Full-automatic packaging device for silk stockings and method thereof

A fully automatic packaging and stocking technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of increasing labor intensity of workers, unfavorable to corporate profits, and declining product quality, reducing labor costs and compact machine structure. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

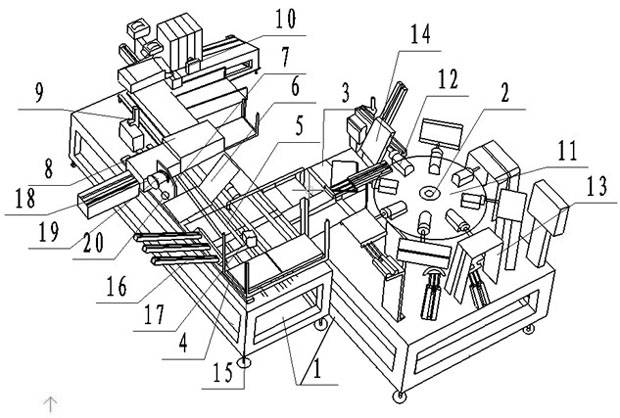

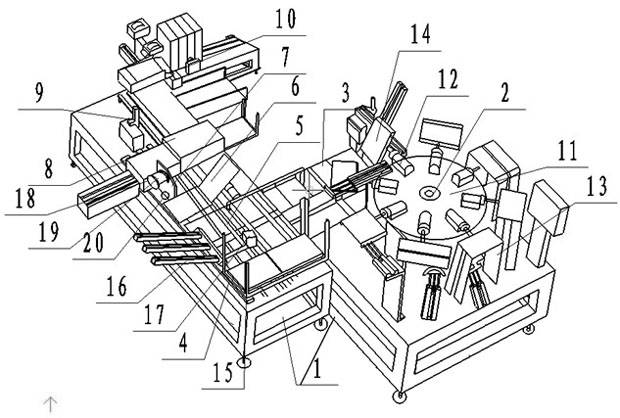

[0019] Such as figure 1 As shown, the fully automatic packaging device for stockings includes a bottom frame 1, a rotating loading device 2, a sock bag conveyor belt 3, a feeding device 4, a lateral conveying roller 5, a double-folding lining mechanism 6, a labeling mechanism 7, a bag-entry device 8, and a sealing Device 9, finished product conveying device 10: the bottom frame 1 is provided with a rotating loading device 2 and a lateral conveying roller 5, the end of the bottom frame 1 is provided with a finished product conveying device 10, and the rotating loading device 2 is connected to one end of the sock bag conveyor belt 3 The other end of the sock bag conveyor belt 3 is connected to the feeding device 4, and the double-folding liner mechanism 6, labeling mechanism 7, bagging device 8, and sealing device 9 are sequentially provided on the transverse conveying roller 5; Object device 2 comprises rotating disk 11, rotating shaft 12, support frame 13, loading plate 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com