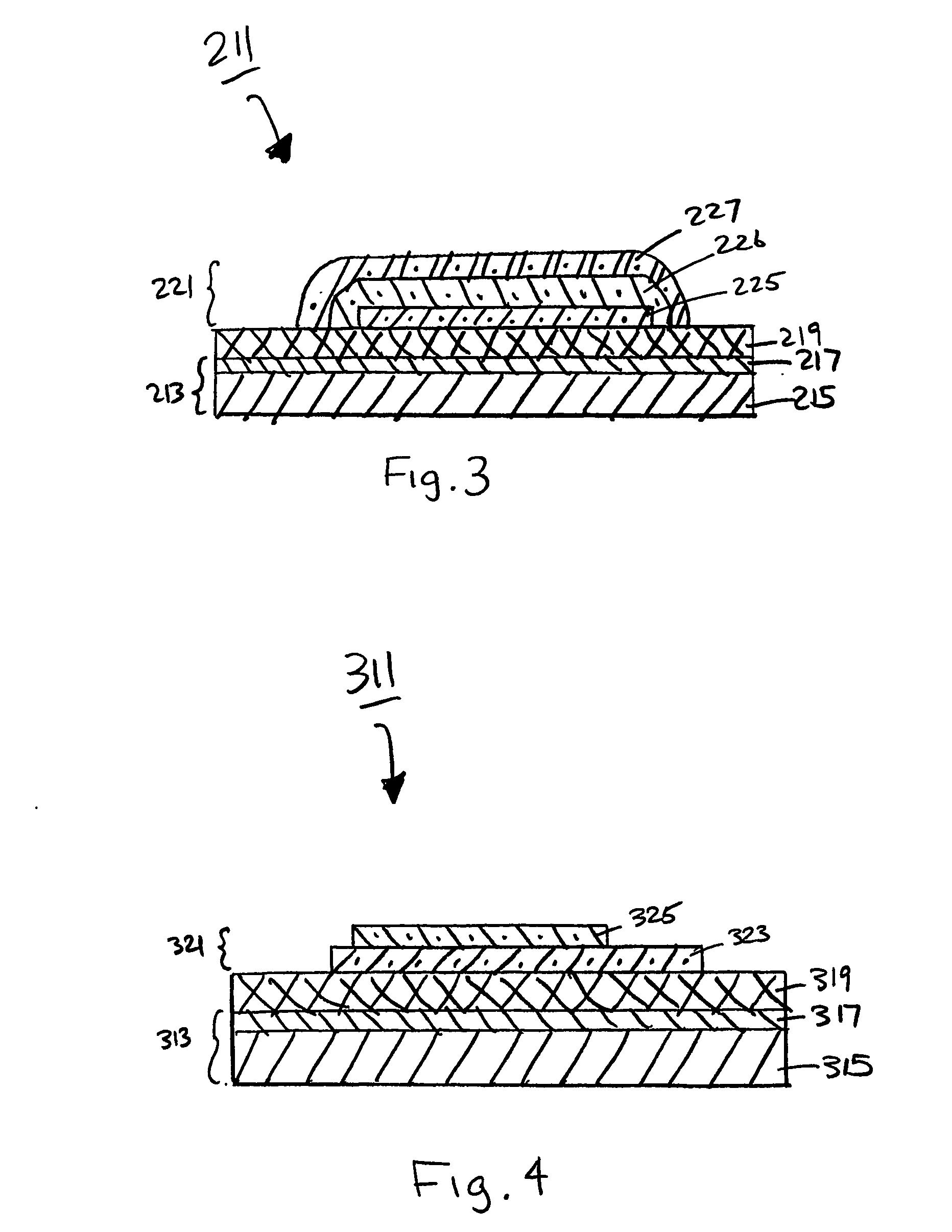

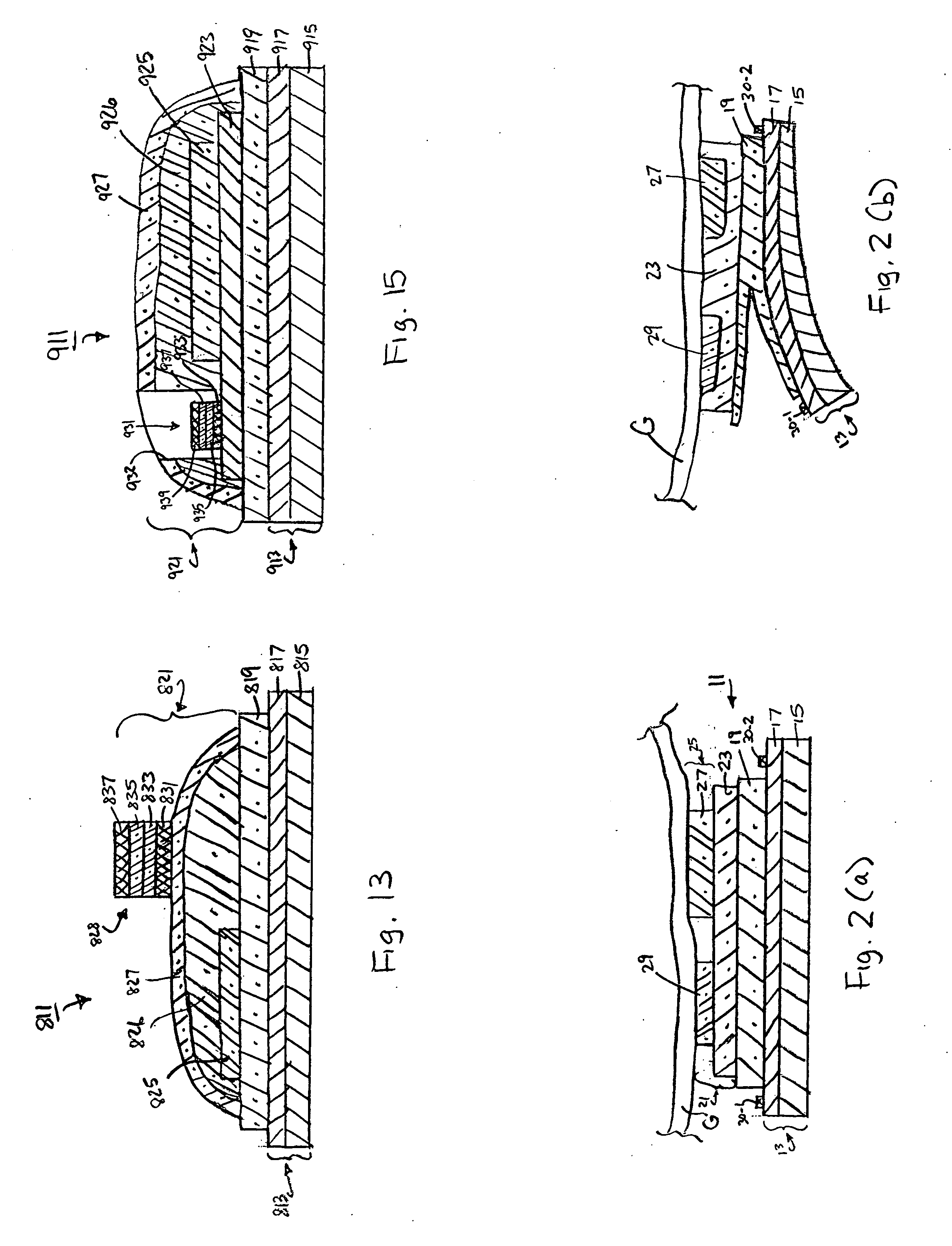

A method for labeling fabrics, such as fabric garments, and a heat-transfer label well-suited for use in said method. In one embodiment, the heat-transfer label comprises (i) a support portion, the support portion comprising a carrier and a release layer; (ii) a wax layer, the wax layer overcoating the release layer; and (iii) a transfer portion, the transfer portion comprising an adhesive layer printed onto the wax layer and an ink design layer printed onto the adhesive layer. Preferably, at least a portion of the ink design layer is printed using a variable printing technique, such as thermal transfer printing.

Owner:AVERY DENNISON CORP

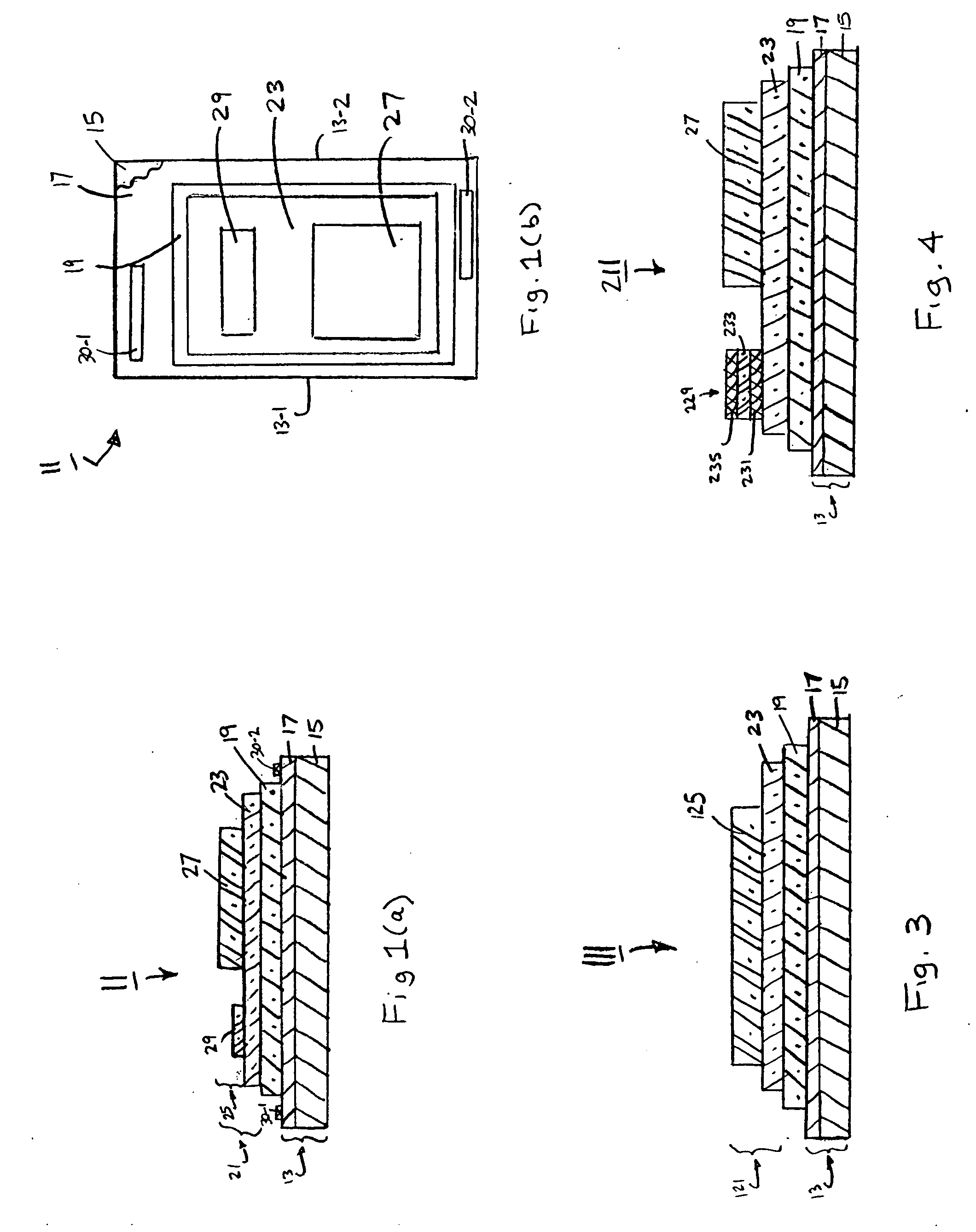

Method for labeling fabrics and heat-transfer label well-suited for use in said method cross-reference to related applications

A method for labeling fabrics, such as fabric garments, and a heat-transfer label (311) well-suited for use in said method. In one embodiment, the heat-transfer label (311) comprises (i) a support portion (313), the support portion (313) comprising a carrier (315) and a release layer (317); (ii) a wax layer (319), the wax layer overcoating the release layer (317); and (iii) a transfer portion (321), the transfer portion (321) comprising an adhesive layer (323) printed directly onto the wax layer (319) and an ink design layer (325) printed directly onto the adhesive layer (323). Each of the adhesive layer (323) and the ink design layer includes a non-cross-linked PVC resin. The ink design layer may be screen printed onto the adhesive layer (323) or may be printed onto the adhesive layer (323) using thermal transfer printing, ink jet printing or laser printing.

Owner:AVERY DENNISON CORP

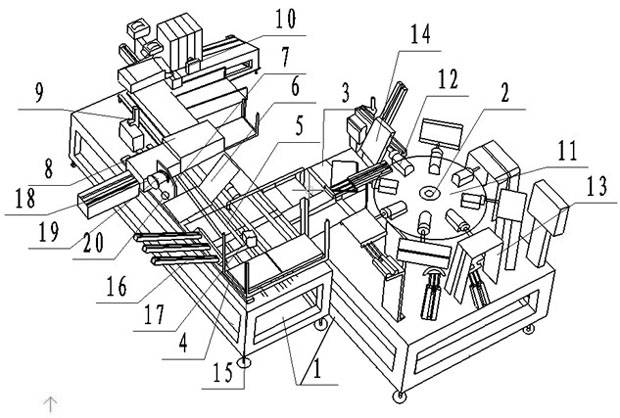

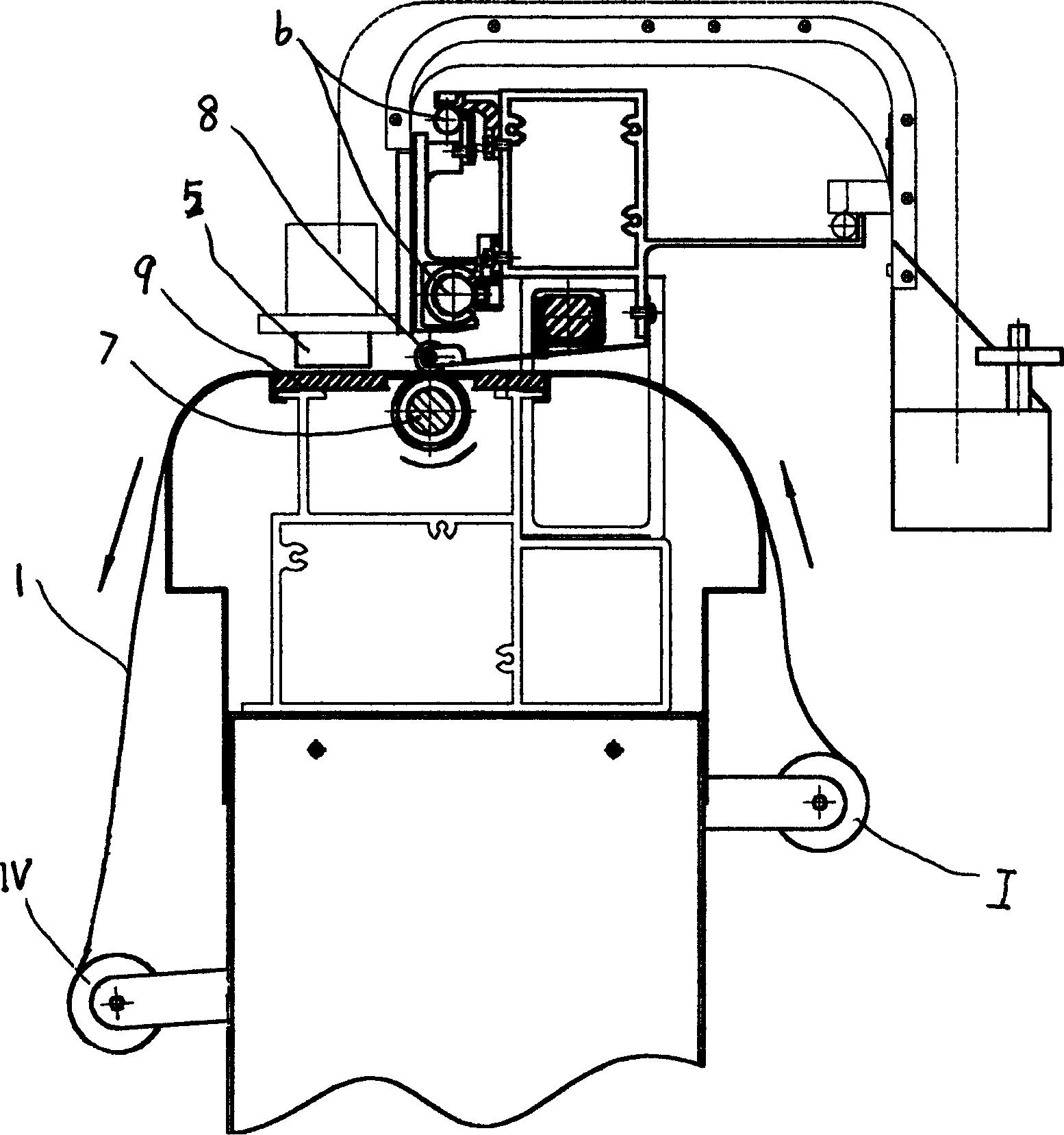

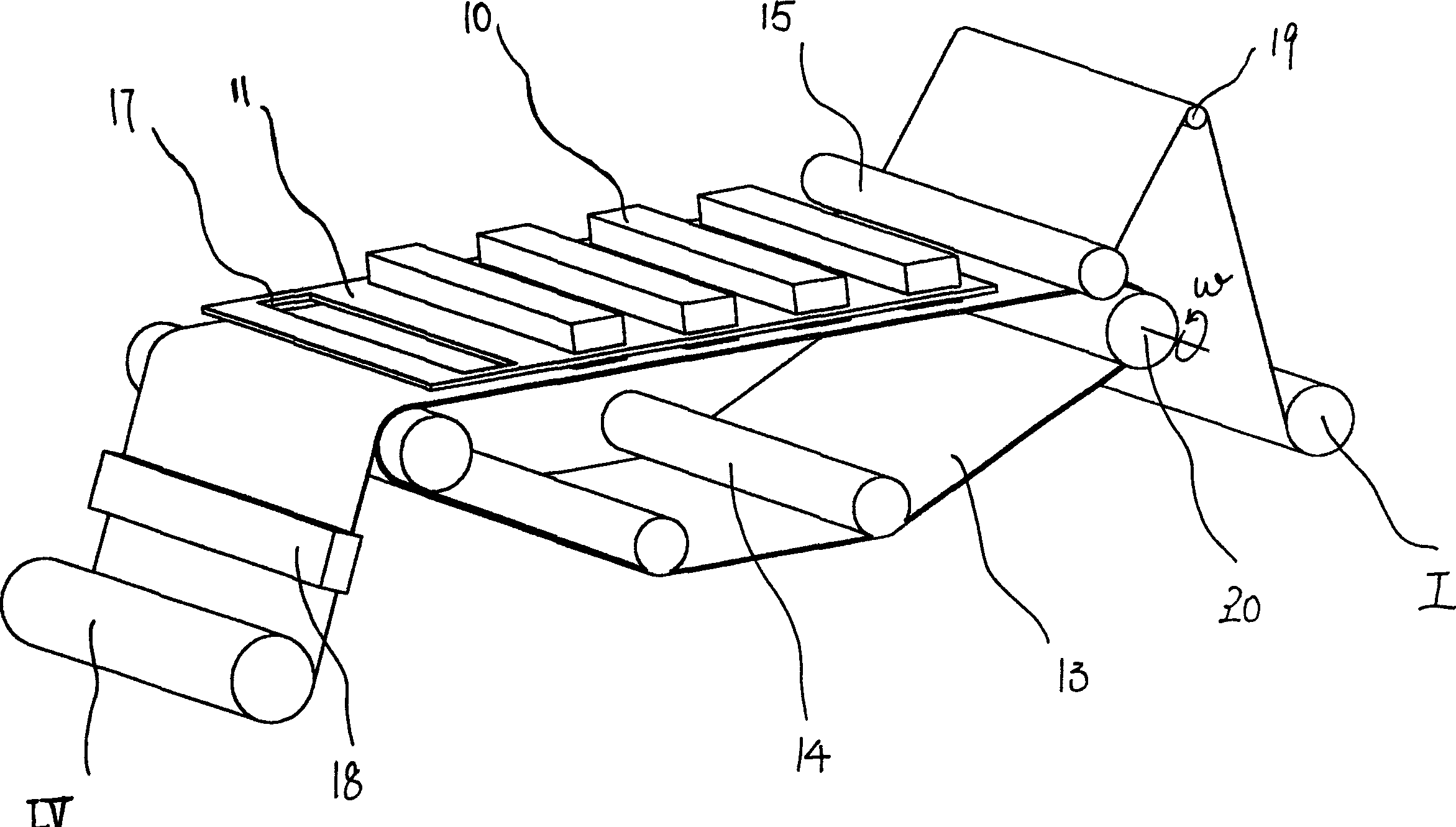

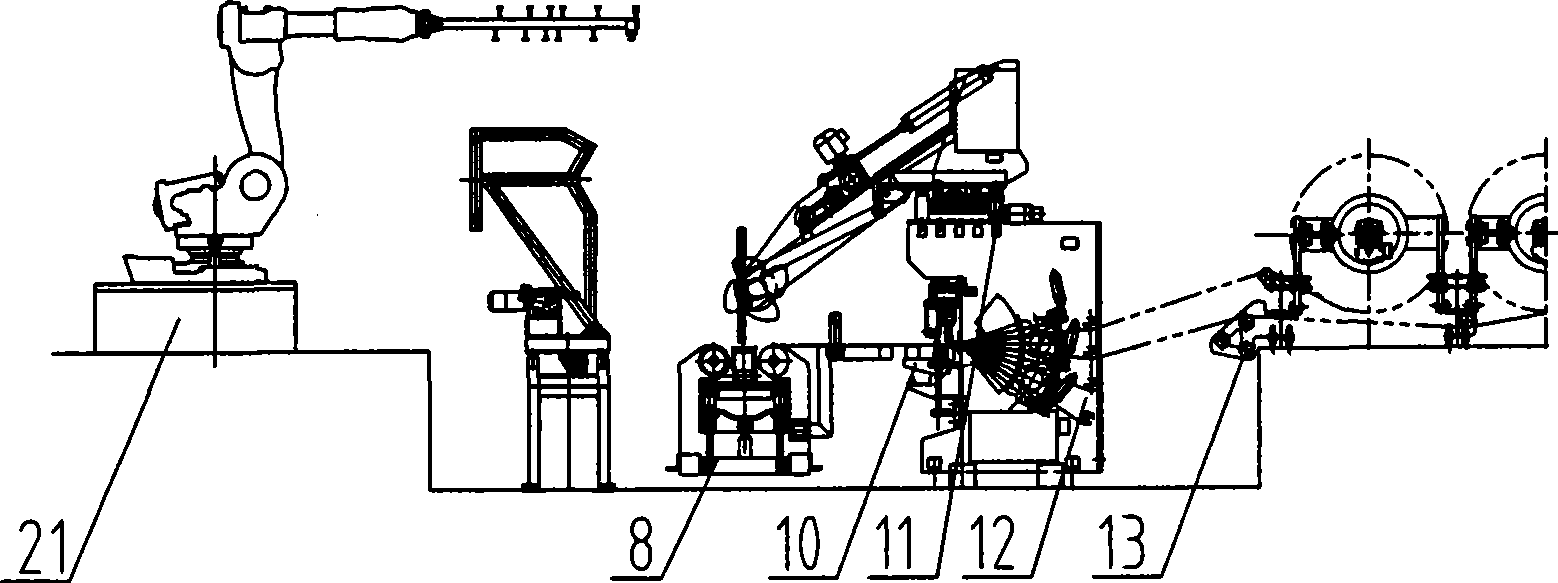

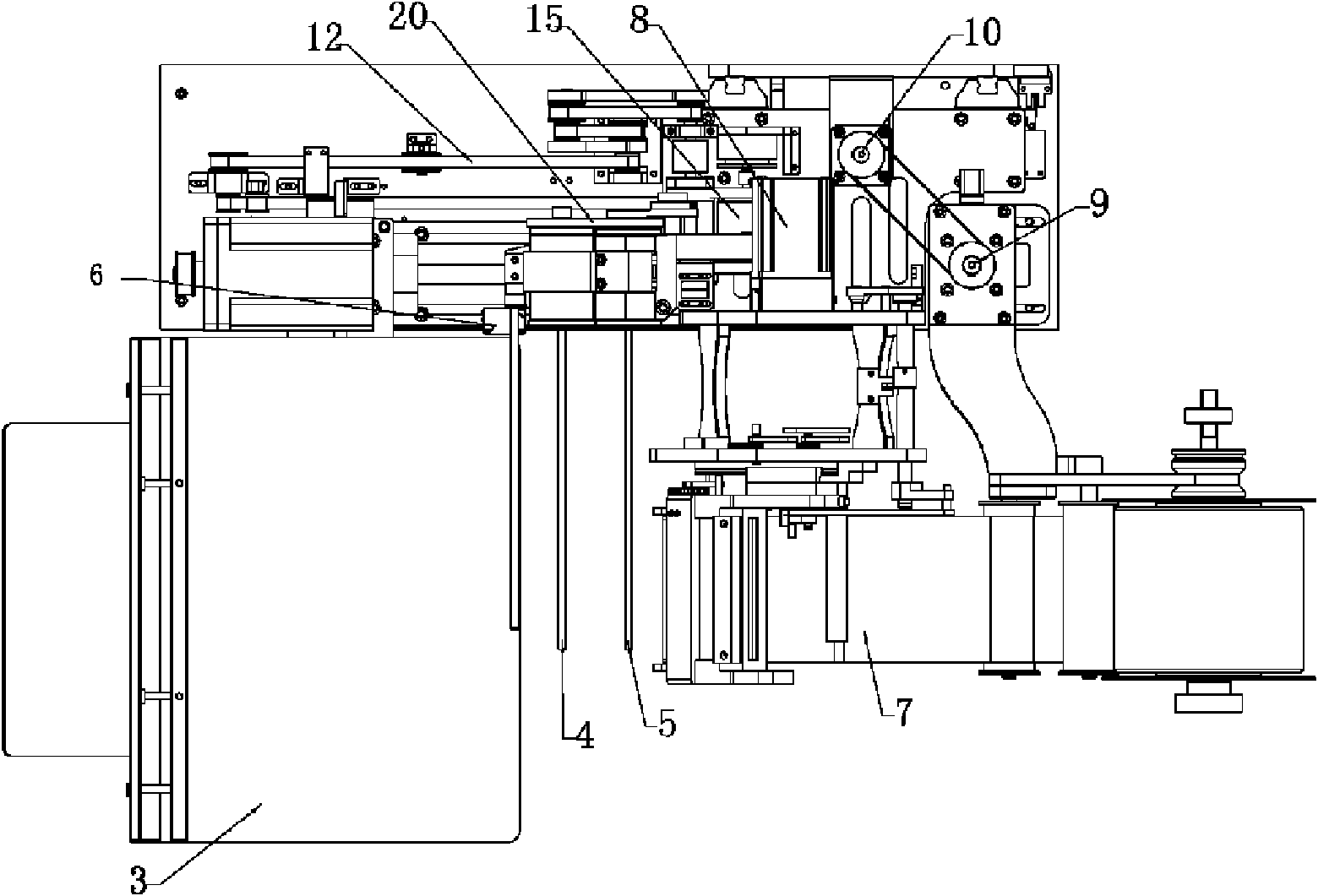

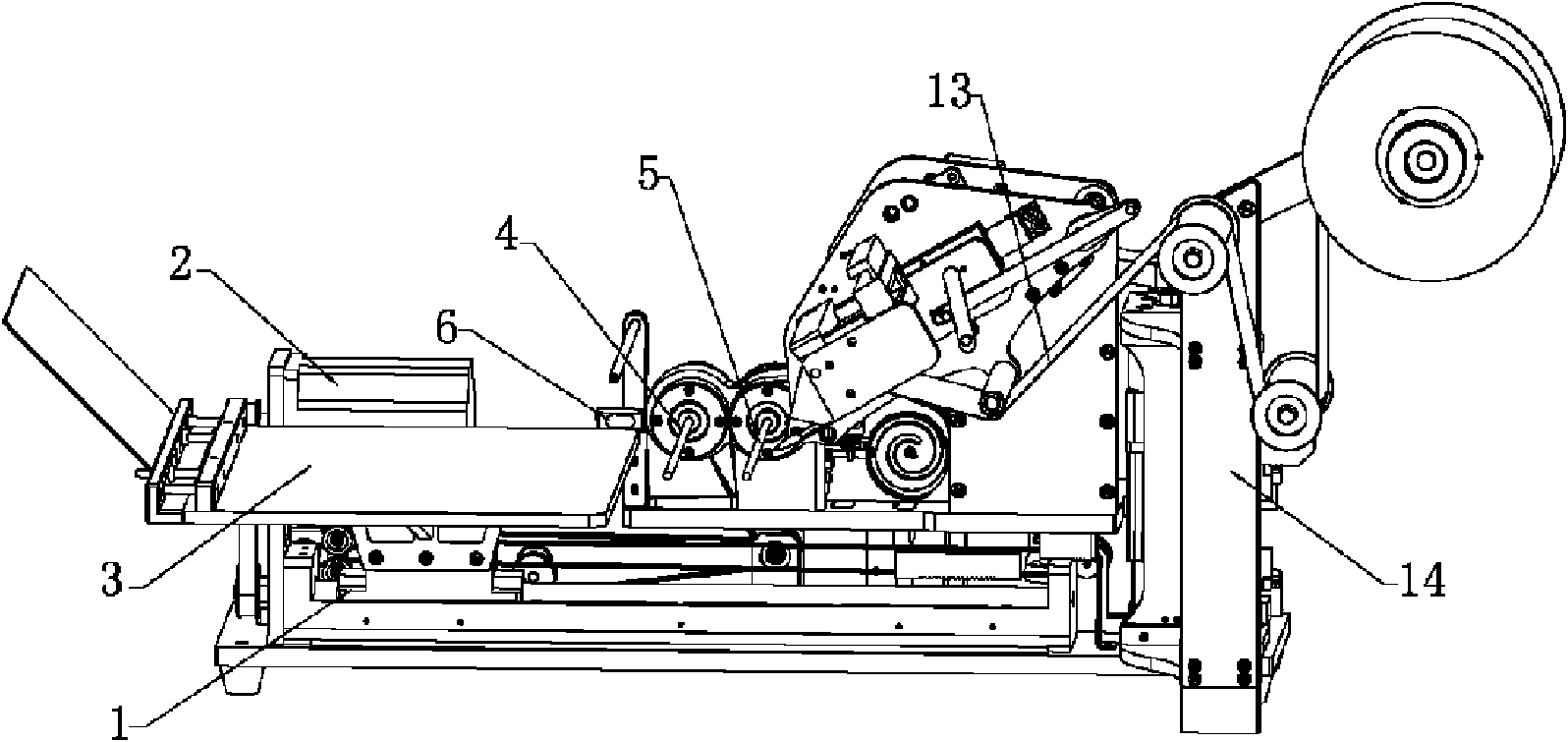

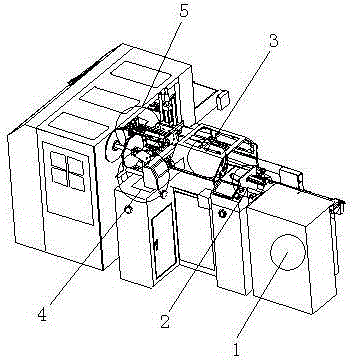

Full-automatic packaging device for silk stockings and method thereof

InactiveCN102689703AIncrease productivityEasy to operateLabelling deformable materialsWrapper twisting/gatheringEngineeringAutomation

The invention discloses a full-automatic packaging device for silk stockings and a method thereof. The full-automatic packaging device for silk stockings comprises an underframe, a rotary object carrying device, a silk stockings package conveying belt, a feeding device, a transversely conveying roller, a double up lining board mechanism, a bag inlet device, a sealing device and a finished productconveying device, wherein the rotary object carrying device and the transversely conveying roller are arranged on the underframe, the finished product conveying device is arranged at the tail end of the underframe, the rotary object carrying device is connected with one end of the silk stockings package conveying belt, the other end of the silk stockings package conveying belt is connected with the feeding device, and the double up lining board mechanism, a labeling mechanism, the bag inlet device and the sealing device are arranged on the transversely conveying roller in sequence. The full-automatic packaging device for silk stockings, provided by the invention, has the advantages that the structure is simple, the use is convenient, the cost is low, the degree of automation is high, the production efficiency is improved, and the labor intensity of workers is reduced.

Owner:陈陵际

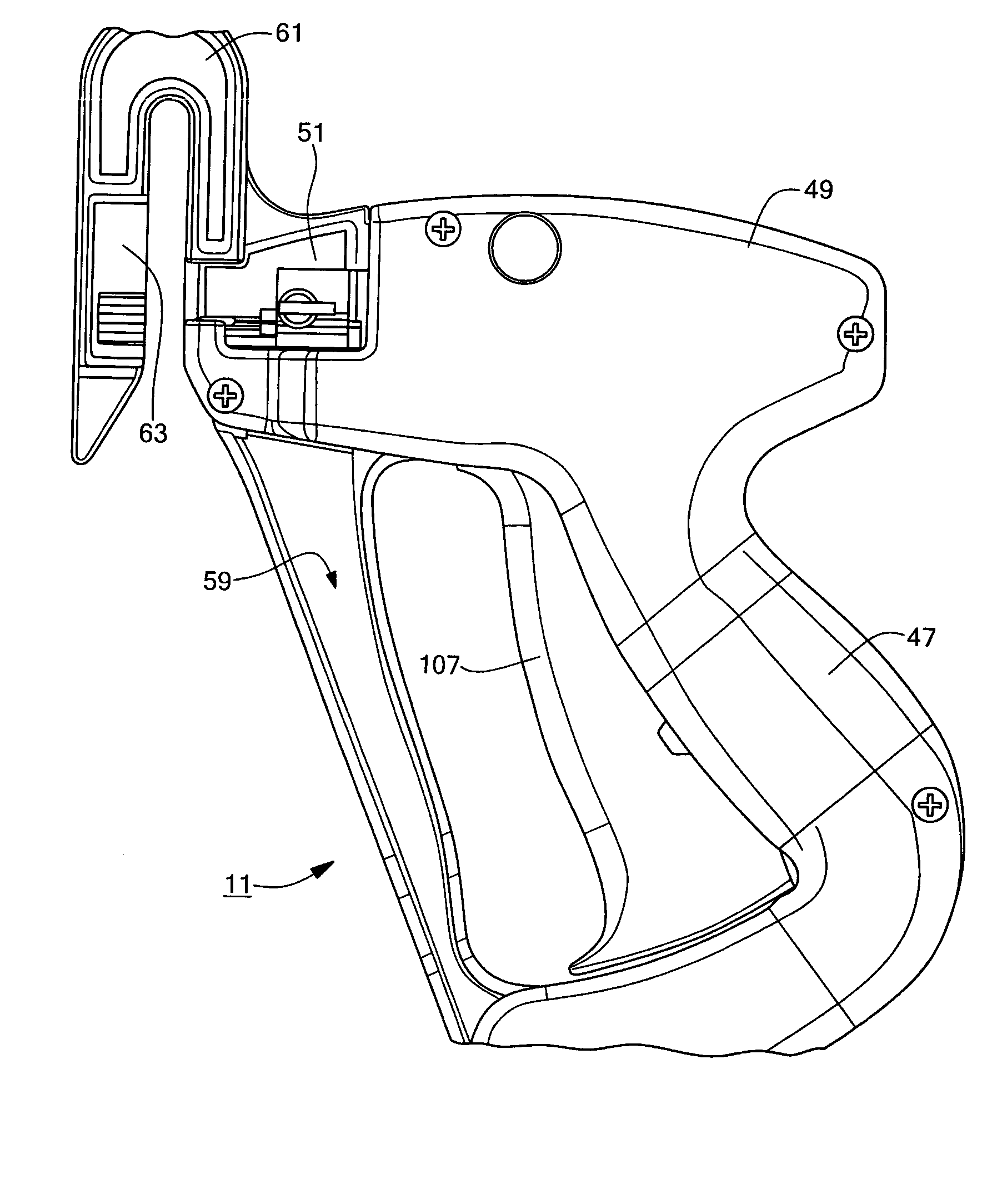

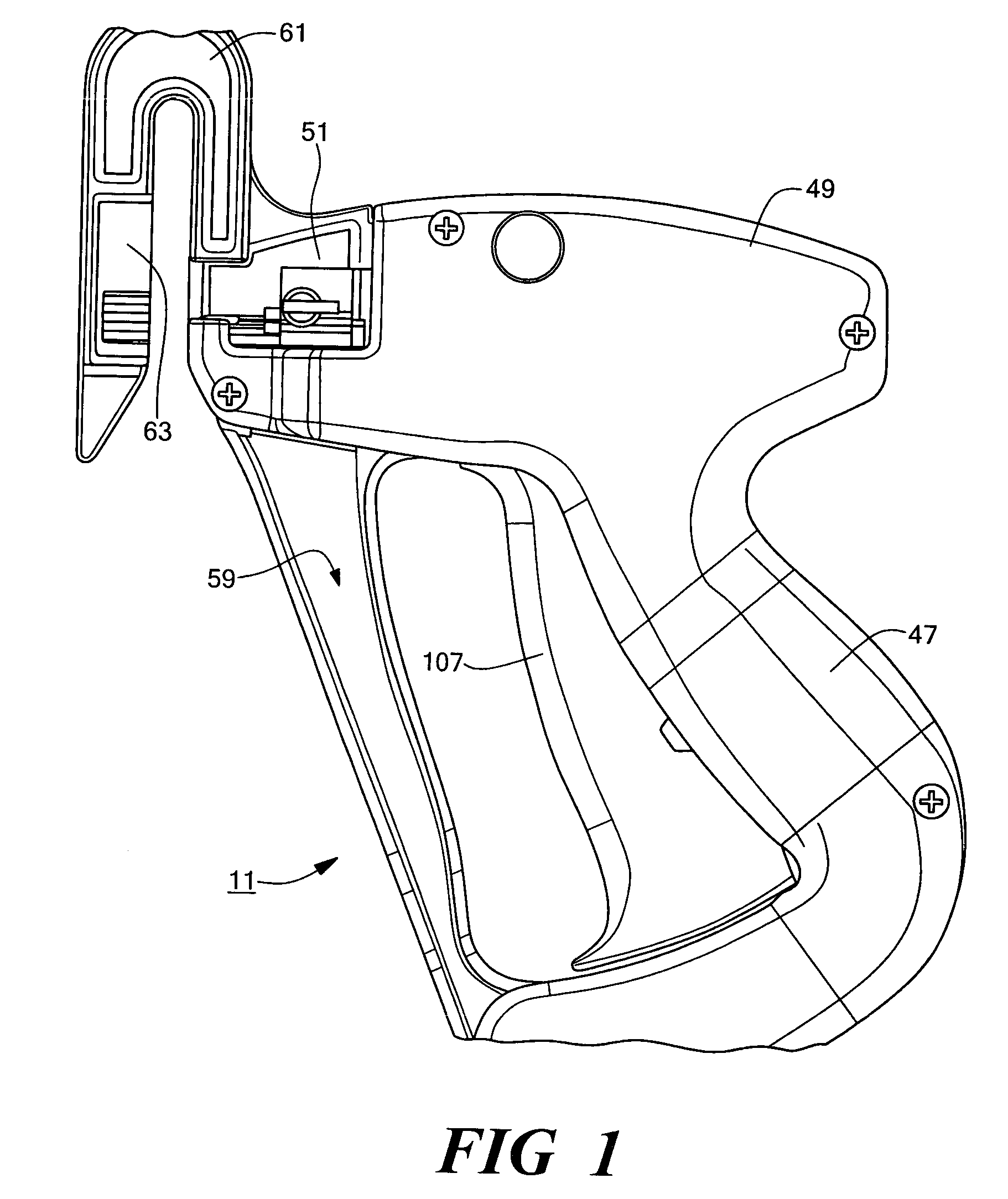

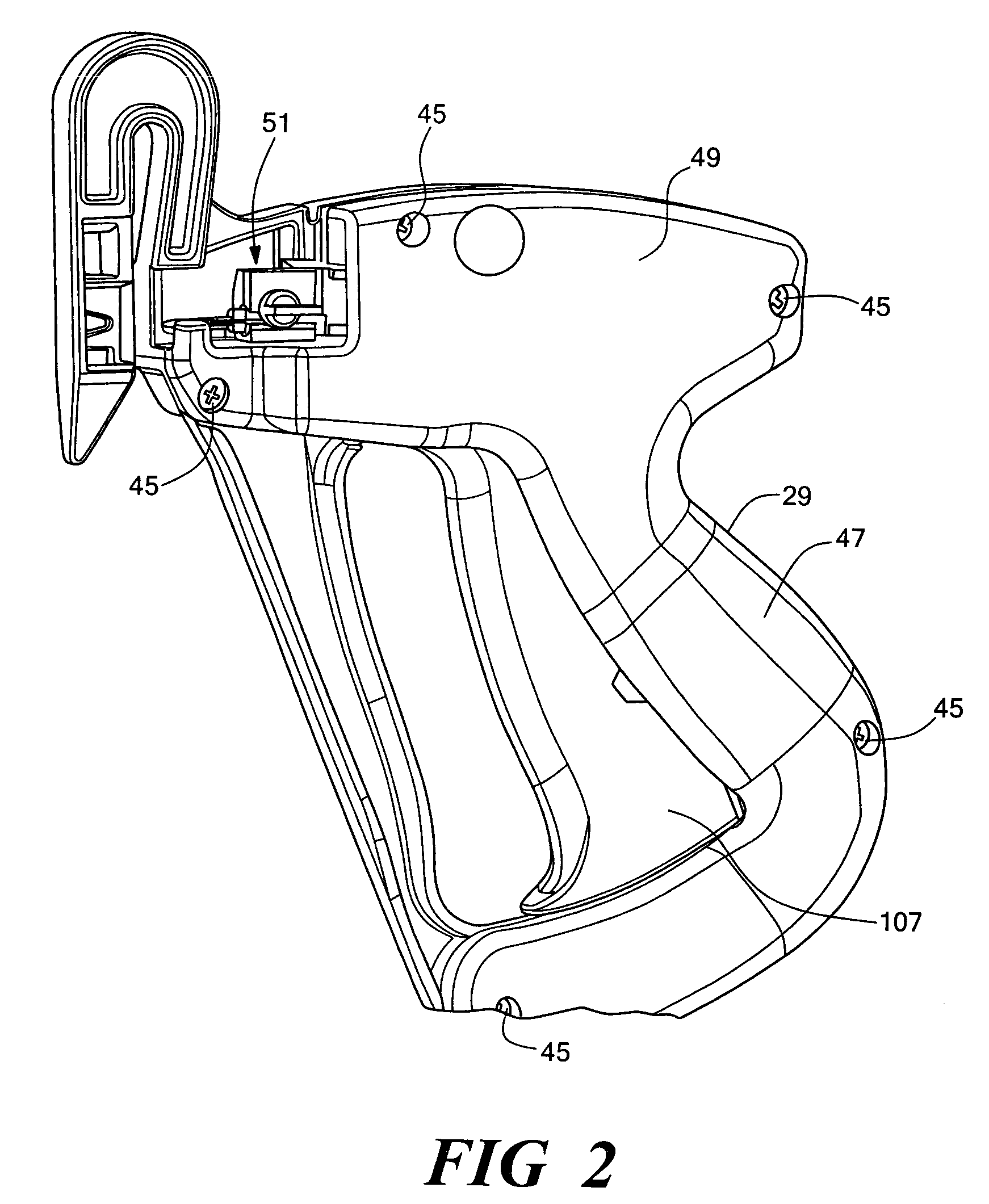

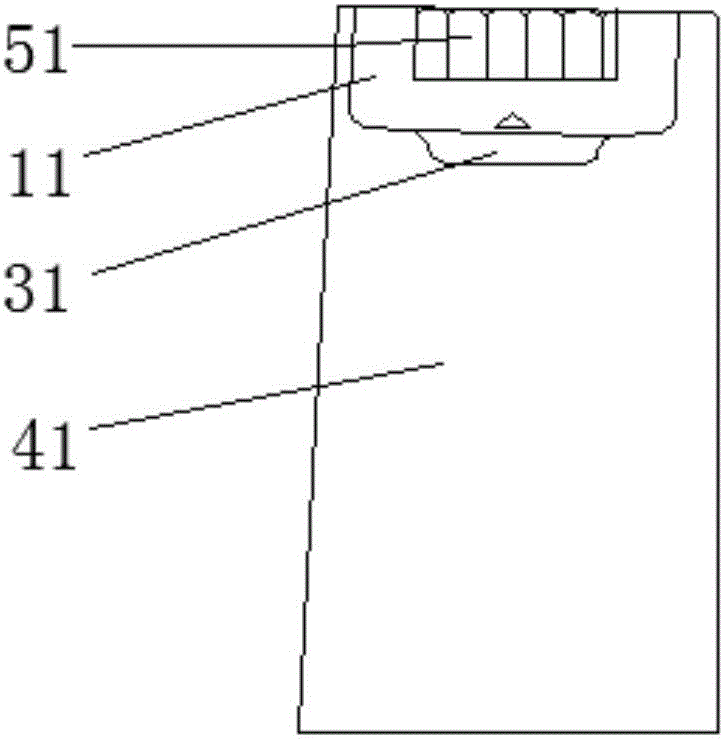

Hand-held drive-in tool

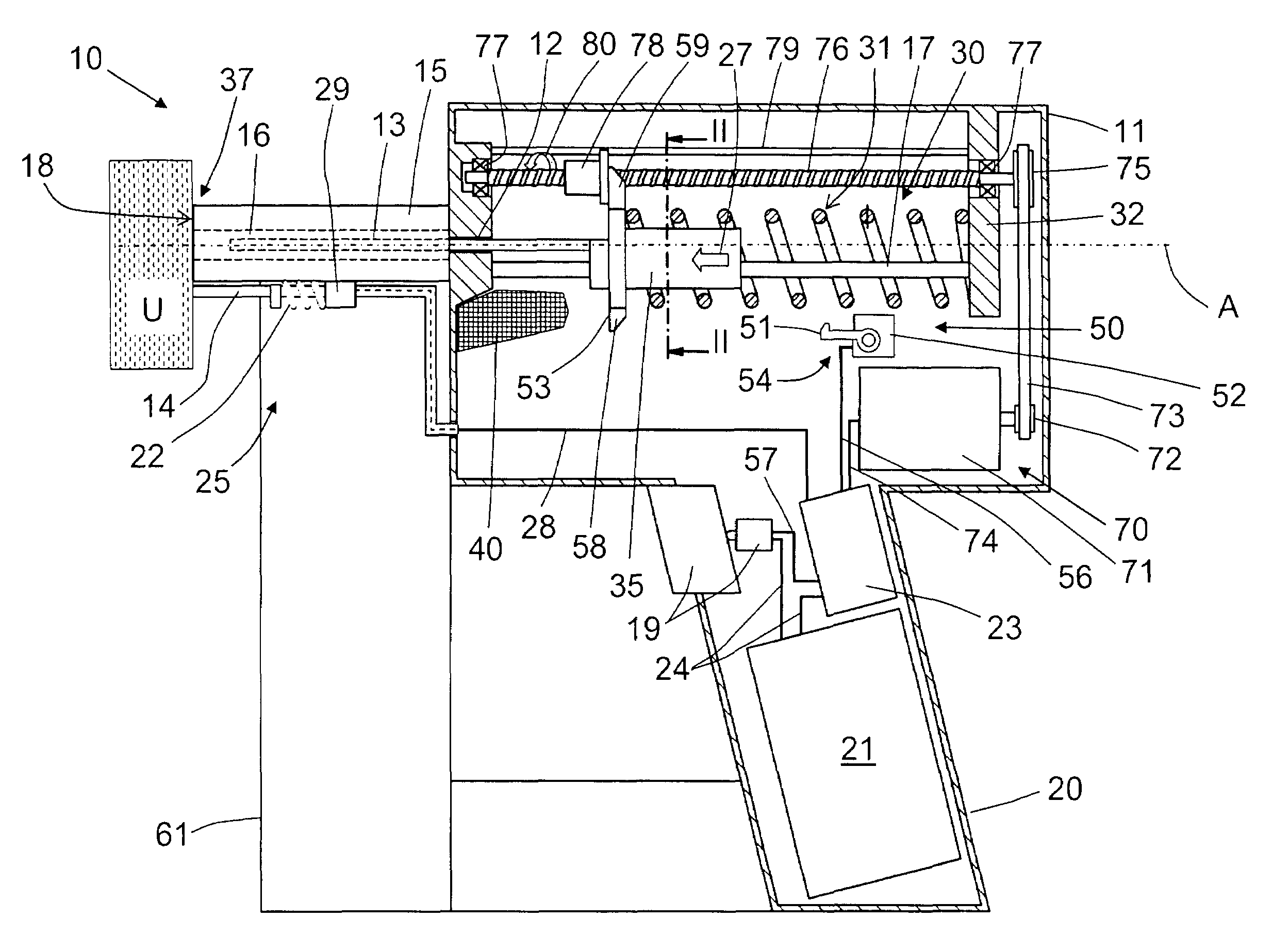

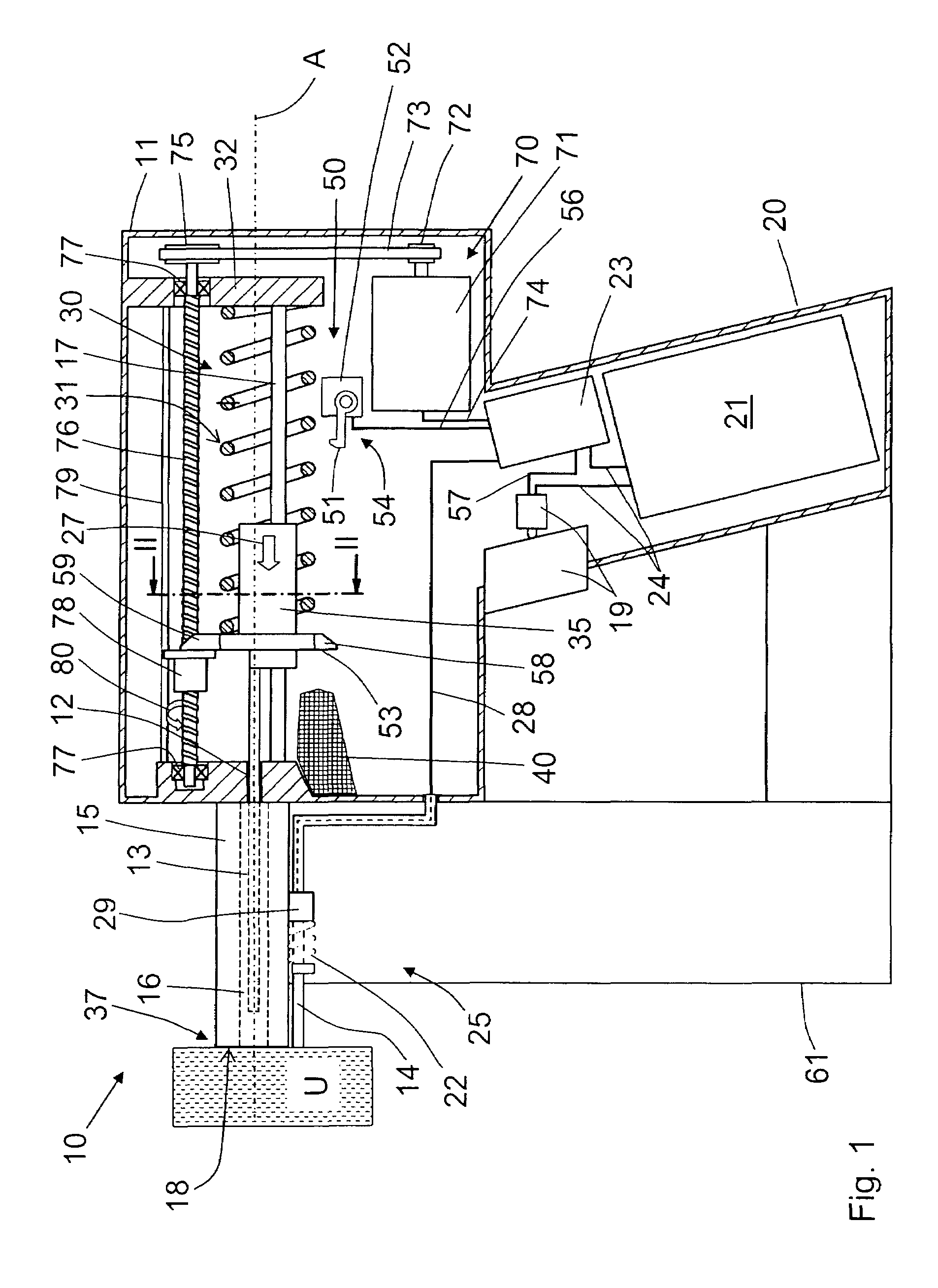

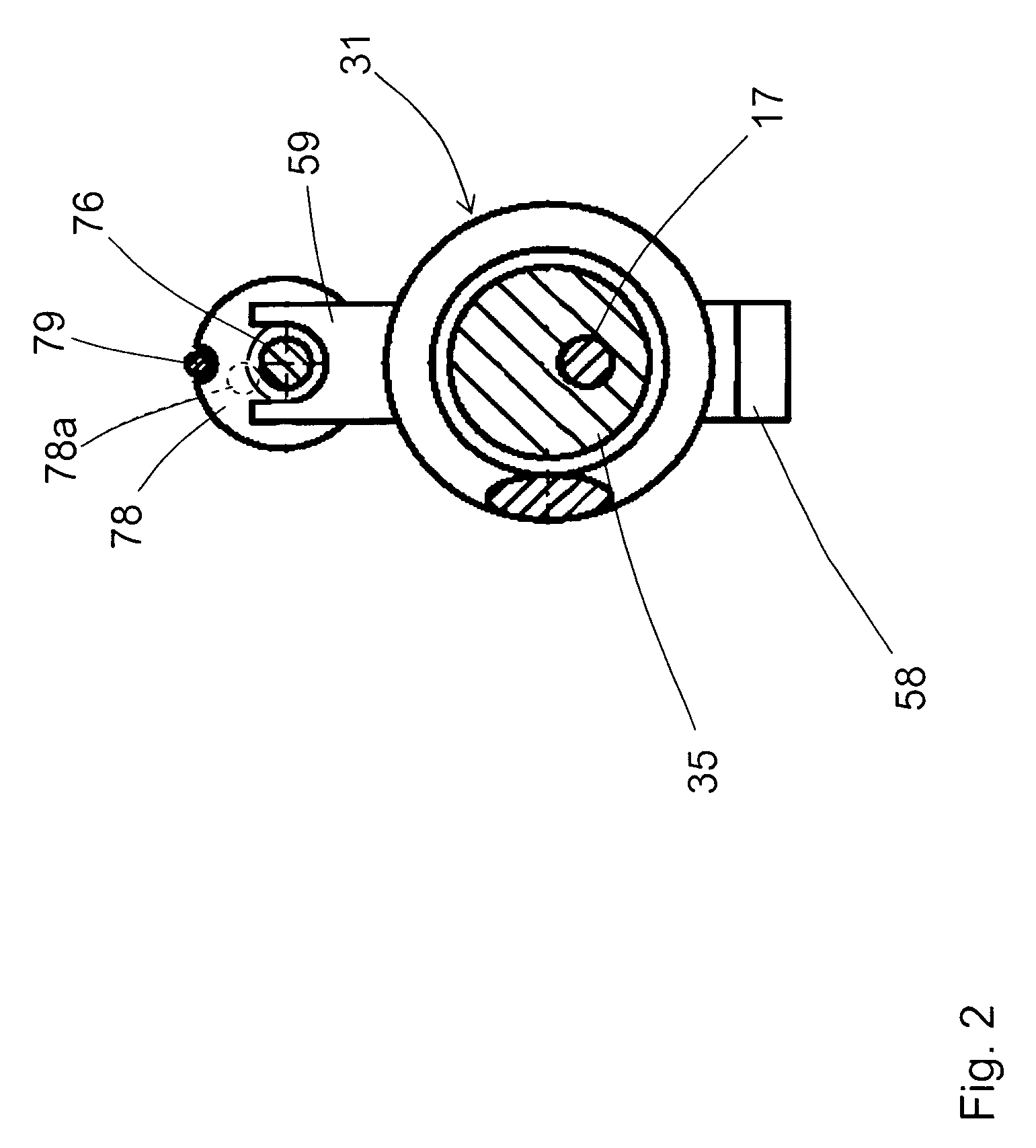

ActiveUS7520414B2EnergeticEasy to keepStapling toolsLabelling deformable materialsAxial displacementHand held

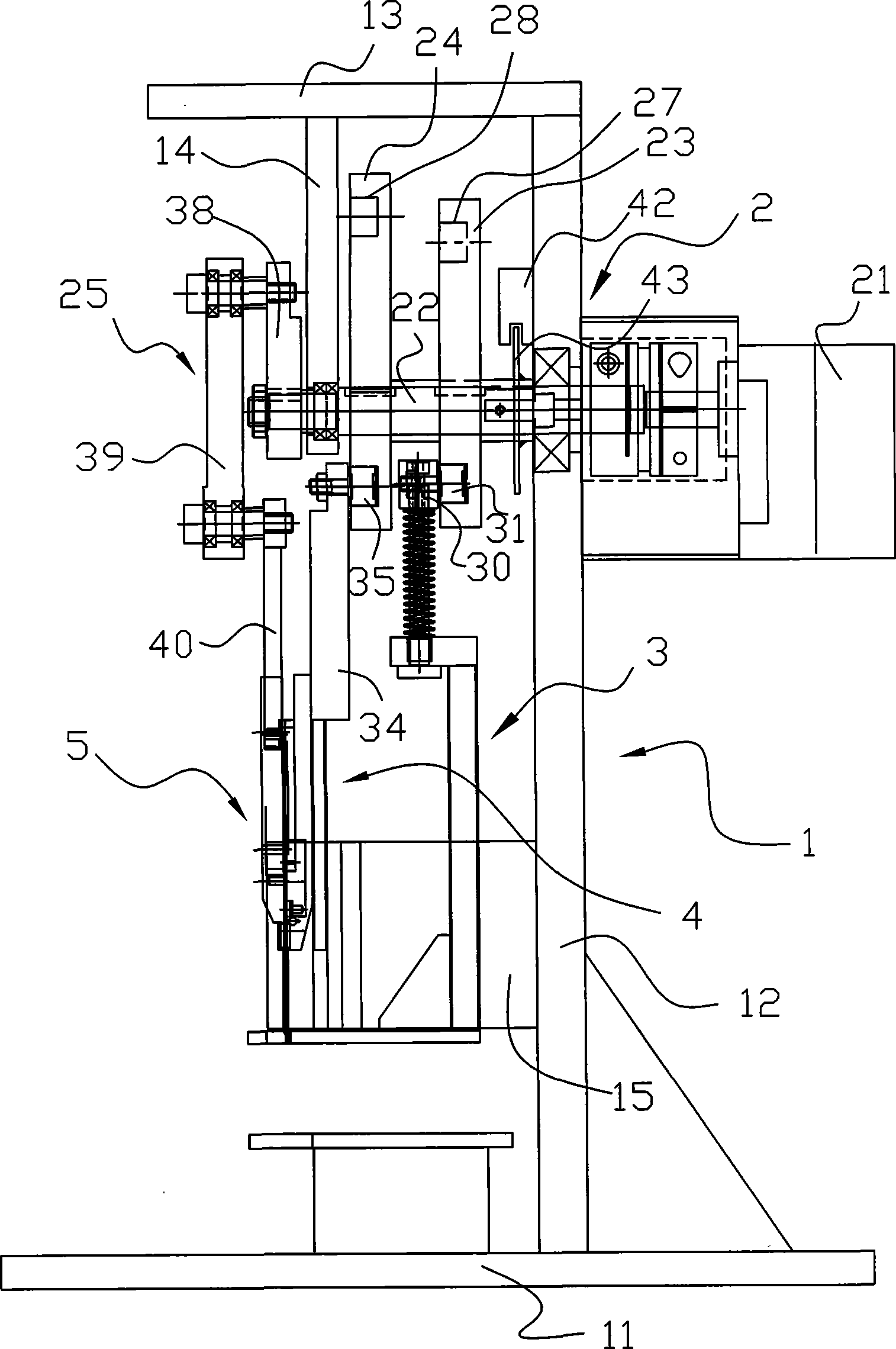

A hand-held drive-in tool for driving fastening elements (60) in a workpiece (U) includes a drive-in ram (13) displaceable in a guide (12), a spring (31) for driving the drive-in ram (13), a tensioning device (70) for loading the driving spring (31), a locking device (50) for retaining, in its locking position (54), the driving spring (31) in its loaded position thereof (33), and a sliding nut (78) supported on a threaded spindle (76), which is rotatable by the motor (71) of the tensioning device (70), without a possibility of rotation thereabout but with a possibility of an axial displacement therealong, the sliding nut (78) being axially displaceable, upon actuation of the motor (71) of the tensioning device (70) by a control unit (23) of the drive-in tool (10), from the first end position (83) to the second end position (84) for displacing the driving spring (31) into the loading position (33) of the driving spring (33), and being subsequently displaceable from its second end position (84) into the first end position (83) to provide for displacement of the driving spring (31) to its release position.

Owner:HILTI AG

Heat-transfer label well-suited for labeling fabrics and methods of making and using the same

Owner:AVERY DENNISON CORP

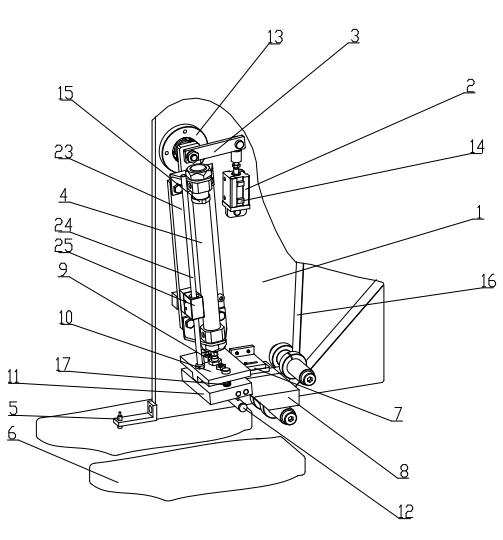

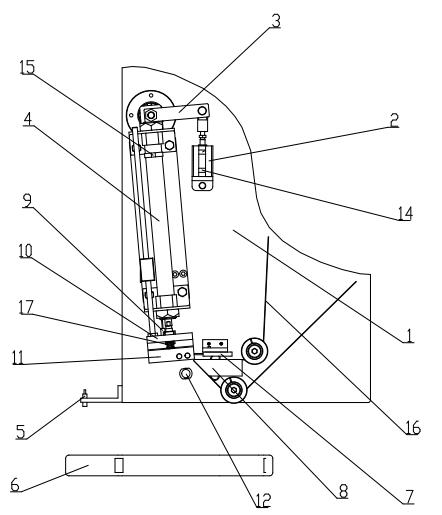

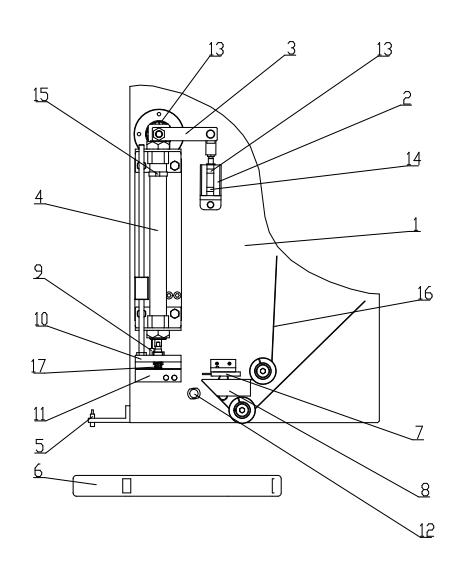

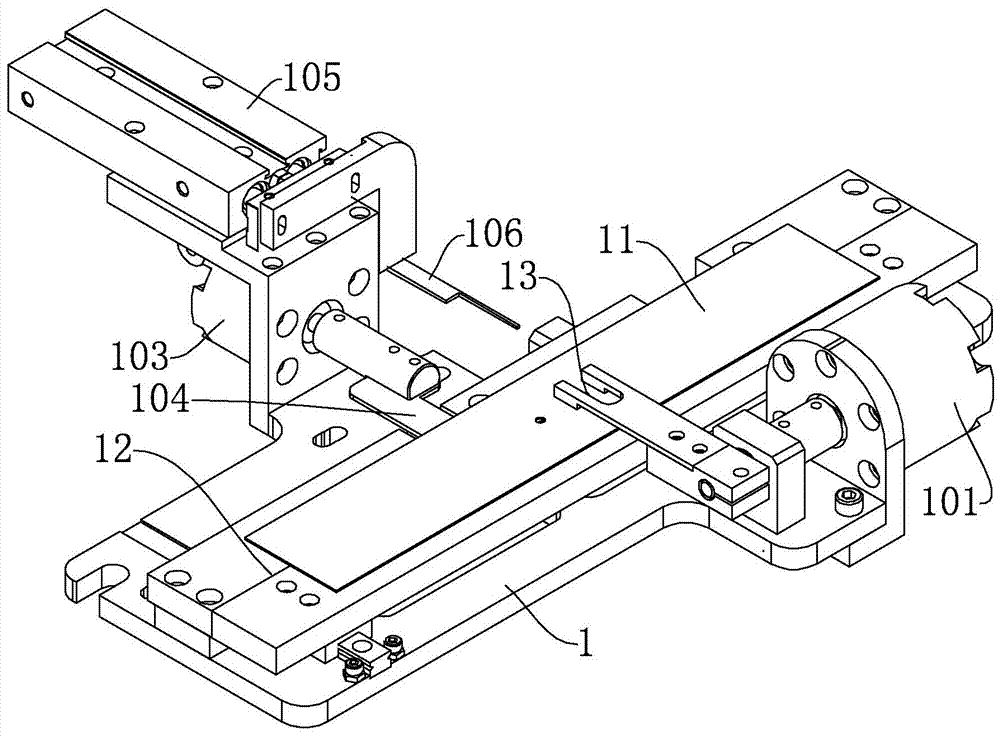

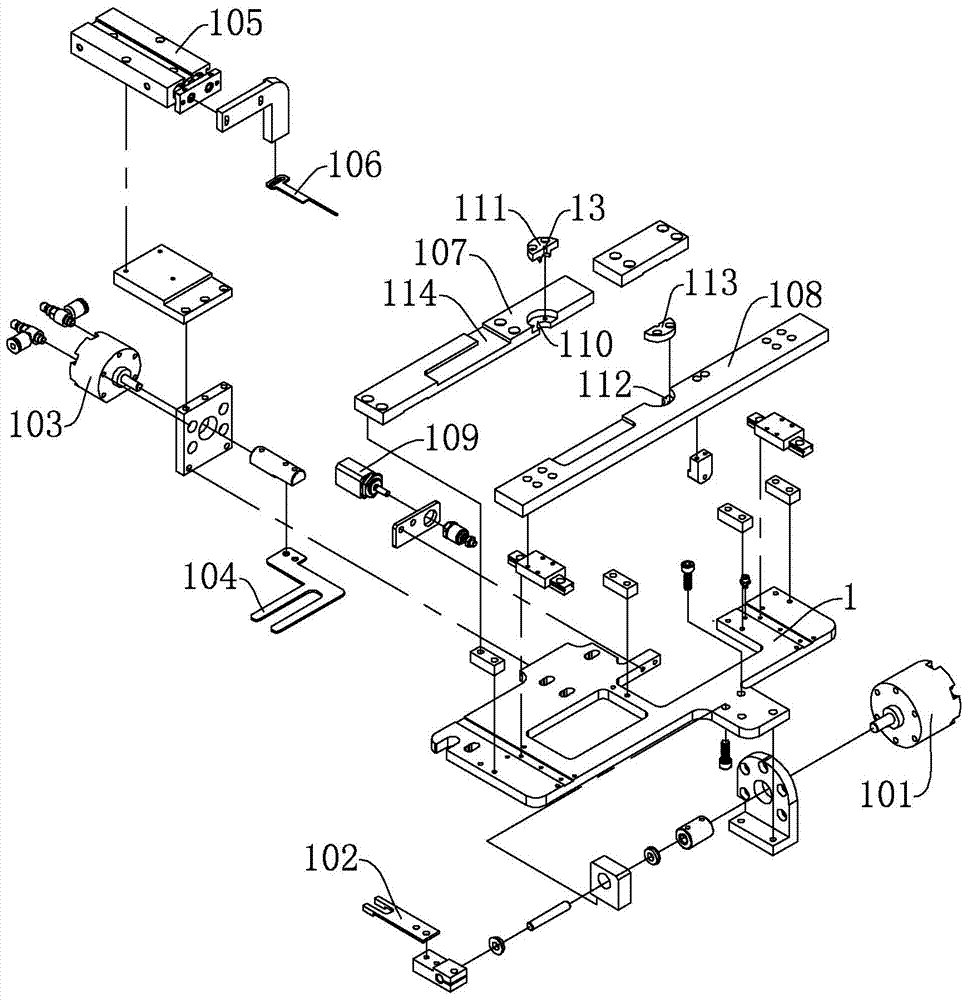

Label picking and sticking device

InactiveCN102658900AGuaranteed accuracyQuality assuranceLabelling deformable materialsLabelling machinesPiston rodAutomation

The invention discloses a label picking and sticking device, which is fixedly arranged on a production line through a seat plate and is arranged above products conveyed by the production line. The top of the cylinder body of a label sticking cylinder is pivoted at the upper part of the seat plate through a deflection shaft and is connected onto the piston rod of an oscillating cylinder through a transverse connecting rod. A label absorbing head is elastically arranged at the head of the piston rod of the label sticking cylinder. A label stripping knife is installed at the lower part of the seat plate and is arranged on one side below the label absorbing head. An air blowing pipe is arranged at the front lower part of the circular-arc knife edge of the label stripping knife. Air holes are arranged in the wall of the air blowing pipe. The label picking and sticking device has the advantages that the structure is simple and compact, the manufacturing cost is low, the problem that the traditional pressure-sensitive label sticking machine cannot stick labels on flexible surfaces is solved, and the label picking and sticking device is also suitable for labels with different sizes; and by controlling the pressure during label sticking, articles are prevented from being excessively deformed and the label sticking accuracy and quality are guaranteed. As an important part of a textile product packaging machine, the label picking and sticking device can realize the high automation of a packaging line.

Owner:JIANGNAN UNIV

Tool for dispensing plastic fasteners

ActiveUS7331497B2Smooth trigger strokeReduce in quantityLabelling deformable materialsAffixing tagsSyringe needleBiomedical engineering

A tool for dispensing fasteners from a fastener clip having a runner bar comprises a housing shaped to include a handle portion, a barrel portion and a guide channel for receiving the used portion of the runner bar. A trigger assembly is pivotally mounted in the handle portion. The tool also includes a needle slide slidably mounted in the barrel portion, a needle coupled to the needle slide, and a needle slide link coupling the needle slide to the trigger assembly. An ejector slide is slidably mounted within the needle slide and adapted to receive an ejector rod which is insertable back and forth through the hollow needle. The needle slide and the ejector slide are independently coupled to the trigger assembly. An anvil extends out in front of the barrel portion and is adapted to receive a removable brush, the needle being aligned to selectively project into the brush.

Owner:AVERY DENNISON CORP

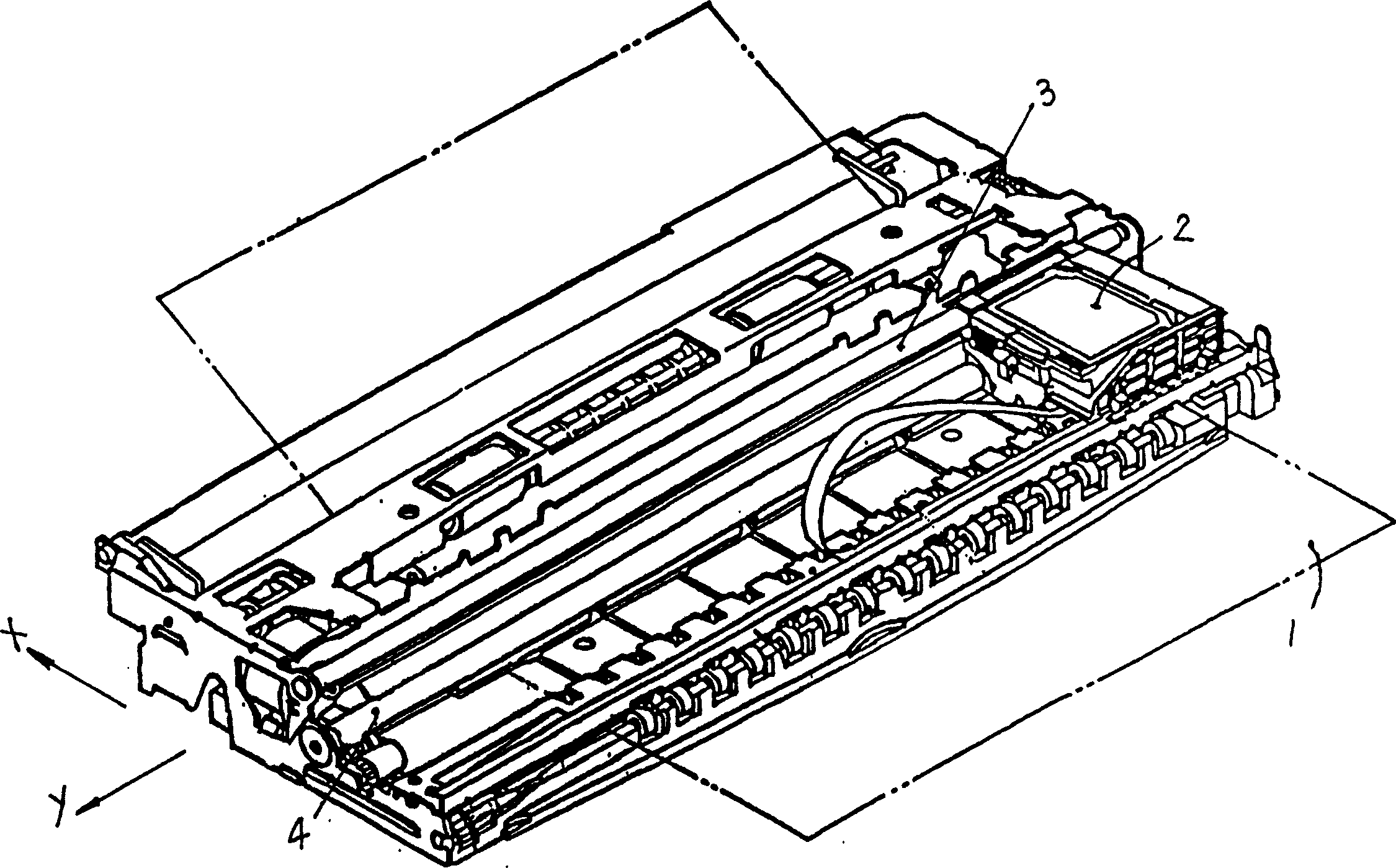

Ink-jet head fixed digital jet printer with guide tape to feed medium

InactiveCN1631674AConvey levelingImprove printing qualityLabelling deformable materialsOther printing apparatusPrinting inkEngineering

The invention relates to a color inkjet printer with a fixed blowing head printing fast on the continuously transferred medium. The printer includes unrolling device, medium transferring device, printing device and rolling device. Its features lies on that the blowing head is fixed on the blowing head stand of which the blowing holes' centers' link is almost perpendicular to the medium transferring direction, guiding belts set in the medium transferring device with a width larger than or equal to the width of the medium, guiding belt glue at least set on the contacting section with the printing medium. So the printer has a wide adapting range and suitable to mediums of different thickness; the service is highly reliable with a fine blowing effect; blowing heads can be handily added or lessened so can the colors of printing inks so to improve the printing quality remarkably. Blow the inks of different at different time by different groups which facilitates the ink drying and solidificating.

Owner:HANGZHOU HONGHUA DIGITAL TECH

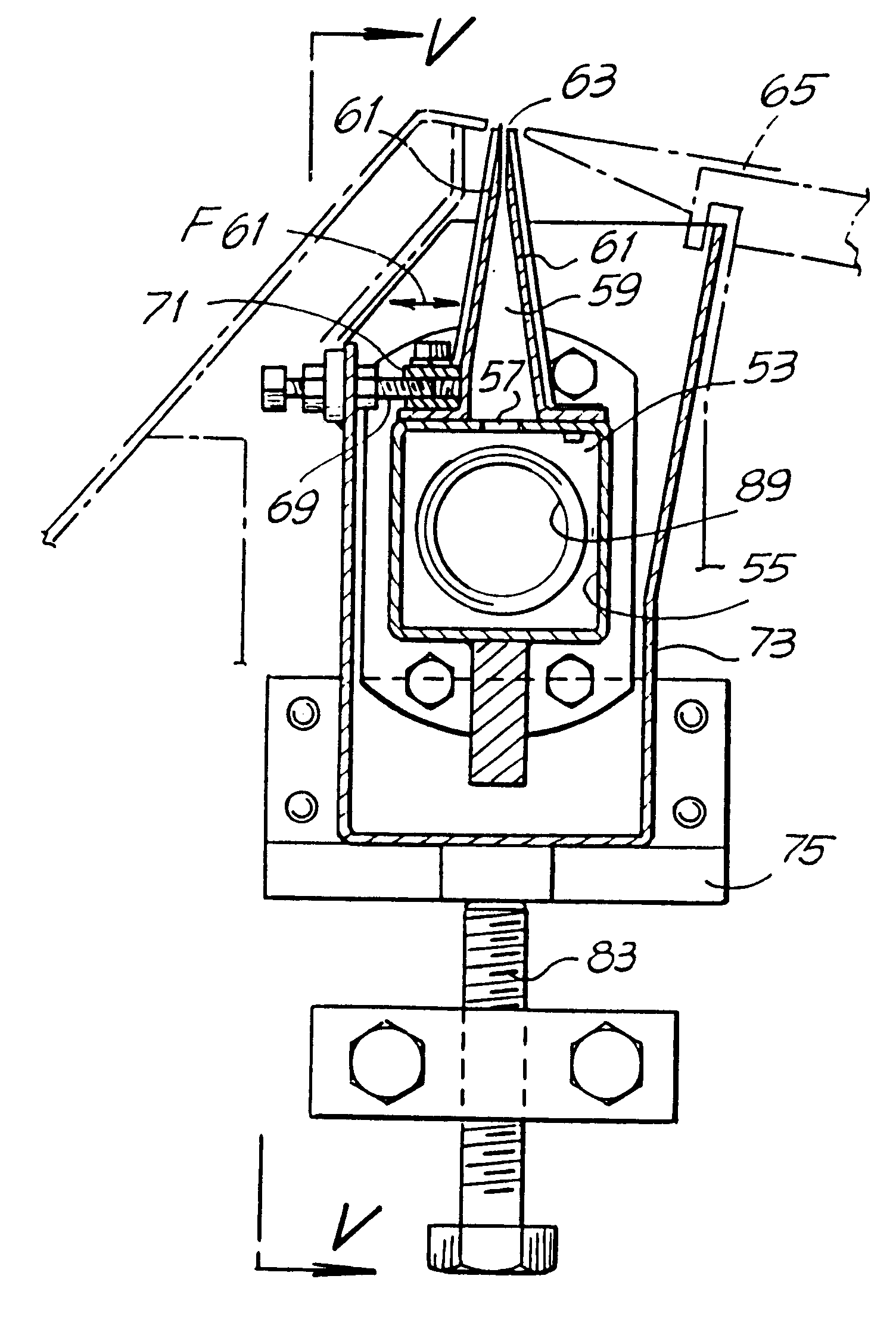

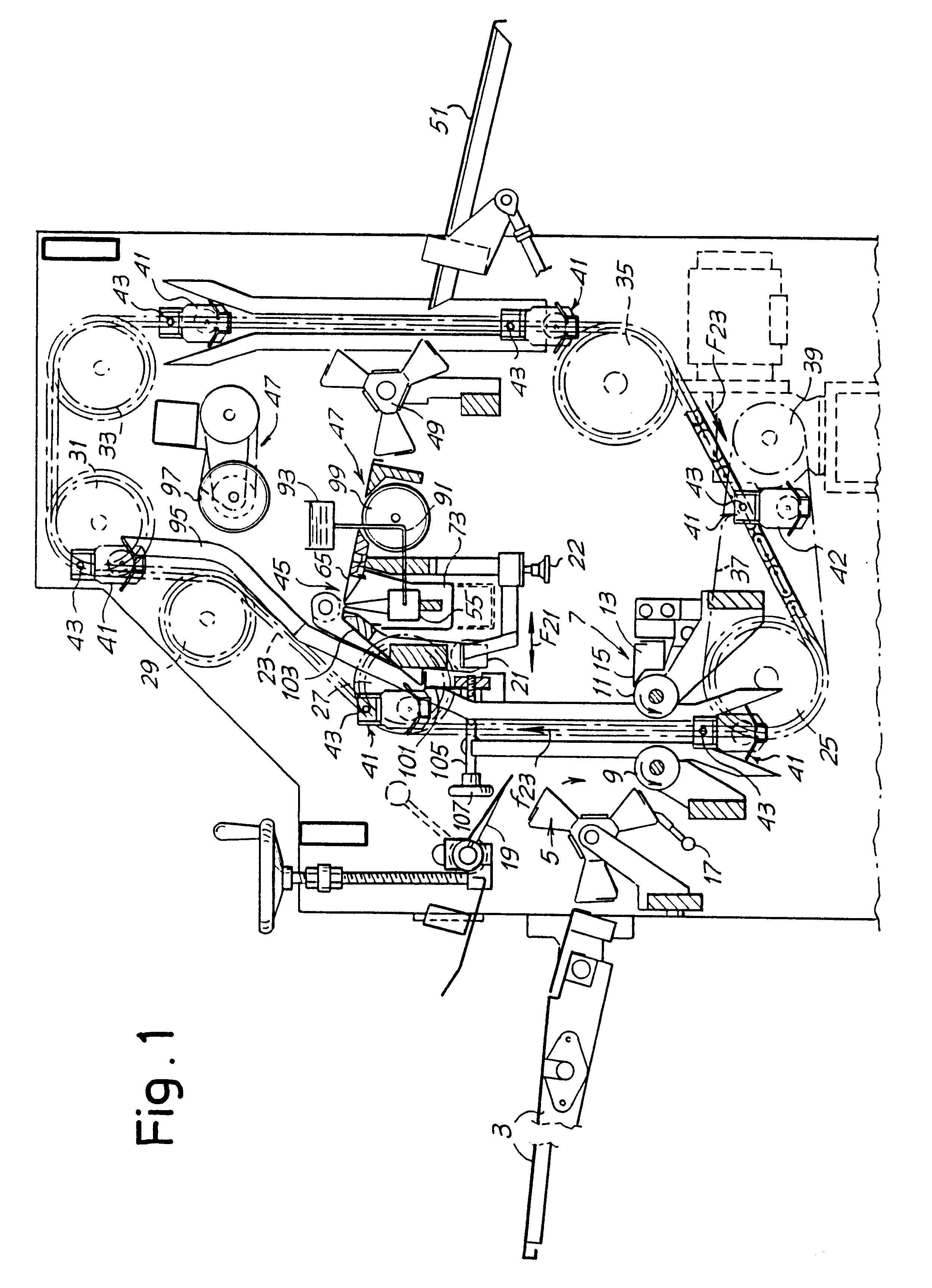

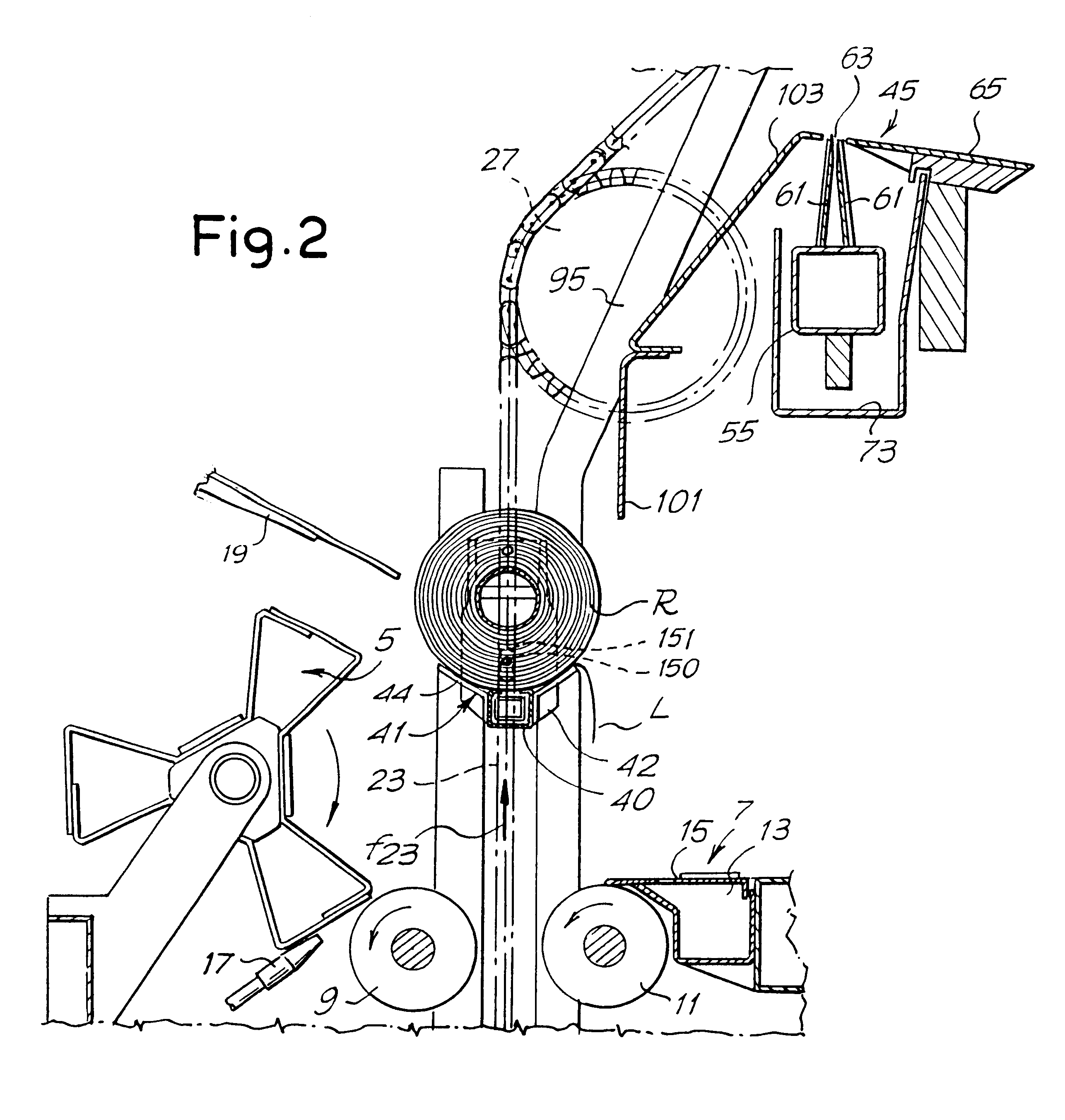

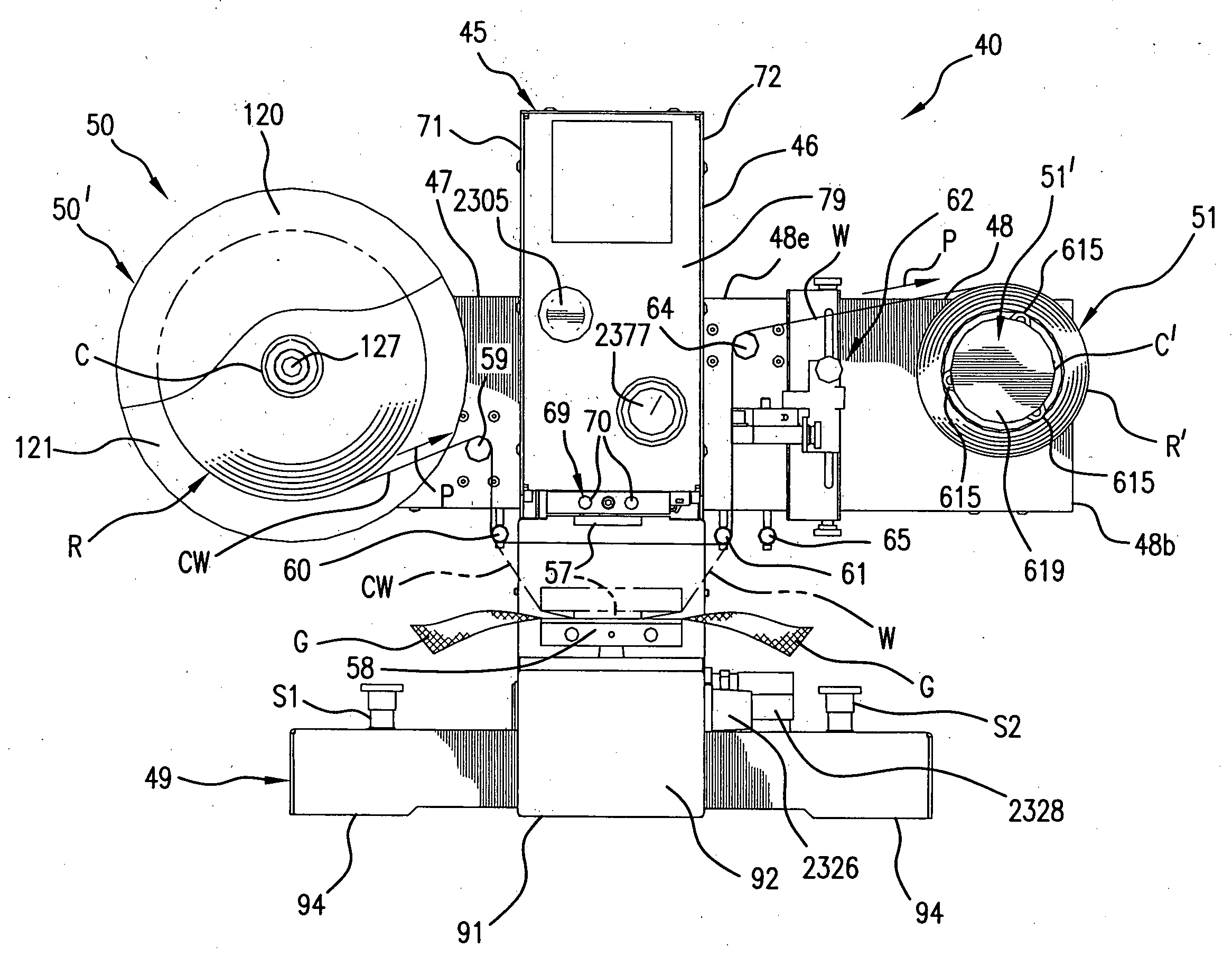

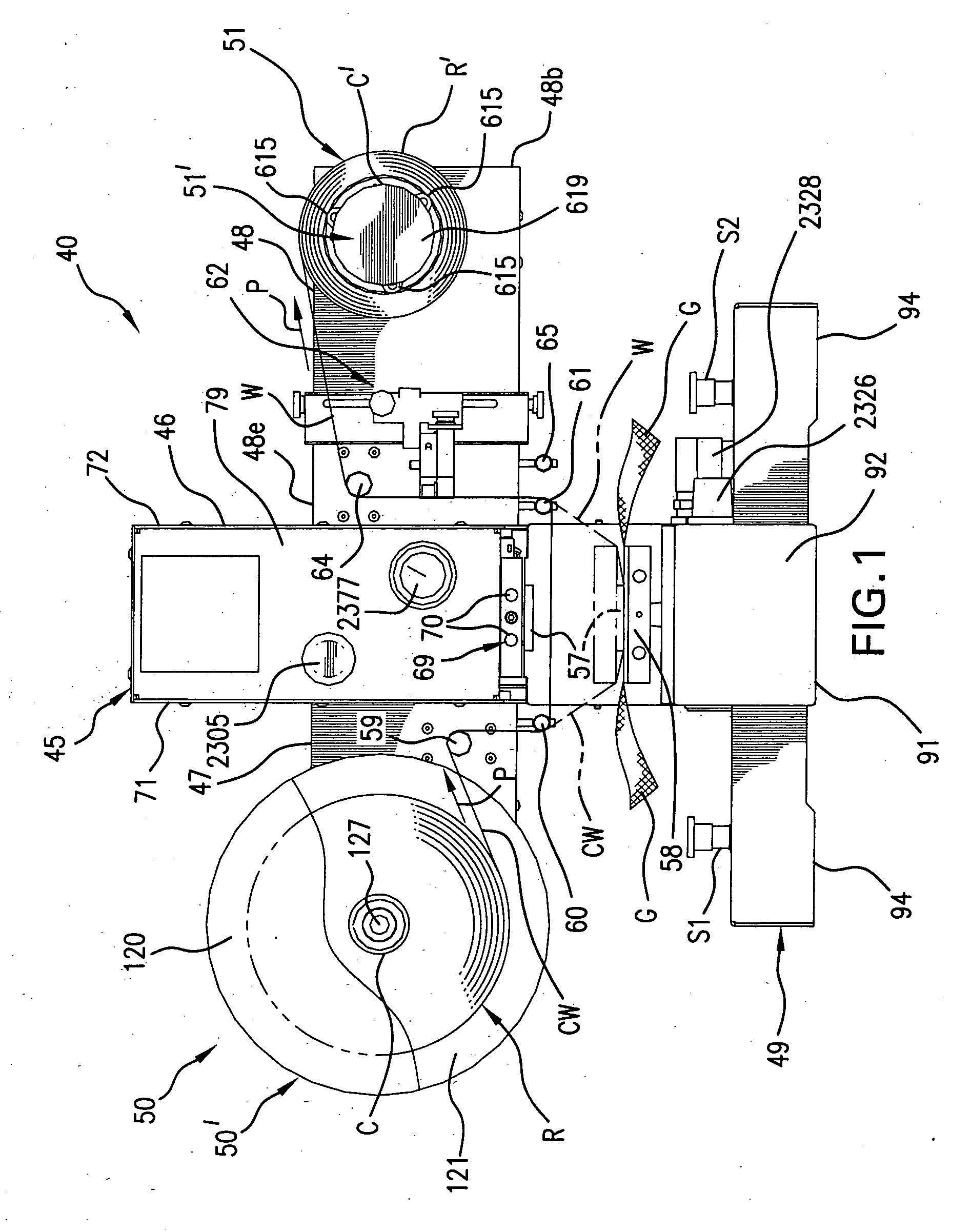

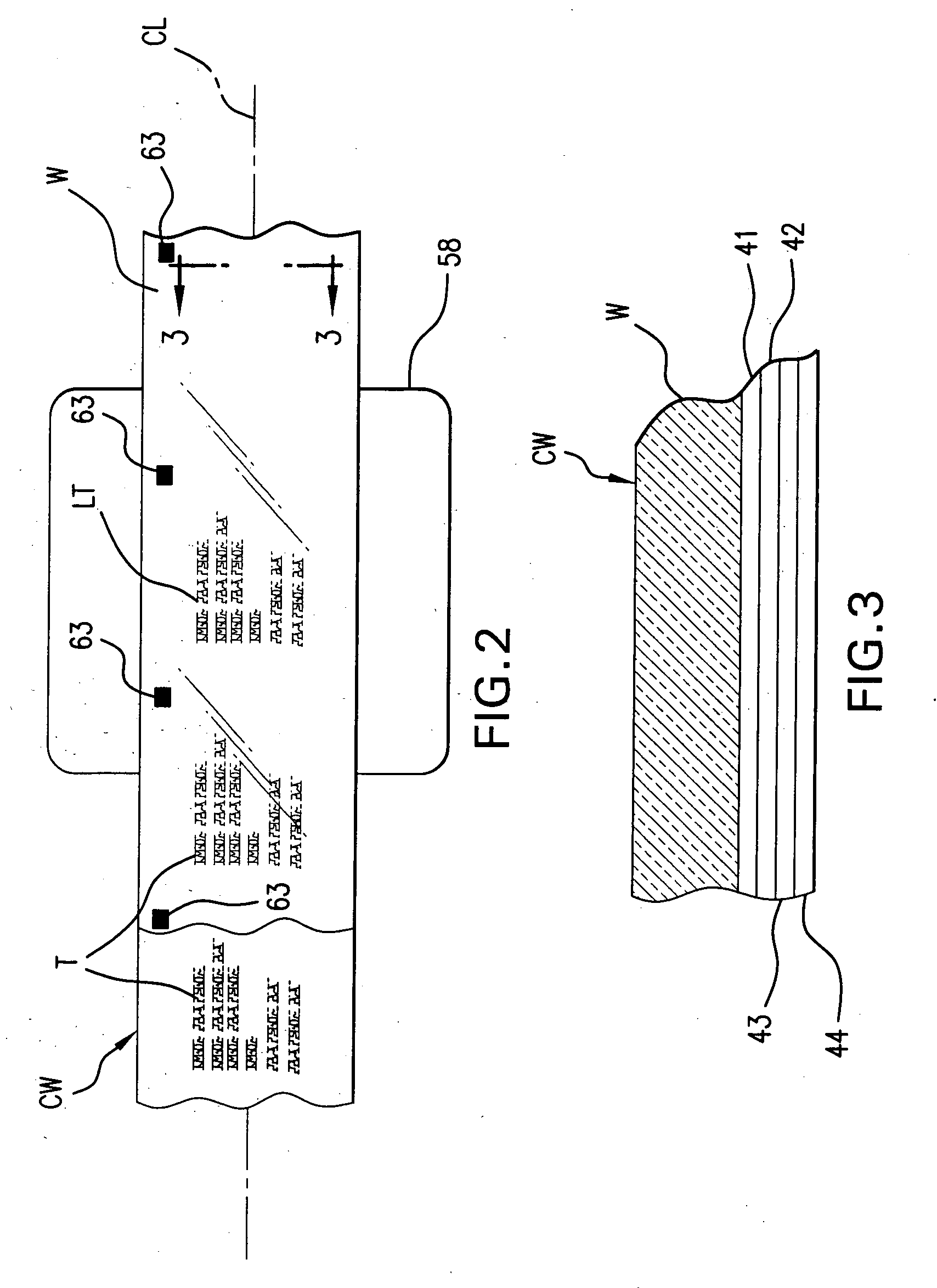

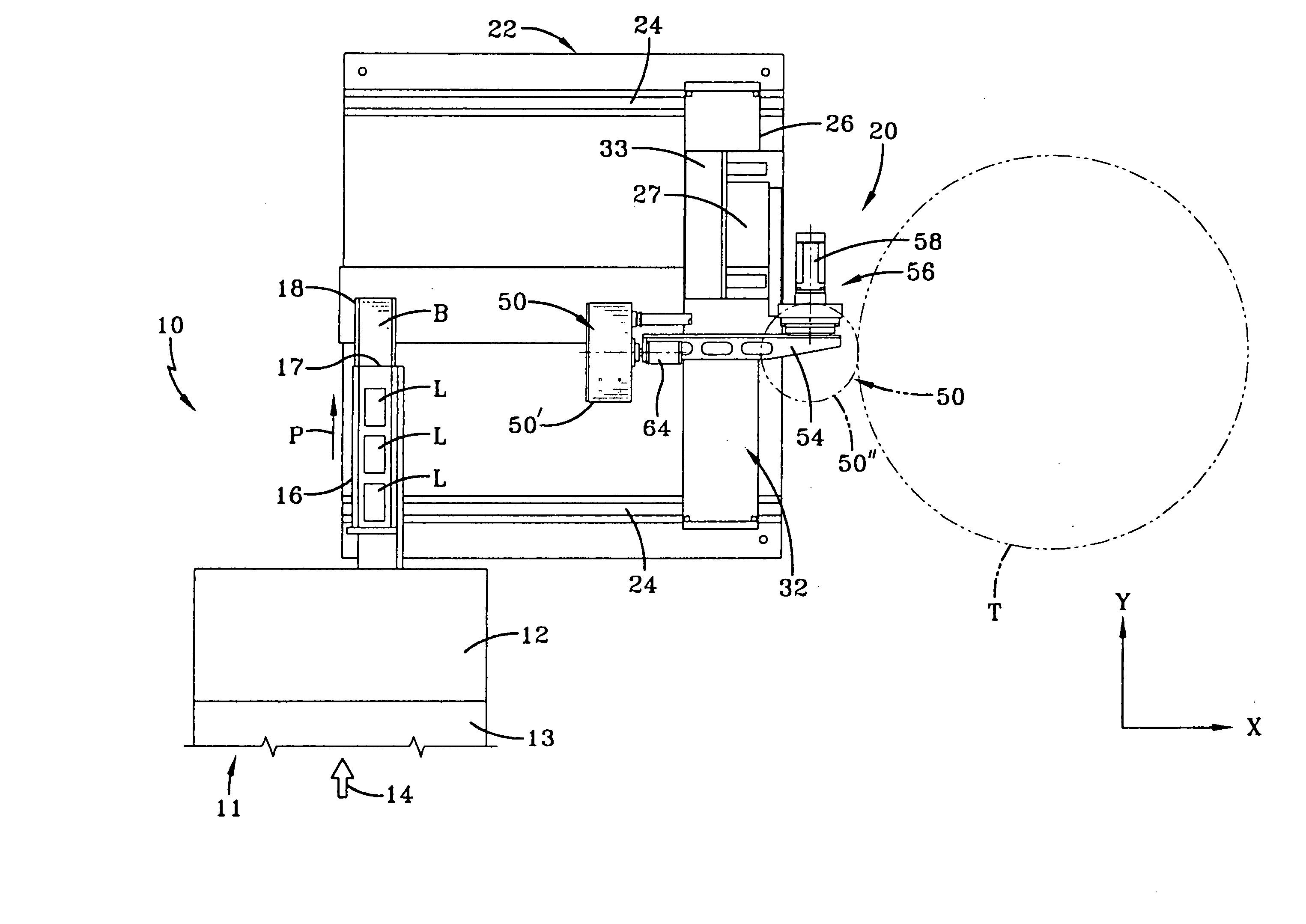

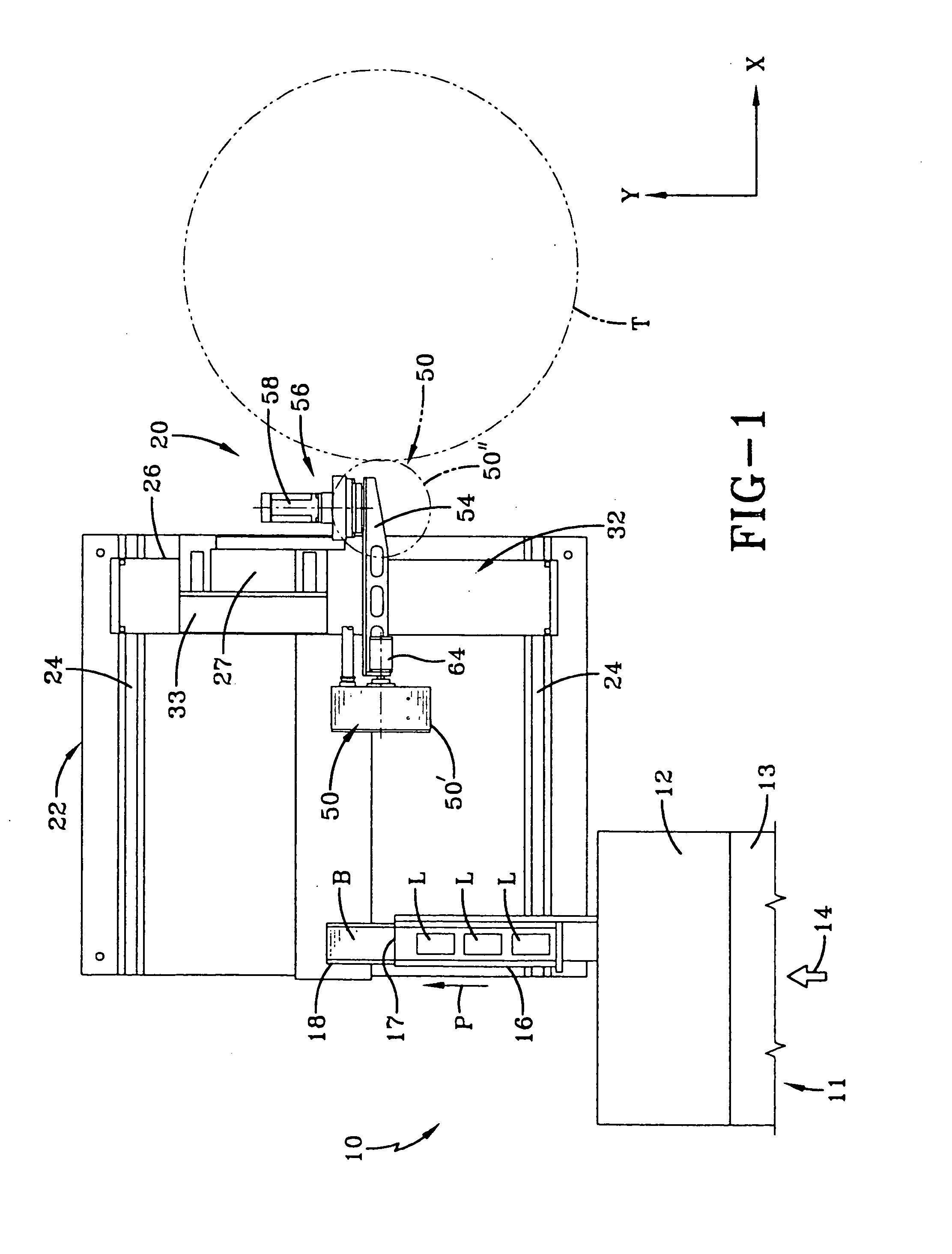

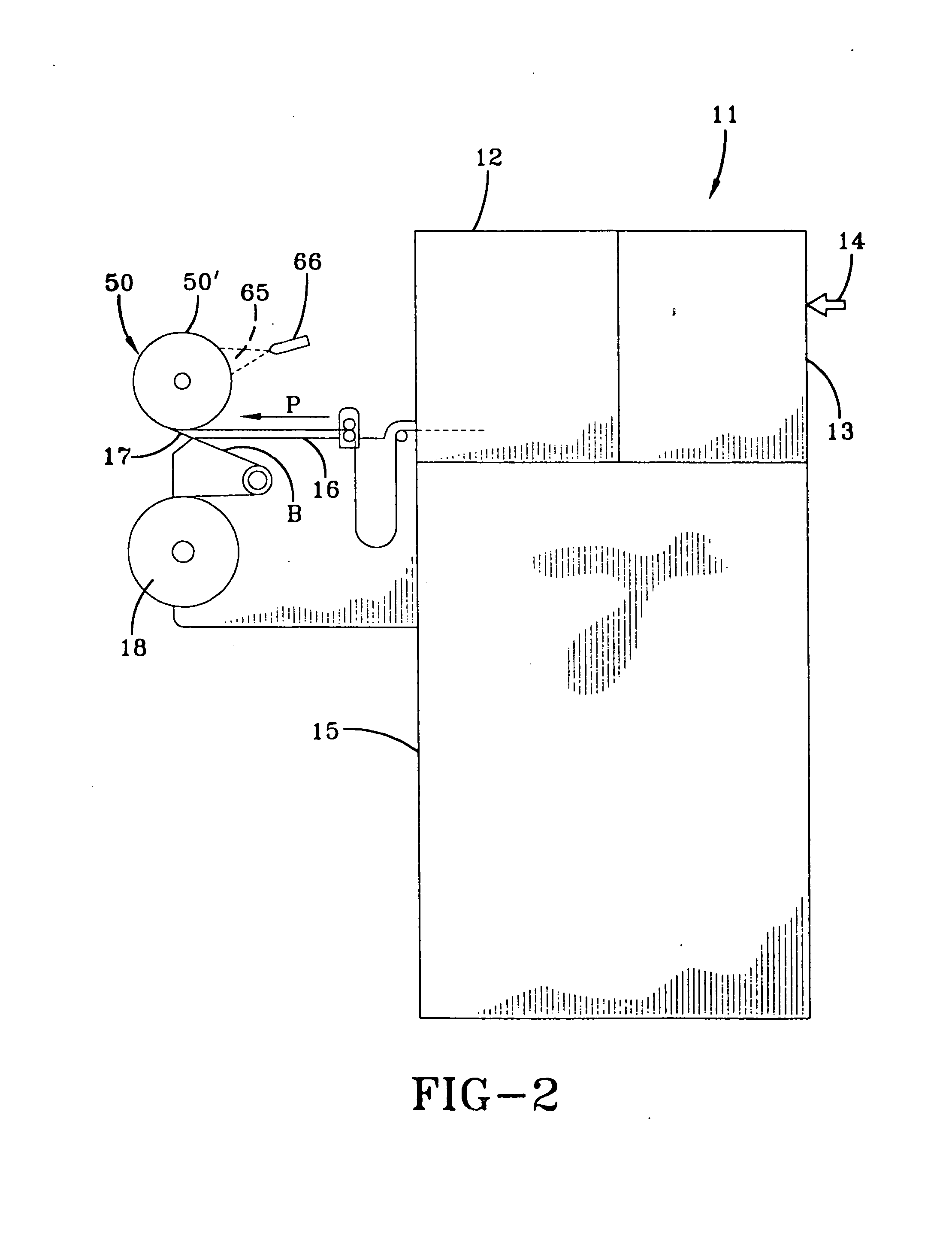

Apparatus for glueing the tail of a web to a log formed of the web material

An apparatus for glueing the tail or outer end of a web of material which has been formed into a log which comprises: device (9, 13) for unwinding the tail from the log (R); applicator (45) for applying glue to the log; tail rolls (97, 99) for re-winding the tail back on the log and glueing the tail to the log; and conveyor (23, 41) for transferring said log. The applicator for applying the glue includes a dispenser device (55-63) provided with a nozzle (61) forming at least one upwardly oriented slit (63) from which the glue is dispensed by overflowing; the log (R) conveyor (23, 41) discharges the log, with the tail (L) being unwound from it, above the glue dispenser, causing it to roll over said slit (63) for the application of the glue to the log.

Owner:FABIO PERINI SPA

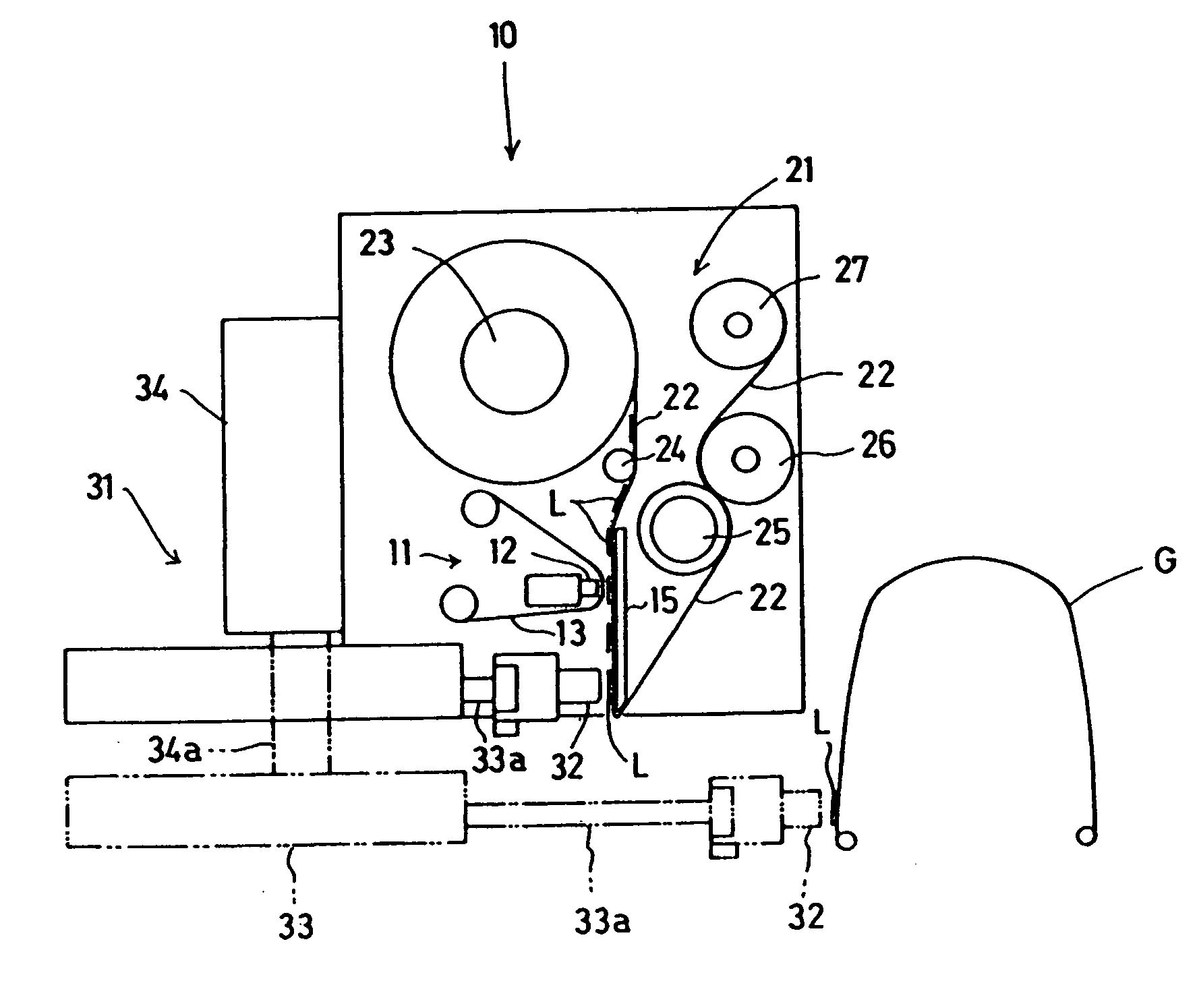

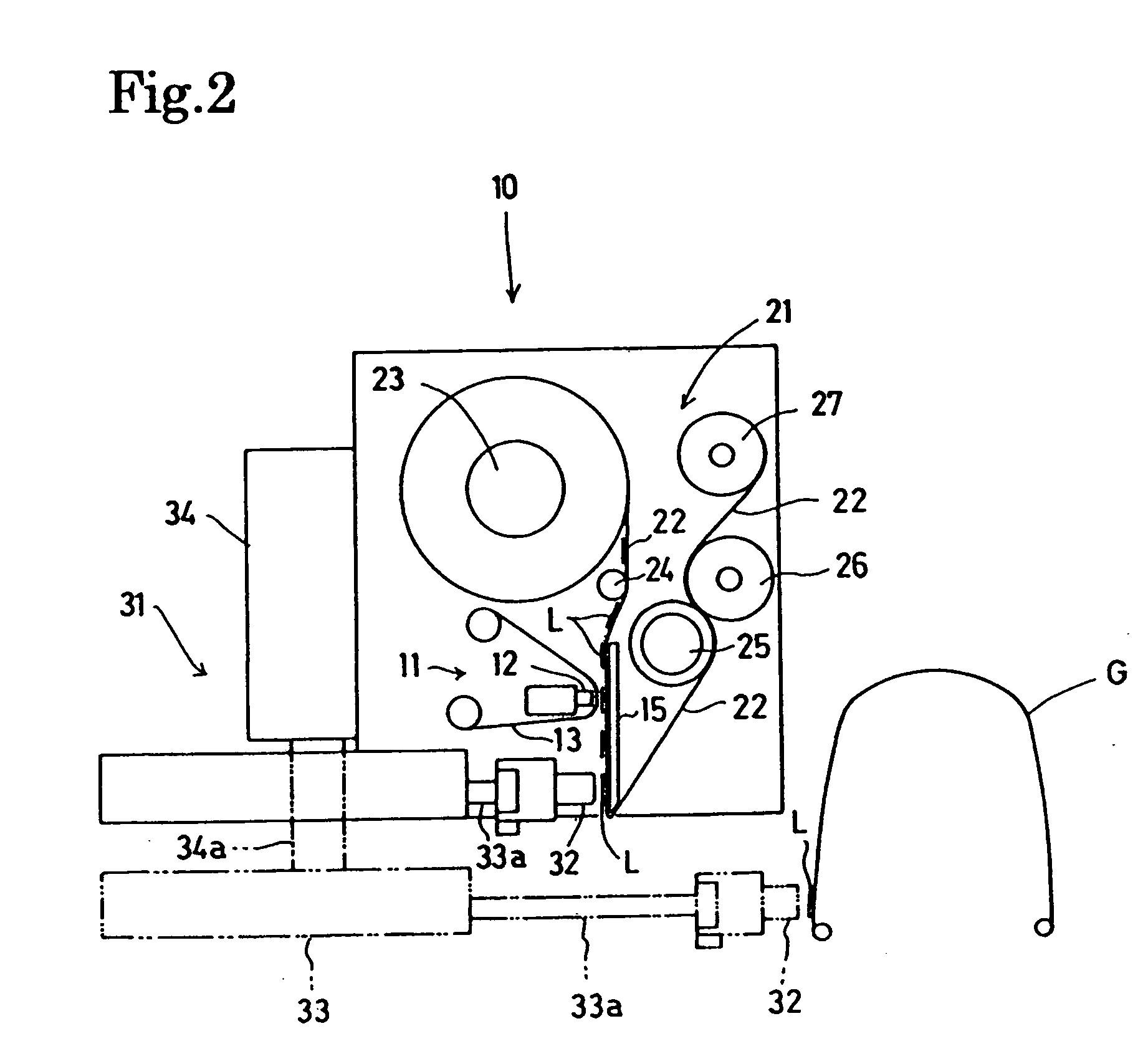

Device and method for stamping label on tire

InactiveUS20050274269A1Increase flexibilityIncrease productivityStampsLabelling deformable materialsRandom orderEngineering

Tire data on tires successively conveyed to a labeling process from a process preceding the labeling process are read in order of conveyance, and the tire data are printed on labels. Since the tire data on each tire is printed on a label and the label is attached to the tire identified by the tire data printed on the label even if different types of tires are produced in random order, the labels can be attached correctly to the tires identified respectively by the tire data. Since the tire data is printed on a blank label immediately before attaching the label to the tire, it is not necessary to prepare labels printed with tire data and it is possible to use only a single kind of blank labels, which is advantageous in respect of space and amount of work.

Owner:NISHIMOTO KICHINOSUKE +2

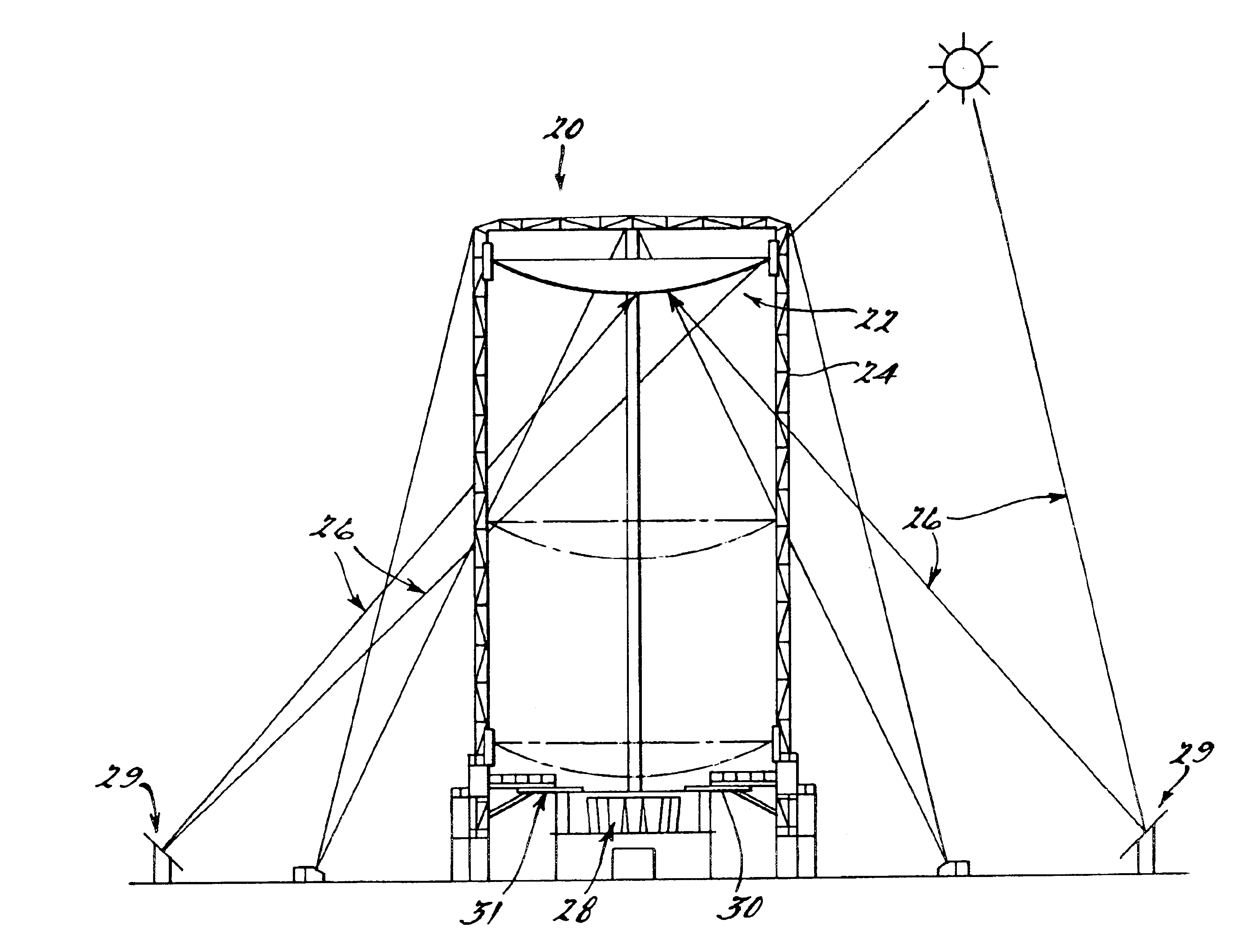

Thermally controlled solar reflector facet with heat recovery

InactiveUS6911110B2Easy to operateEffectively wastedLabelling deformable materialsAdhesive processesHigh concentrationAbove ground

A high concentration central receiver system and method provides improved reflectors and a unique heat removal system. The central receiver has a plurality of interconnected reflectors coupled to a tower structure at a predetermined height above ground for reflecting solar radiation. A plurality of concentrators are disposed between the reflectors and the ground such that the concentrators receive reflective solar radiation from the reflectors. The central receiver system further includes a heat removal system for removing heat from the reflectors and an area immediately adjacent the concentrators. Each reflector includes a mirror, a facet, and an adhesive compound. The adhesive compound is disposed between the mirror and the facet such that the mirror is fixed to the facet under a compressive stress.

Owner:SOLARRESERVE TECH

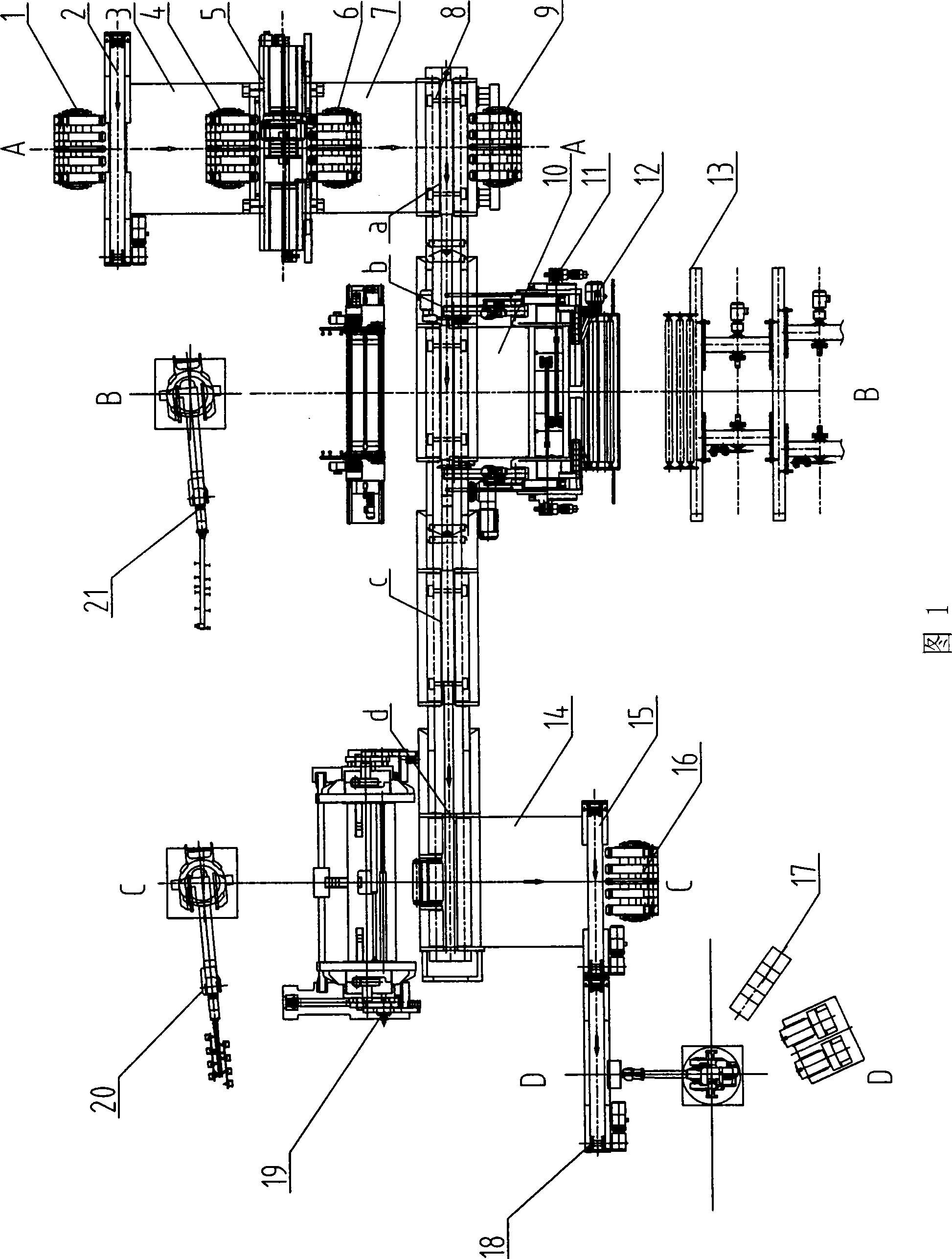

Multi-station fully automatic rolled paper packaging machine

ActiveCN101376436AShorten the timeShorten the time, that is, increase the conveying speed of the stationPaper article packagingLabelling deformable materialsPaper sheetHot press

The invention discloses a multi-position full automatic paper roll packing machine, which comprises a paper receiving system, a paper roll packing system, a hot pressing system, a paper roll conveying system which allows a paper roll to move among the systems and a controlling system for controlling the systems. The paper roll conveying system adopts a position trolley system, the position trolley system comprises a position frame (812), a position track and a position trolley positioned on the position track are arranged on the position frame, the paper receiving system, the paper roll packing system and the hotpressing system are arranged near to the position frame in sequence, and form three packing positions with the position frame which are a paper receiving position a, a packing and edge folding position b and a hotpressing position d, and the position trolley can convey the paper roll among the positions. The packing machine has the advantages that the packing time of each paper roll can be greatly reduced, the automation level is high, and the packing quality is good.

Owner:中轻长泰(长沙)智能科技股份有限公司

Binding equipment for textile industry

InactiveCN101450719ALow costOptimize layoutLabelling deformable materialsAffixing tagsSOCKSElectric machinery

The invention relates to binding equipment in the textile industry, which comprises a frame, an actuating unit, a hold-down mechanism, a steel needle movement mechanism and a plastic pin extruding mechanism, wherein the hold-down mechanism, the steel needle movement mechanism and the plastic pin extruding mechanism which are connected to the actuating unit are driven by the actuating unit to reciprocate up and down along a guide rail on a guide rail support of the frame; and the actuating unit is fixed on the frame. The binding equipment is characterized in that the actuating unit is an electric mechanism. The equipment is suitable for binding clothes, shoes and hats, and socks in families or individual workshops, and can be used for binding hangtags or a plurality of pairs of socks. The equipment is suitable for binding products with different thicknesses, and can bind plastic pins with different specifications through adjustment. The equipment is operated by means of driving two cams and a connecting rod by a motor, and changes the phenomenon that the prior equipment realizes binding through three cylinders. The binding equipment has the advantages of no air source limitation tooperation places and simple and reliable operation.

Owner:上海允科自动化有限公司

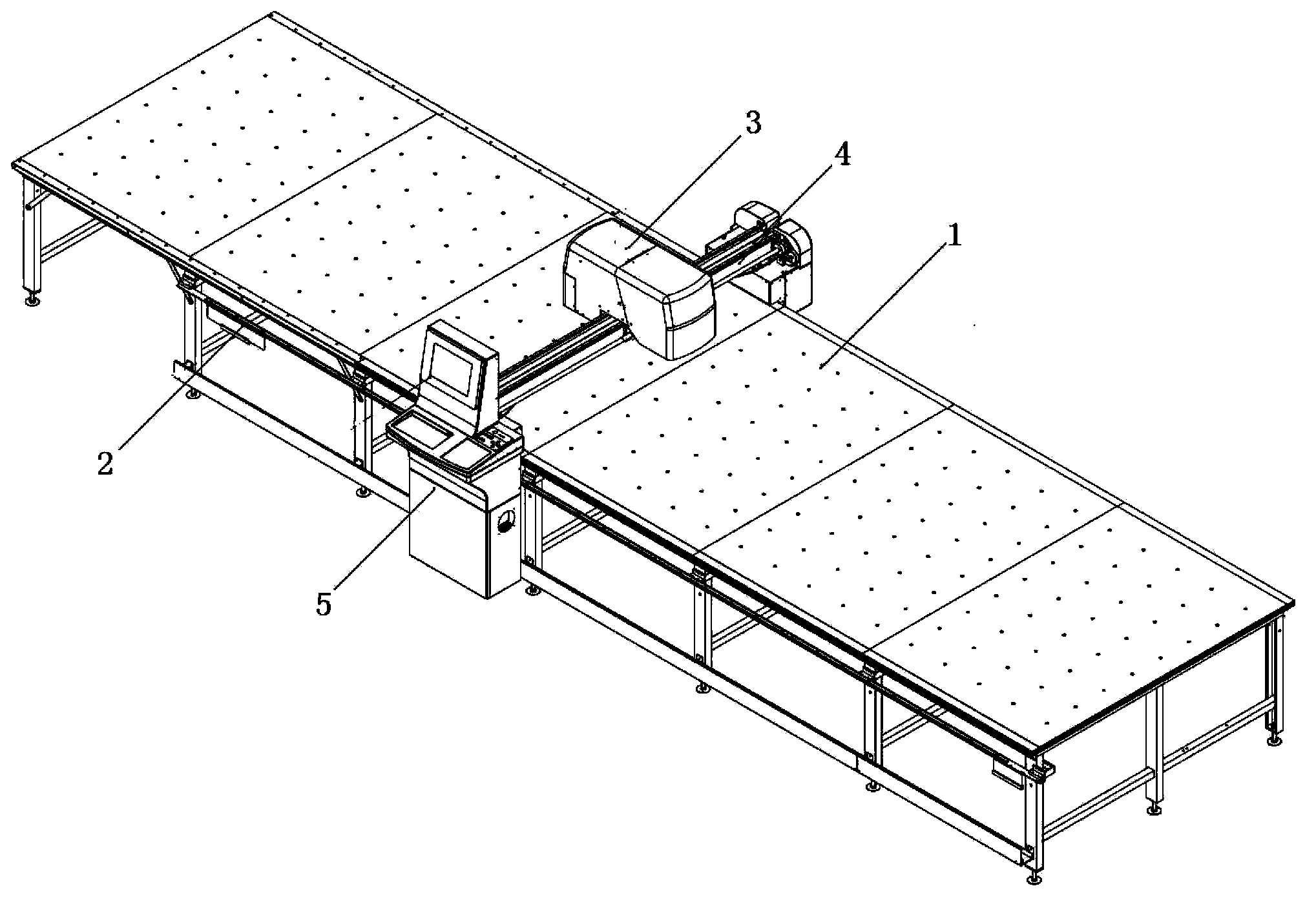

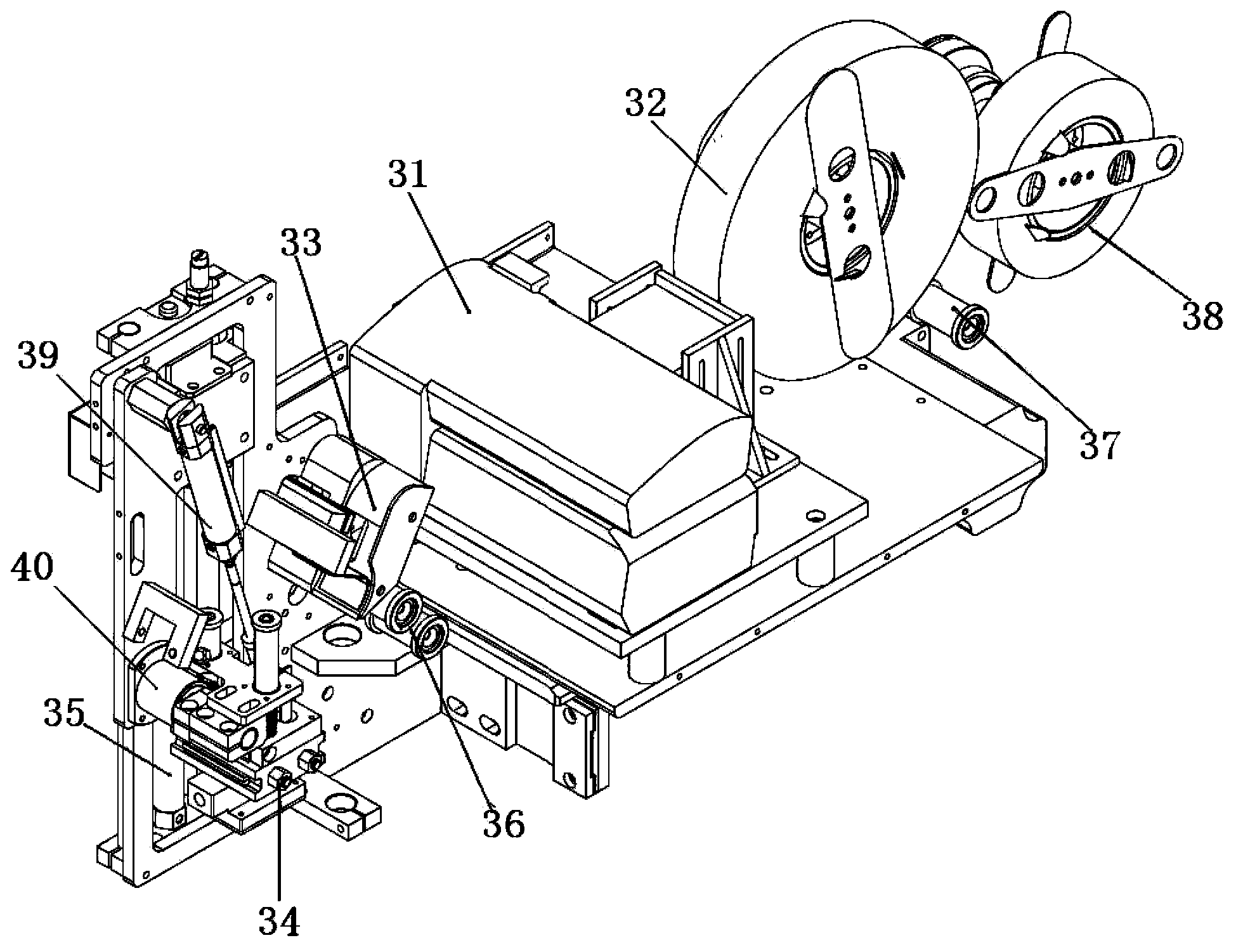

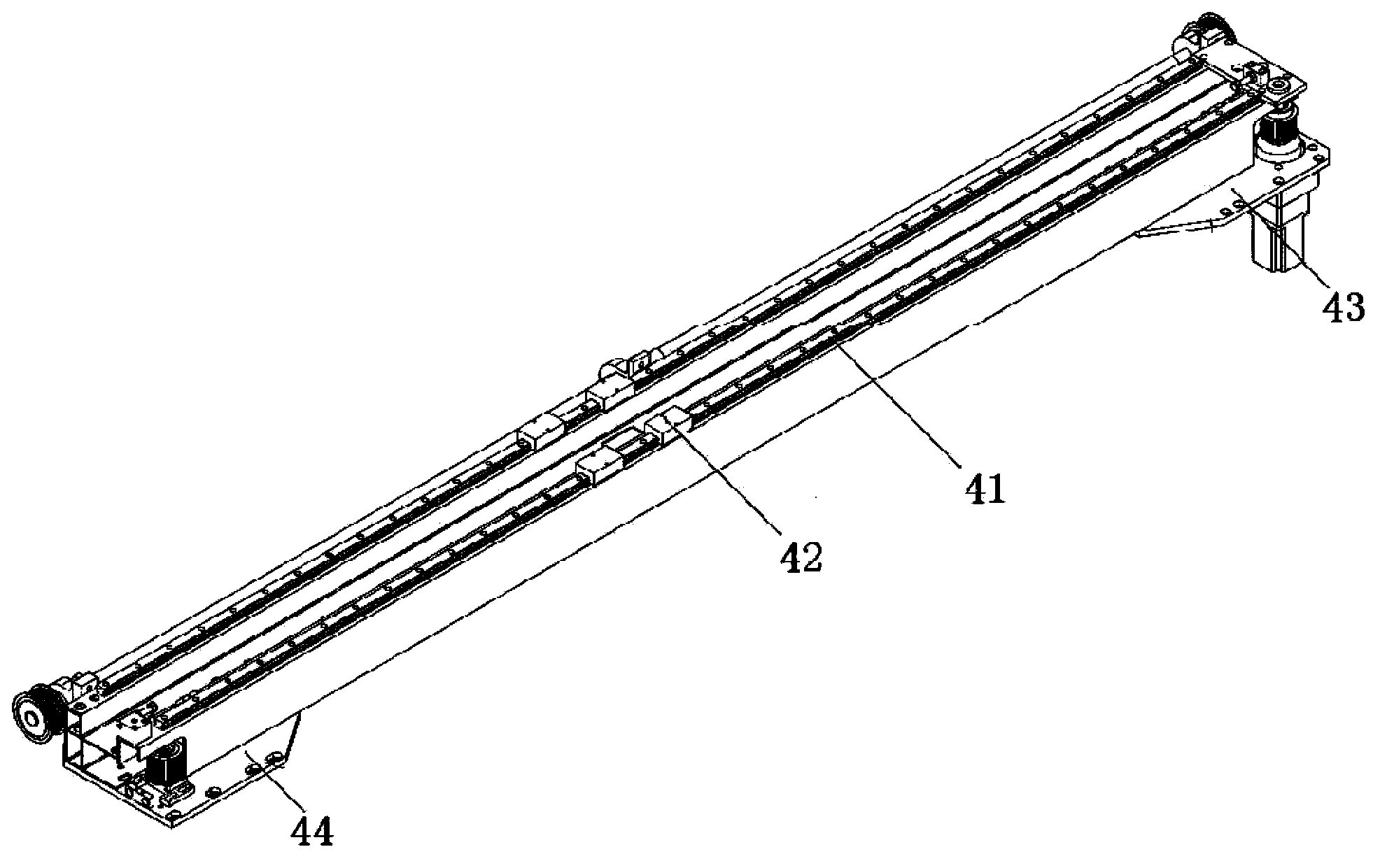

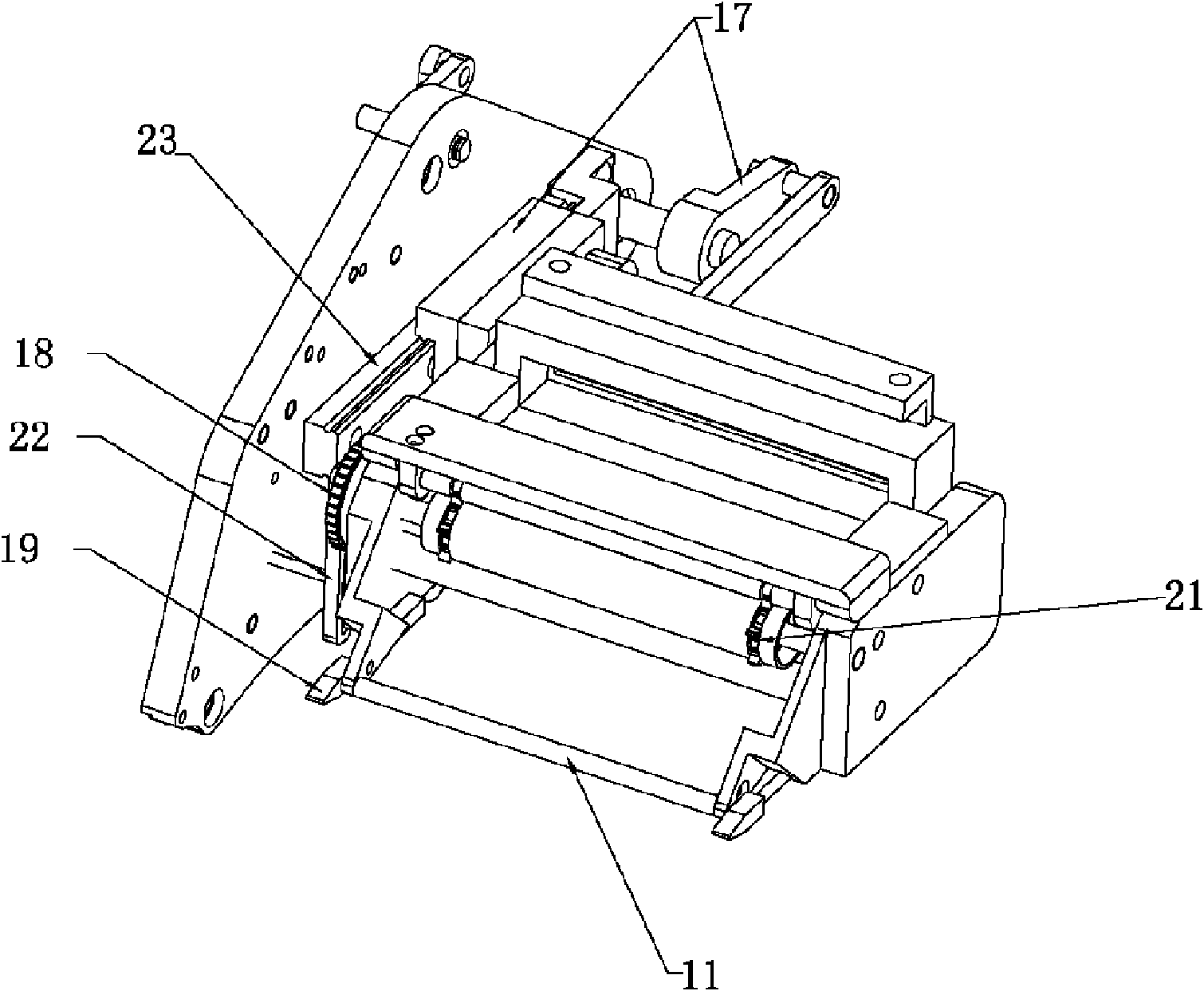

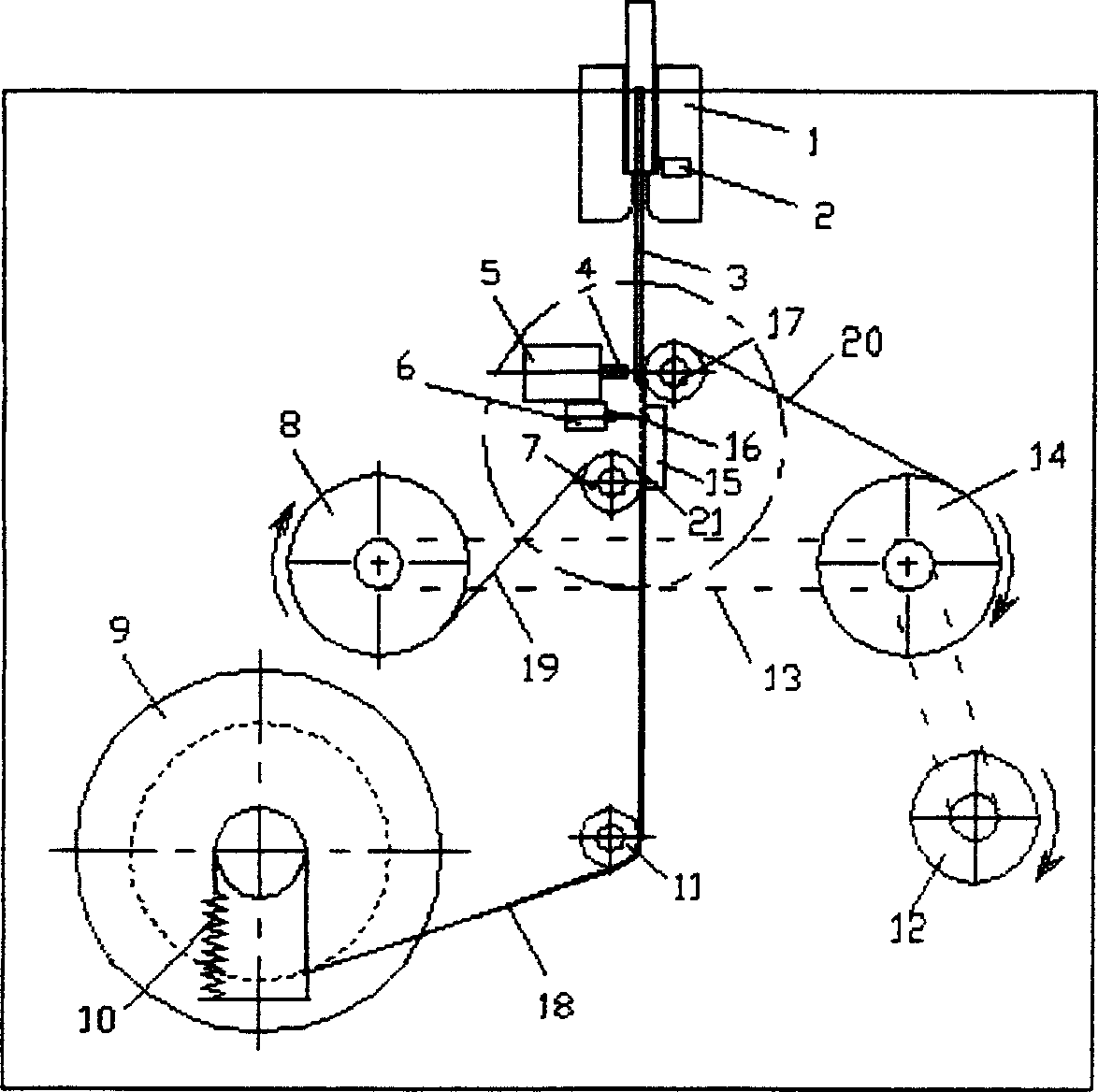

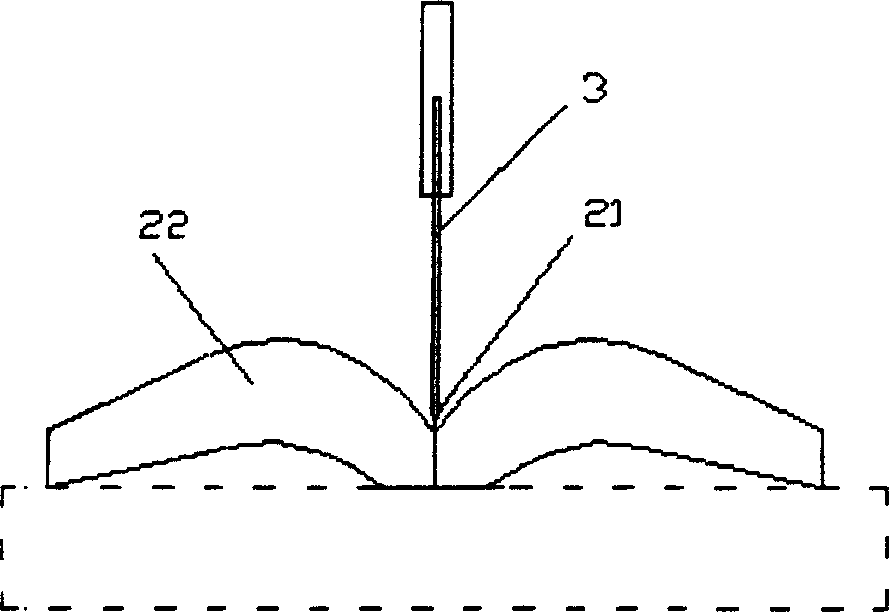

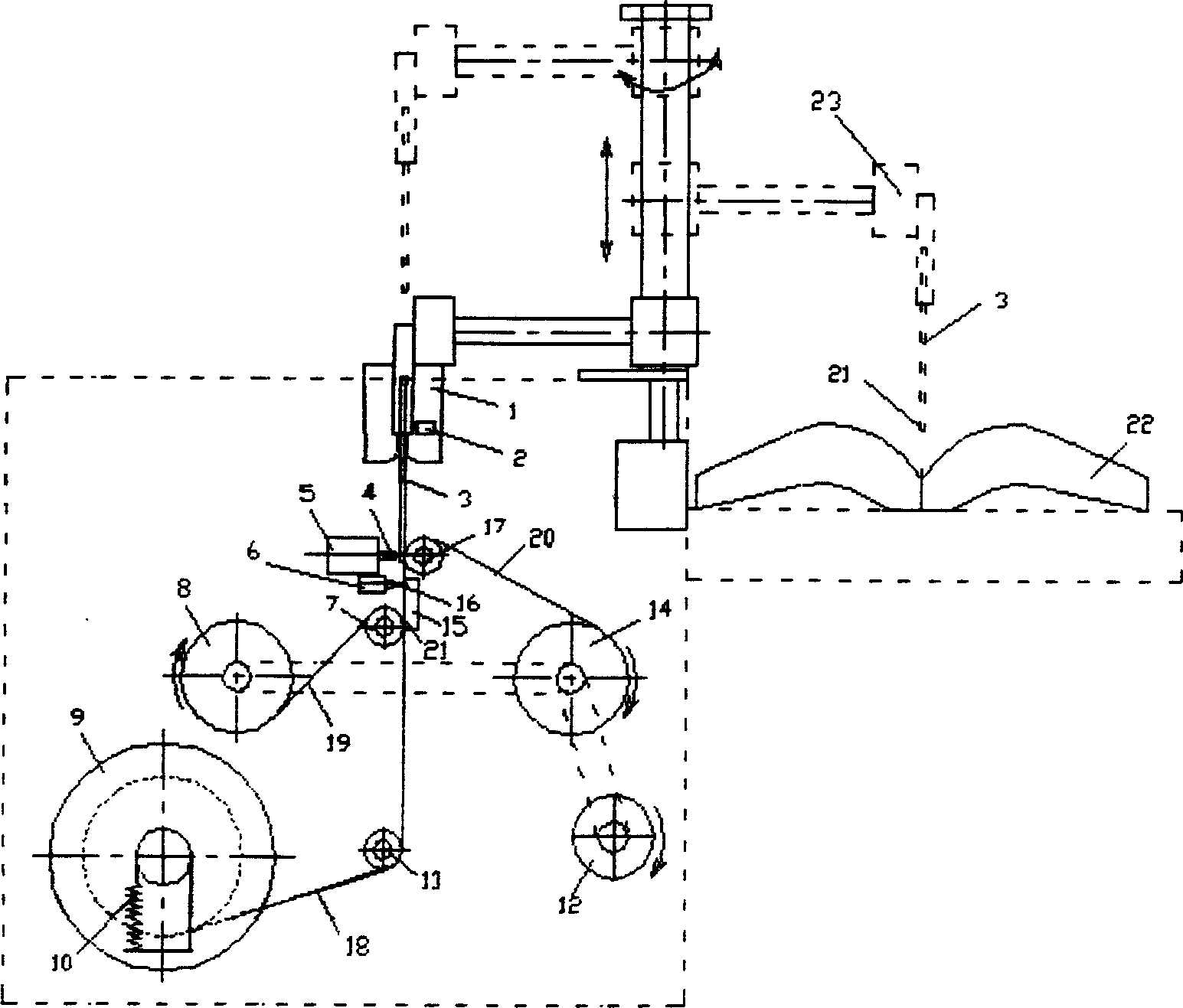

Automatic labeling machine for encoding garment pieces

InactiveCN103662227AFully automatedReduce labor intensityLabelling deformable materialsLabelling machinesLocation detectionControl system

The invention provides an automatic labeling machine for encoding garment pieces. The automatic labeling machine comprises an operating region table plate, a position detection device, a label printing and adhering unit, a driving unit and a control system, wherein the control system is used for controlling the driving unit to move the label printing and adhering unit to a designated position to adhere labels according to a garment piece initial coordinate detected by the position detection device and sending label printing content to the label printing and adhering unit. According to the automatic labeling machine, the label printing and adhering unit is arranged above the operating region table plate, and the printed content and moving position of the label printing and adhering unit can be controlled through the control system, so that the labels can be automatically adhered to the garment pieces on the operating region table plate, the labor intensity of operators can be further effectively reduced, and the working efficiency is increased; furthermore, various types of information can be printed on the labels according to the requirements, so that the production and the operation management are convenient.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

Portable applicator

ActiveUS20080185093A1Easy and low-cost to constructAvoid lostLabelling deformable materialsDecorative surface effectsEngineeringMechanical engineering

There is disclosed an applicator and method for applying transfers such as heat transfers, decals or labels to transfer-receptive materials. The applicator has a lightweight, T-shaped, sheet metal support or frame having an applicator station. A motorized supply roll unwind and a motorized take-up roll rewind are mounted on the support to hold supply and take-up rolls, to tension the transfer-containing web and to advance the web onto the take-up roll after the transfer has been applied at the applicator station.

Owner:AVERY DENNISON CORP

Method of private labeling a garment

InactiveUS20060021270A1Uniform widthSecure bondingLabelling deformable materialsStampsEngineeringImproved method

An improved method for private labeling of garments which eliminates tedious and cost intensive sewing operations, wherein the original manufacturer's brand label is removed and replaced with a pressure-sensitive adhesive private label that is secured to the original care instruction label in such manner as not to obstruct the readability thereof. The private label is produced from a durable printable woven fabric that is washable, and carries a pressure-sensitive adhesive strip that adheres to non-printed portions of the care instruction label so as to form a movable flap thereover. This method is particularly useful for private labeling smaller quantities of garments, where labor intensive sewing operations are cost prohibitive.

Owner:HANLEY PATRICK B

Book RFID tag labeling device and application method thereof

InactiveCN101537897AHigh precisionLabelling deformable materialsLabelling machinesWhole bodyEngineering

The invention discloses a book RFID tag labeling device and an application method thereof, and the technical problem to be solved is to rapidly and effectively open a book and carry out the concealed installation of a tag. In the book RFID tag labeling device, a driving device is connected with a book conveying device, a book turning device is arranged at the front end of the book conveying device, a labeling component is arranged at the upper end of the book turning device, and the labeling component is connected with a discharging device. The application method comprises the following steps of placing the book on a book conveying platform, wherein the book turning device and the labeling component move up and down as a whole body, adhering the tag in a book ridge by a labeling head of the labeling component, and implementing the reverse returning by a negative sequence. Compared with the prior art, the adoption of the book turning device and the labeling component to carry out the concealed installation of the tag leads the tag to be capable of being arranged in a middle seam of the book, the precision is higher, and the device can be universal for paper books with different sizes and thicknesses and materials by mechanism integration.

Owner:深圳市远望谷文化科技有限公司

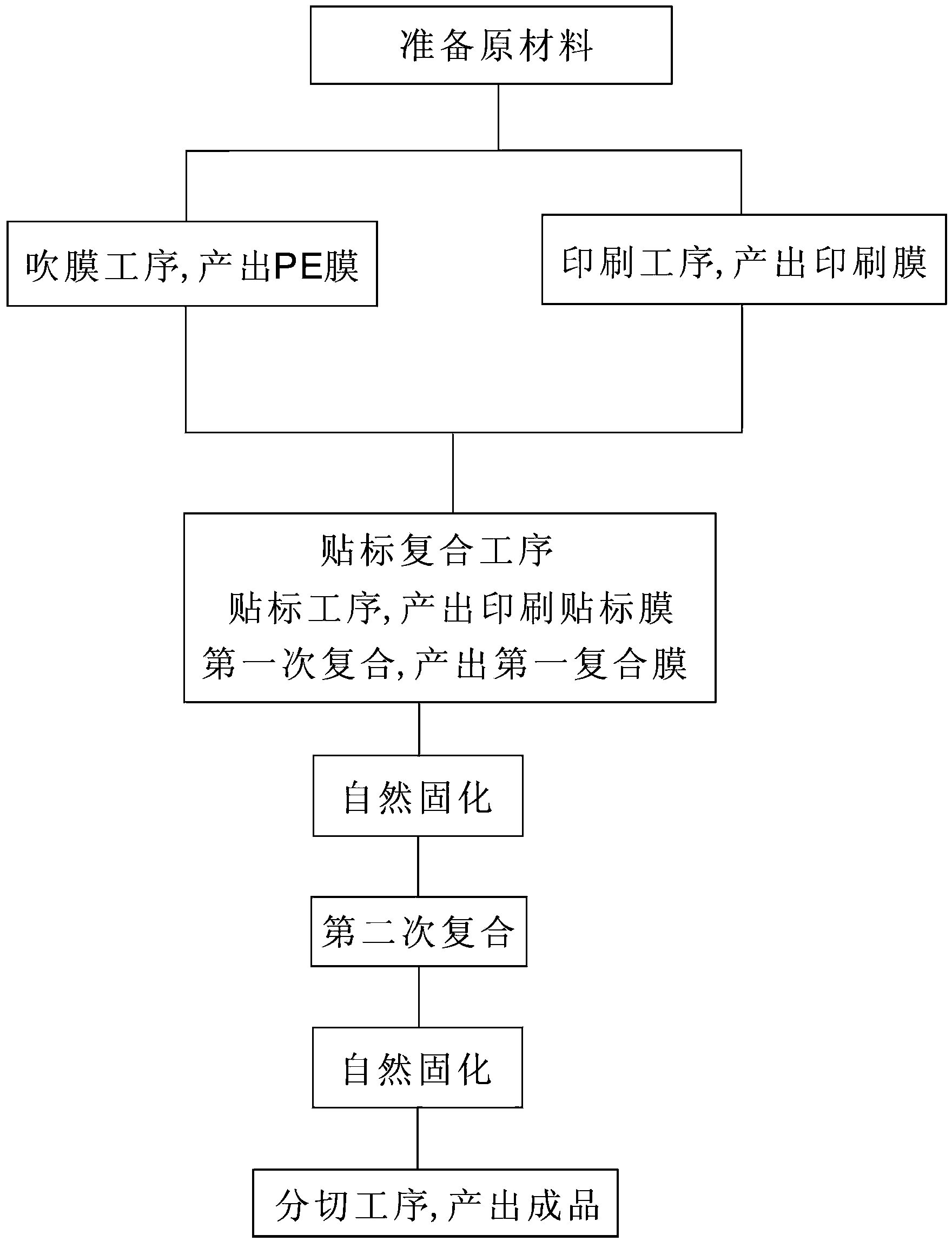

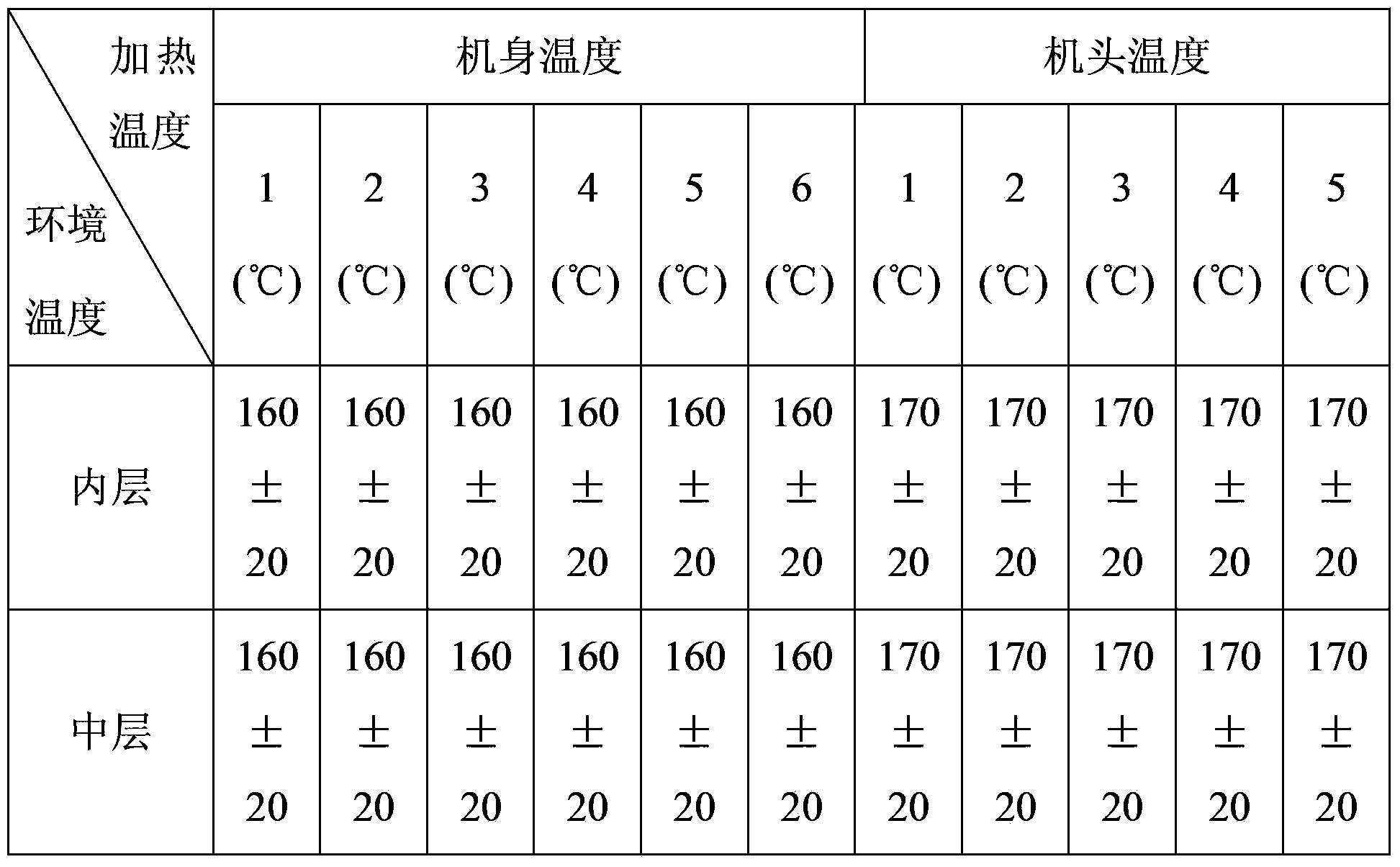

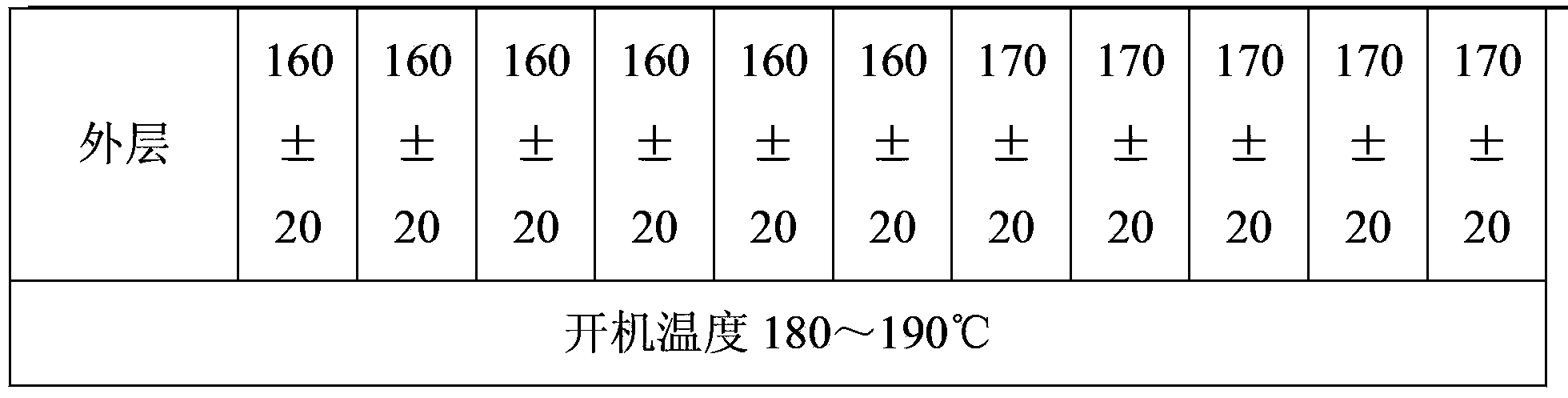

Manufacturing method of paper-plastic composite packaging bag

ActiveCN103407674AStrong anti-counterfeiting functionNot easy to forgeLabelling deformable materialsLamination ancillary operationsMolded pulpComposite film

The invention provides a manufacturing method of a paper-plastic composite packaging bag. The manufacturing method sequentially comprises steps as follows: (1) raw materials are prepared; (2) a film blowing procedure is performed, and a PE (polyethylene) film is produced by resin particles through the film blowing procedure; (3) a printing procedure is performed, and a printing film is produced by a substrate film through the printing procedure; (4) labelling and composition procedures are performed and comprise a labelling procedure, a first composition procedure and a second composition procedure, a labelling film is produced on the printing film through the labelling procedure to form a printing and labelling film, then, first composition of industrial printing paper and the PE film is performed through the first composition procedure, second composition of the printing and labelling film and a first composite film is performed after spontaneous curing of the first composition, and spontaneous curing is performed after the second composition; and (5) a slitting procedure is performed, the spontaneously cured product is slit through the slitting procedure, and a finished product is put in storage. The manufacturing method is simple in technique, the anti-fake capacity is higher, the solvent-free composition strength is high, and the product is environment-friendly.

Owner:HUBEI YUNHE SALT IND PACKAGE

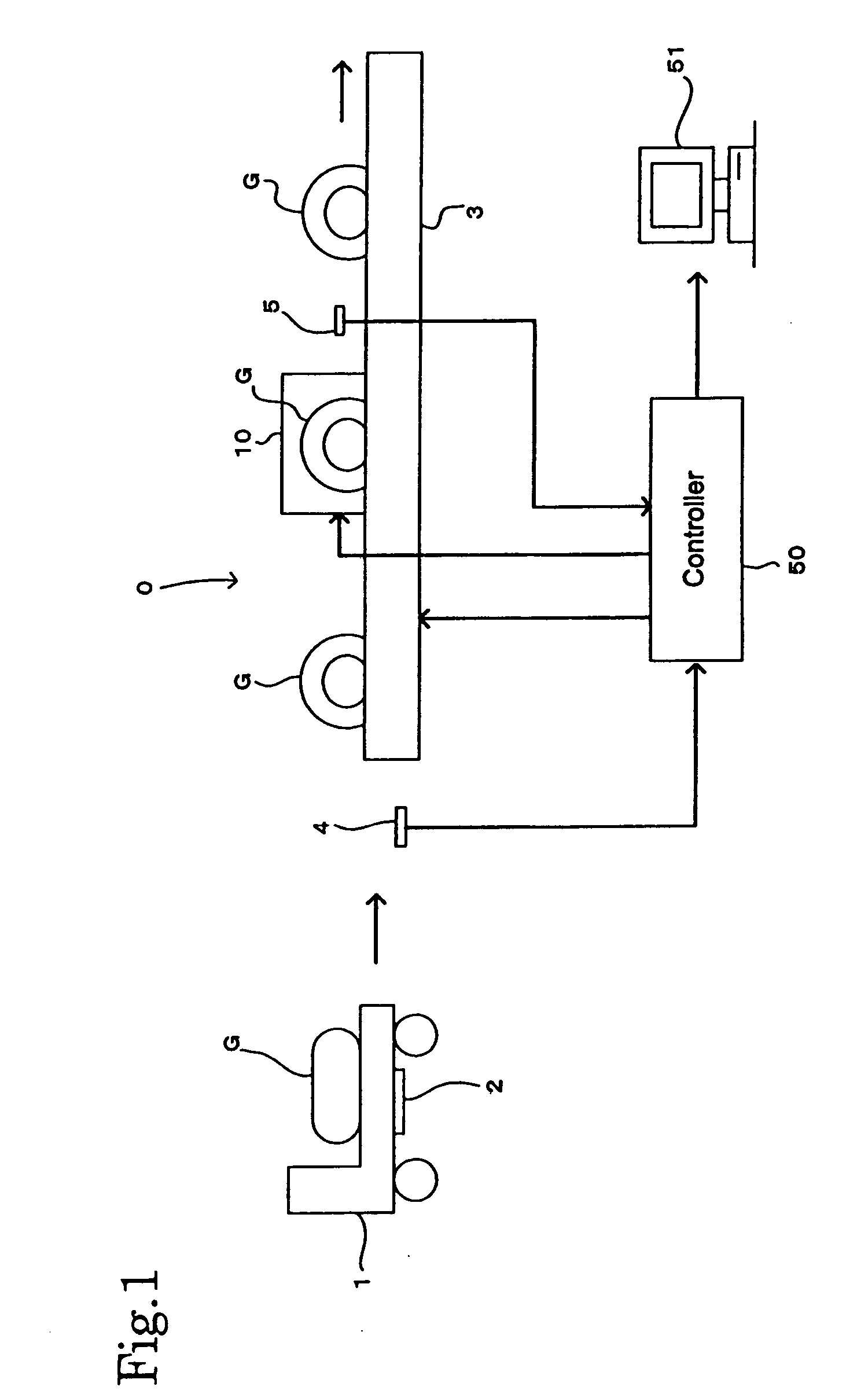

Tire Labeling System

ActiveUS20070295447A1Promote sportsLabelling deformable materialsTyre partsEngineeringElectrical and Electronics engineering

Owner:COMML TIME SHARING

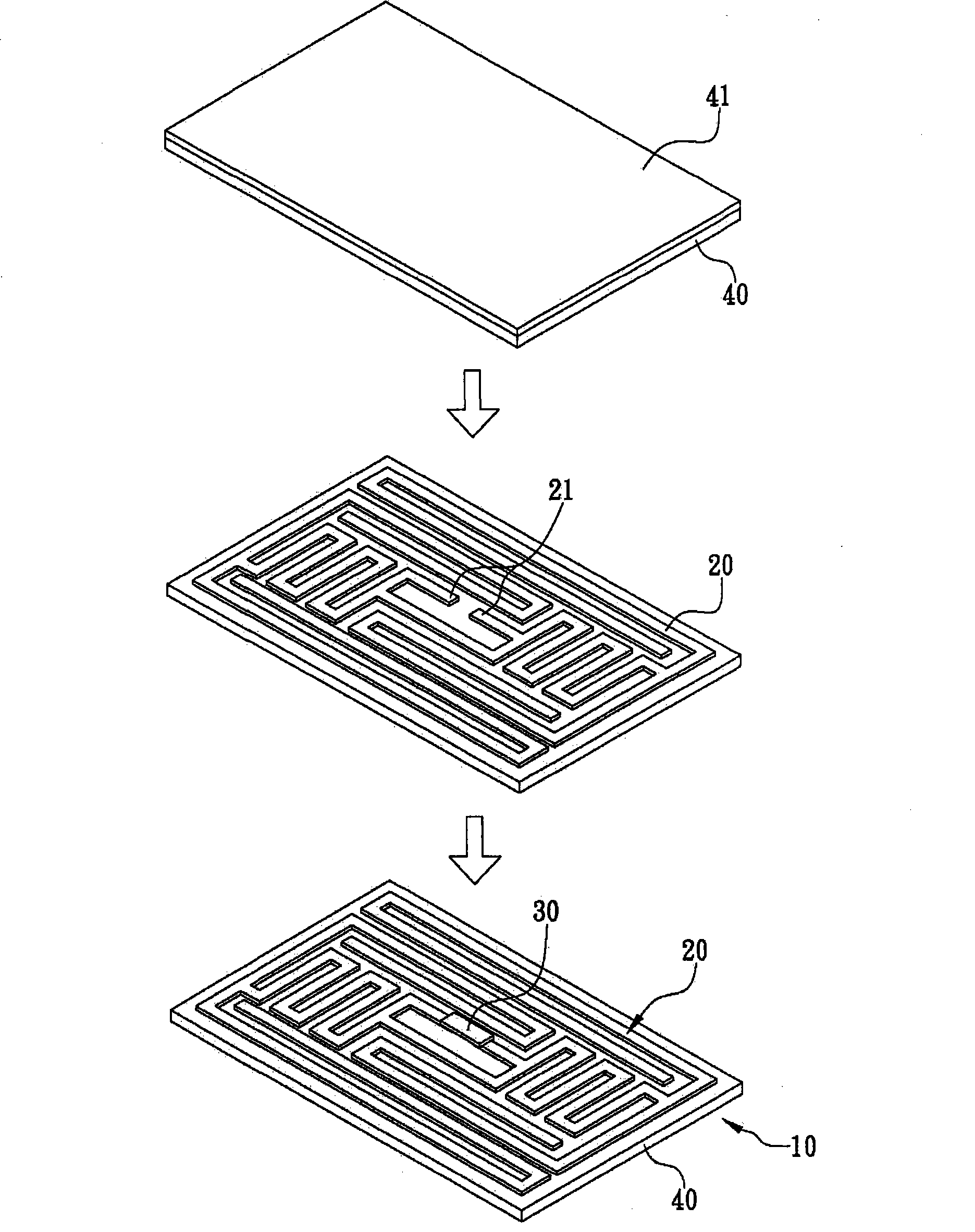

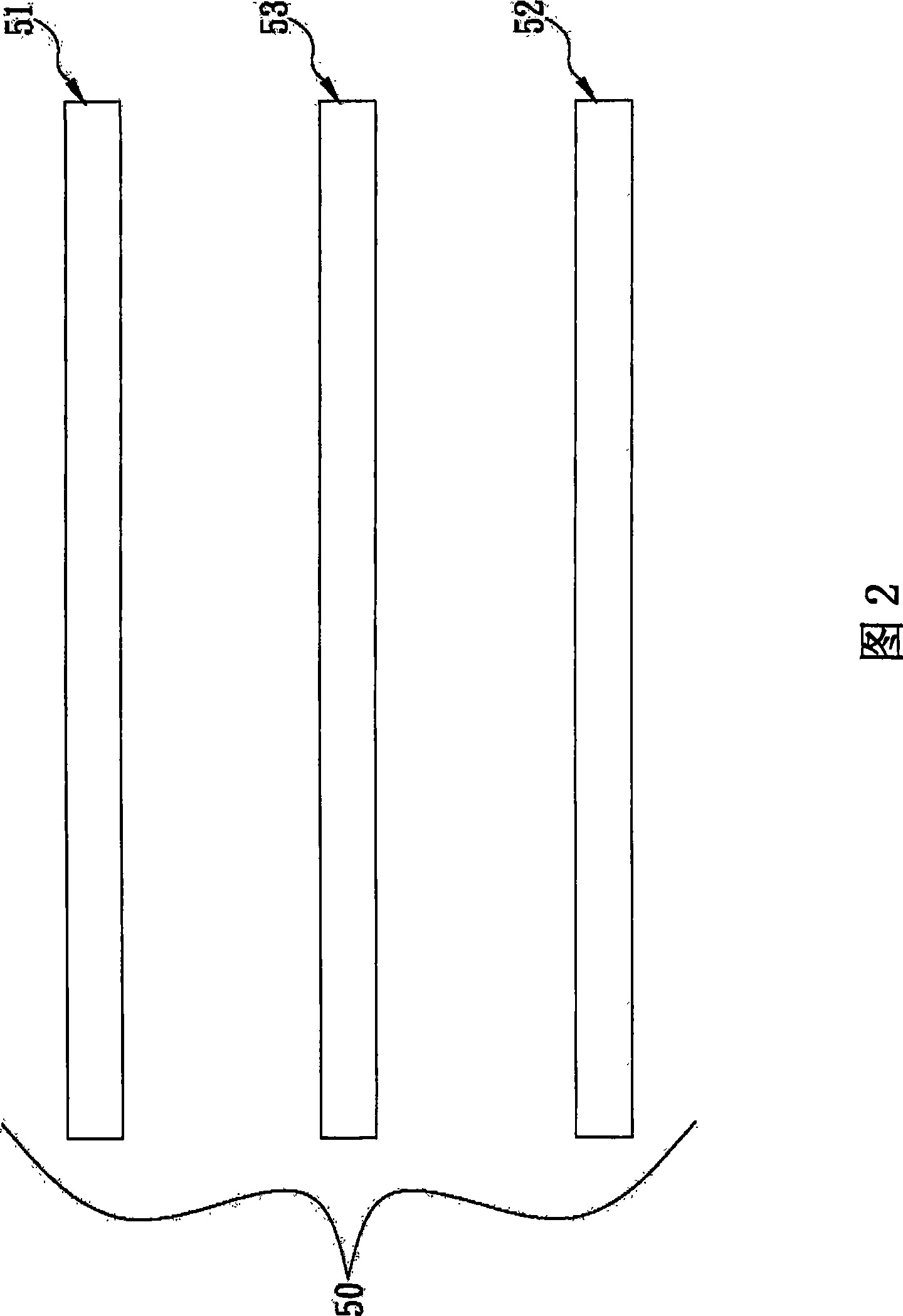

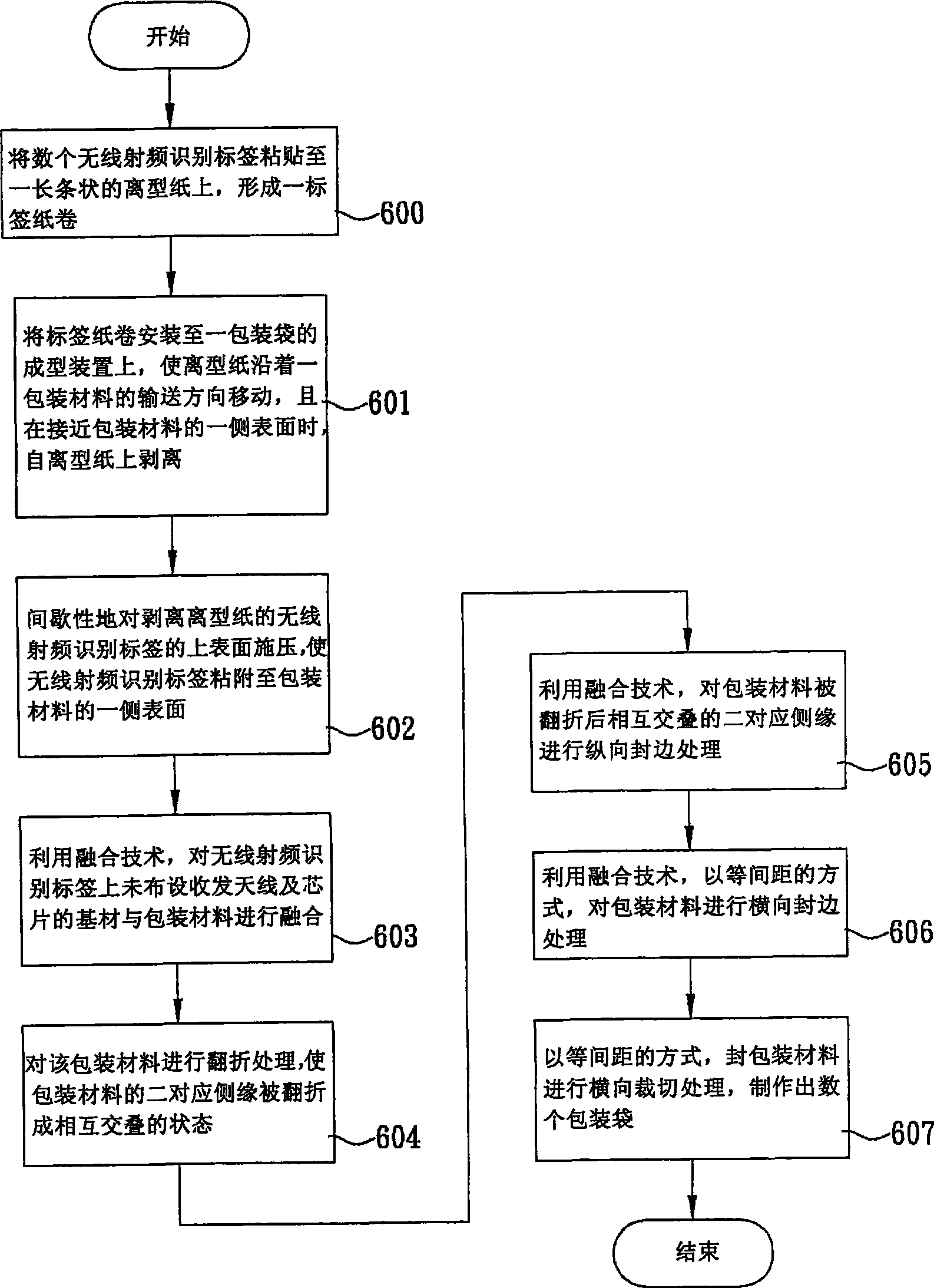

Method and apparatus for making wireless radio frequency identification tag on packing bag

InactiveCN101462603AProtectSimple processLabelling deformable materialsFlexible coversRadio frequencyRelease liner

The invention relates to a method for making radio frequency identification labels on packaging bags and a device thereof. The method comprises: pasting a plurality of radio frequency identification labels on a piece of strip-shaped release paper one by one to form a label scroll; then, installing the label scroll on a forming device of packaging bags and ensuring that the release paper moves in the conveying direction of a packaging material; moreover, changing the movement direction of the release paper when approaching one side surface of the packaging material; ensuring that a label is stripped off the release paper due to the instant change in the movement direction of the release paper and moves on in the conveying direction of the packaging material; pressing the upper surface of the label intermittently to paste the label on one side surface of the packaging material; fixing all labels on predetermined positions of the packaging material one by one; and folding, sealing and cutting the packaging material to make a plurality of packaging bags respectively with radio frequency identification labels. The method not only has simple and quick manufacturing process, but also remarkably reduces manufacturing cost.

Owner:TAIWAN LAMINATION INDS

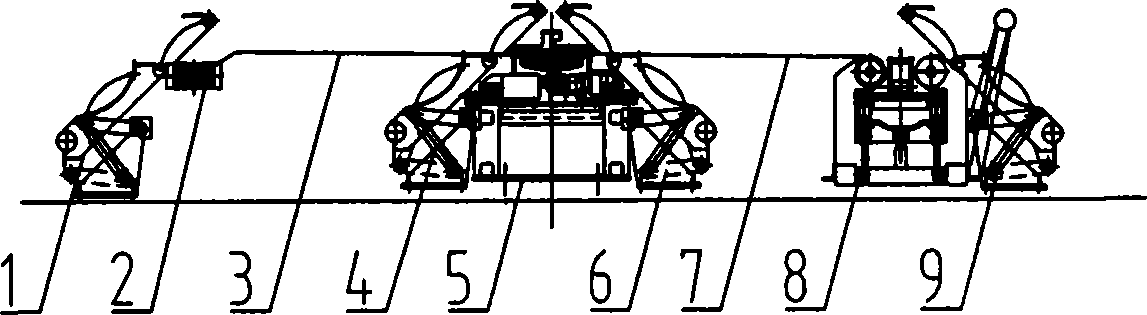

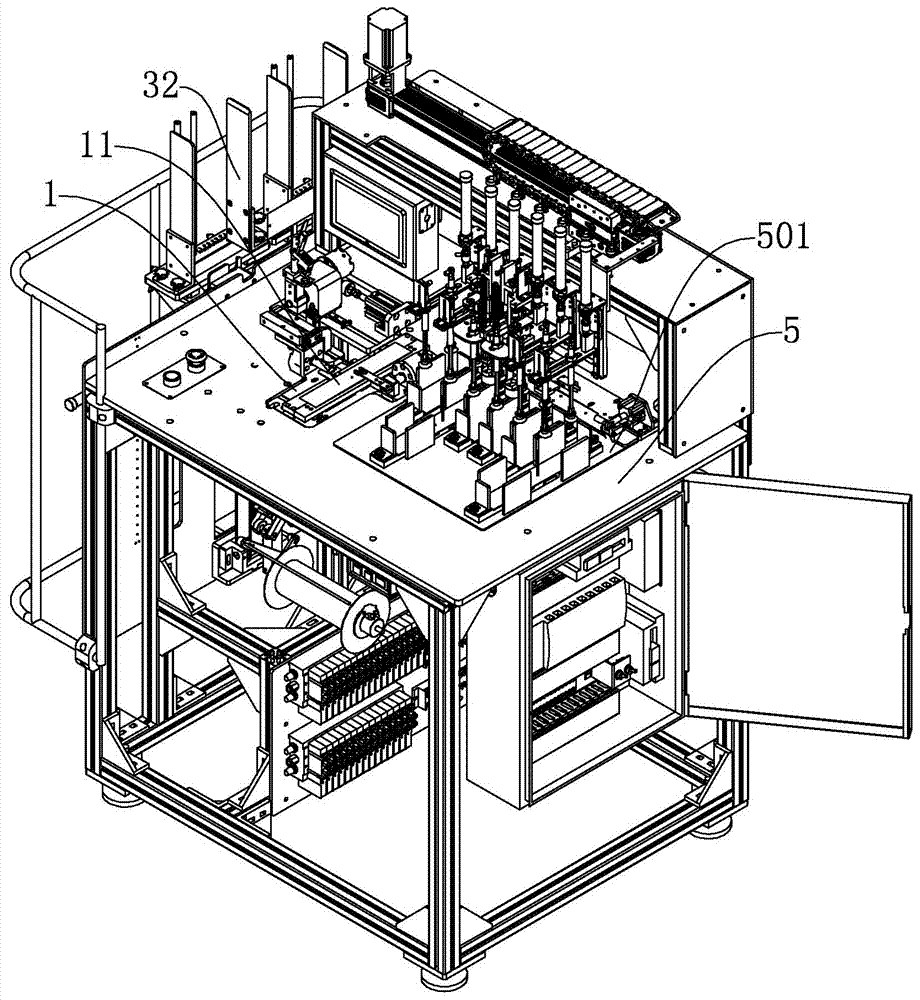

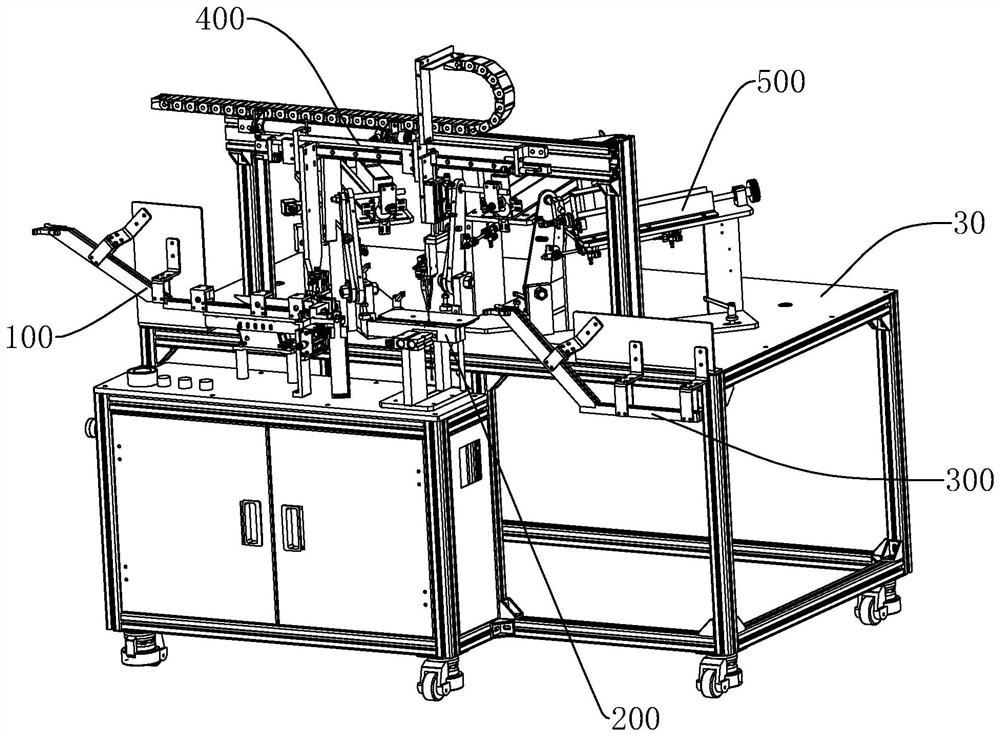

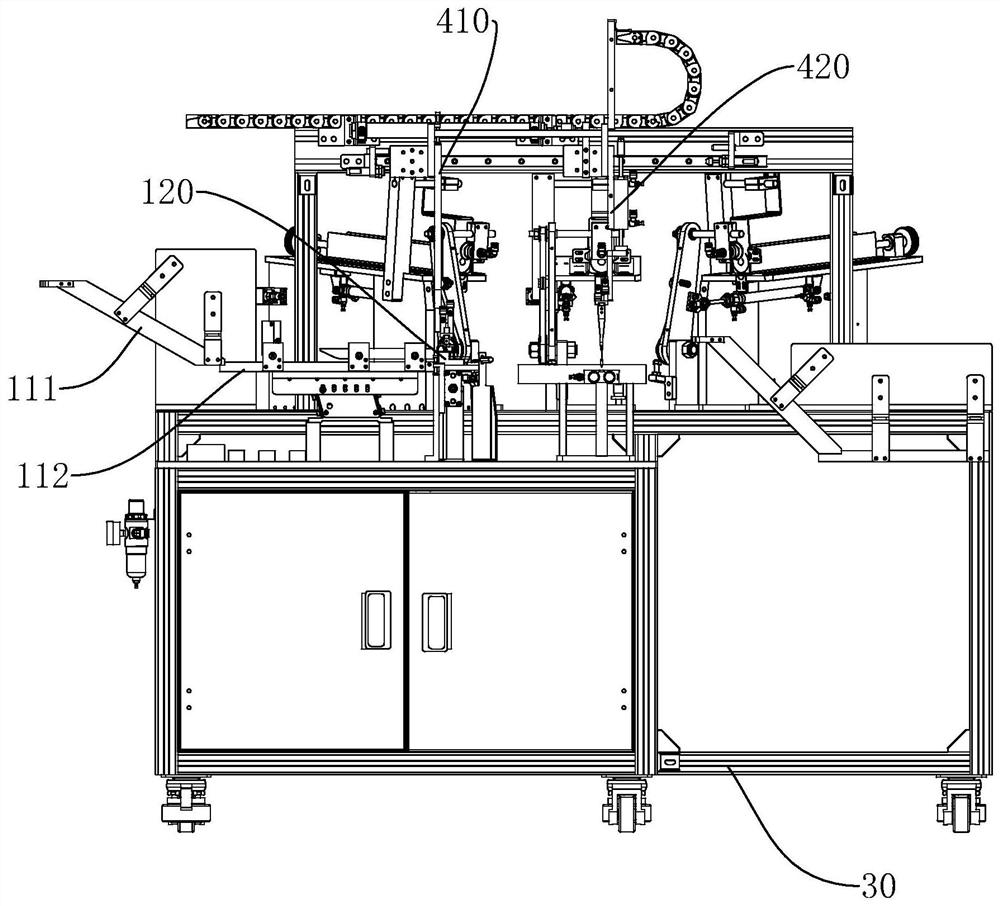

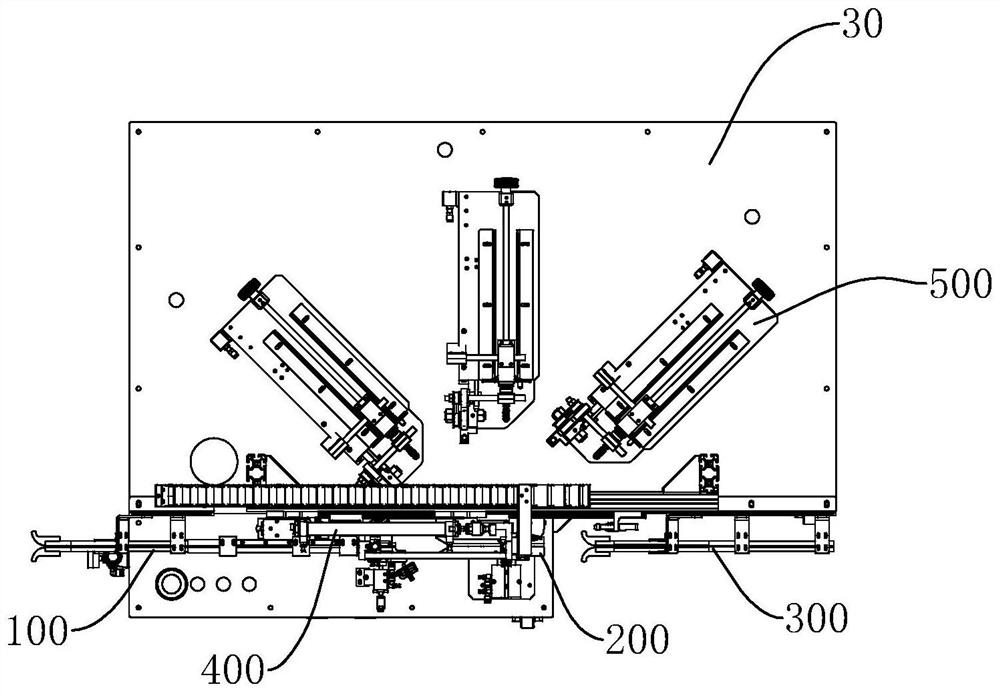

Labeling and bagging machine for socks

ActiveCN105292640AFast baggingReduce mistakesLabelling deformable materialsLabelling flat rigid surfacesSOCKSEngineering

The invention relates to a labeling and bagging machine for socks. The machine comprises a rack, wherein a sock receiving device, a sock labeling device, a paper card positioning device, a behind-paper card labeling device and a bagging device are arranged on the rack sequentially; a rotary sock clamping module, a sock clamping positioning module, a sock transmission module and a sock clamping transmission module; the sock clamping positioning module is arranged between the rotary sock clamping module and the sock transmission module; the behind-paper card labeling device is arranged between the sock transmission module and the sock clamping transmission module; and a bag paging module, a bag moving module, a sock bagging module, a film tearing and sealing module and a bag opening sealing module are sequentially arranged inside the bagging device. According to the labeling and bagging machine for socks, manual packaging is replaced with an automatic device; positioning is carried out at the central position of each pair of socks; the paper card positioning device is used, the front side and the back side are labeled automatically, and small errors are caused at the labeling positions; the bagging device can page bags accurately, so that the sock bagging speed is increased; and the film tearing and sealing speed is high, and films are sealed smoothly.

Owner:佛山市南海大欣针织业有限公司

Sock packer

ActiveCN107776944AAvoid violent collisionsSave productivityLabelling deformable materialsSortingSOCKSBiochemical engineering

The invention provides a sock packer, belongs to the technical field of machinery and solves the technical problems of low efficiency and the like in prior sock packing. The sock packer comprises a rack and is characterized in that a first rail and a second rail which are in closed circulation are fixed on the rack, a first gap is formed between one end of the first rail and one end of the secondrail, a second gap is formed between the other end of the first rail and the other end of the second rail, and the second gap is smaller than the first gap; a first guide groove is formed in the firstrail, a first through hole communicated with the first guide groove is formed in the lower part of the first rail, a second guide groove is formed in the second rail, and a second through hole communicated with the second guide groove is formed in the lower part of the second rail. The sock packer has the advantage that socks are packed automatically and efficiently.

Owner:全椒县瑞祥工艺品有限公司

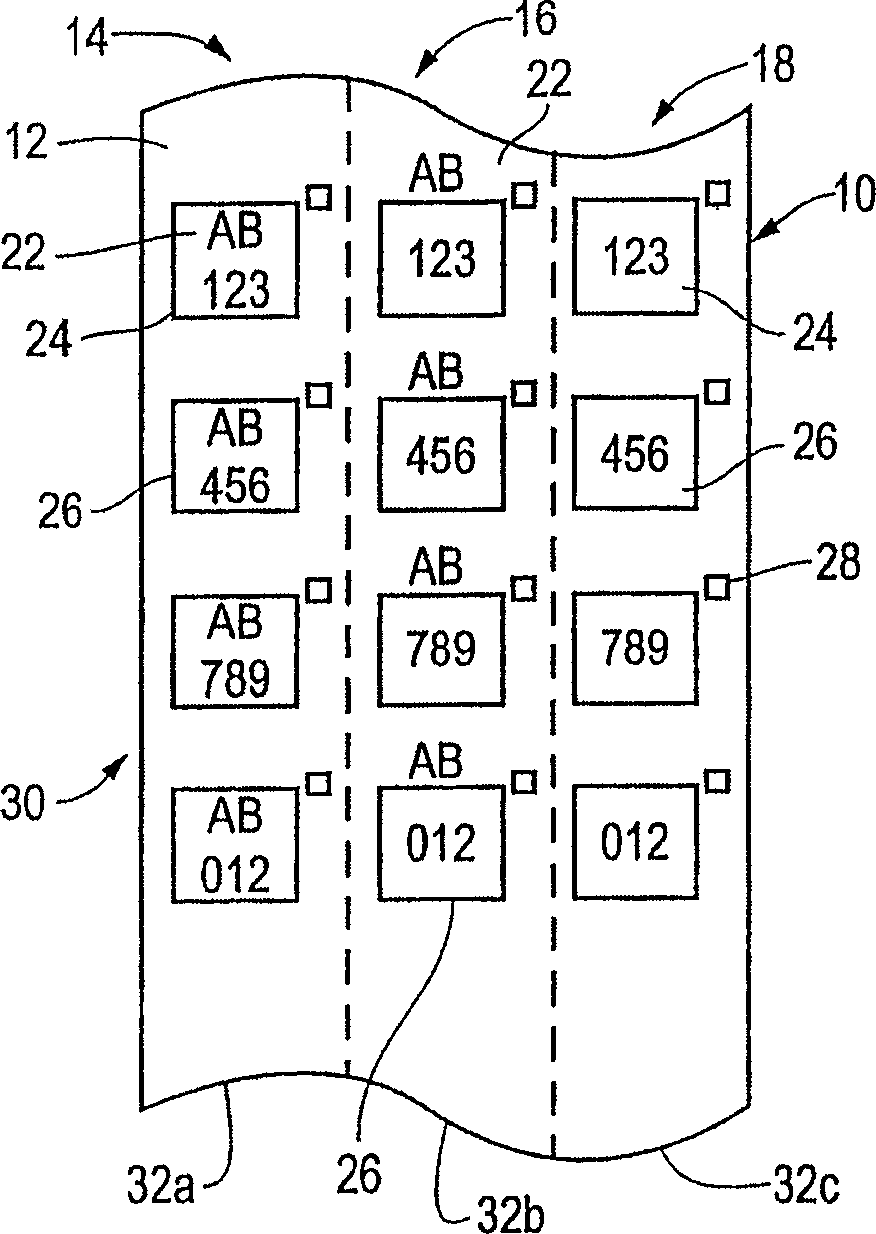

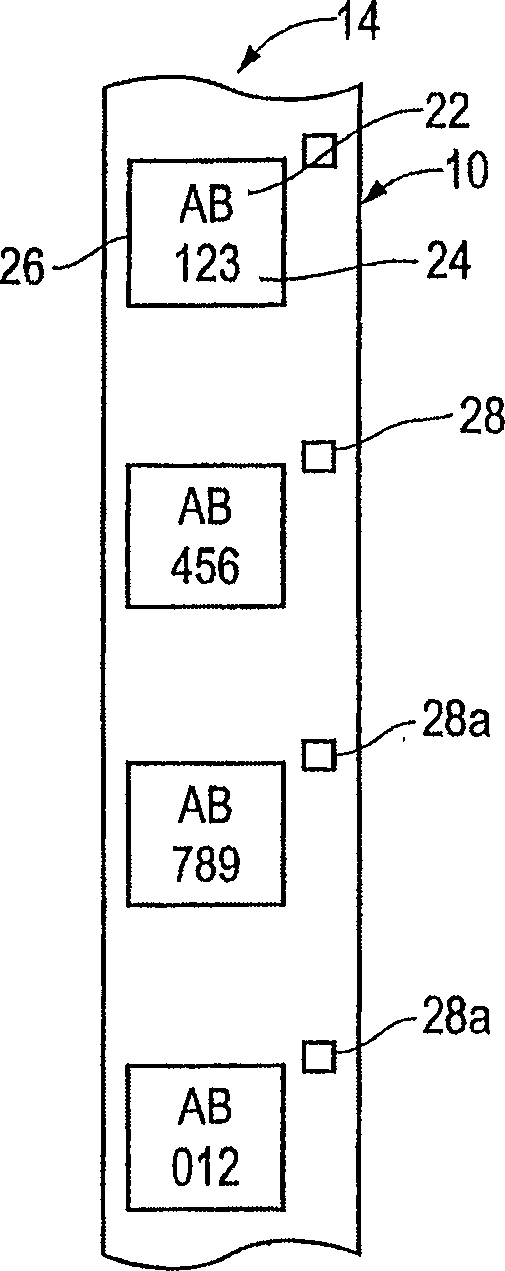

Variable data heat transfer label, method of making and using same

InactiveCN1890084ALabelling deformable materialsOther printing matterEngineeringElectrical and Electronics engineering

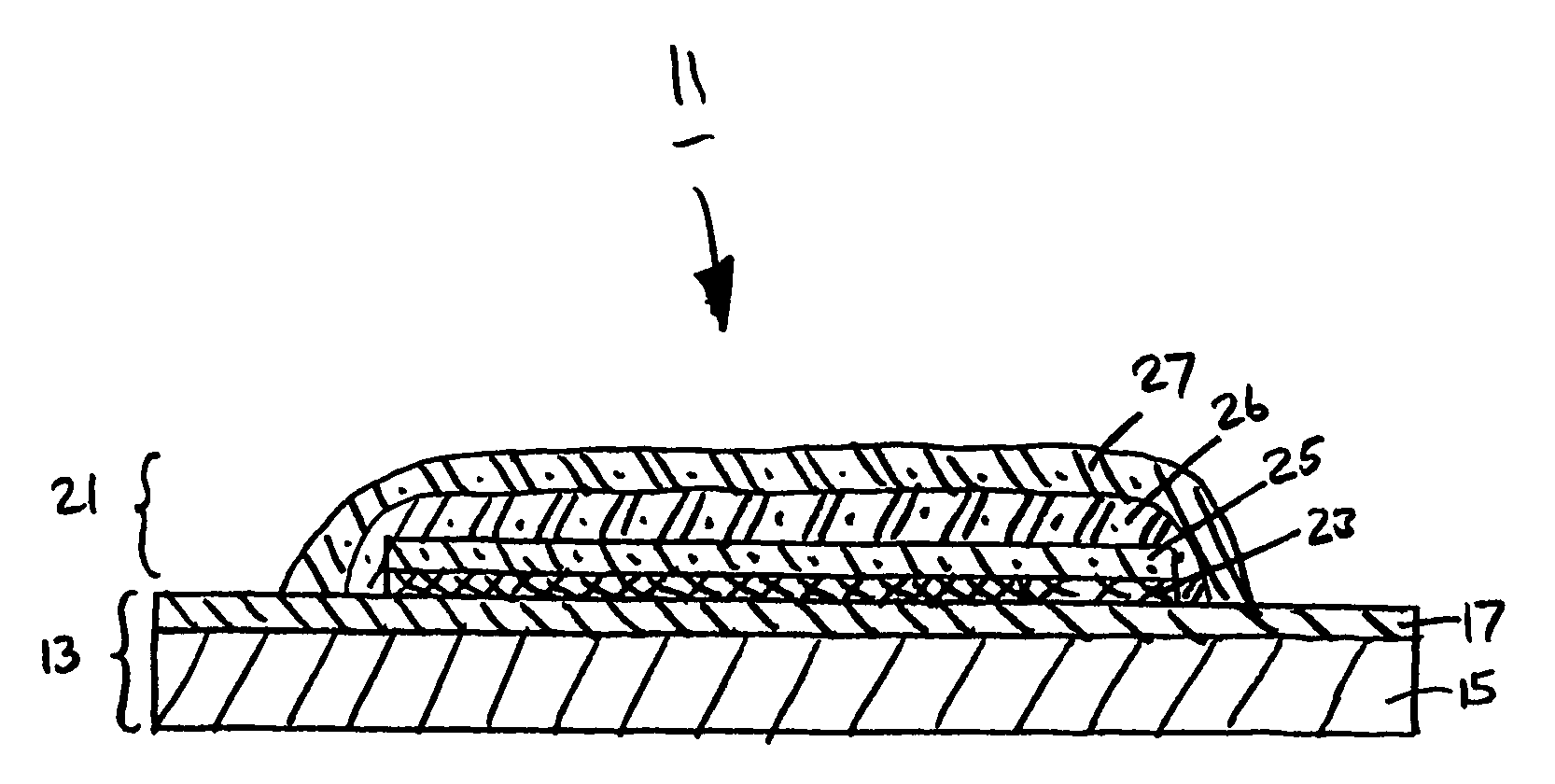

A heat transfer label for application to an item includes a heat transferable substrate having a transparent window area (26), a carrier (12) for carrying the substrate and a variable graphic component (24) including printed indicia on the window area. The variable graphic component is printed separate from the application of the substrate to the carrier and on an opposing side of at least a portion of the substrate from the carrier. The variable graphic component is printed prior to application of the heat transfer label to the item.

Owner:ILLINOIS TOOL WORKS INC

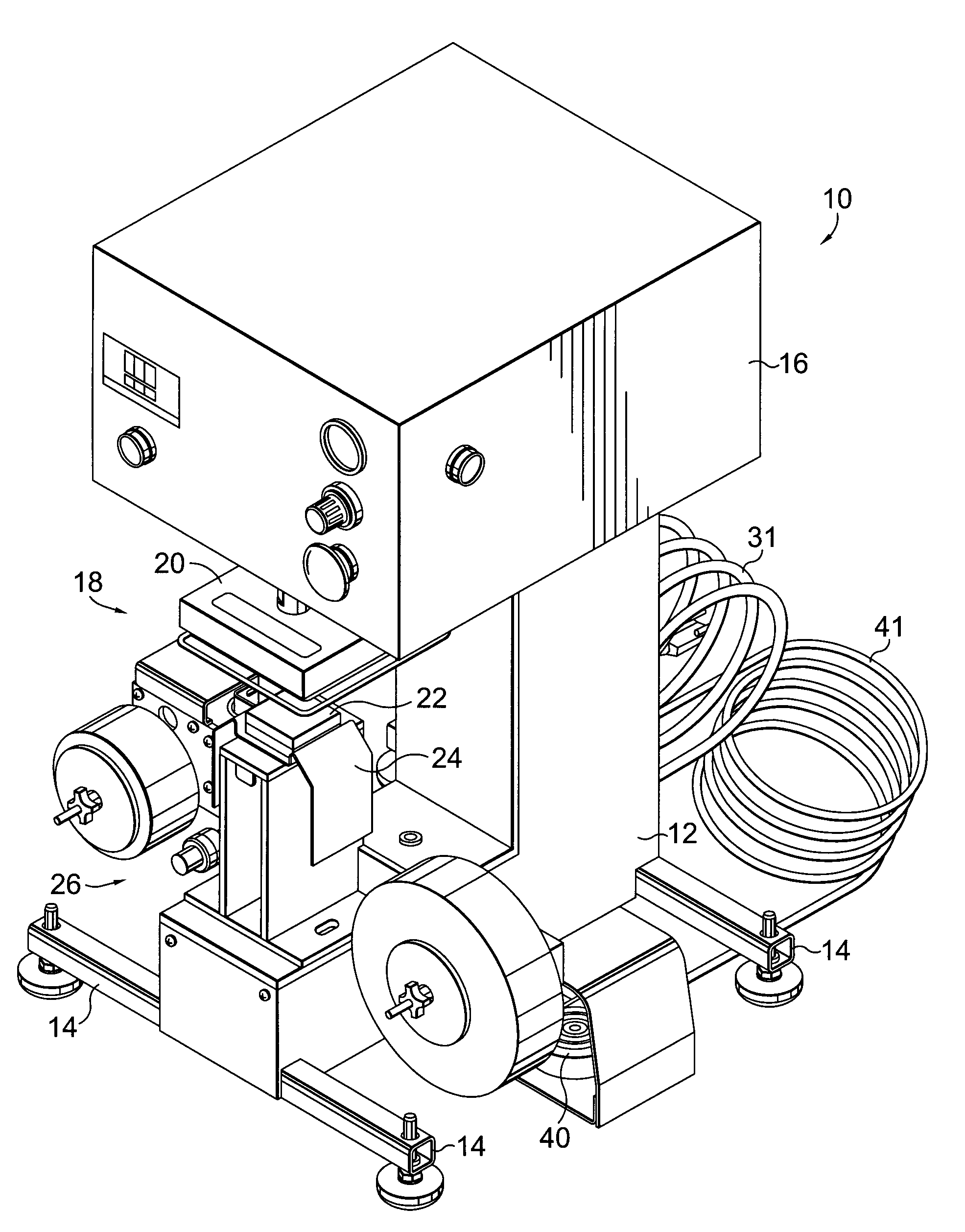

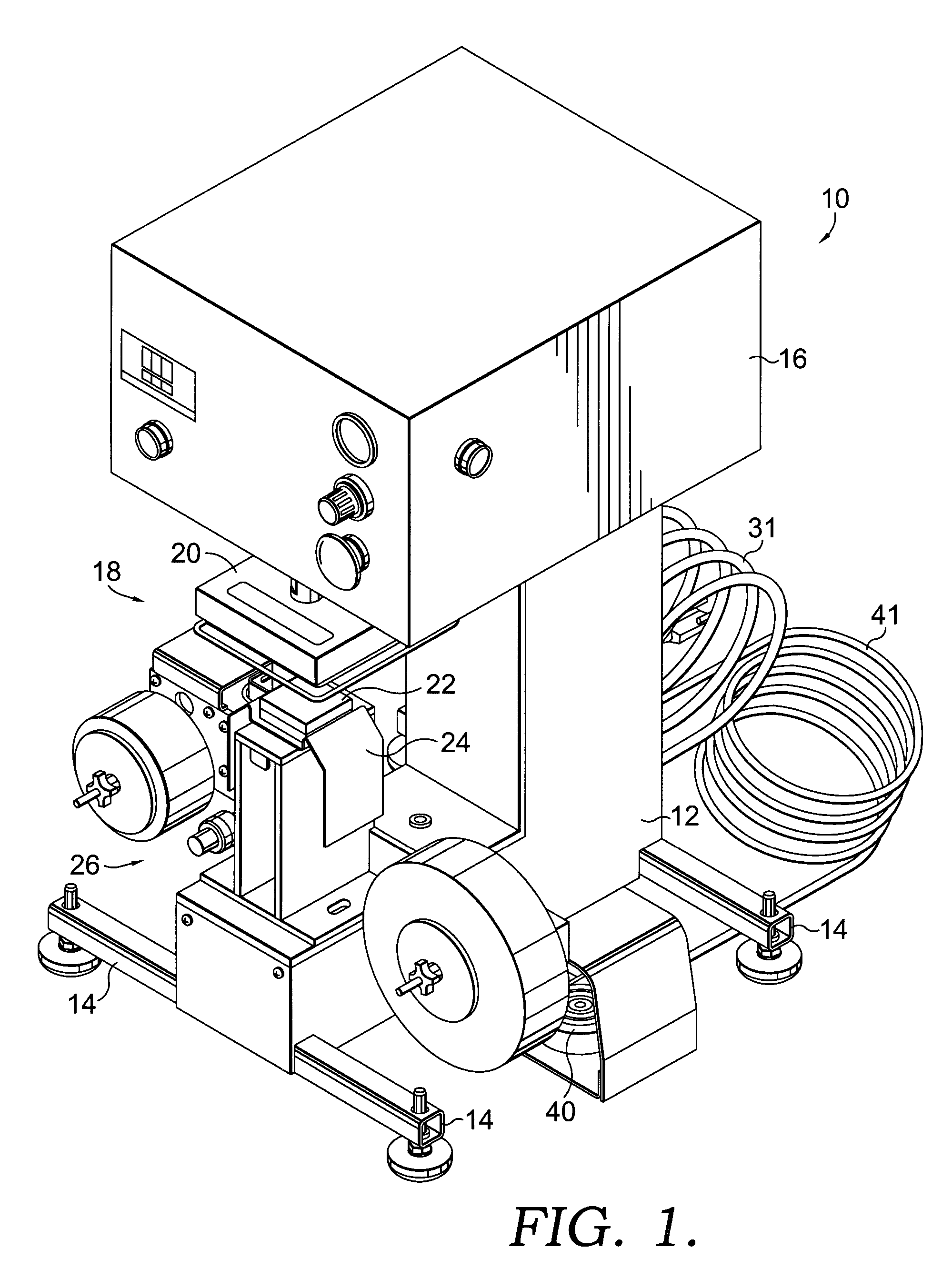

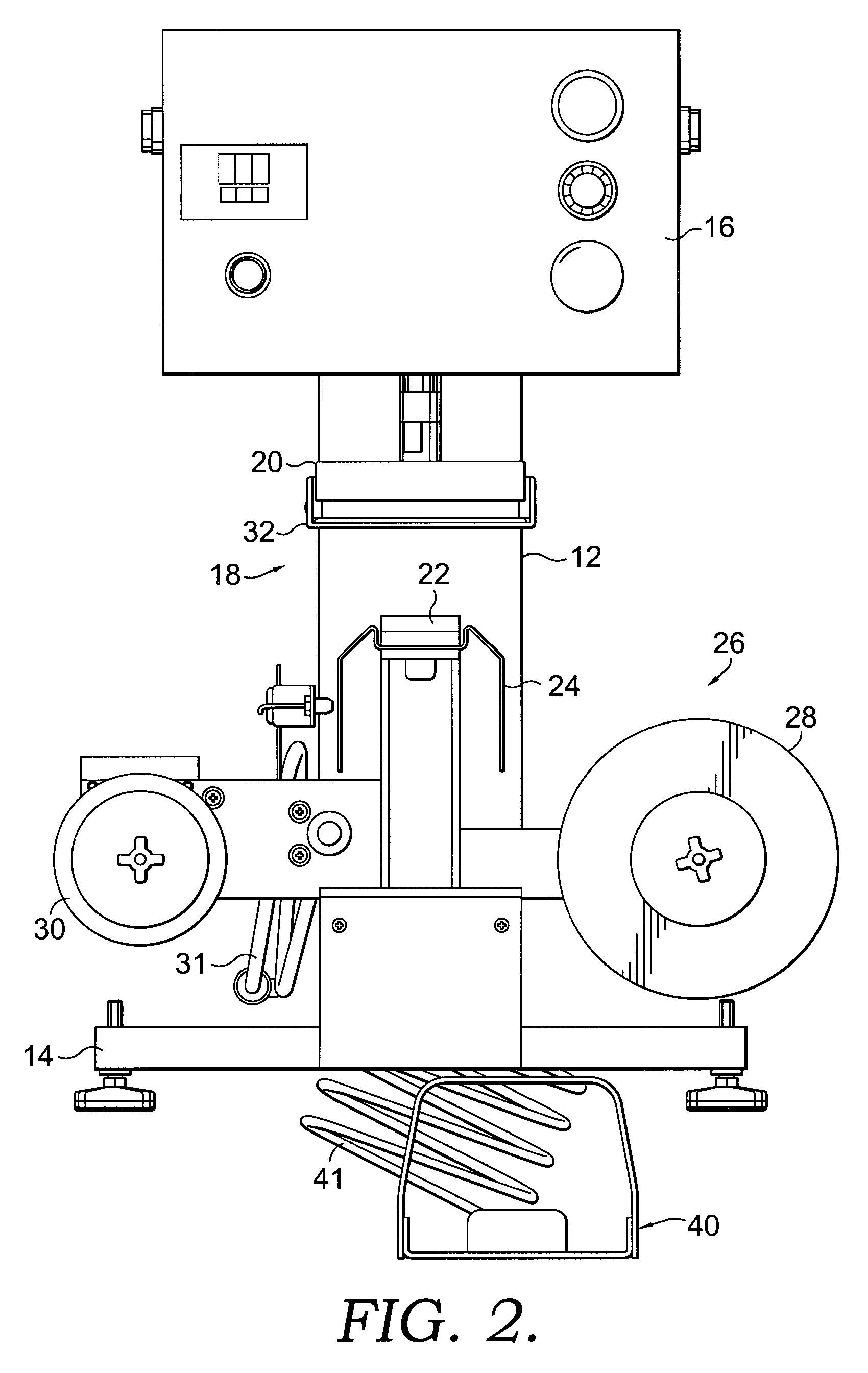

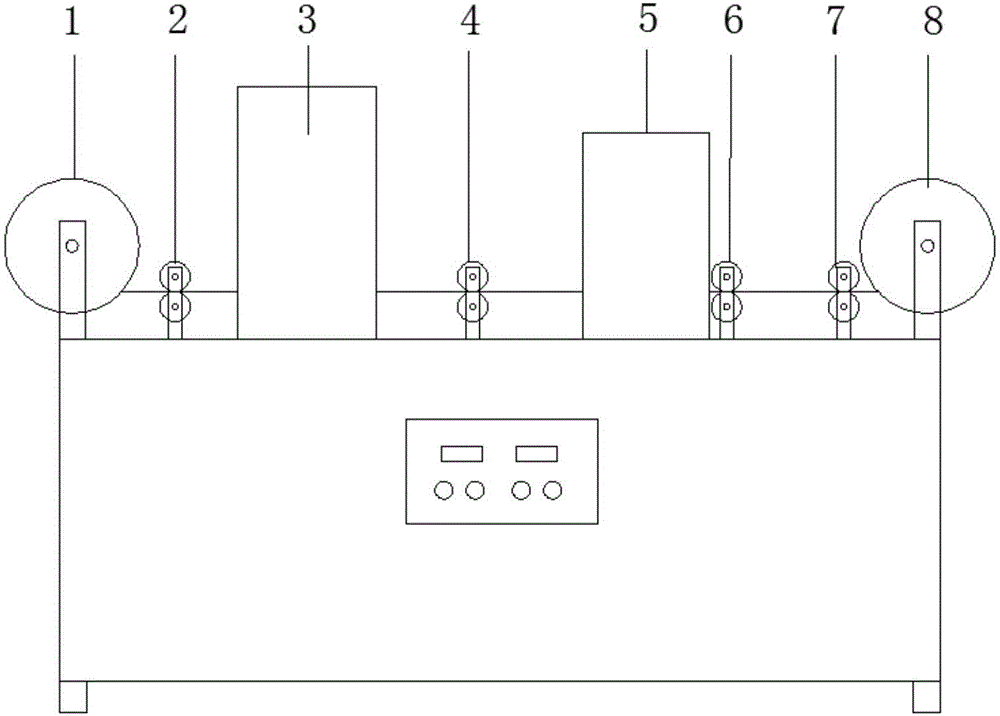

Roll-to-roll heat transfer machine

InactiveUS20070084547A1Efficient and accurate applicationLabelling deformable materialsDecorative surface effectsEngineeringMechanical engineering

An apparatus for applying a pre-printed transfer to a substrate at an elevated temperature and under increased pressure is disclosed. The apparatus includes a framework, an enclosure containing a plurality of control mechanisms, a heated platen assembly, and an index mechanism. The heated platen assembly comprises a first member capable of vertical travel and a second member that is removable. The pre-printed transfer is positioned proximate the second member and the substrate is positioned proximate the first member. The index mechanism has at least a supply portion for holding a continuous web of pre-printed transfers and a collection portion for receiving the continuous web after the pre-printed transfer has been applied to the substrate. Also disclosed is a method of applying a pre-printed transfer to a desired substrate utilizing this apparatus.

Owner:HIX CORP

Label sticking method for book metal anti-theft label

InactiveCN1616306AImprove labeling efficiencyLabelling deformable materialsManual insertionPaper tape

The present invention provides an anti-theft label sticking method for book and belongs to the field of book label technology. The present invention has stepped motor and sync belt driver to drive the label roll, guide wheel and magnetic steel plate to separate the upper paper layer and the lower paper layer from the label belt, electromagnet driven cutter to cut the adhesive film between two successive labels, electromagnet driven magnetic steel block to transfer the label onto the label inserting board, and elevating and rotating manipulator to insert and stick the label inserting board into book seam. The present invention has high label sticking efficiency and quality.

Owner:SHANGHAI JIAO TONG UNIV

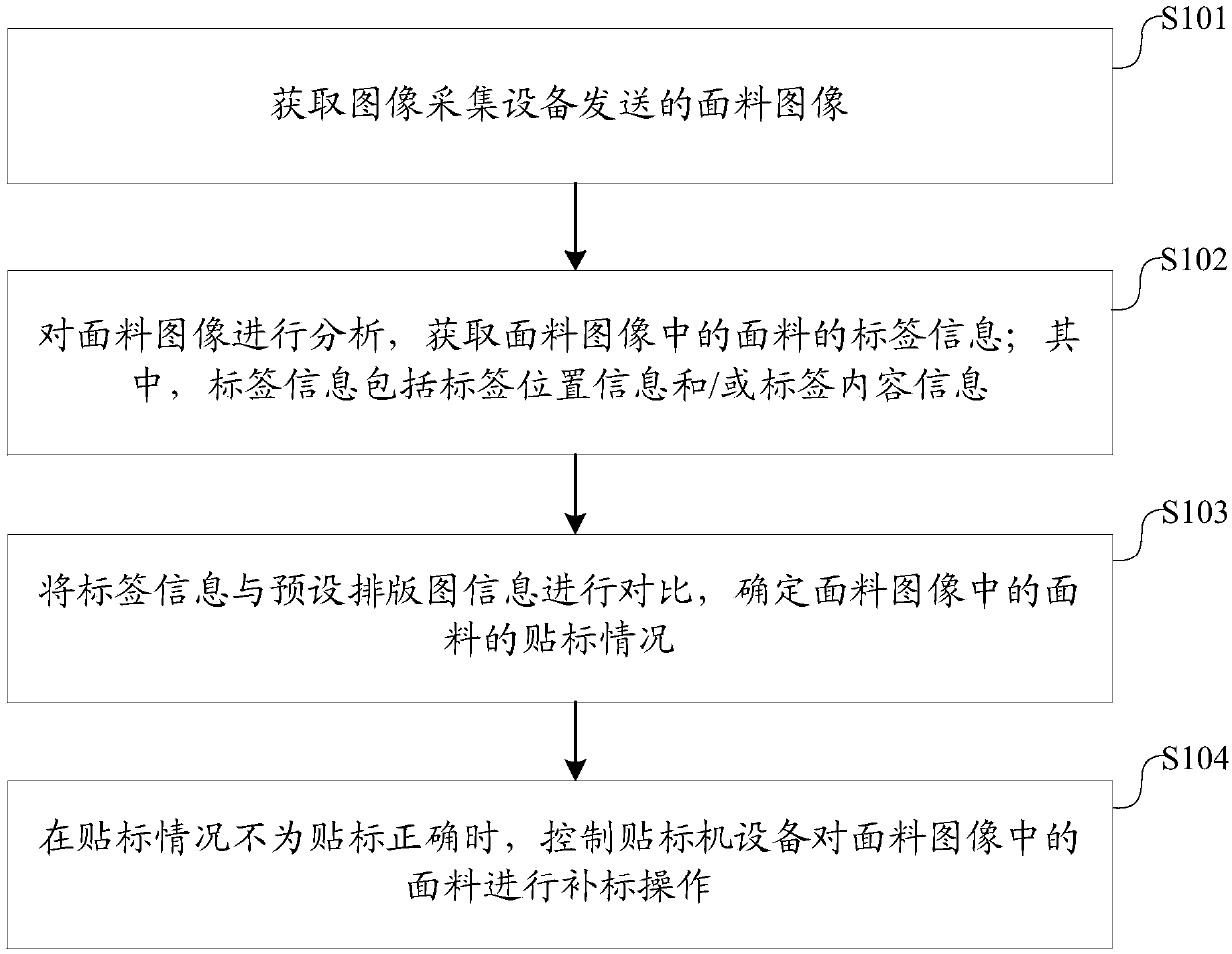

Labeling condition detecting method and device based on image recognition and labeling control system based on image recognition

PendingCN109606880AImprove efficiencyImprove accuracyLabelling deformable materialsLabelling machinesPattern recognitionAutomatic control

The invention discloses a labeling condition detecting method, device and equipment based on image recognition and a labeling control system based on image recognition. The method comprises the following steps that fabric images sent by image collecting equipment are obtained; the fabric images are analyzed, and tag information of fabric in the surface images is obtained; the tag information is compared with preset layout drawing information to determine the labeling condition of the fabric in the surface images; and when the labeling condition is not right, labeling equipment is controlled toconduct label supplement operation on the surfaces in the surface images. The image processing technology is adopted to automatically analyze the images, of the labeled surfaces, collected by the image collecting equipment, and the labeling condition of the surfaces is determined. The labeling equipment is automatically controlled to supplementarily label a tag to the surface with wrong labeling,so that manual checking and operation are reduced, efficiency and accuracy of detecting and processing of the labeling condition of the surfaces are improved, subsequent production is more efficient,and user experience is improved.

Owner:BULLMER ELECTROMECHANICAL TECH

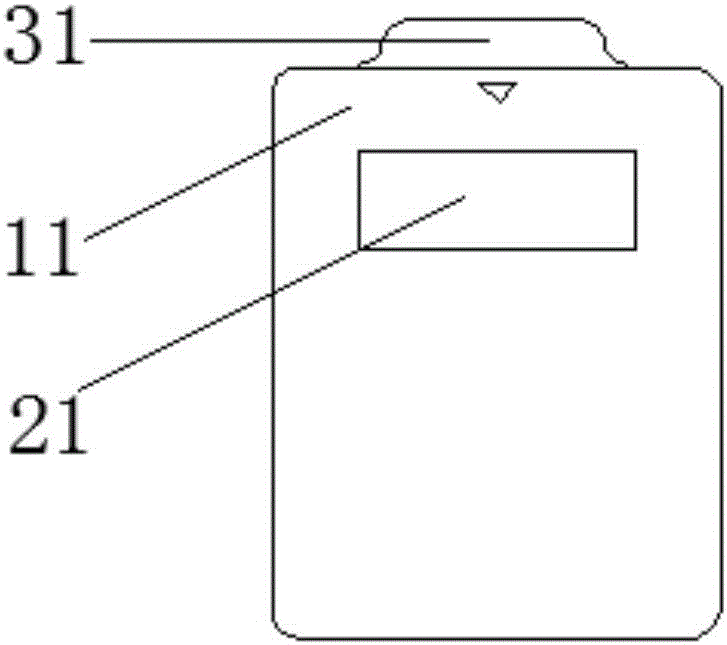

Hang tag automatic stringing machine

ActiveCN106995083ARealize rope operationStringing is accurateLabelling deformable materialsLabelling machinesEngineeringMechanical engineering

The invention discloses a hang tag automatic stringing machine which comprises a rack. A fixed plate used for containing a hang tag is arranged on the rack and provided with an up-and-down through stringing hole. A stringing rod mounting seat is arranged below the fixed plate and provided with a stringing rod enabling a hang string to penetrate the stringing hole. The hang tag is placed on the fixed plate after being grabbed by a suction assembly, the stringing rod penetrates the stringing hole in the hang tag, and automatic stringing operation of the hang tag is achieved.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

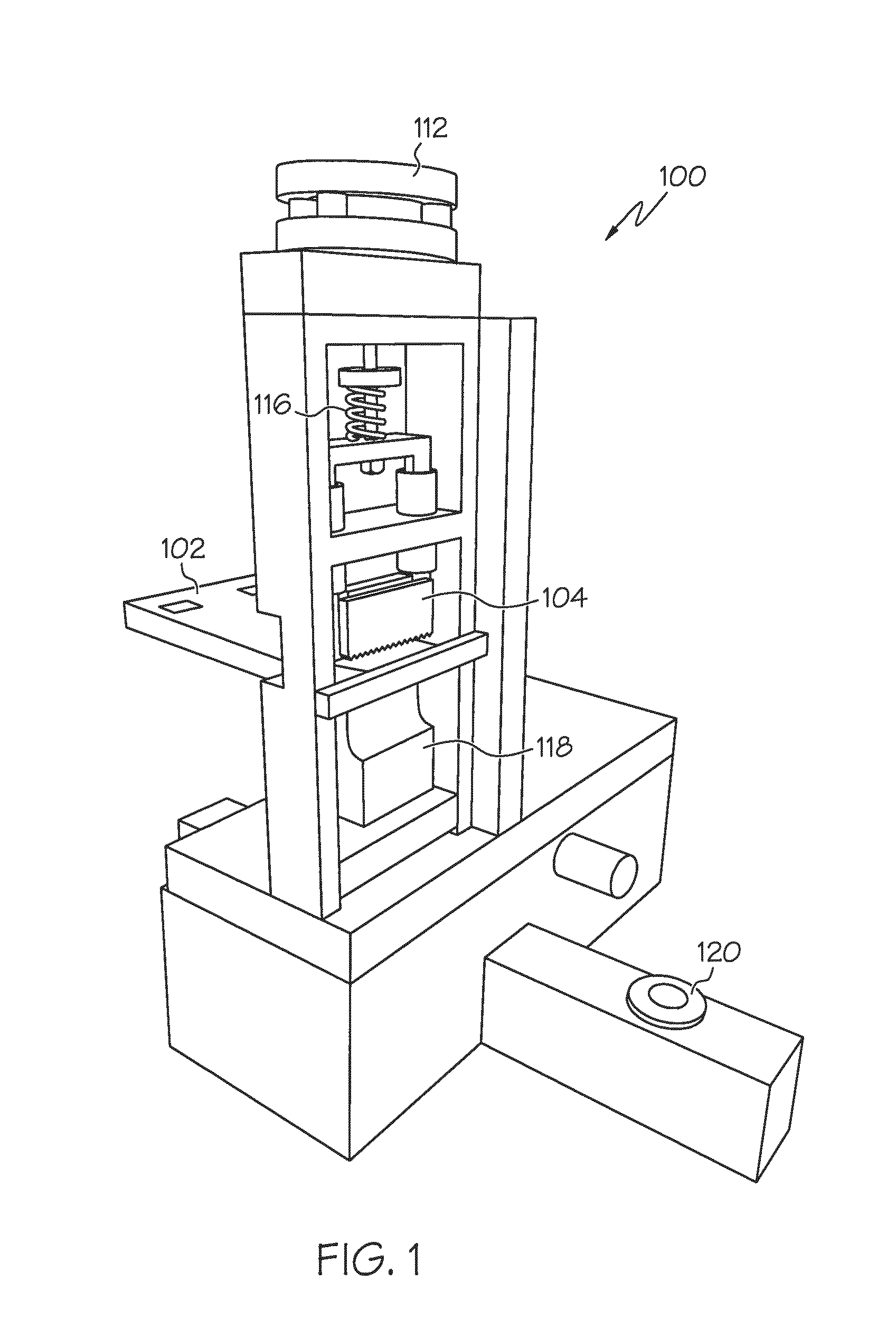

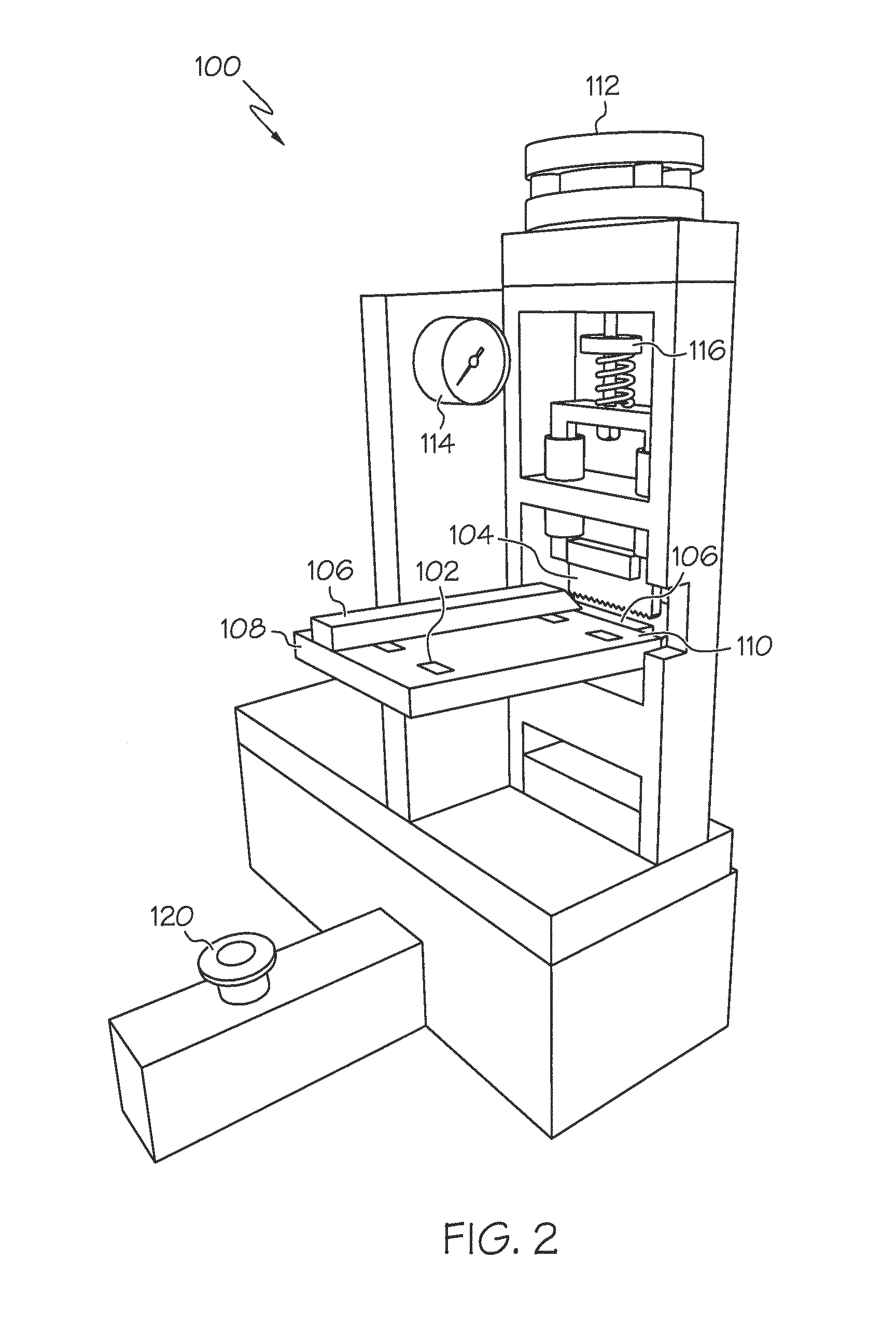

Manual Sonic Welding Machine

ActiveUS20130122235A1Pressure on headLabelling deformable materialsStampsAcoustic waveElectric signal

A system and method is presented that provides a manual sonic welding device for welding multiple labels or other articles together. The manual sonic welding device includes an anvil and a head. The anvil is where the labels are placed on the welding device and allows the high frequency vibration from the welding device to be directed to the proper interfaces of the labels. The head allows the multiple labels to be assembled under pressure. Additionally, the manual sonic welding device includes a converter, a sonic horn, and a power supply to seal the multiple labels together. The power supply delivers a high power AC signal, the converter converts the electrical signal into a mechanical vibration, and the sonic horn applies the mechanical vibration to the labels to be welded. The manual sonic welding device also includes dual safety switches which activate the device.

Owner:AVERY DENNISON CORP

Hang tag stringing device and method

PendingCN112298721AHigh degree of automationIncrease productivityLabelling deformable materialsStructural engineeringString (device)

The invention relates to a hang tag stringing device and method. The hang tag stringing device and method are used for stringing at least one hang tag into a hang rope. The hang tag stringing device comprises a hang rope feeding mechanism comprising a first channel and a separation part, wherein the separation part is arranged at the tail end of the first channel and used for separating out the hang rope at the tail end of the first channel; a combination mechanism comprising a combination position; a finished product storage mechanism comprising a second channel; a hang rope conveying mechanism used for conveying the hang rope on the separation part to the combination position and conveying the hang rope at the combination position after the hang tag penetrates into the hang rope to the second channel; and at least one hang tag taking and placing mechanism. When the hang rope is placed or conveyed in the first channel and the second channel, a rope of the hang rope penetrates throughthe first channel and the second channel, and a first end head is clamped above the first channel and the second channel; the hang rope conveying mechanism clamps the first end head for conveying; andthe combination position can clamp the lower end of the first end head. The automation degree of hang tag stringing can be improved, and the production efficiency is improved.

Owner:中山恒裕智慧科技有限公司

Opening labeling machine and cigarette packaging production system

ActiveCN106240983AHigh degree of automationIngenious structural designLabelling deformable materialsLabelling machinesProduction lineVisibility function

The invention relates to the technical field of cigarette packaging, in particular to an opening labeling machine and a cigarette packaging production system. The opening labeling machine comprises a feeding mechanism, a die-cutting machine, the labeling machine body and a collection mechanism which are sequentially arranged on a production line. The feeding mechanism, the die-cutting machine, the labeling machine body and the collection mechanism are in mutual collaboration to form a stable labeling system. The labeling system is high in automation degree, capable of producing lined paper with moisturizing, aroma conservation and visibility functions, the structural design is ingenious, and application and popularization are facilitated.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com