Heat-transfer label well-suited for labeling fabrics and methods of making and using the same

a technology of heat transfer label and fabric, applied in the field of heat transfer label, can solve the problems of wearer irritation, loss of information contained on the label, significant damage to the garment,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

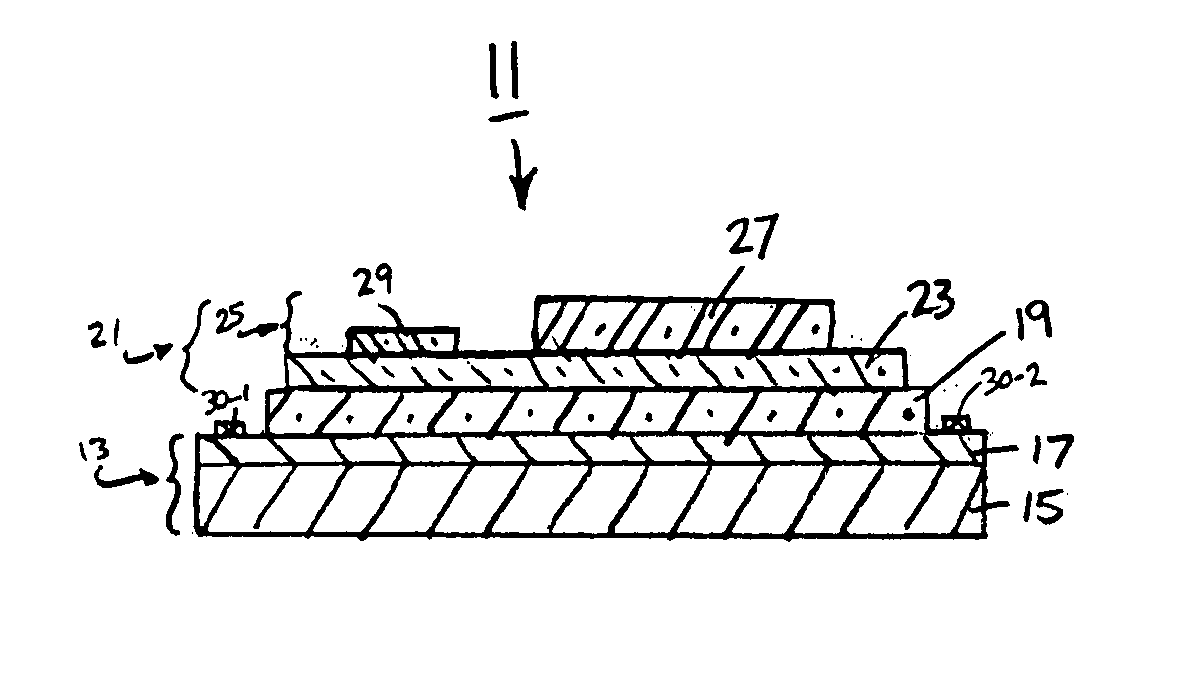

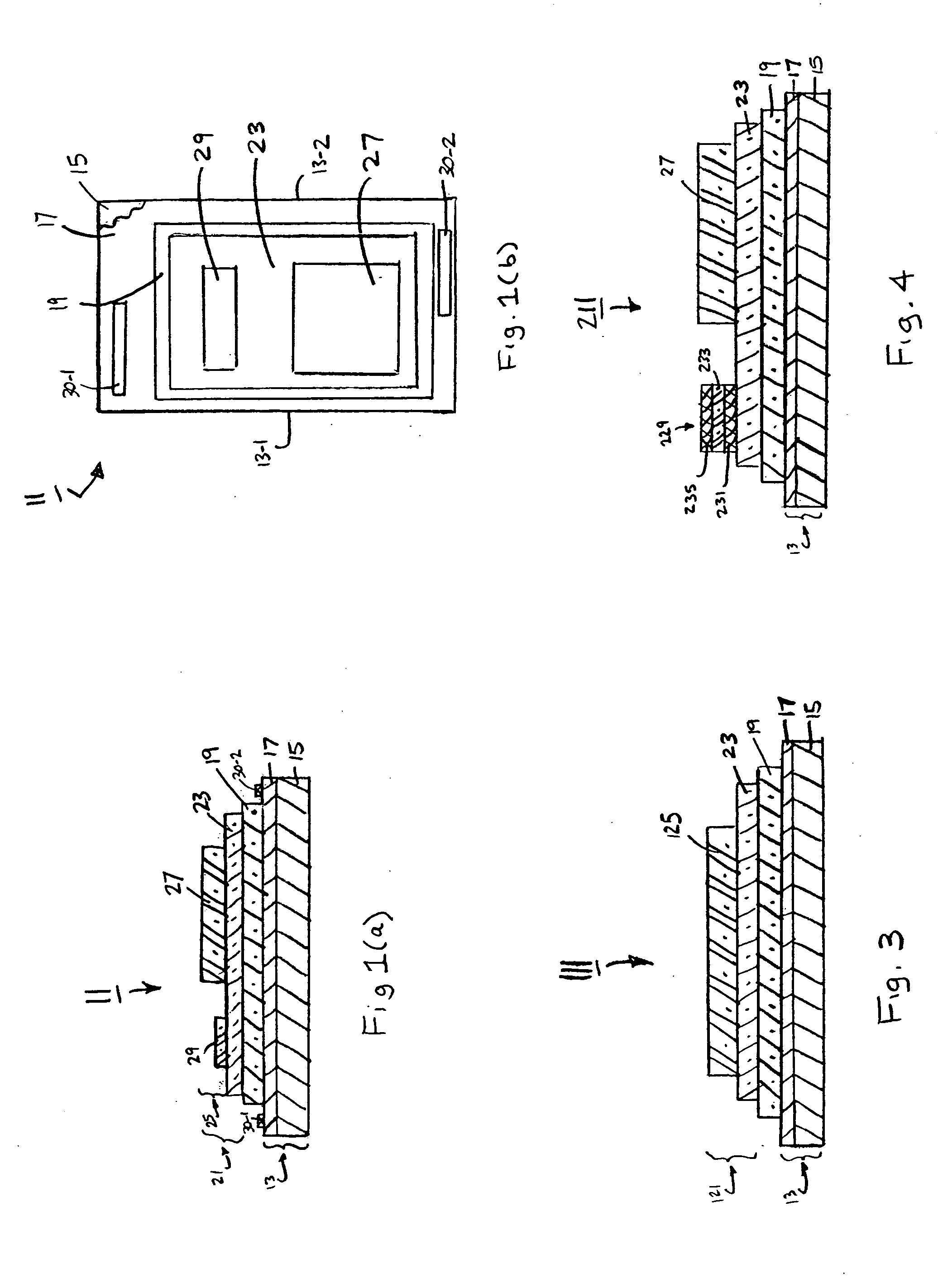

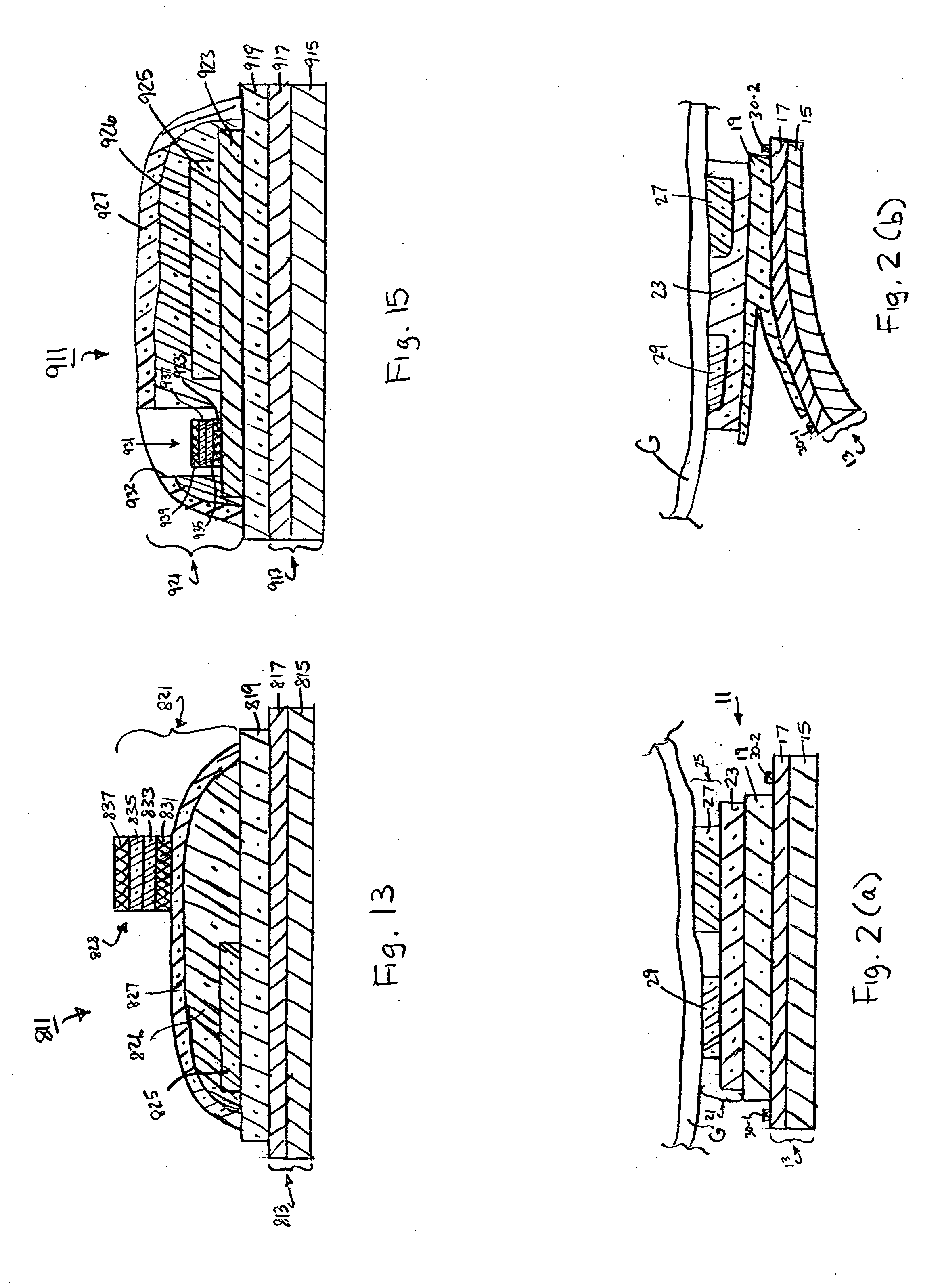

Image

Examples

example 1

[0193] The surface roughness of the exposed adhesive of each of (i) a UNIMARK-brand 3D Flexistretch heat transfer paper with heat transfer for fabric labeling (Matsui International Company, Inc., Gardena, Calif.); (ii) a POLYMARK-brand Polystretch heat transfer paper with heat transfer for fabric labeling (Illinois Tool Works, Glenview, Ill.); and (iii) Sample Nos. 1 and 2 (a pair of labels like label 11 of the present invention wherein adhesive layer 23 was made from the above-described PVC-containing adhesive composition) was investigated in the manner hereinafter described.

[0194] The label samples were laid flat on a glass slide with a double-sided tape. Using Dektak 8 stylus profiler (Veeco Instruments, Woodbury, N.Y.), random scans were performed on three different locations of each label over a length of 2000 um of the requested areas. The average roughness, Ra, was generated over a length of 1800 um, with 100 um cut off from both the starting point and the endpoint. The scan...

example 2

[0197] The ink coverage achieved when a thermal transfer marking was printed onto the exposed adhesive of each of (i) a UNIMARK-brand 3D Flexistretch heat transfer paper with heat transfer for fabric labeling (Matsui International Company, Inc., Gardena, Calif.); (ii) a POLYMARK-brand Polystretch heat transfer paper with heat transfer for fabric labeling (Illinois Tool Works, Glenview, Ill.); and (iii) Sample Nos. 3 and 4 (a pair of labels like label 111 of the present invention wherein adhesive layer 23 was made from the above-described PVC-containing adhesive composition) was investigated in the manner hereinafter described.

[0198] Markings were made on an exposed area of the adhesive surface of each of the aforementioned labels using an APR600 wax and resin-based thermal ribbon (Armor, Nantes Cedex, France), installed in an Avery 64-04 near-edge head printer run at 6 ips, at a temperature setting of 99 and a pressure setting of 3.

[0199] The printed surface of each label was then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com