Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

375results about "Marking textiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

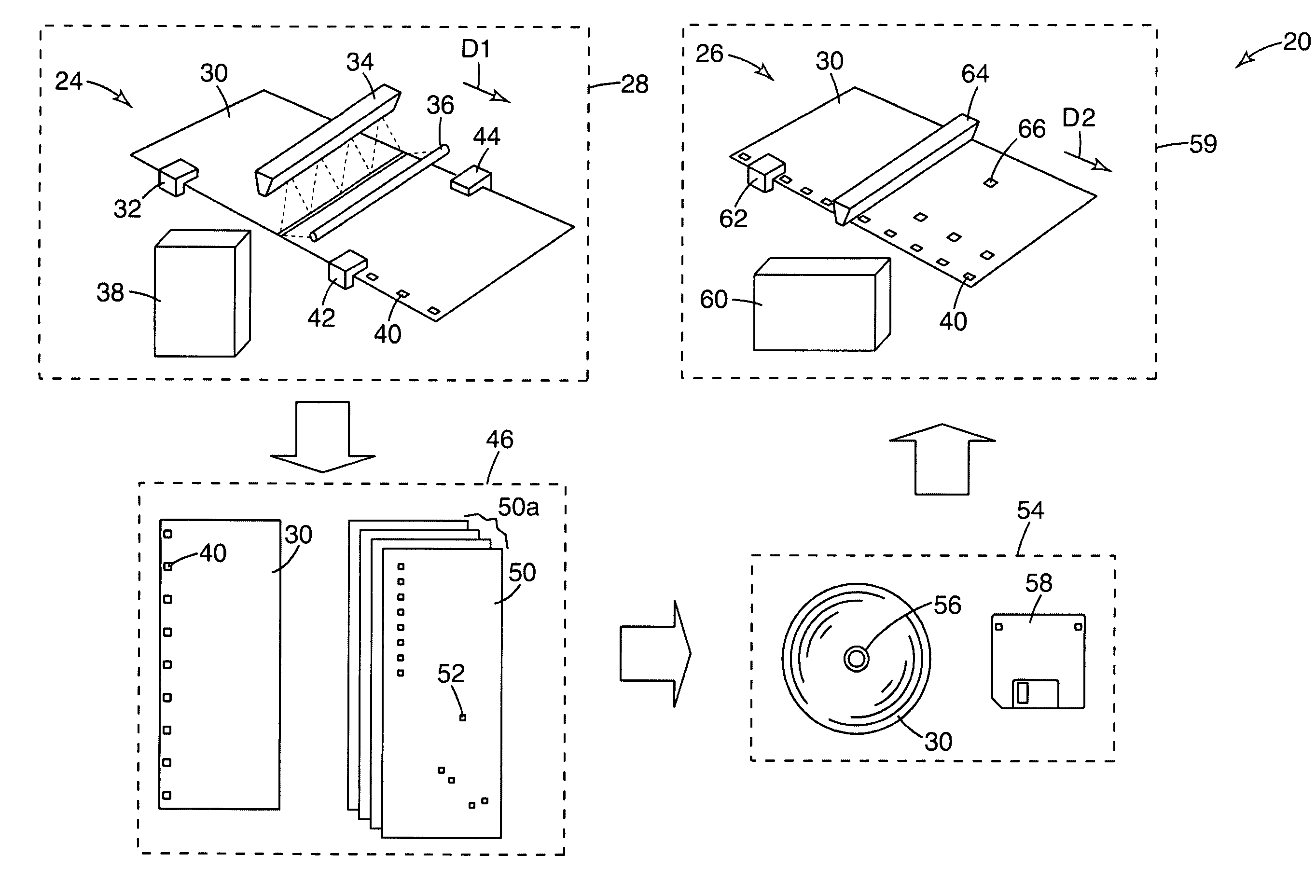

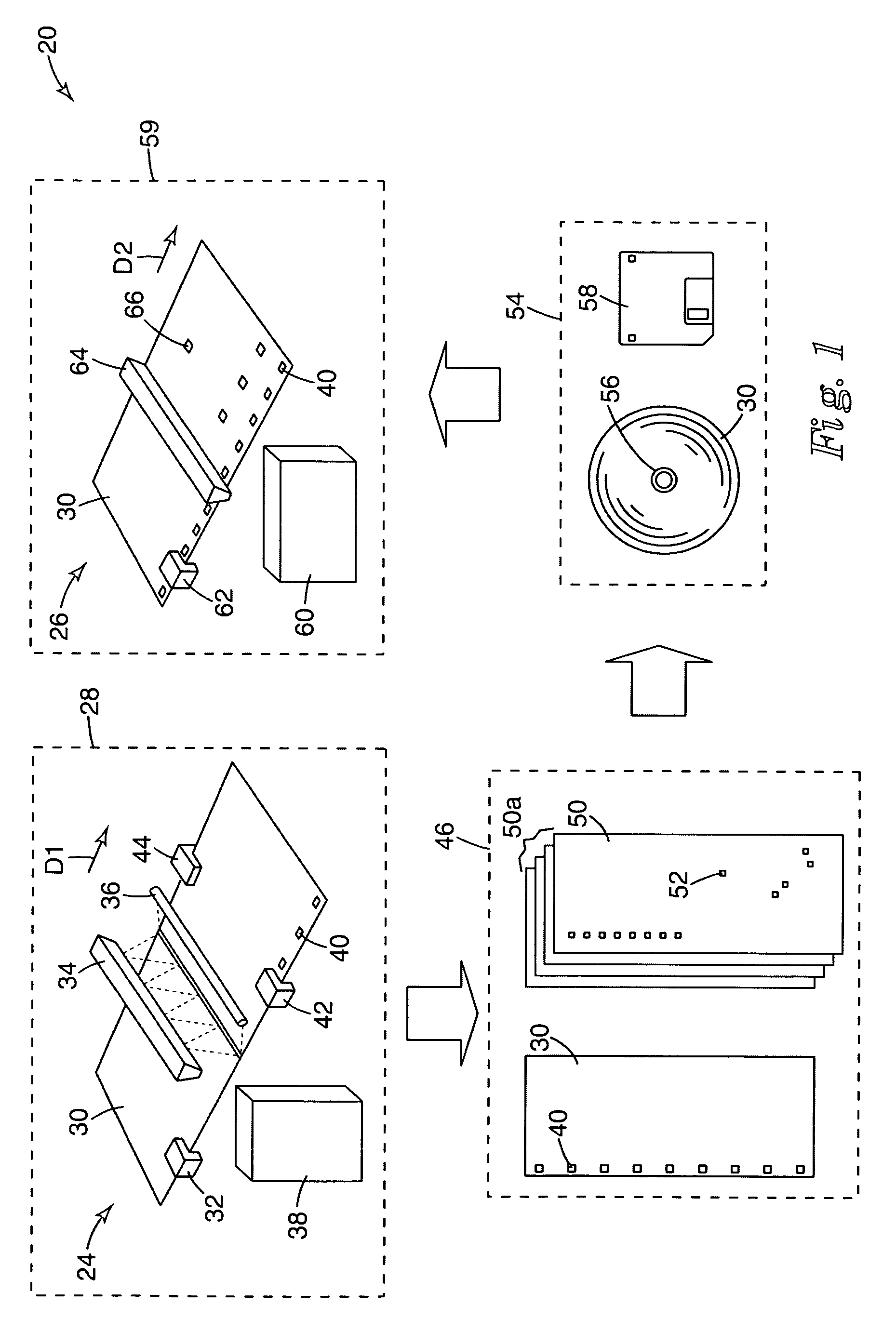

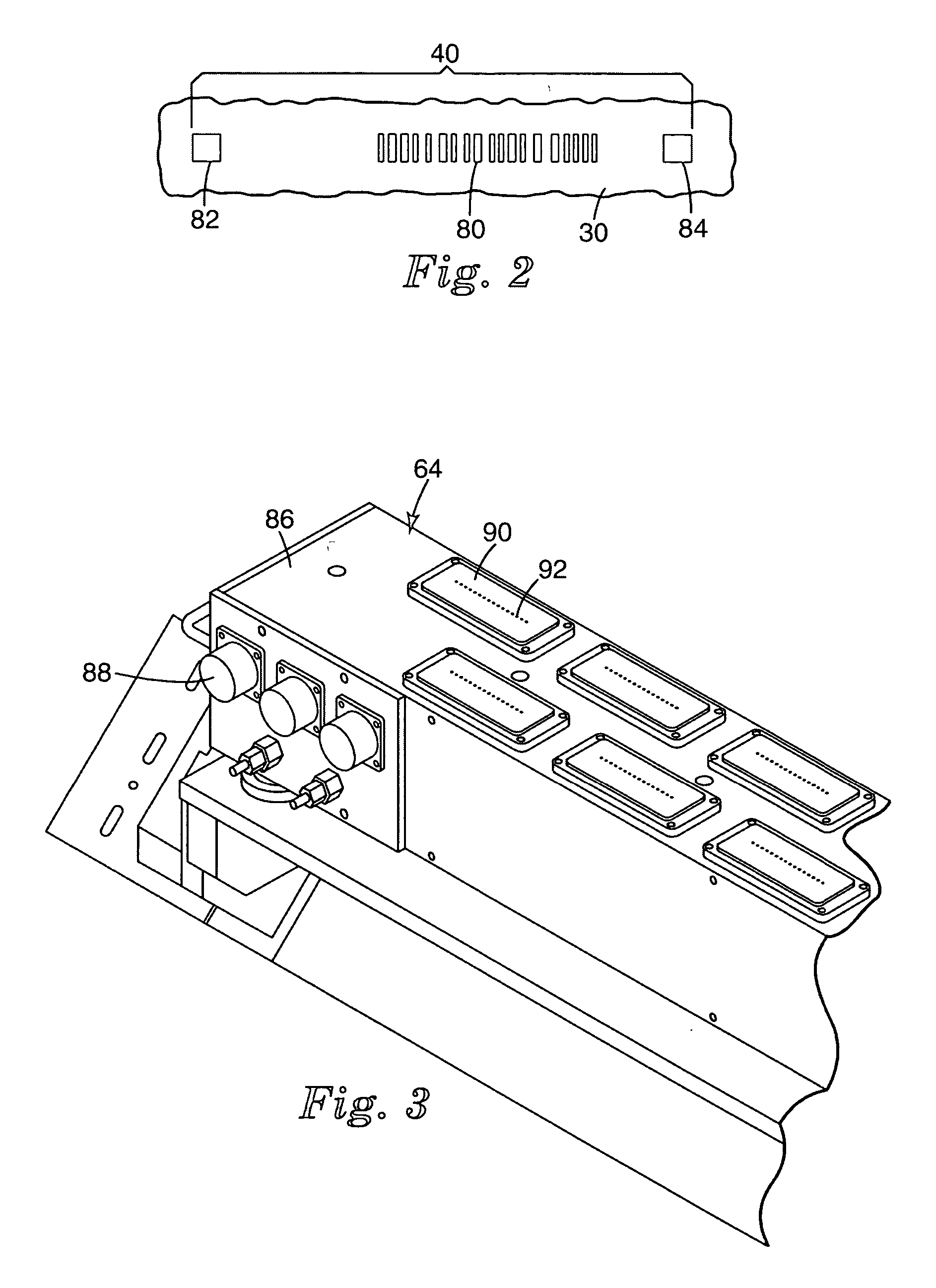

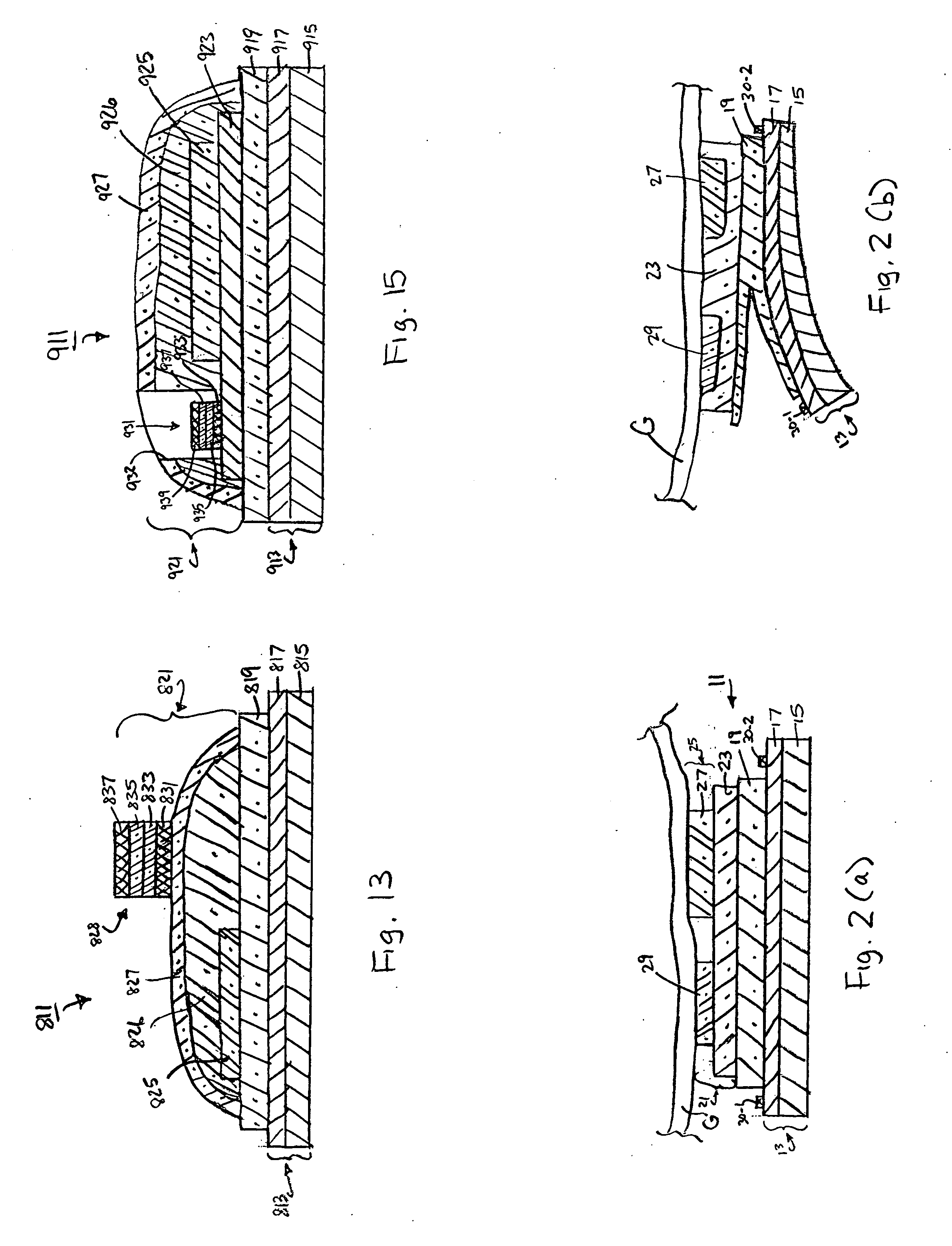

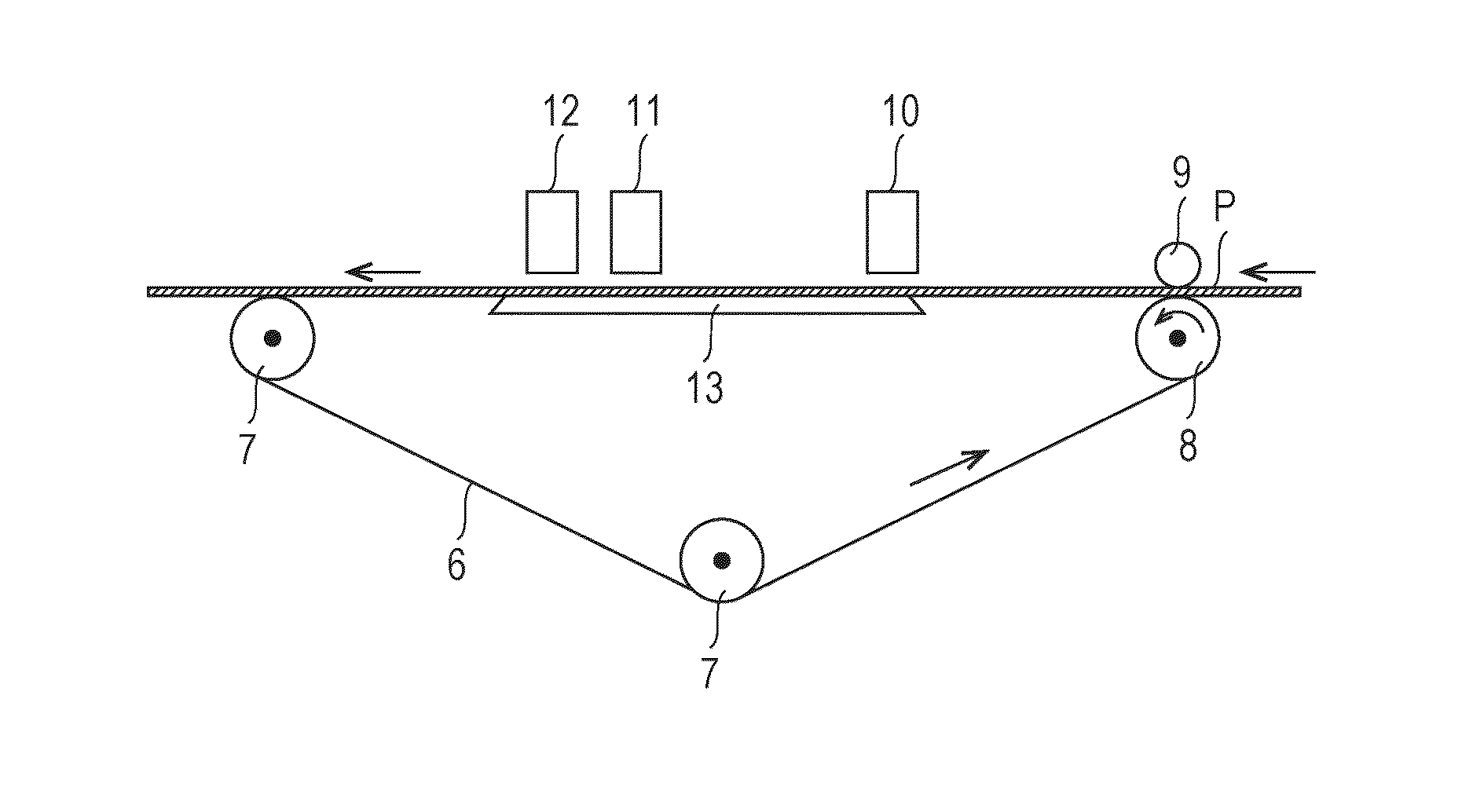

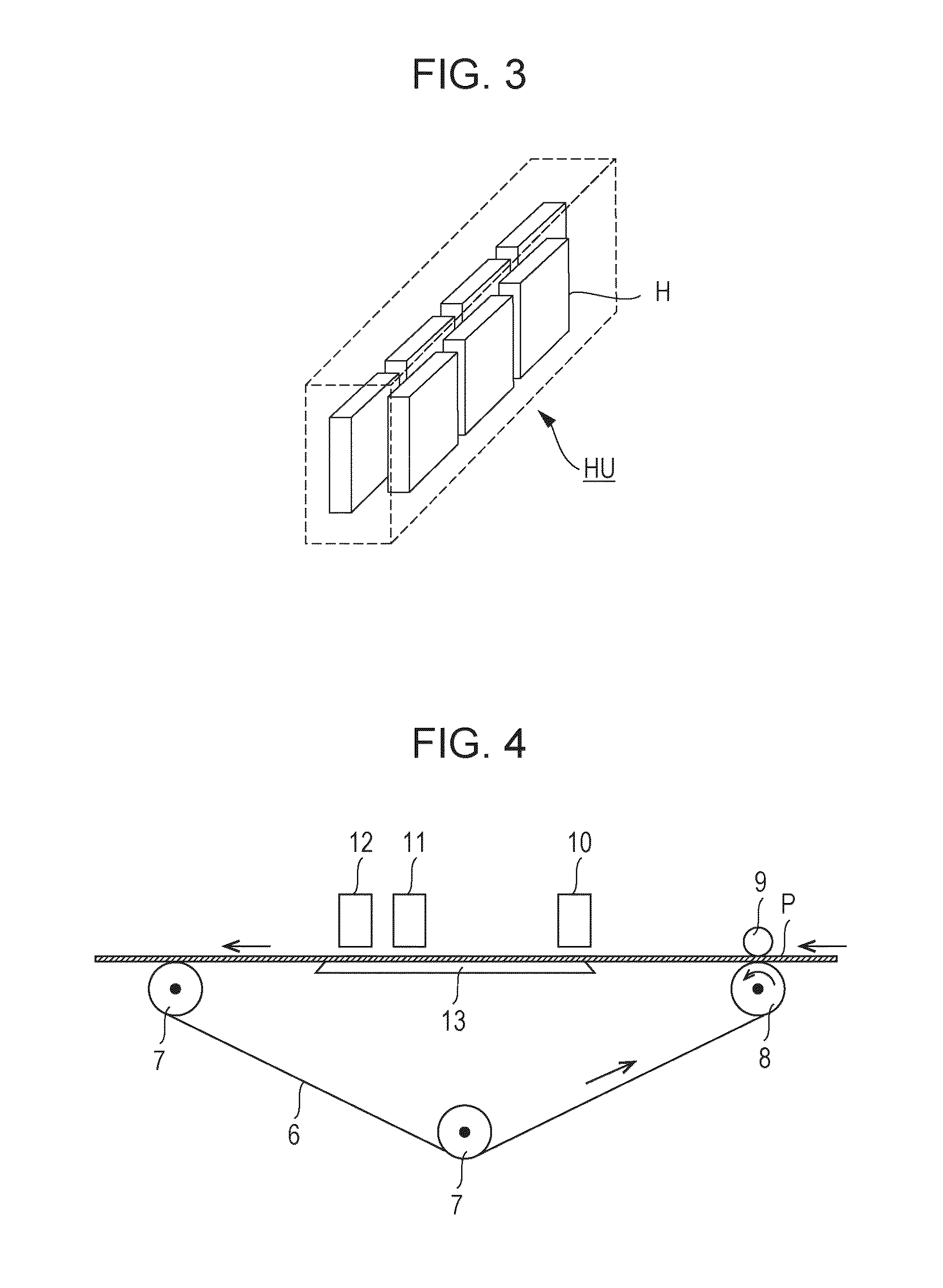

Apparatus and method for the automated marking of defects on webs of material

ActiveUS20050232475A1Conveniently performedReduce material wasteMarking textilesInspecting textilesEngineering

A system for the characterization of webs that permits the identification of anomalous regions on the web to be performed at a first time and place, and permits the localization and marking of actual defects to be performed at a second time and place.

Owner:3M INNOVATIVE PROPERTIES CO

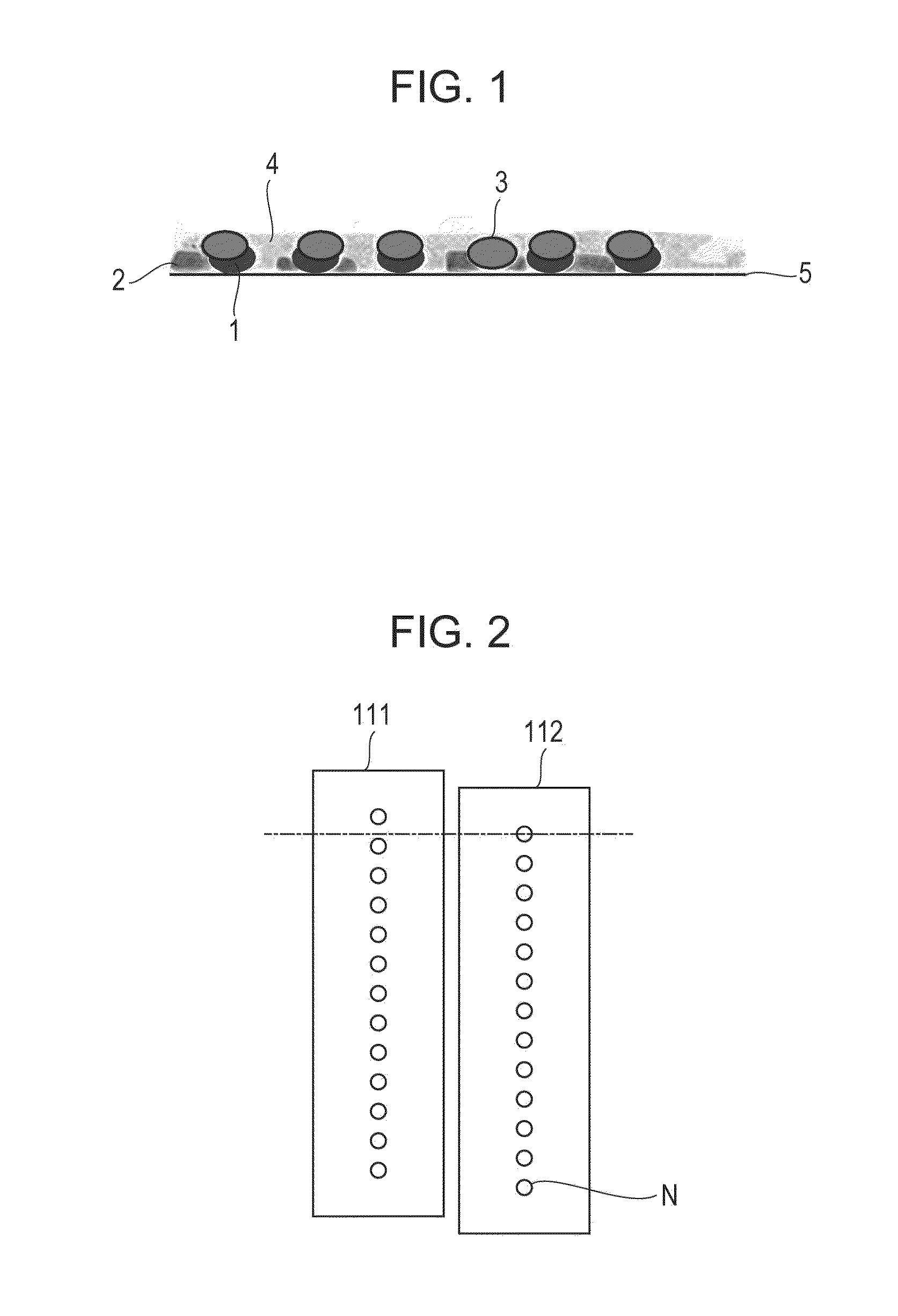

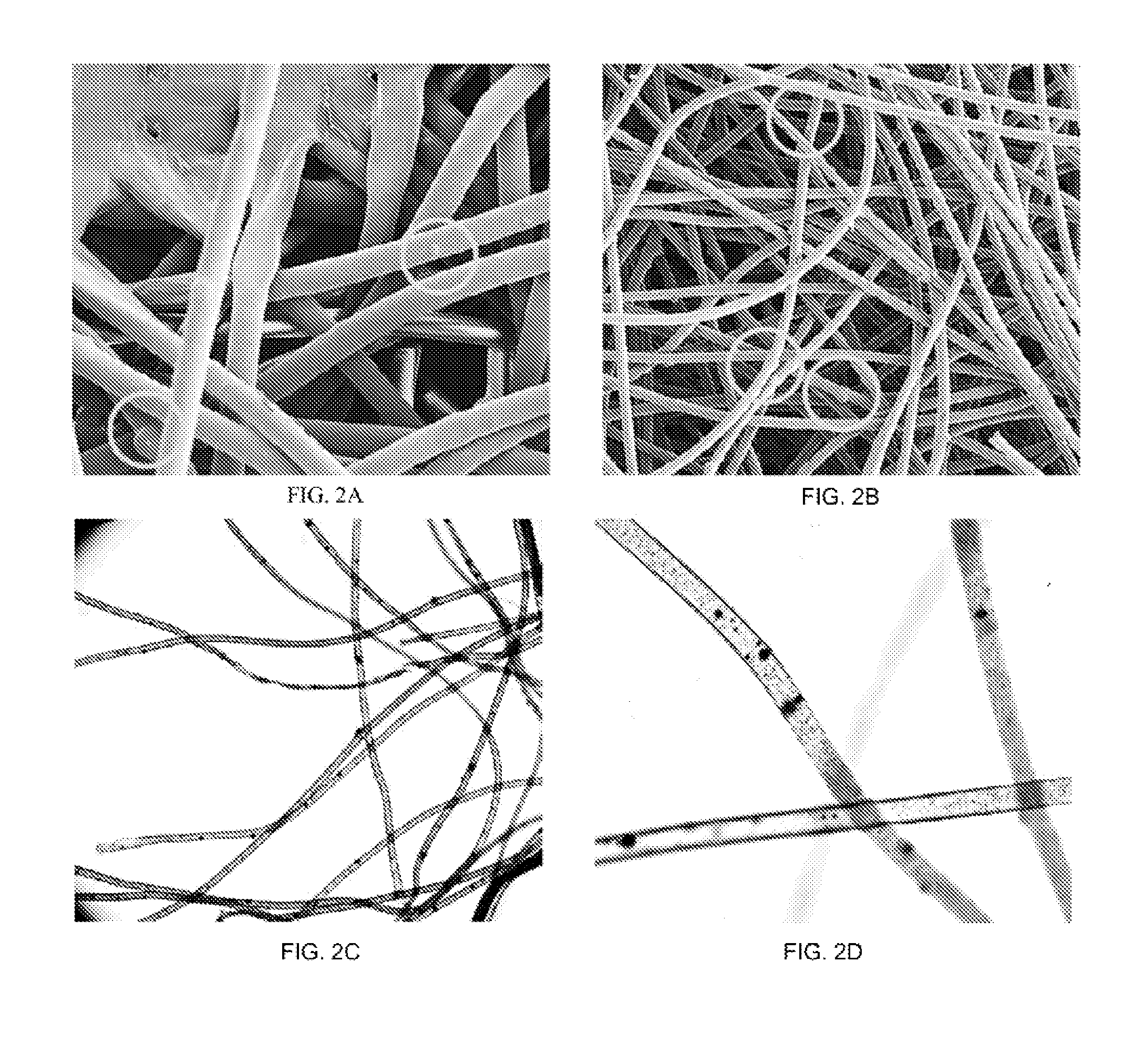

Taggant fibers

InactiveUS20050227068A1Less noticeable in useLikely to degradeMarking textilesFilament/thread formingMaterials sciencePolymer

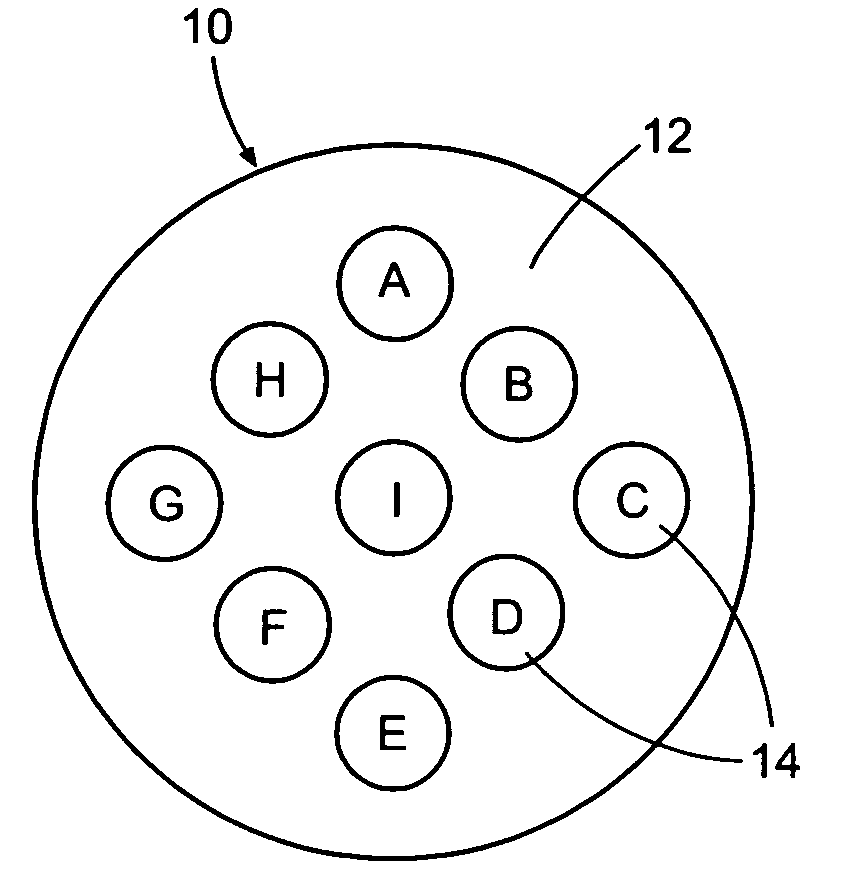

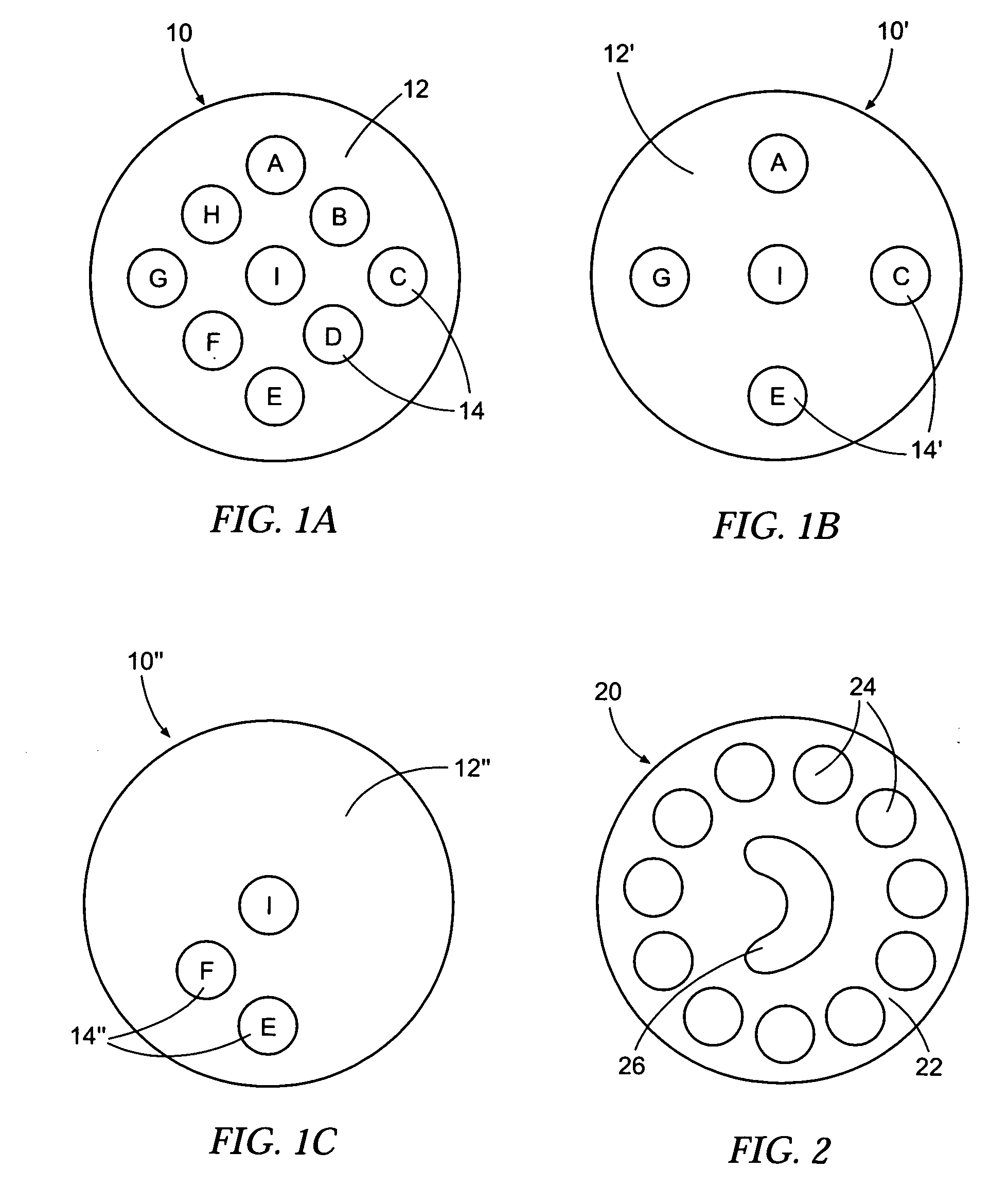

Multicomponent fibers are provided that include a plurality of coextruded polymeric components arranged in discrete structured domains. The polymer domains have one or more identifying characteristics that can be varied to form a plurality of different identifying patterns. A plurality of islands in the sea fibers can be provided, the plurality of fibers including two or more subsets of fibers, each subset comprising a uniquely identifiable cross sectional pattern of island domains, each pattern being formed from an array comprising a predetermined number of island domains in predetermined locations within the array, wherein each pattern is determined by classifying individual island domains within the array as present or absent from the pattern. The plurality of fibers can be meltspun simultaneously to form a filament yarn or tow.

Owner:FIBER INNOVATION TECH

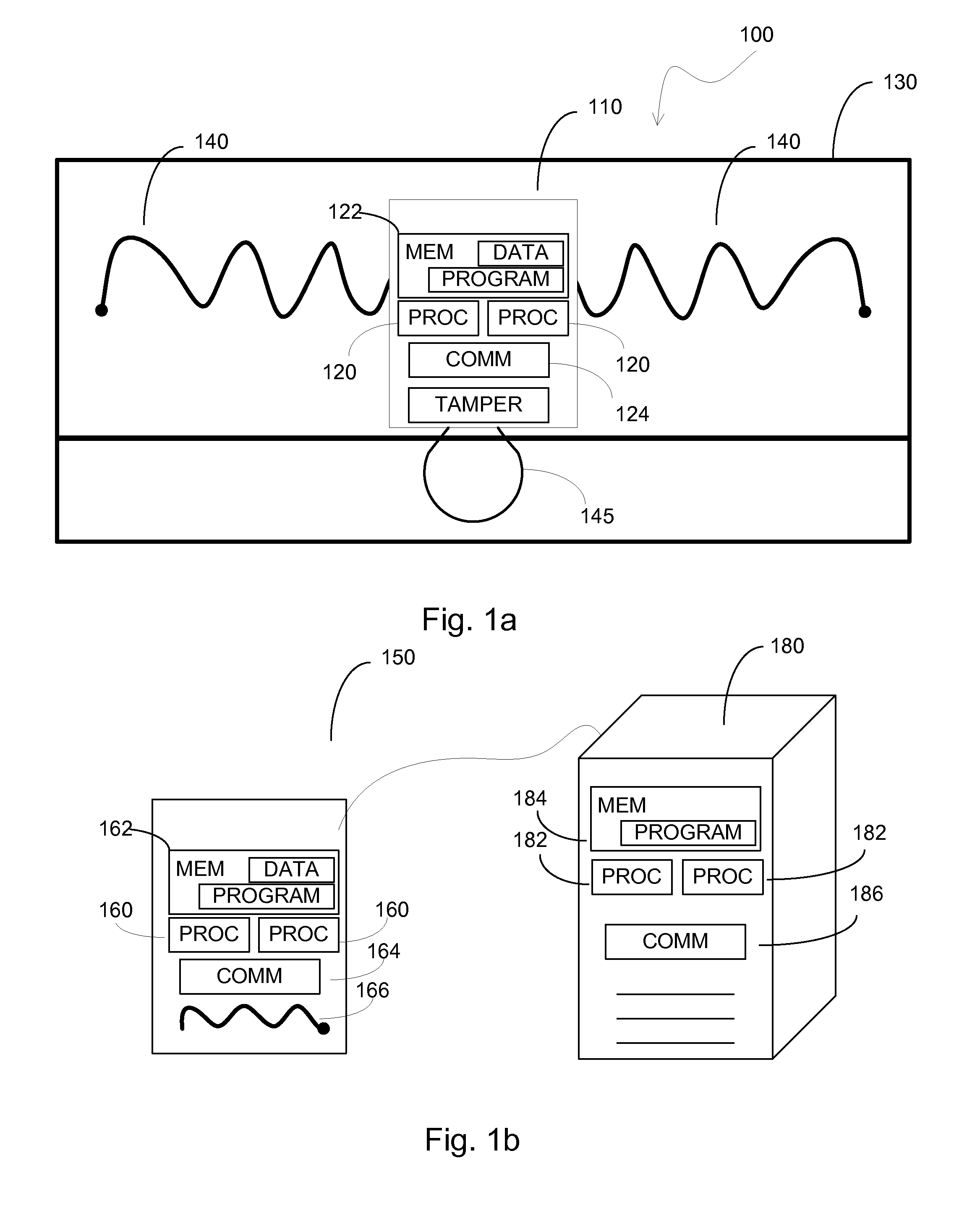

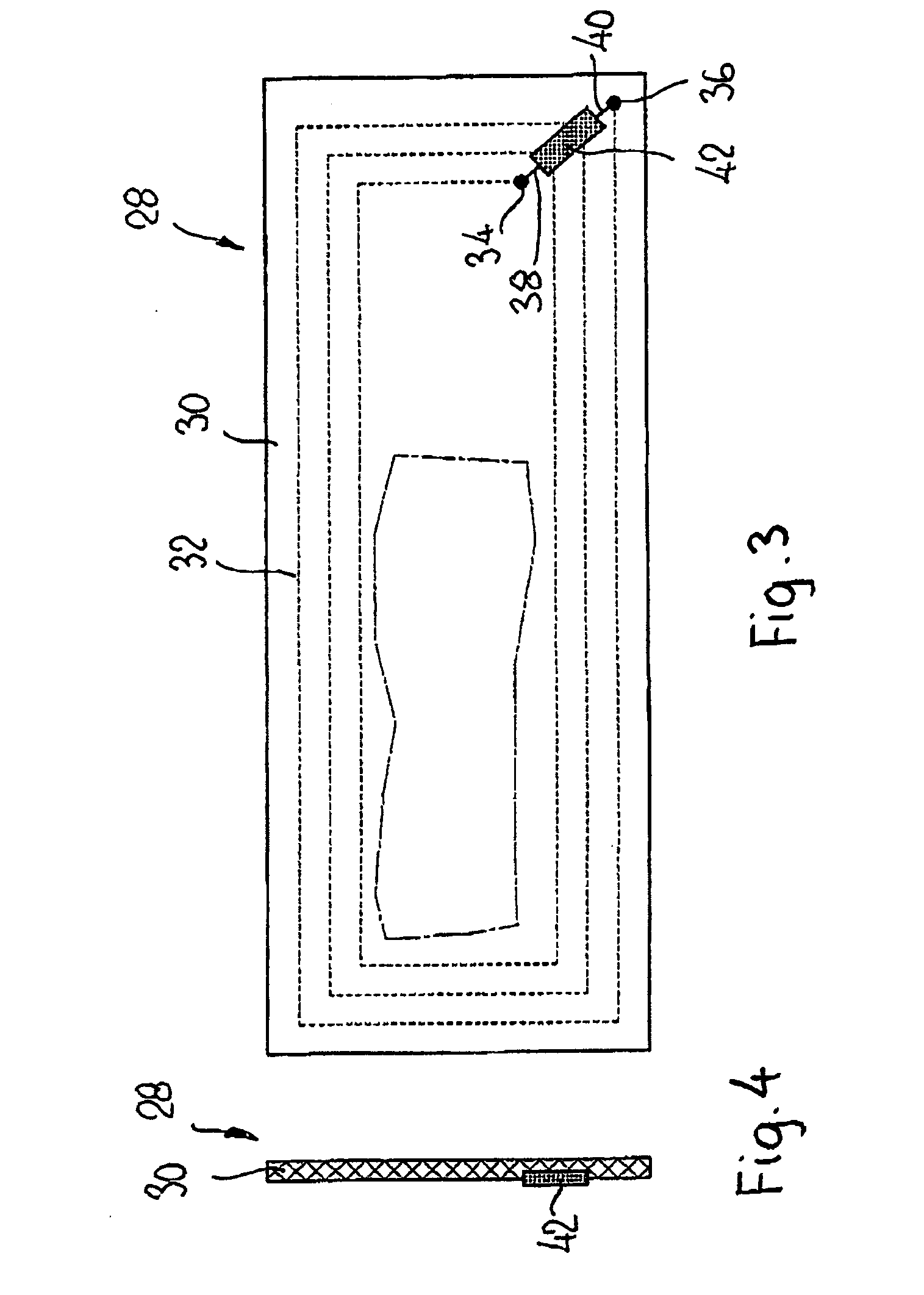

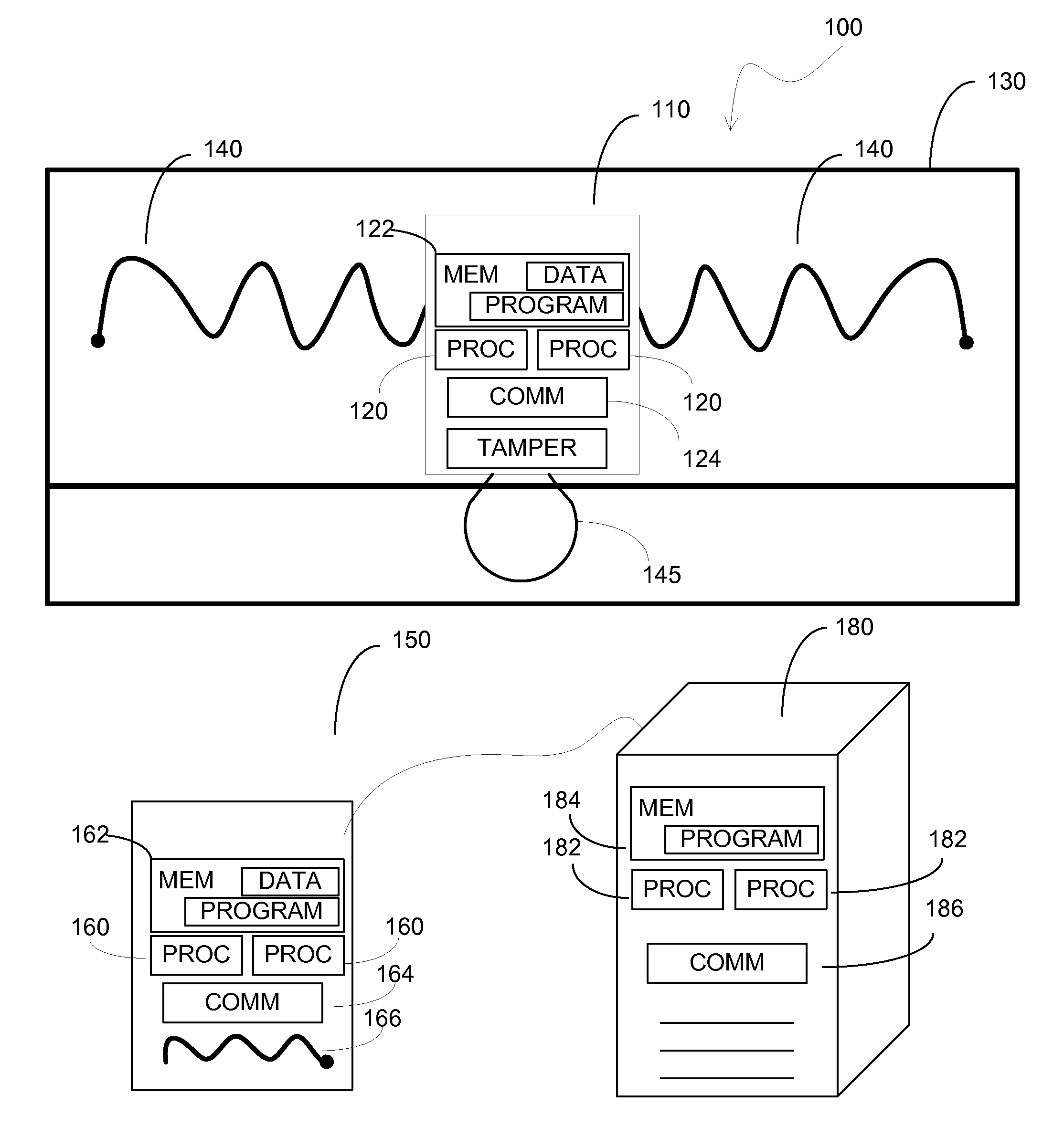

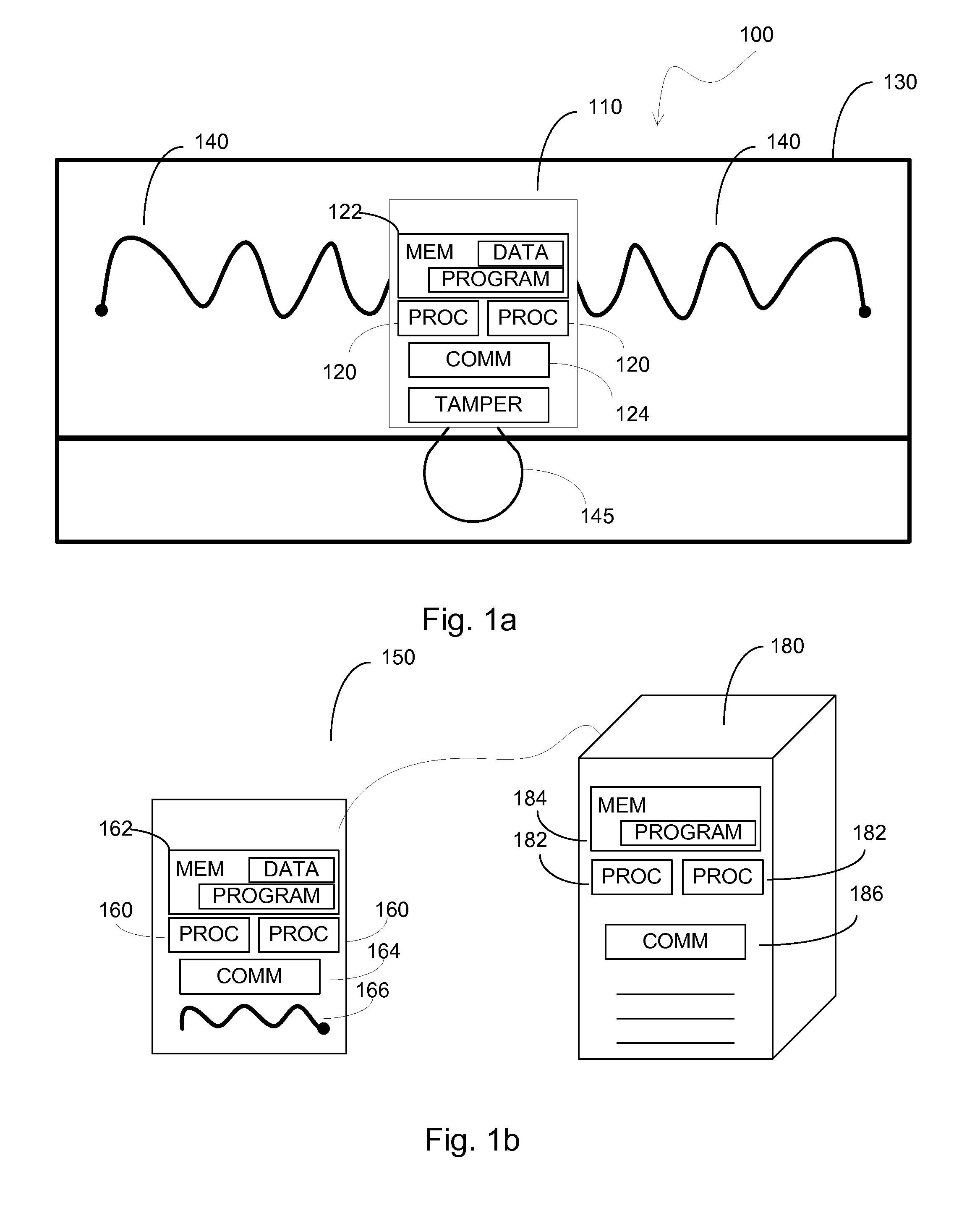

Transponder with tamper protection

InactiveUS20140263659A1Avoid breakingEasily and reliably attached to itemStampsMarking textilesEngineeringAntenna element

The invention relates to sewable tamper detection elements for radio frequency identification devices, and to radio frequency identification devices with such tamper detection elements. The devices can be sewn into a seam of a garment so that the tamper detection element is partially inside the garment, e.g. as part of a care label. This makes removing the device difficult without breaking the tamper detection element, and thereby shoplifting attempts can be more reliably noticed. For this purpose, the tamper detection element is formed so that sewing through it does not break the element. The radio frequency identification device may be formed asymmetric so that the tamper detection element is on a different side from the antenna elements with respect to the chip. In this manner, the disturbance from the tamper detection element to the antenna can be minimized. The tamper detection element may be formed so that it contains a transparent opening on which text can be printed.

Owner:SMARTRAC INVESTMENT BV

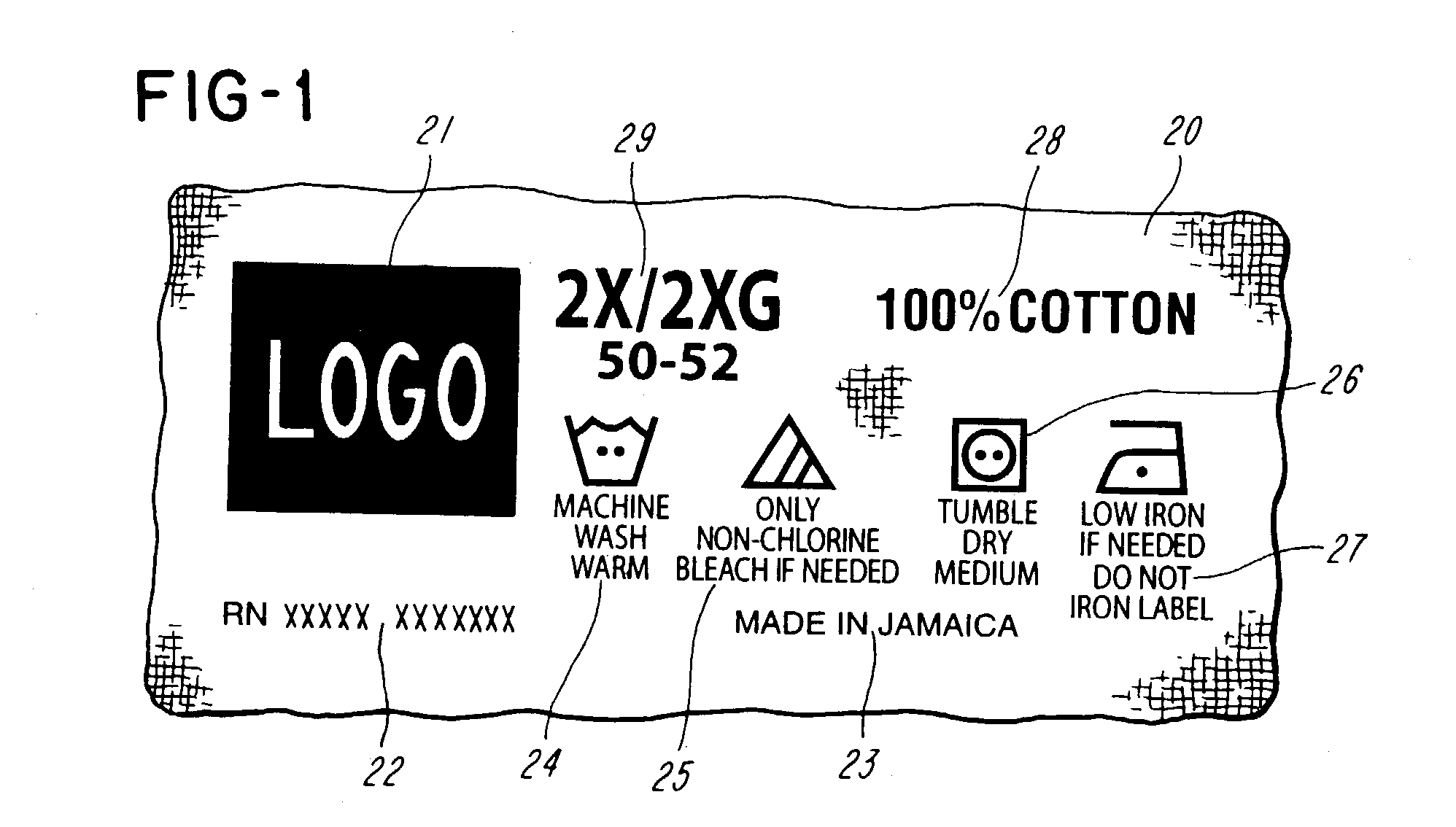

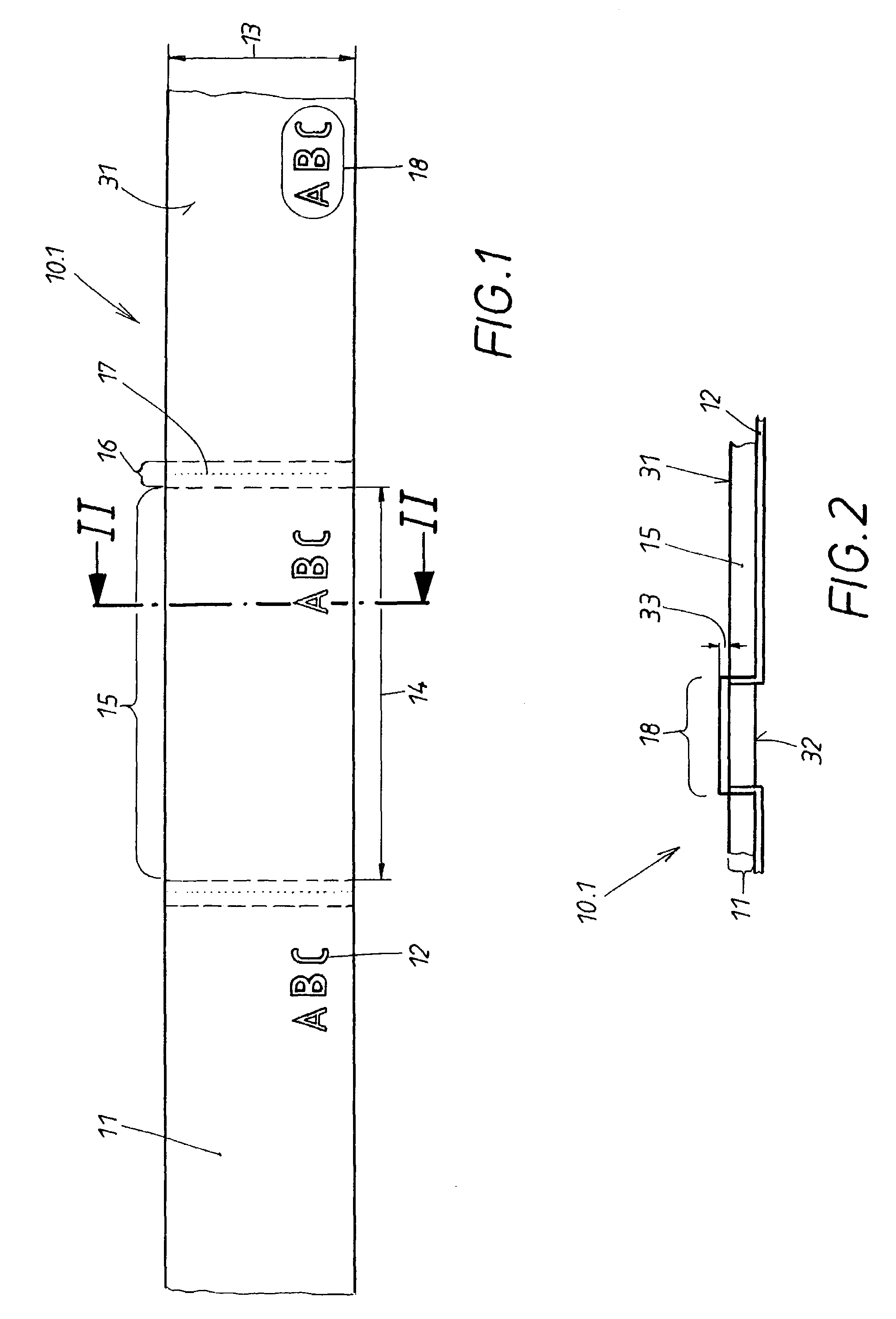

Heat-transfer label well-suited for labeling fabrics and methods of making and using the same

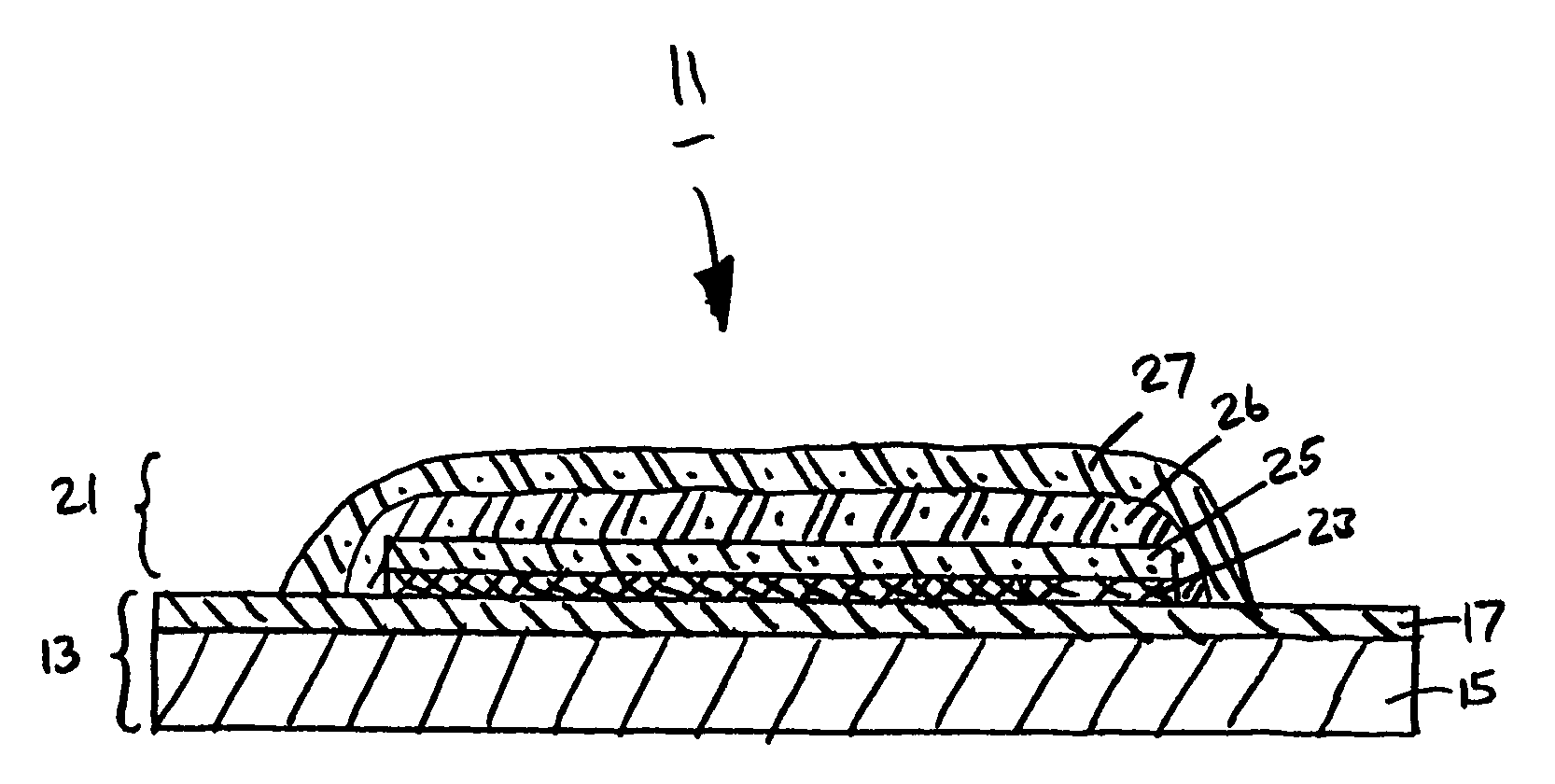

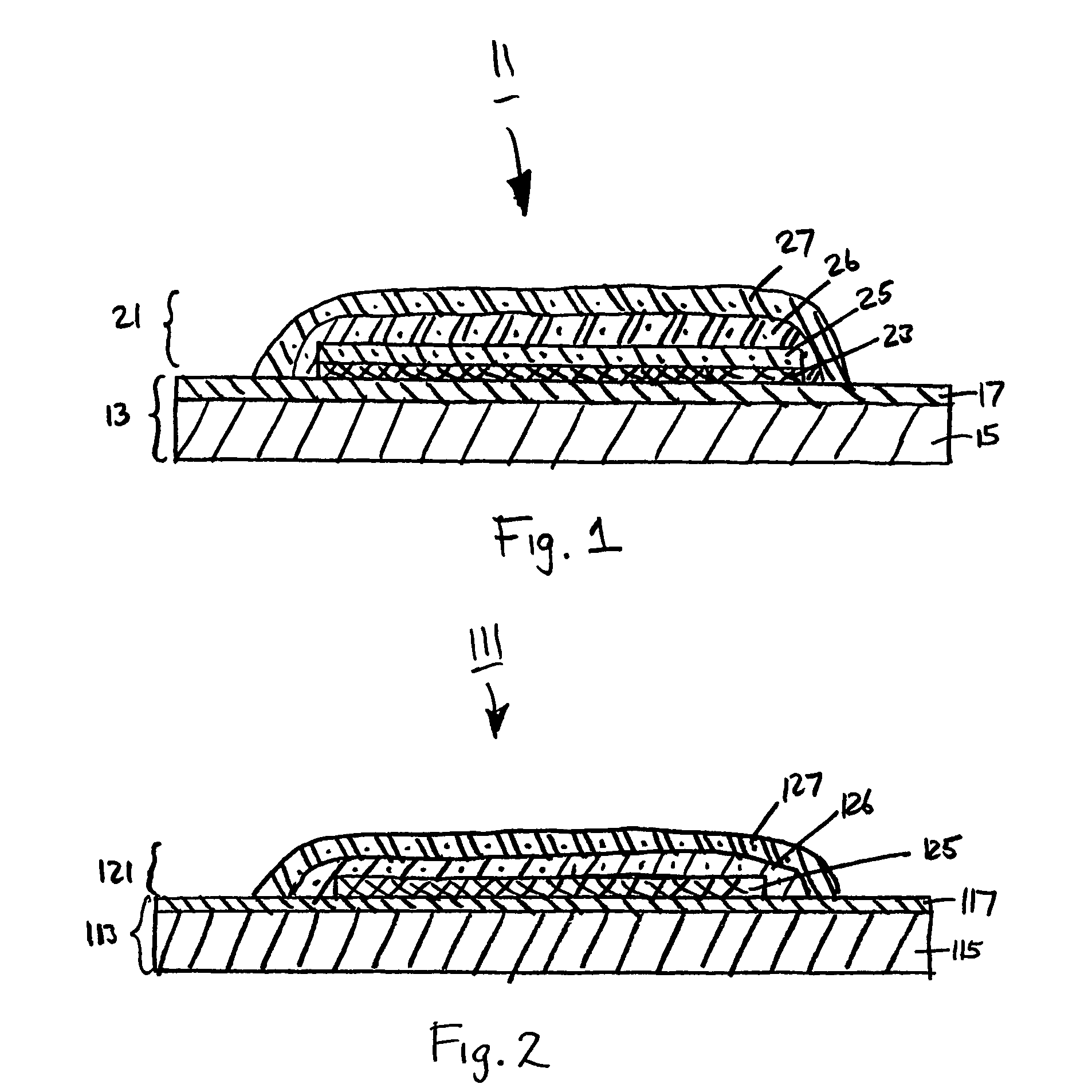

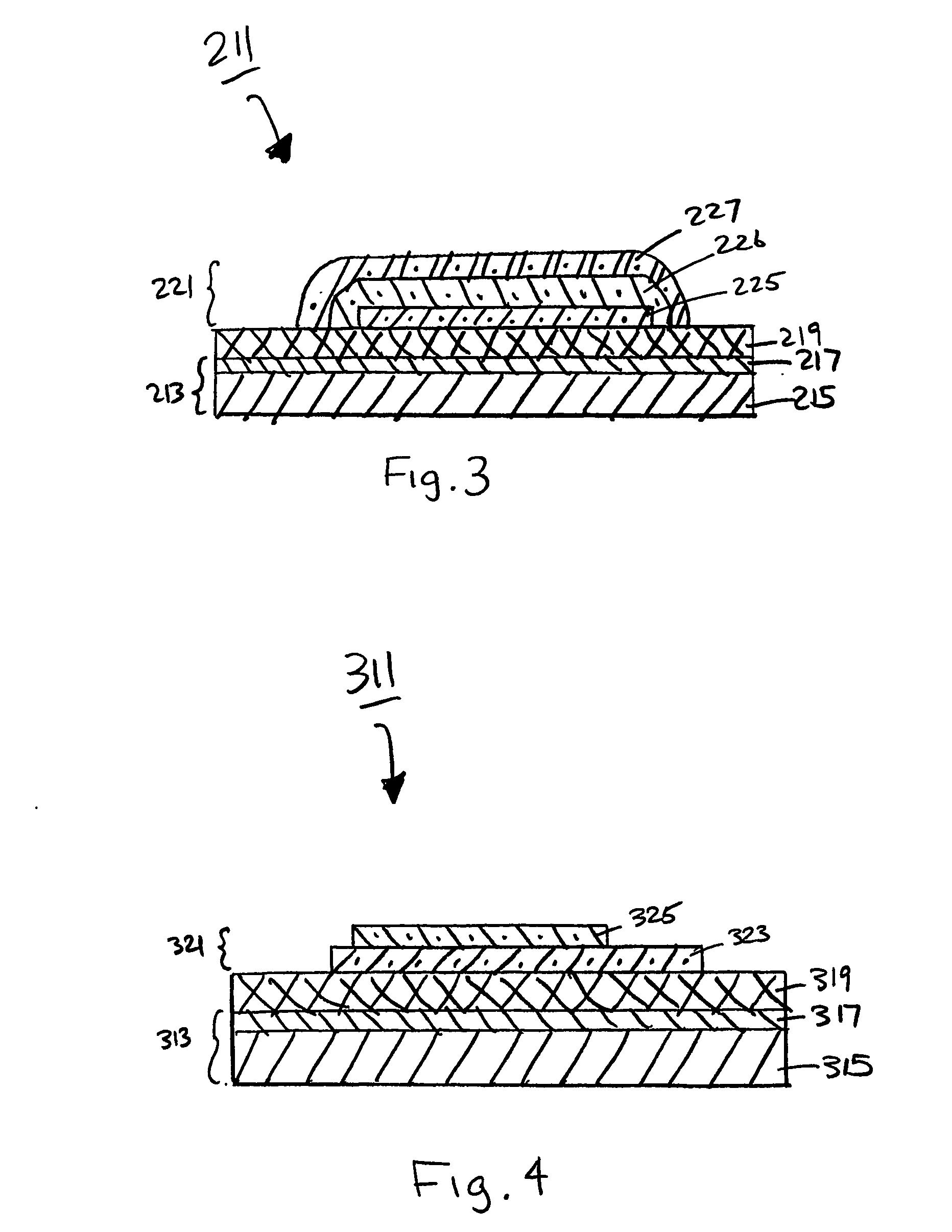

A method for labeling fabrics, such as fabric garments, and a heat-transfer label well-suited for use in said method. In one embodiment, the heat-transfer label comprises (i) a support portion, the support portion comprising a carrier and a release layer; (ii) a wax layer, the wax layer overcoating the release layer; and (iii) a transfer portion, the transfer portion comprising an adhesive layer printed onto the wax layer and an ink design layer printed onto the adhesive layer. Preferably, at least a portion of the ink design layer is printed using a variable printing technique, such as thermal transfer printing.

Owner:AVERY DENNISON CORP

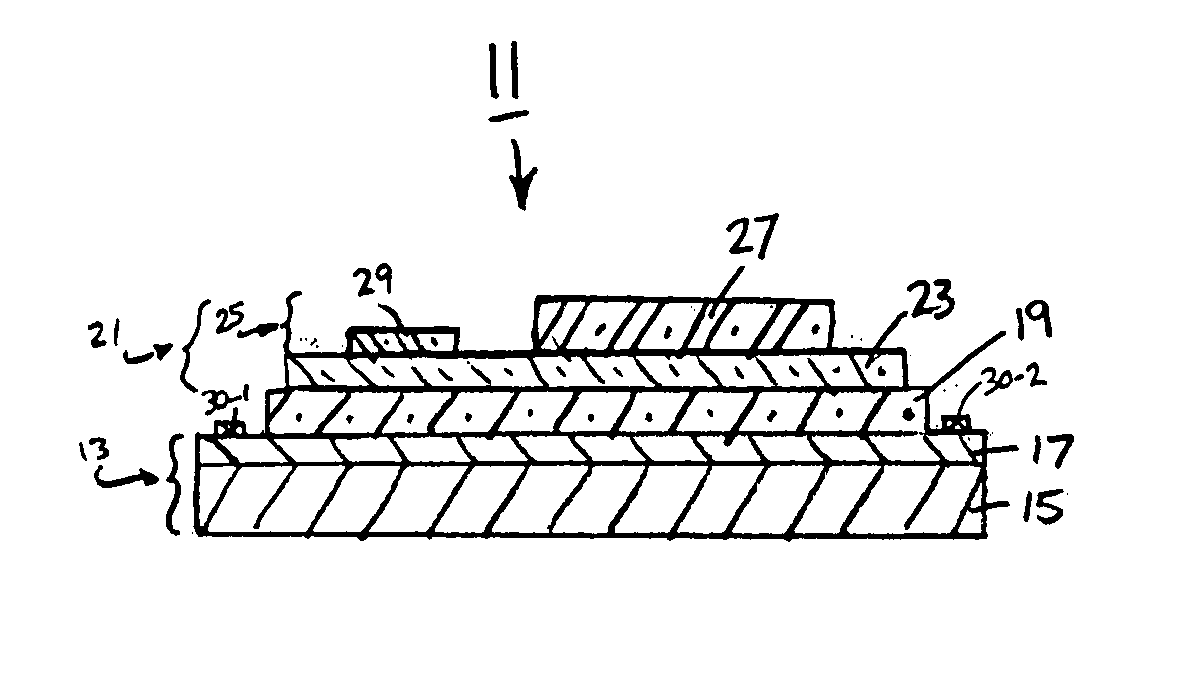

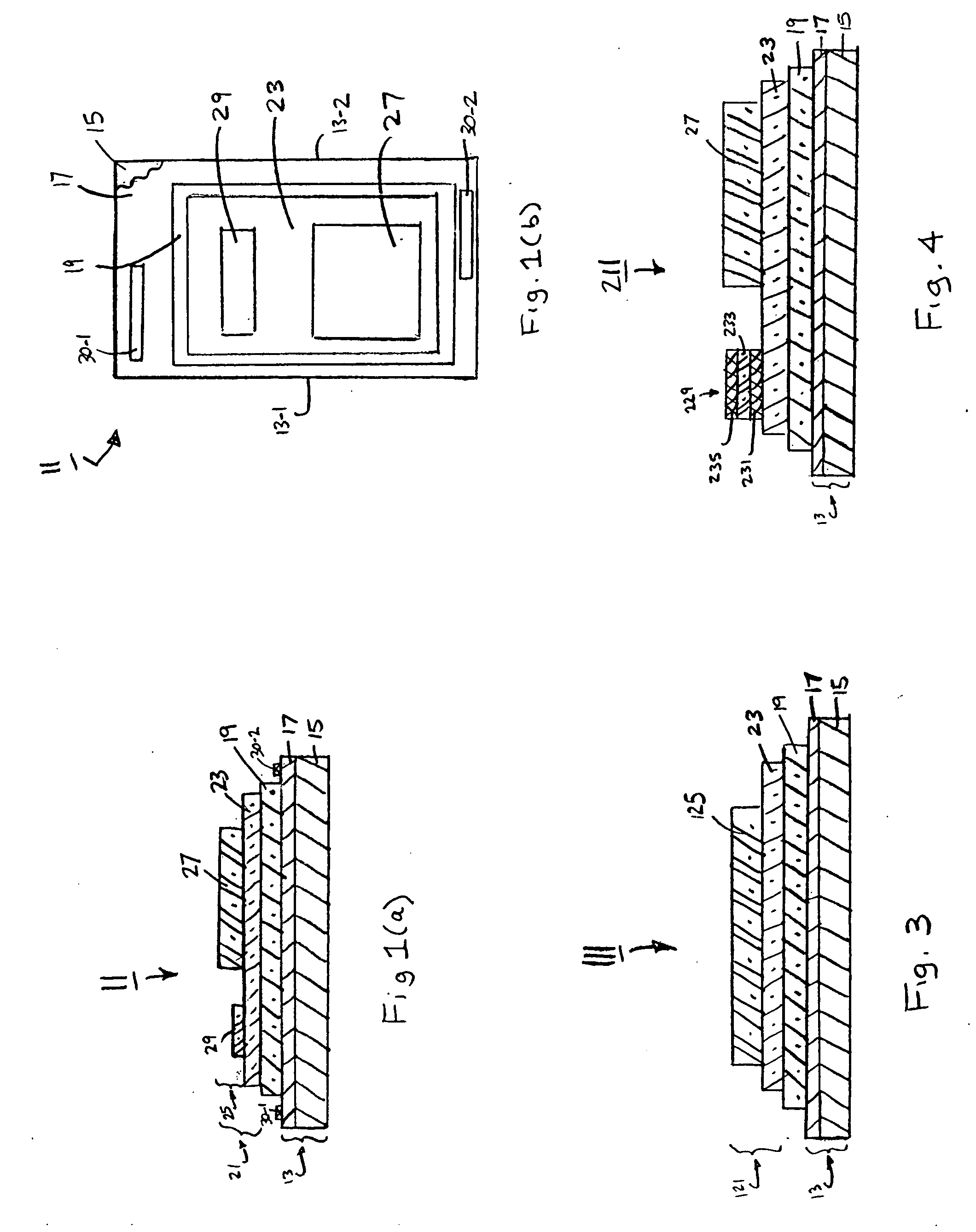

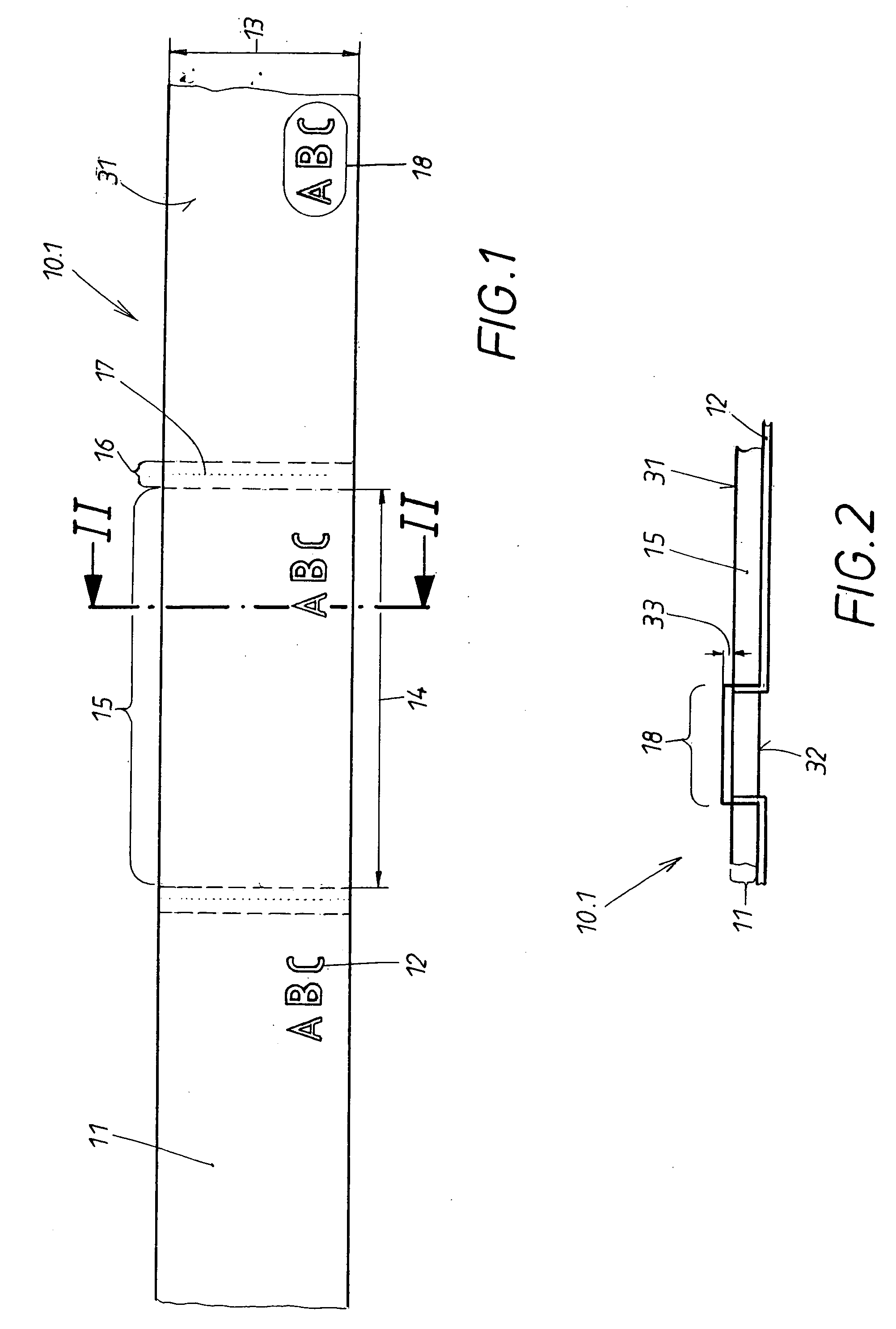

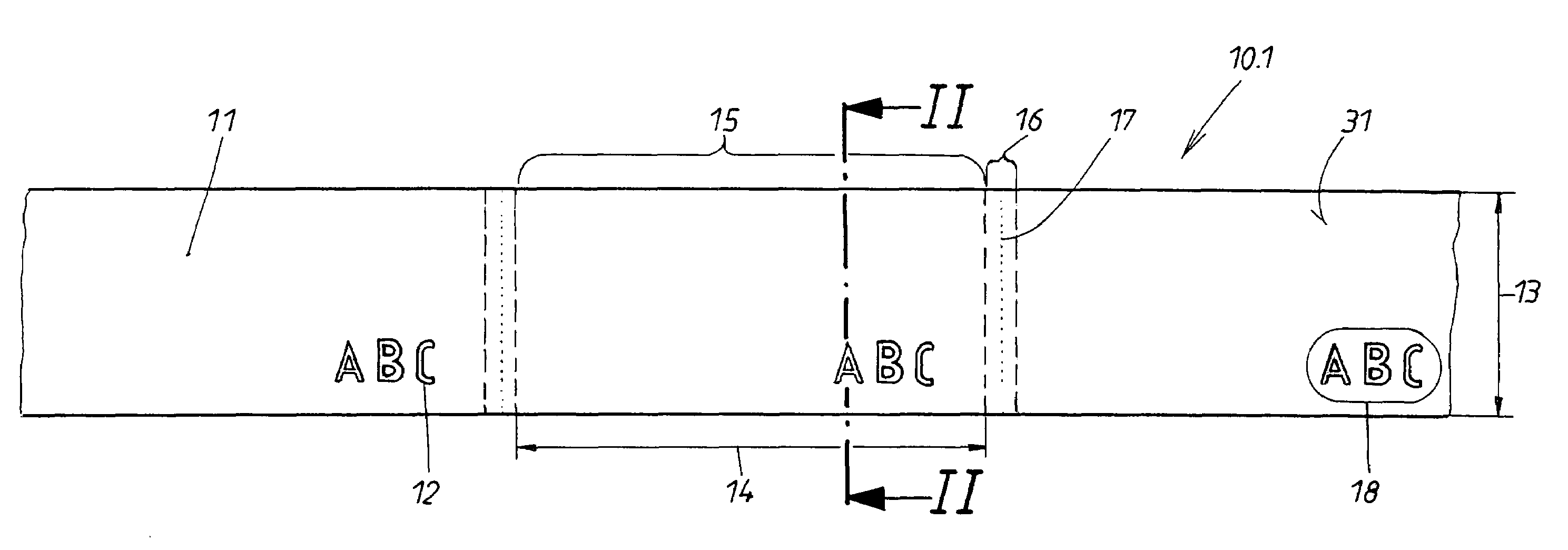

Method for labeling fabrics and heat-transfer label well-suited for use in said method cross-reference to related applications

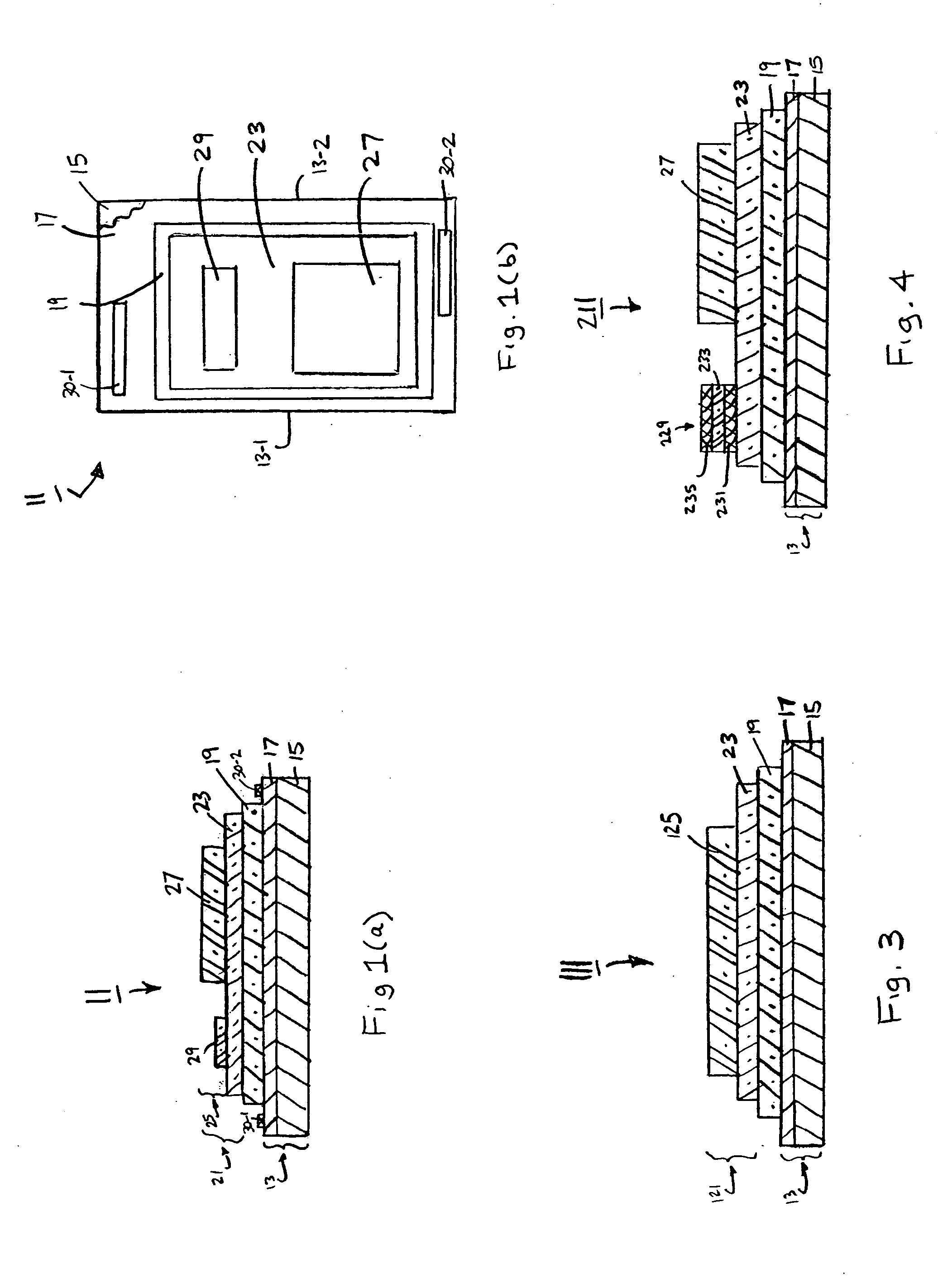

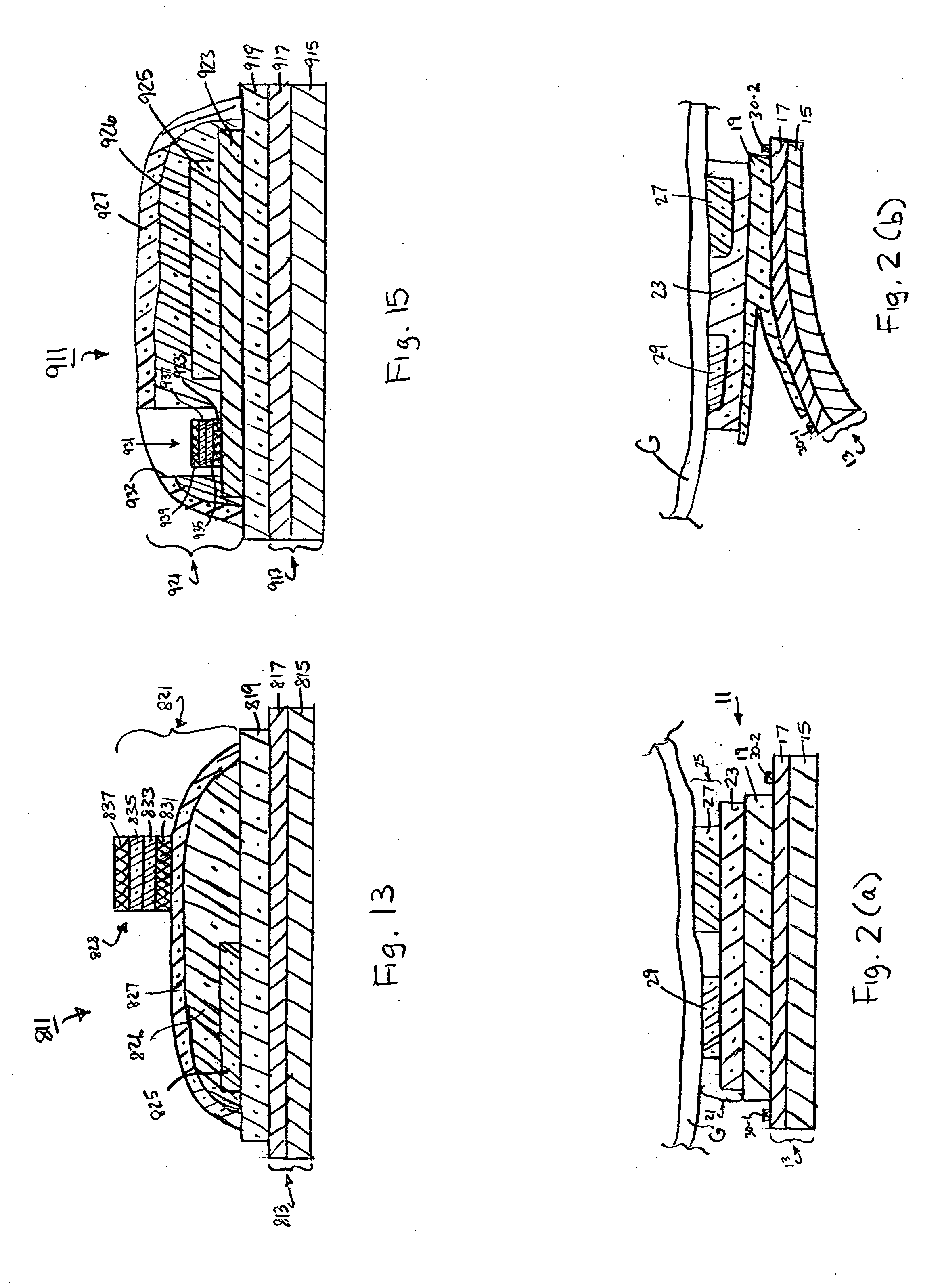

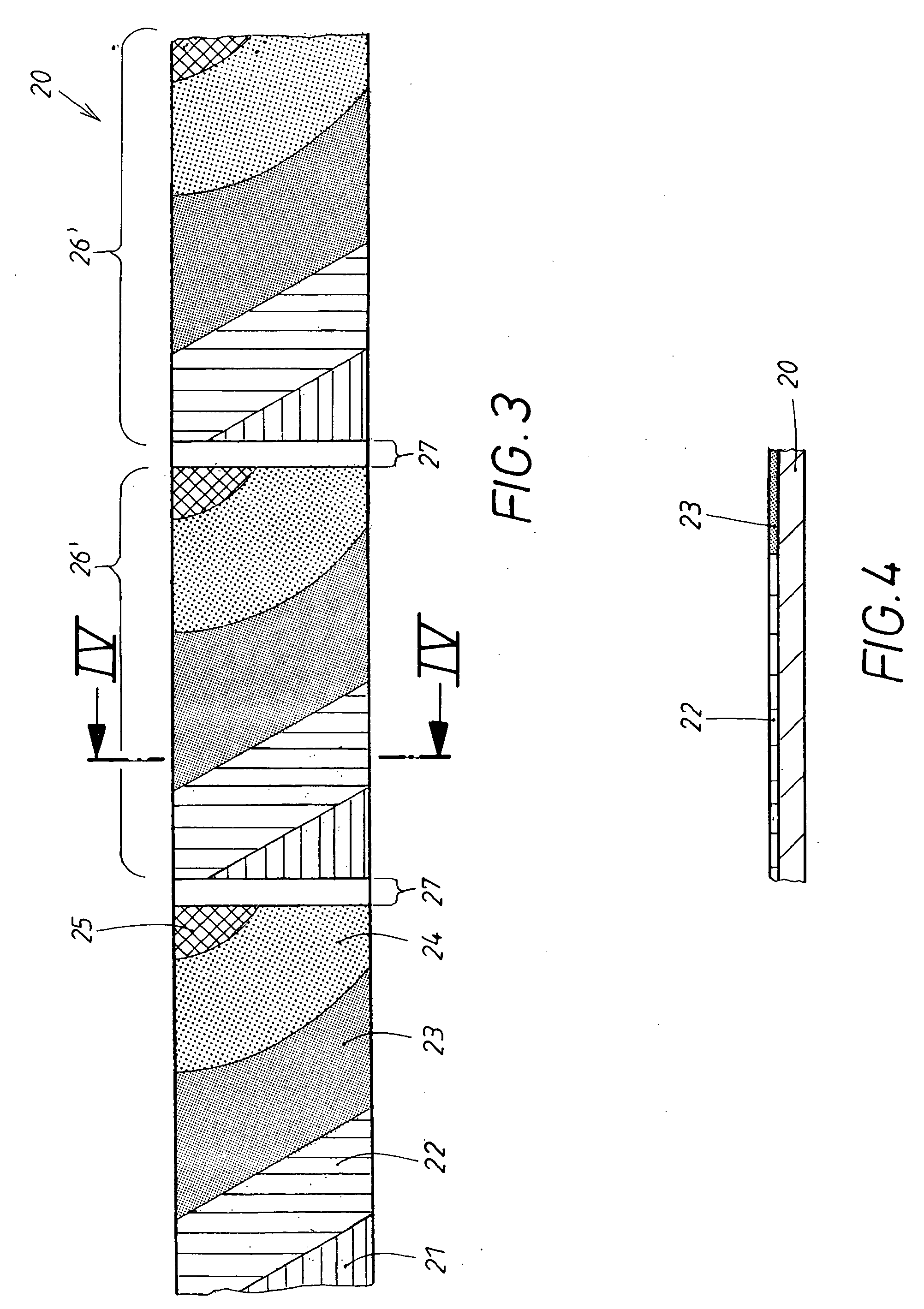

A method for labeling fabrics, such as fabric garments, and a heat-transfer label (311) well-suited for use in said method. In one embodiment, the heat-transfer label (311) comprises (i) a support portion (313), the support portion (313) comprising a carrier (315) and a release layer (317); (ii) a wax layer (319), the wax layer overcoating the release layer (317); and (iii) a transfer portion (321), the transfer portion (321) comprising an adhesive layer (323) printed directly onto the wax layer (319) and an ink design layer (325) printed directly onto the adhesive layer (323). Each of the adhesive layer (323) and the ink design layer includes a non-cross-linked PVC resin. The ink design layer may be screen printed onto the adhesive layer (323) or may be printed onto the adhesive layer (323) using thermal transfer printing, ink jet printing or laser printing.

Owner:AVERY DENNISON CORP

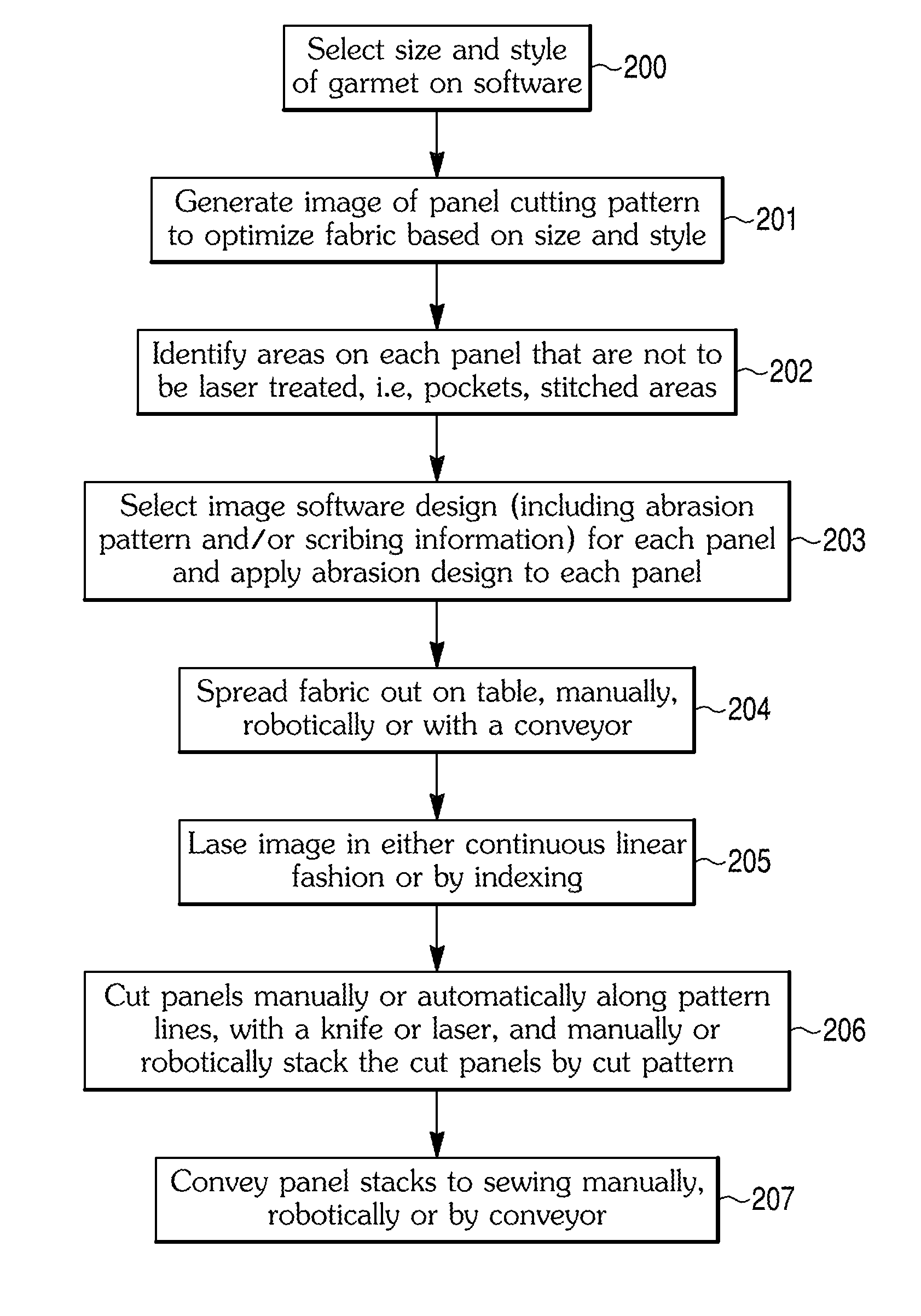

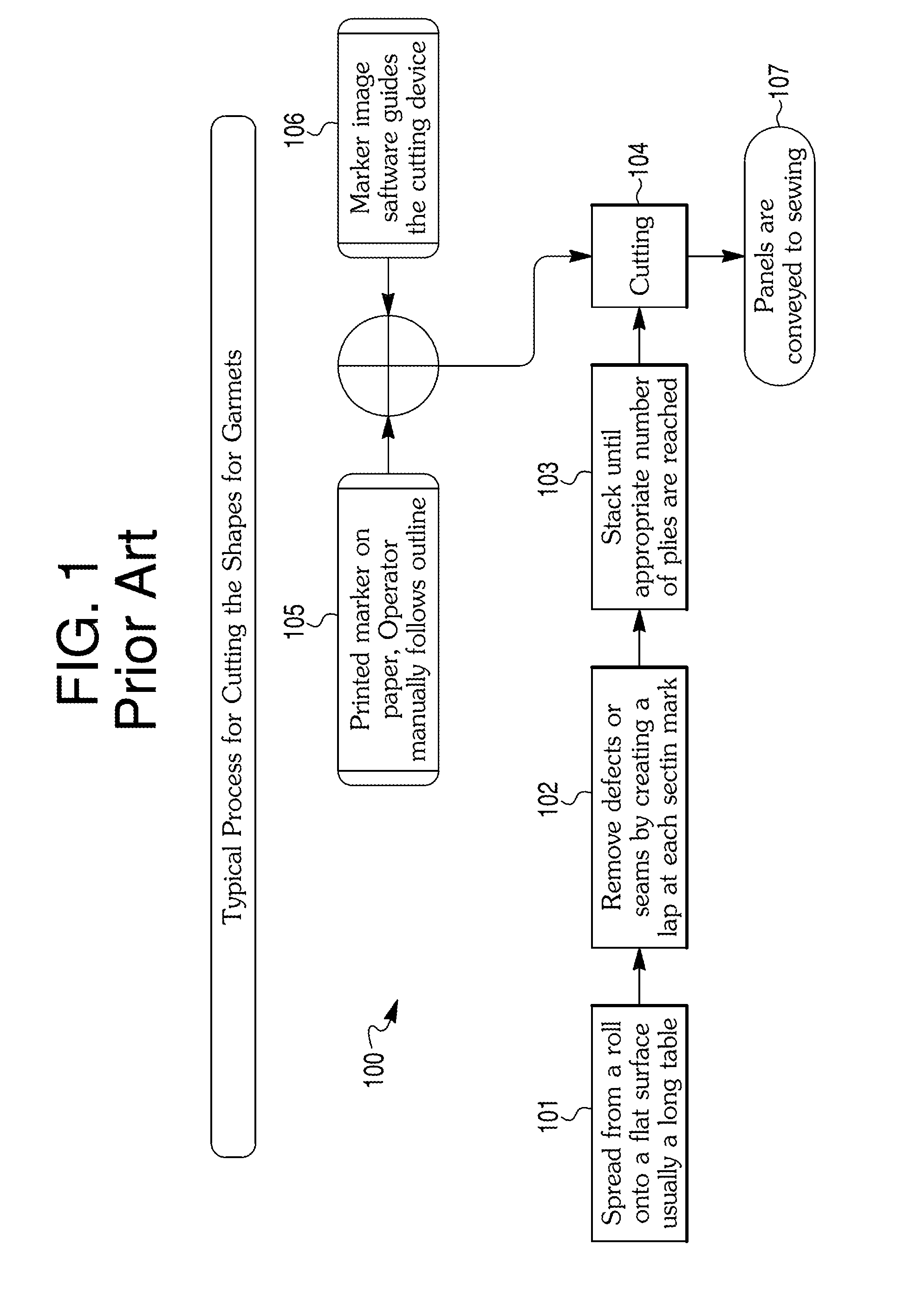

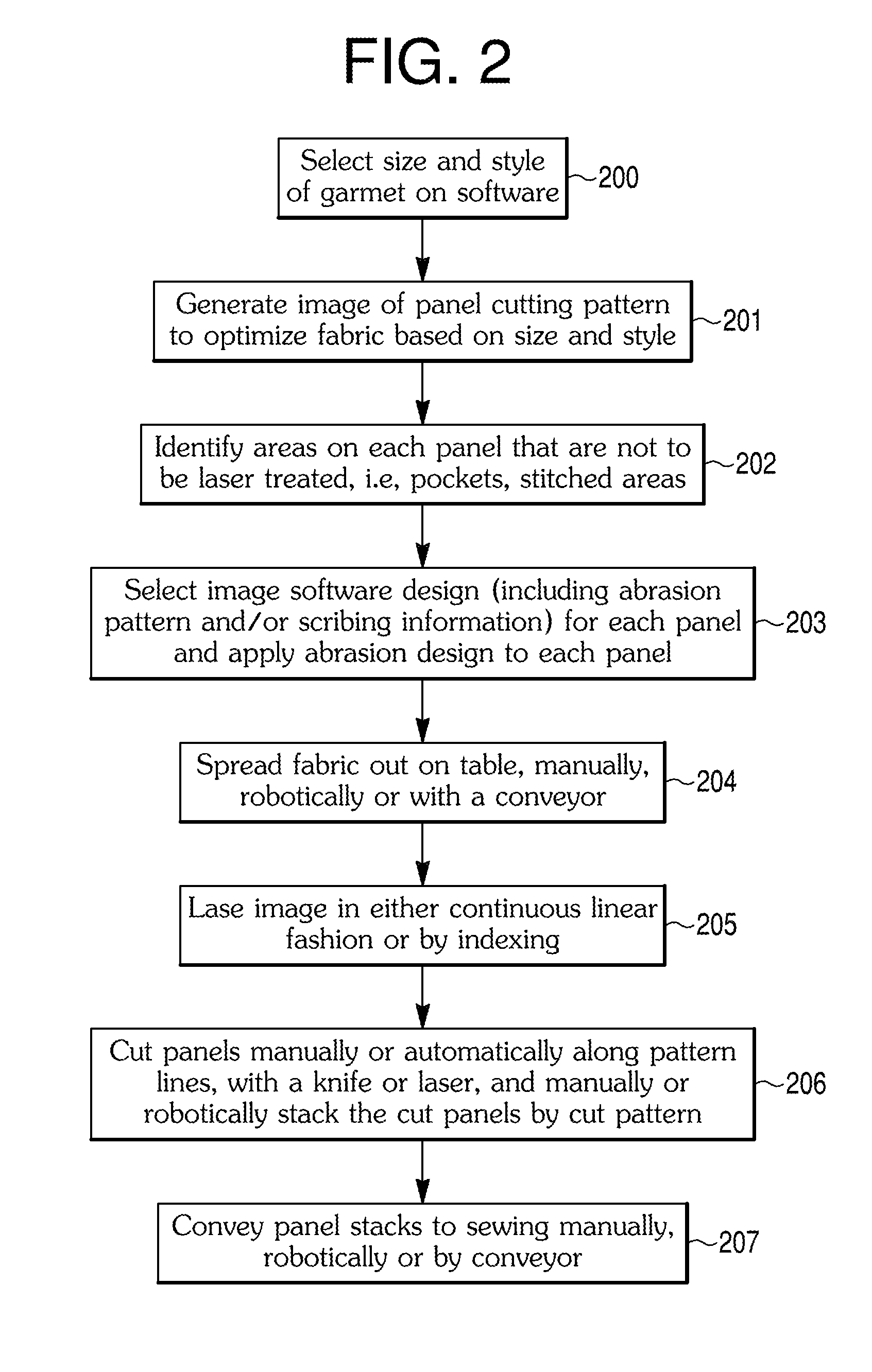

System and method of generating a pattern or image on fabric with linear laser irradiation, fabric made by said method, and products made with said fabric

A method of scribing abrasion aesthetics, patterns, images, serial numbers, ply markings and / or other information, such as sizing or care information, on fabric such as denim, before or during the fabric cutting process is provided. The method comprises loading the panel abrasion software, pattern marker software, and fabric scribing software; placing the fabric on a flat surface under at least one laser; laser scribing ply numbers, serial labels, fabric markers, and panel abrasions on the fabric; cutting the fabric into fabric lengths; spreading the pre-abraded and pre-marked fabric lengths on top of each other to create multiple plies in precise alignment; cutting shaped panels along the lines of the pattern marker with a conventional knife, laser, or other appropriate cutting tool; and stacking the abraded, labeled and shaped panels robotically or manually for sewing.

Owner:REVOLAZE LLC

Heat-transfer label well-suited for labeling fabrics and methods of making and using the same

Owner:AVERY DENNISON CORP

Apparatus and method for the automated marking of defects on webs of material

ActiveUS7623699B2Reduce material wasteConveniently performedMarking textilesInspecting textilesEngineering

A system for the characterization of webs that permits the identification of anomalous regions on the web to be performed at a first time and place, and permits the localization and marking of actual defects to be performed at a second time and place.

Owner:3M INNOVATIVE PROPERTIES CO

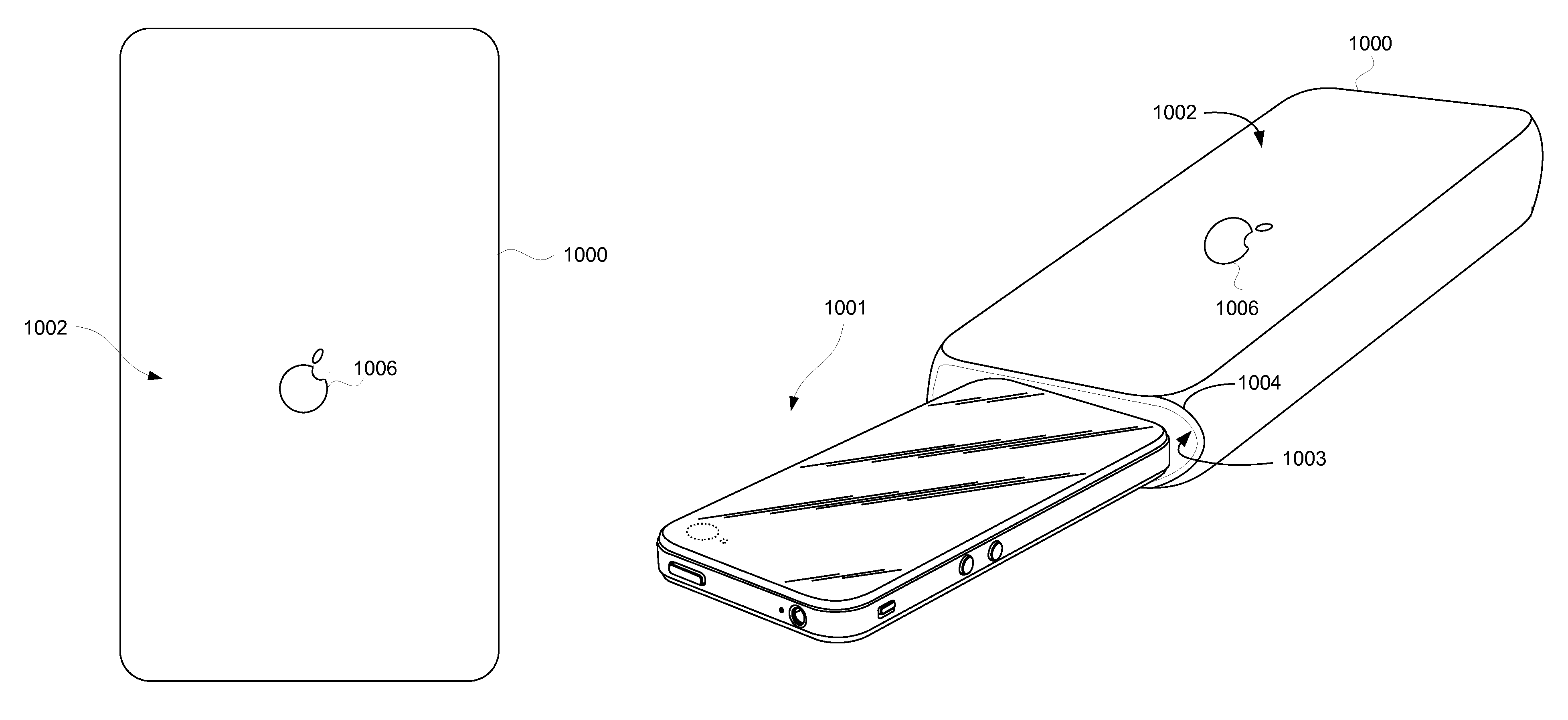

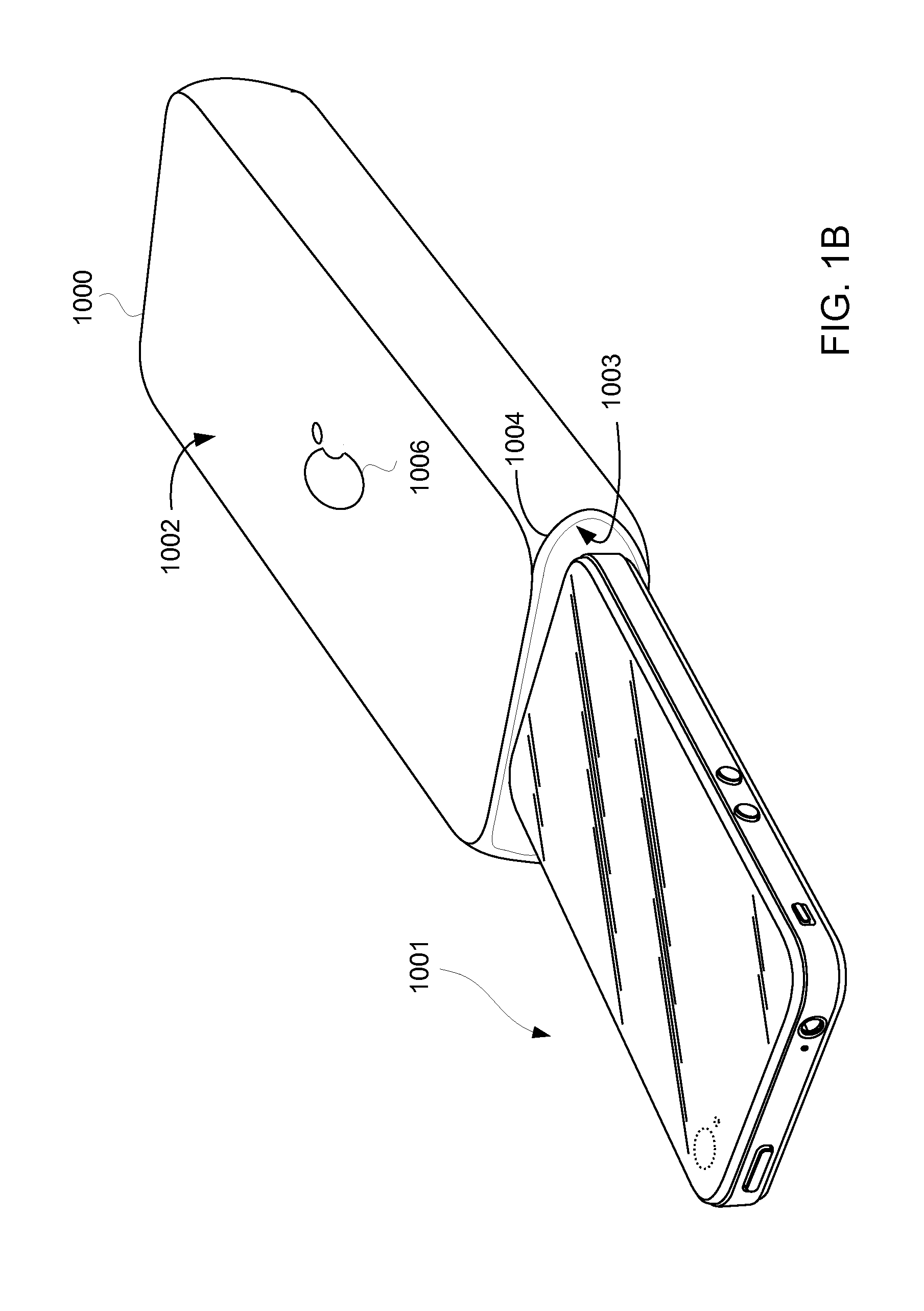

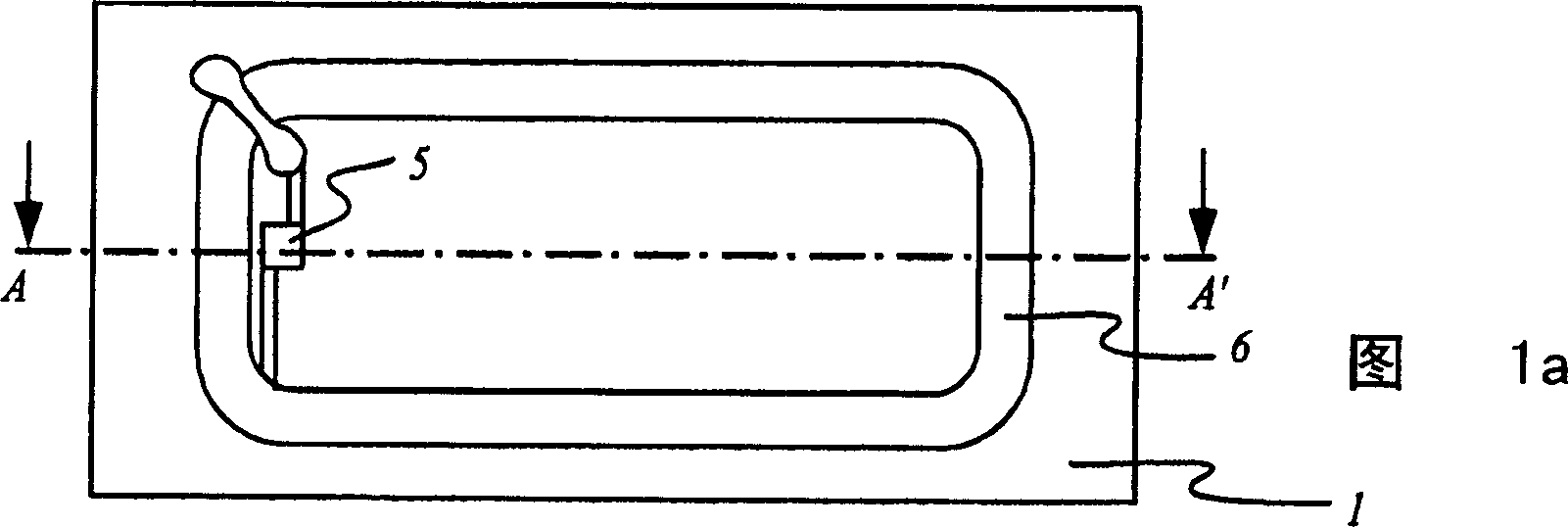

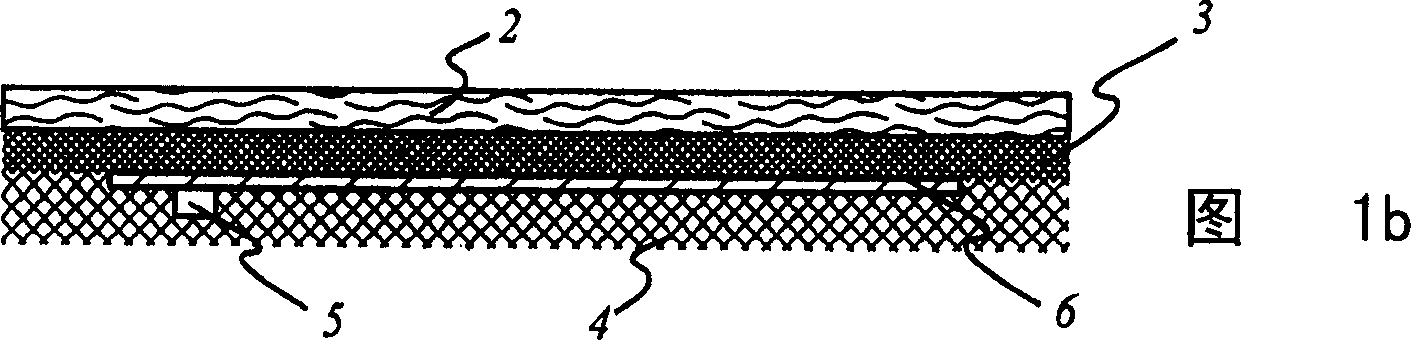

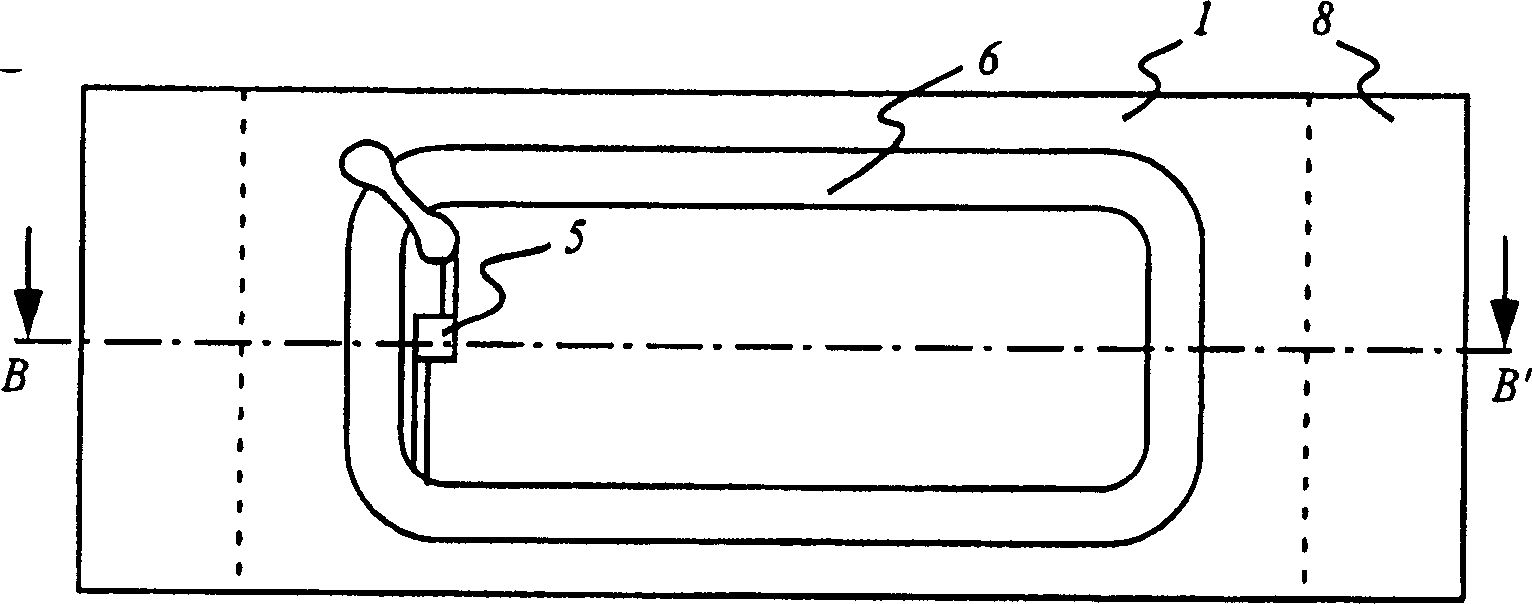

Marking of Fabric Carrying Case for Portable Electronic Device

InactiveUS20120248001A1Lamination ancillary operationsMarking textilesElectric equipmentElectronic equipment

Owner:APPLE INC

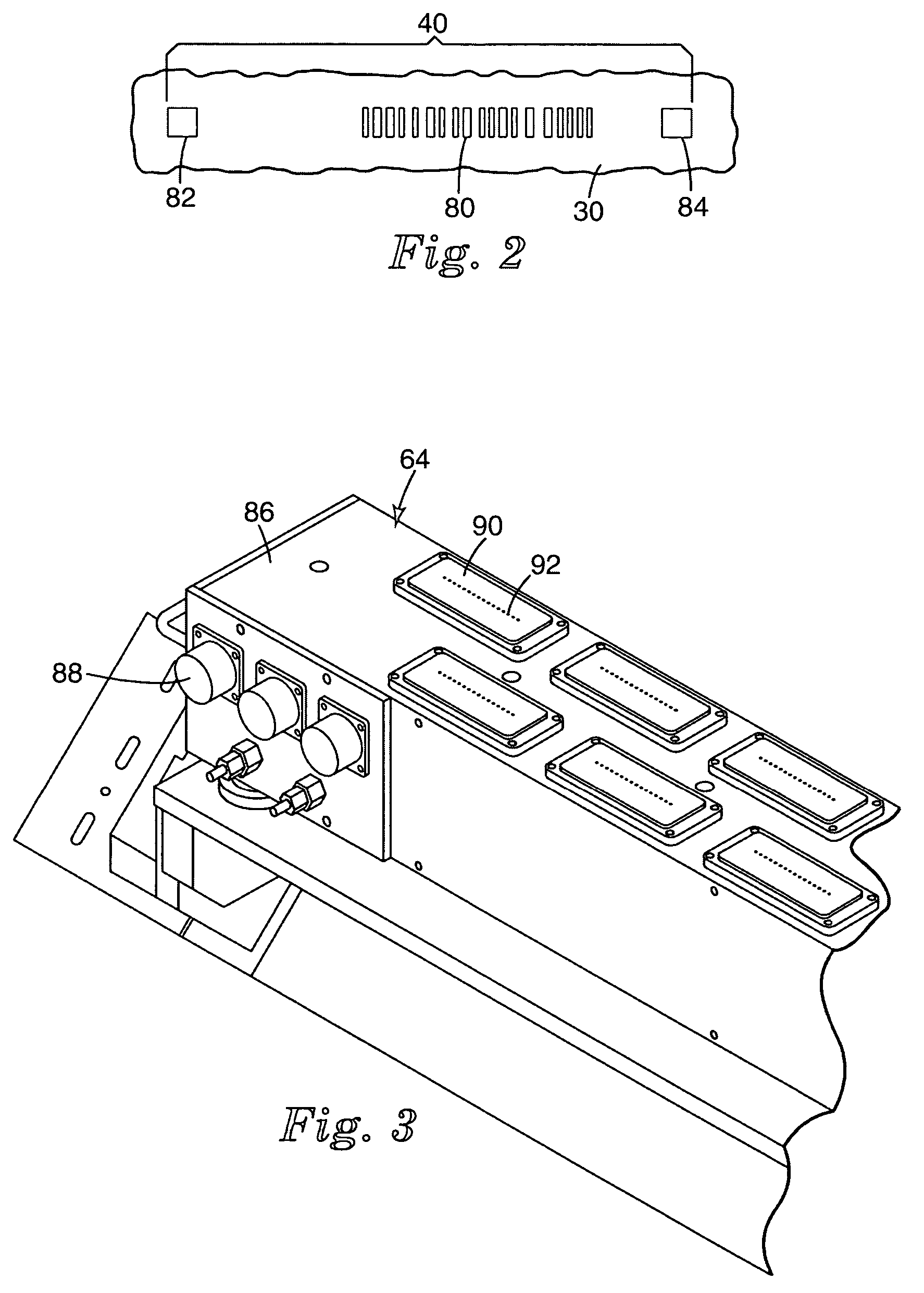

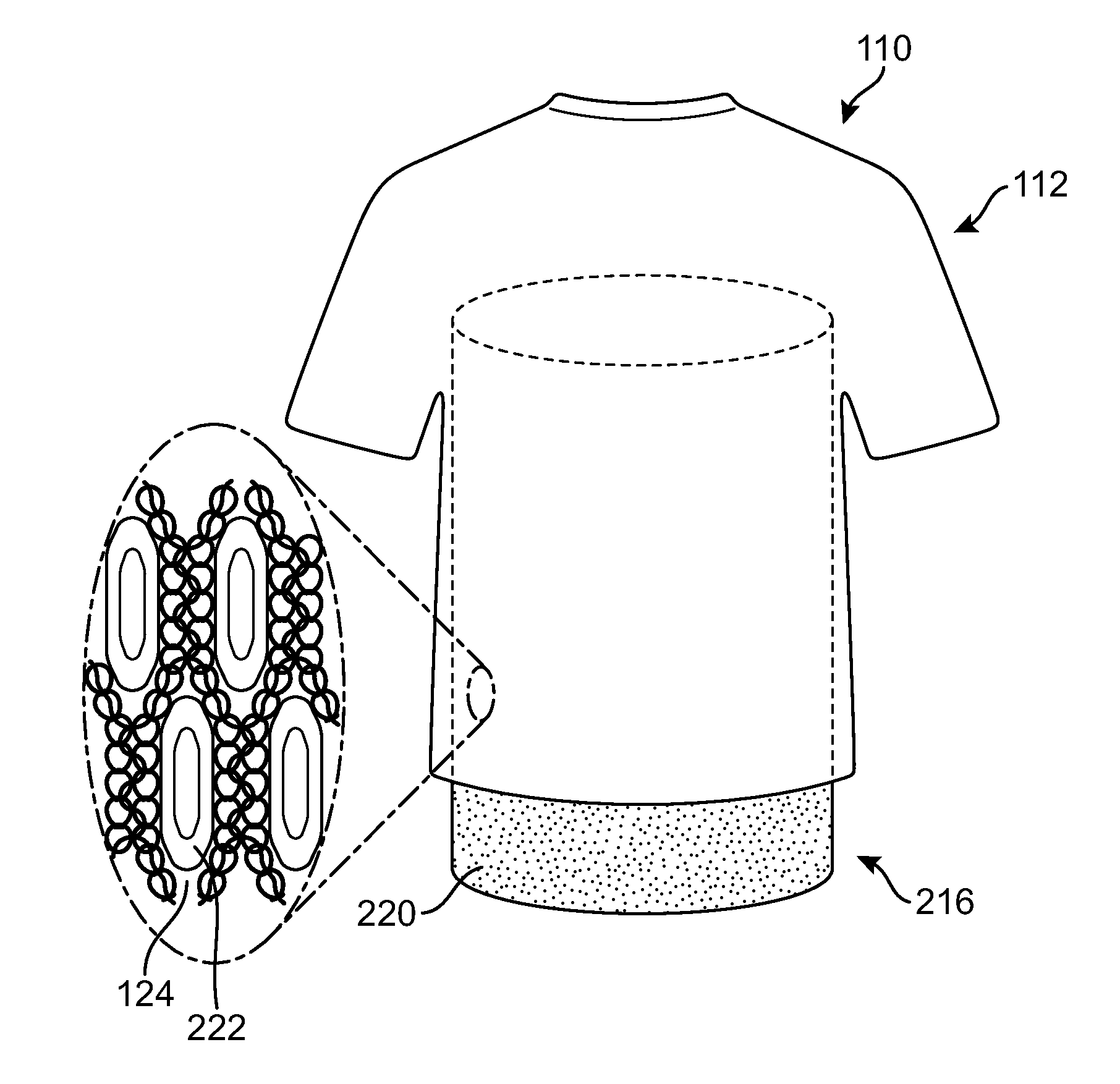

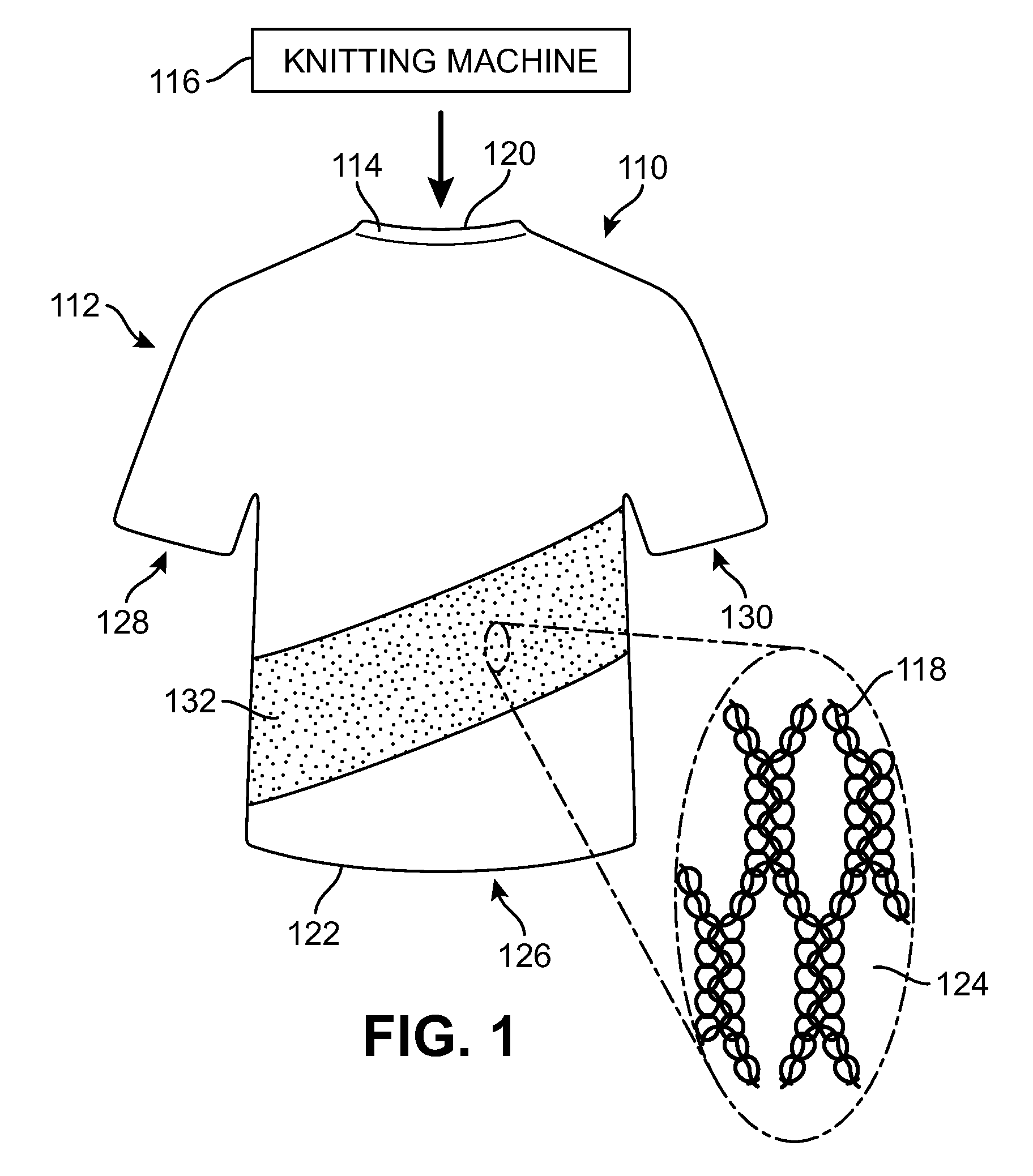

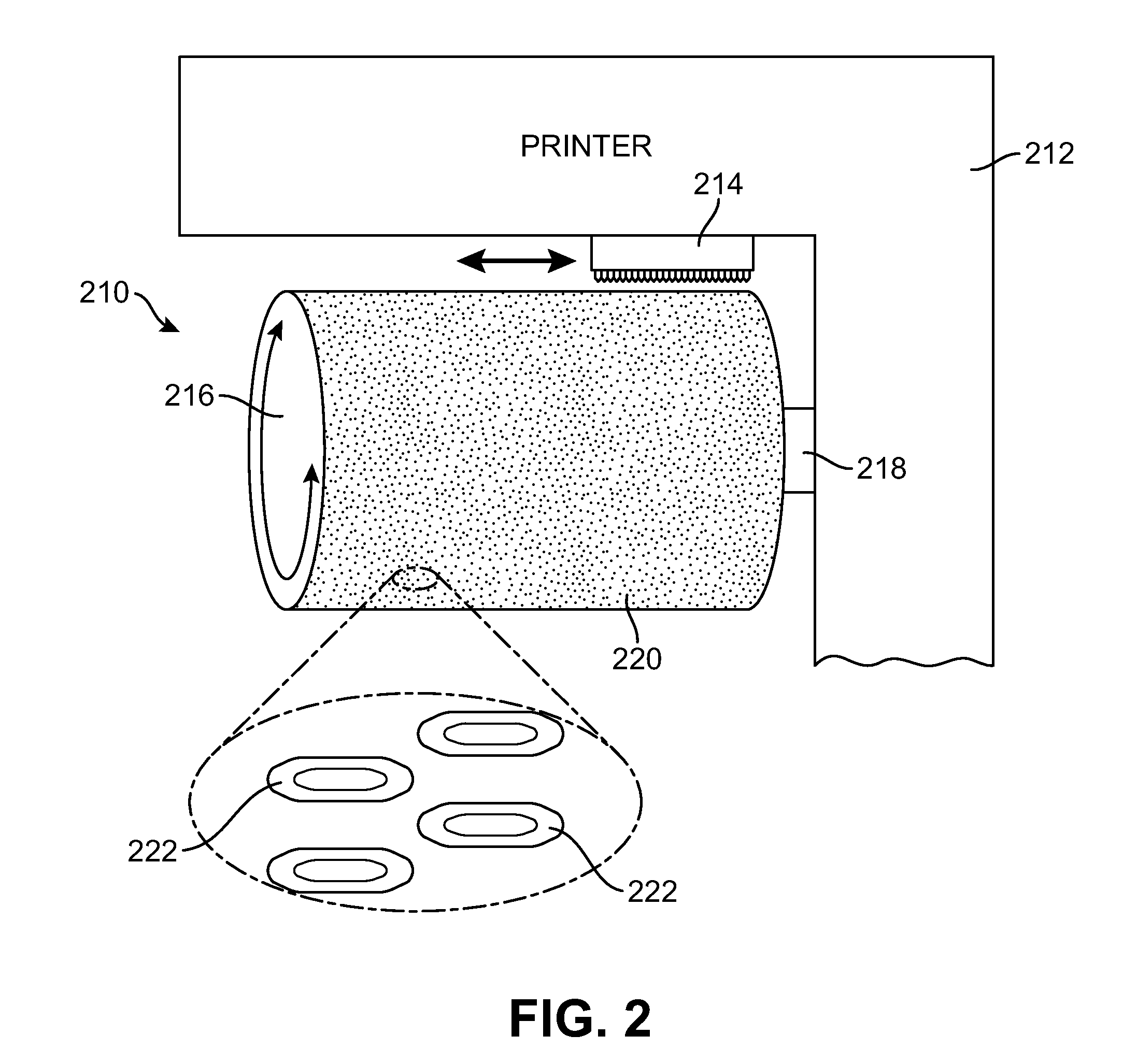

Knit article of apparel and apparel printing system and method

An article of apparel including a tubular knit textile region is provided, as well as an apparel printing system for printing on regions of the tubular knit textile region and related methods. The article of apparel can include a tubular knit textile region having an internal side and an opposite external side configured to be exposed during use, a plurality of yarns in an arrangement of interlocked loops forming parallel rows and channels therebetween, and a printed ink design on its external side. The printed ink design can be formed from ink applied to the parallel rows of loops and to the channels. An apparel printing system for printing on the article of apparel can include a textile printer having a print head and a tubular platen that includes features on the platen surface to retain and register the tubular knit textile on the platen surface during printing.

Owner:NIKE INC

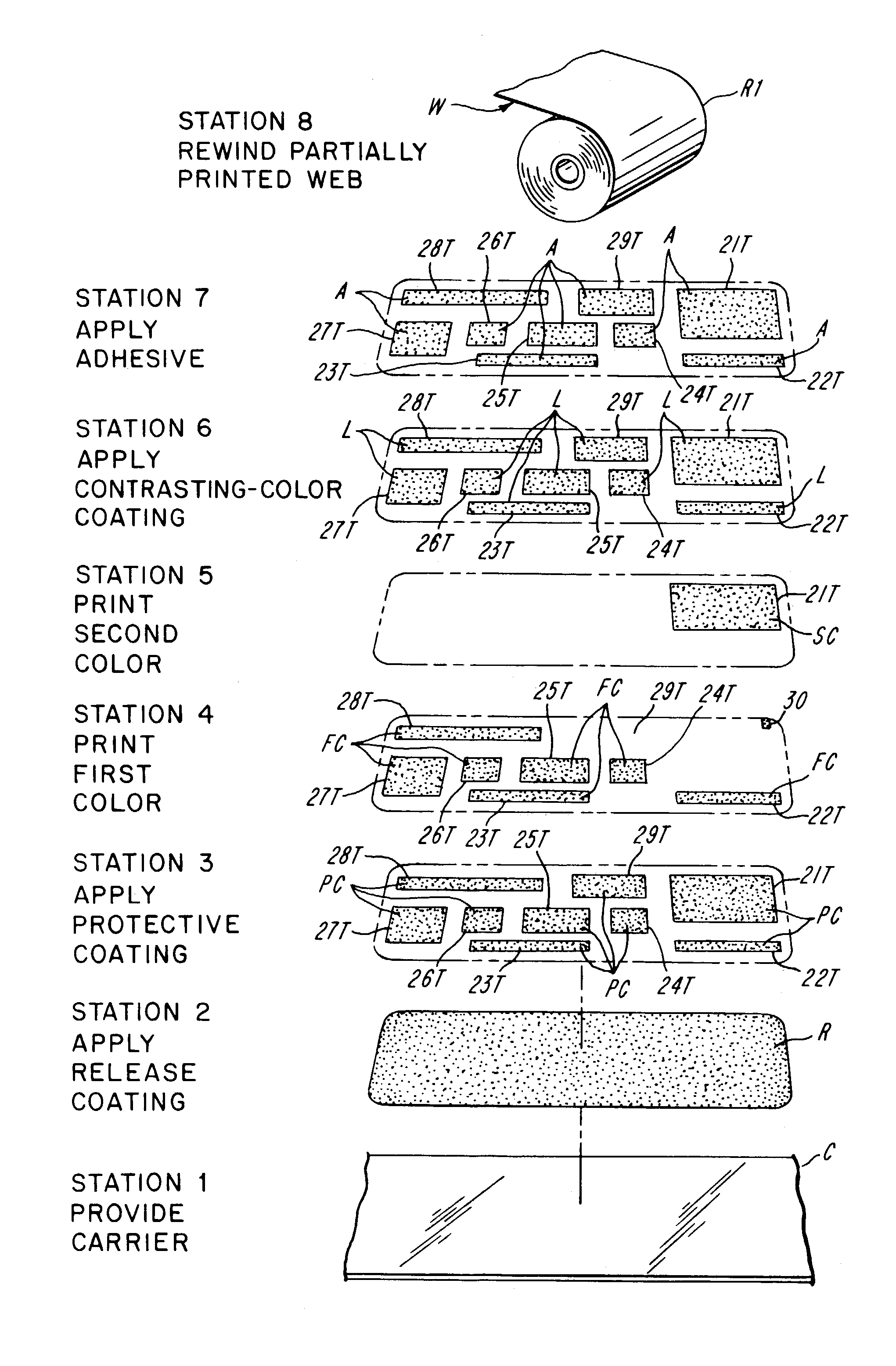

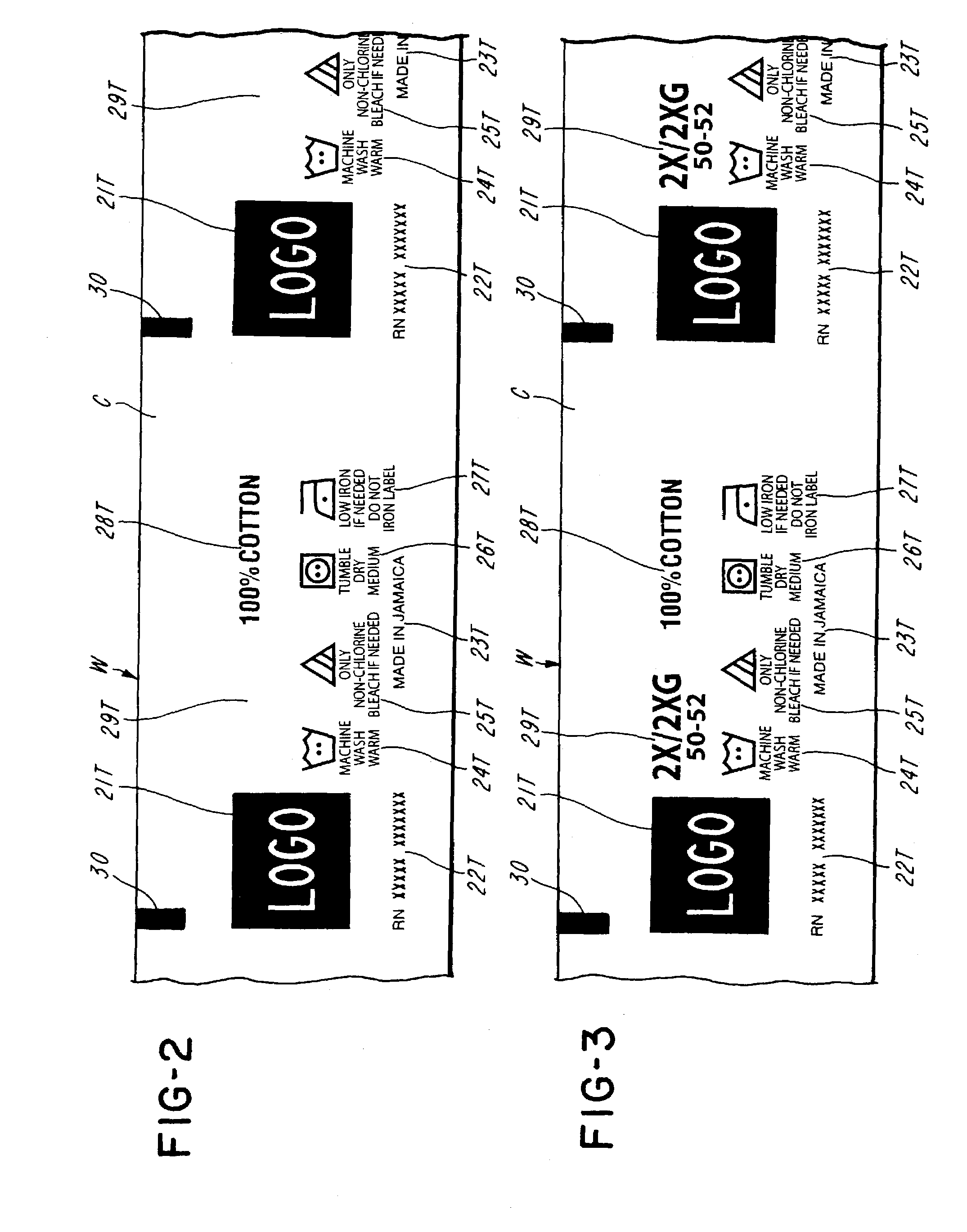

Thermal transfer media and method of making and using same

There is disclosed thermal transfer media containing both fixed and variable printed information, and method of making and using such a thermal transfer medium. The fixed information is printed in one or more fixed-information zone(s) preferably on a web during a long production run and thereafter as the need arises the variable information is printed or imprinted in one or more variable information zone(s) on sections of the web during shorter production runs. The transfer medium is particularly suited for printing onto fabrics that are subject to repeated home laundering and commercial dry cleaning.

Owner:AVERY DENNISON CORP

Ink jet textile printing method

An ink jet textile printing method includes applying a pretreatment liquid that contains a coagulant to a fabric, discharging a first ink composition from a first recording head to apply the first ink composition to the fabric, and discharging a second ink composition from a second recording head to apply the second ink composition to the fabric. The first ink composition contains water, pigment, and a cohesive resin. The second ink composition contains water, pigment, and a non-cohesive resin.

Owner:SEIKO EPSON CORP

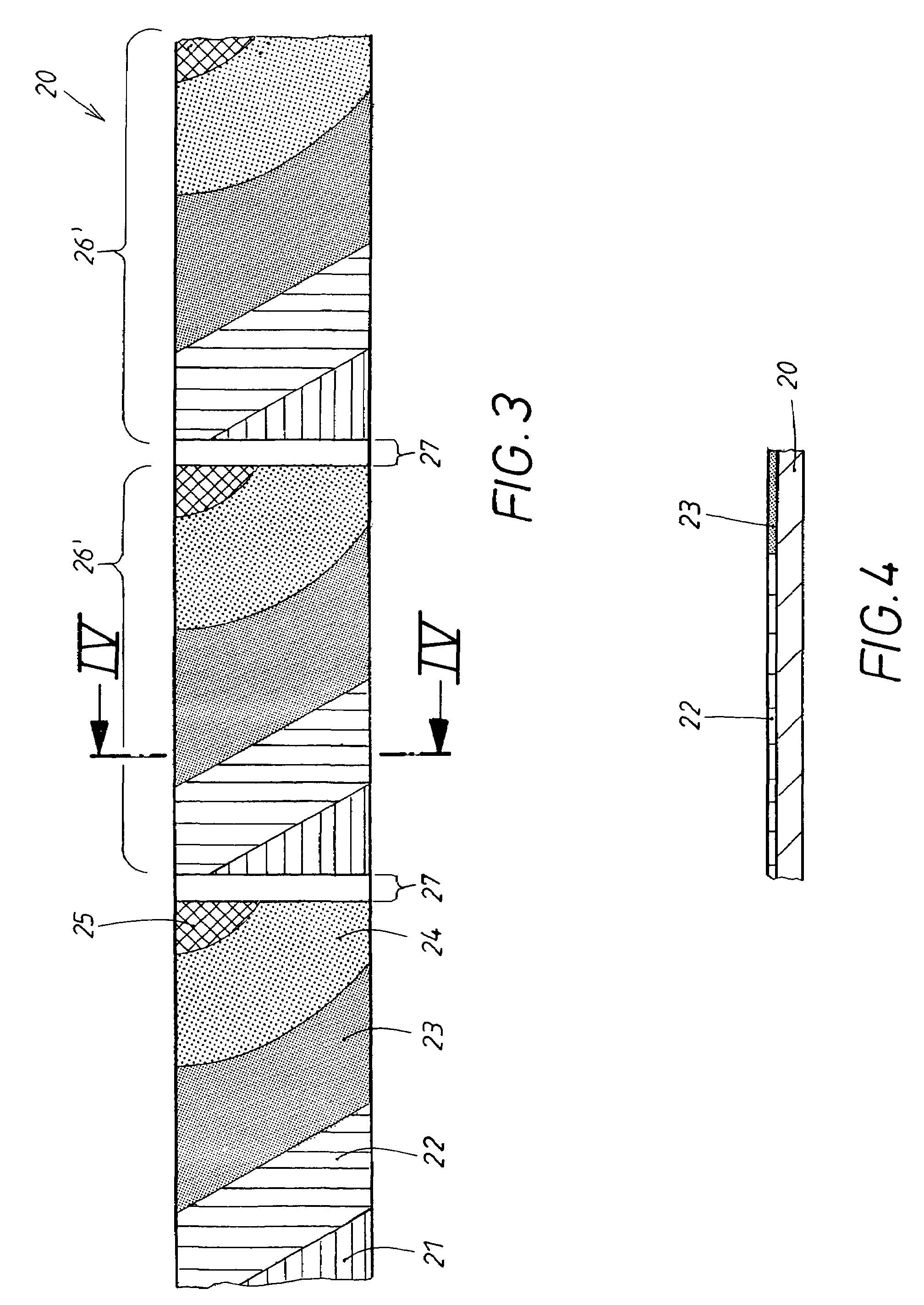

Method of manufacturing a printed textile ribbon

InactiveUS20050264642A1Inexpensive mannerMade preciselyStampsRecording apparatusEngineeringHeat treated

A method of manufacturing printed textile ribbons reliably and inexpensively, initially a web is produced which forms the later ribbon. The web is composed of two different materials, wherein a figure is applied on one side of the web. The web is subsequently subjected to a heat and pressure treatment with sublimation colors, such that the sublimation colors are absorbed by the first ribbon material and produce on one side a desired printed image. The figure is composed on this side of materials which do not absorb the sublimation colors. As a result, the color of the figure remains unchanged on this side of the ribbon, although the figure had contact with the sublimation colors.

Owner:AVERY DENNISON RINKE

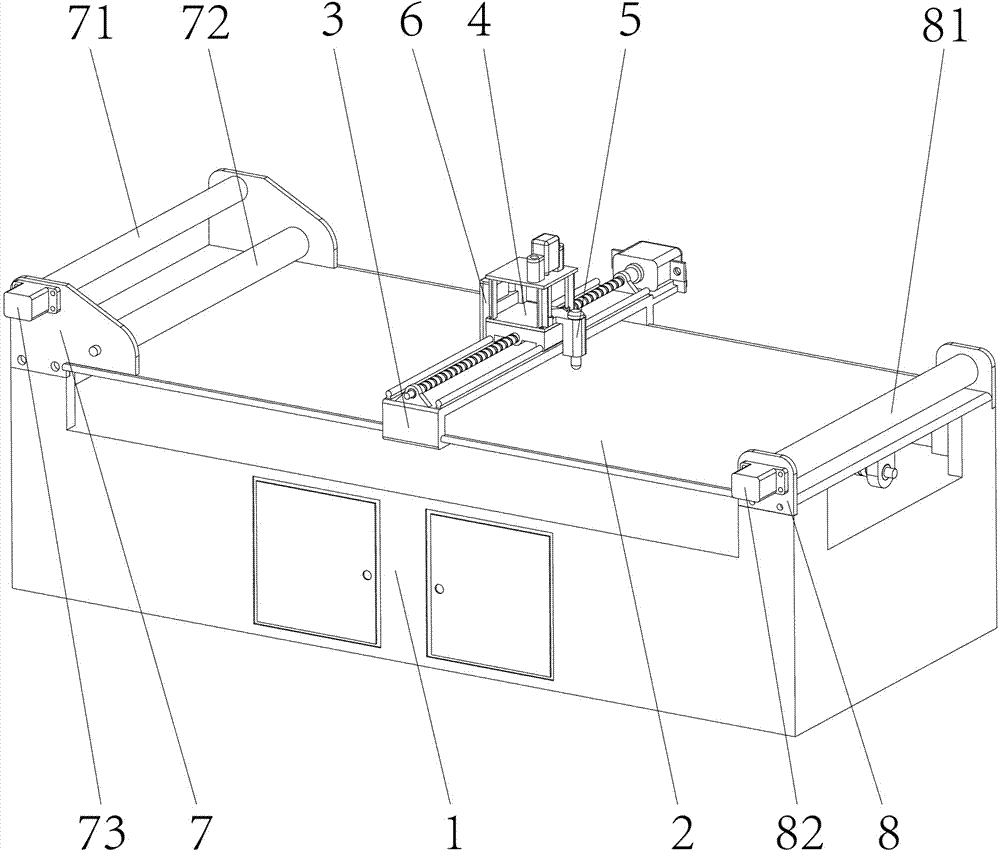

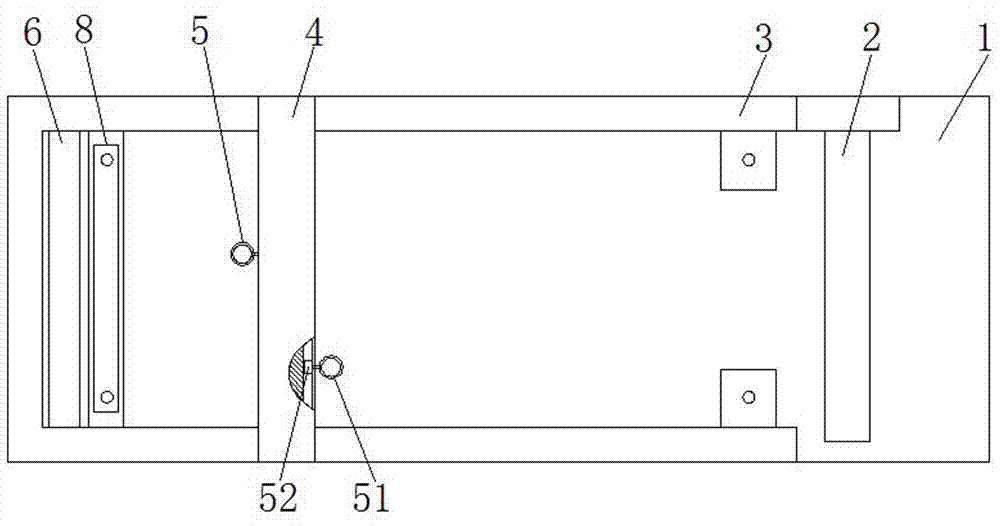

Cloth cutting device for garment processing

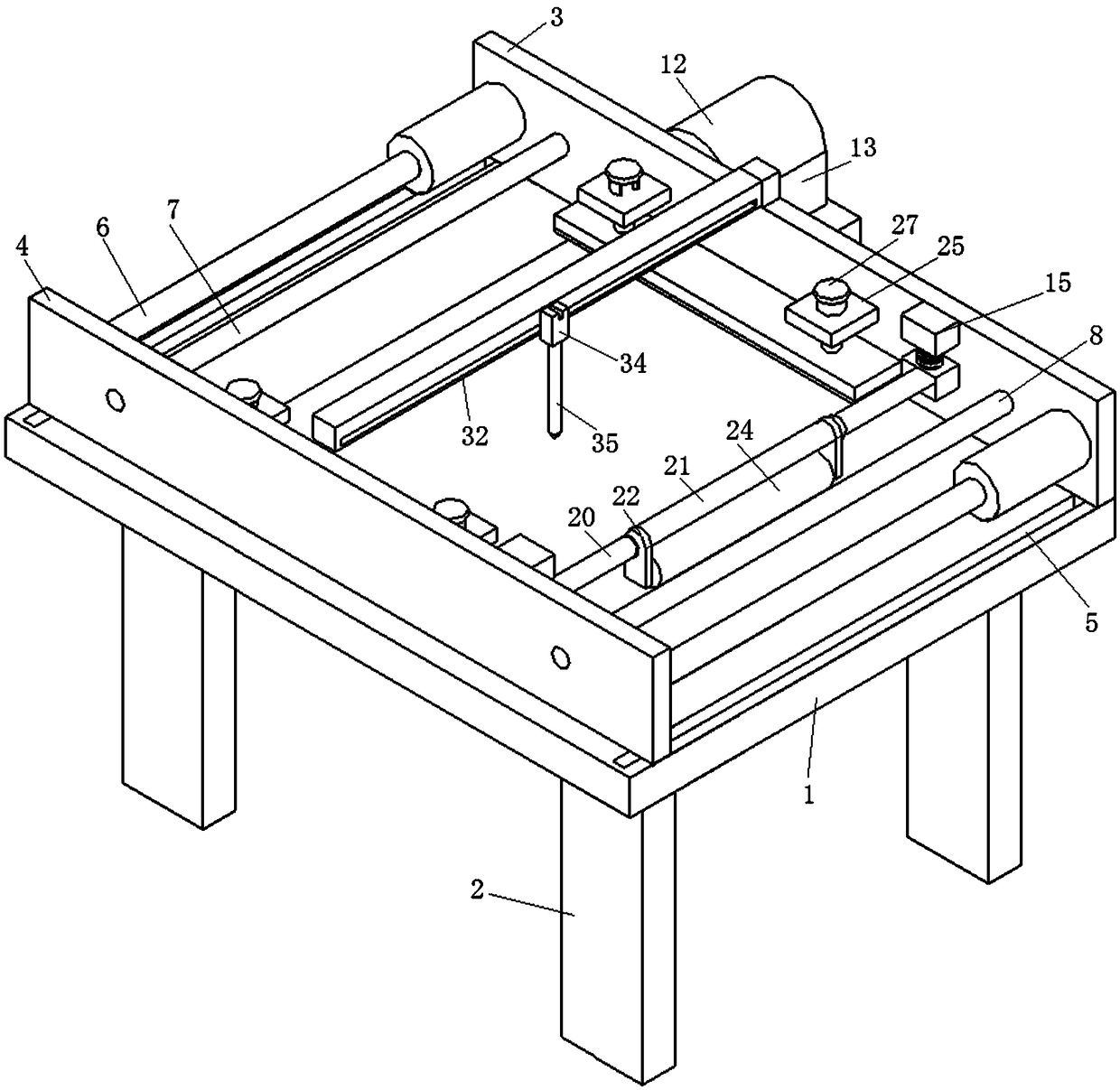

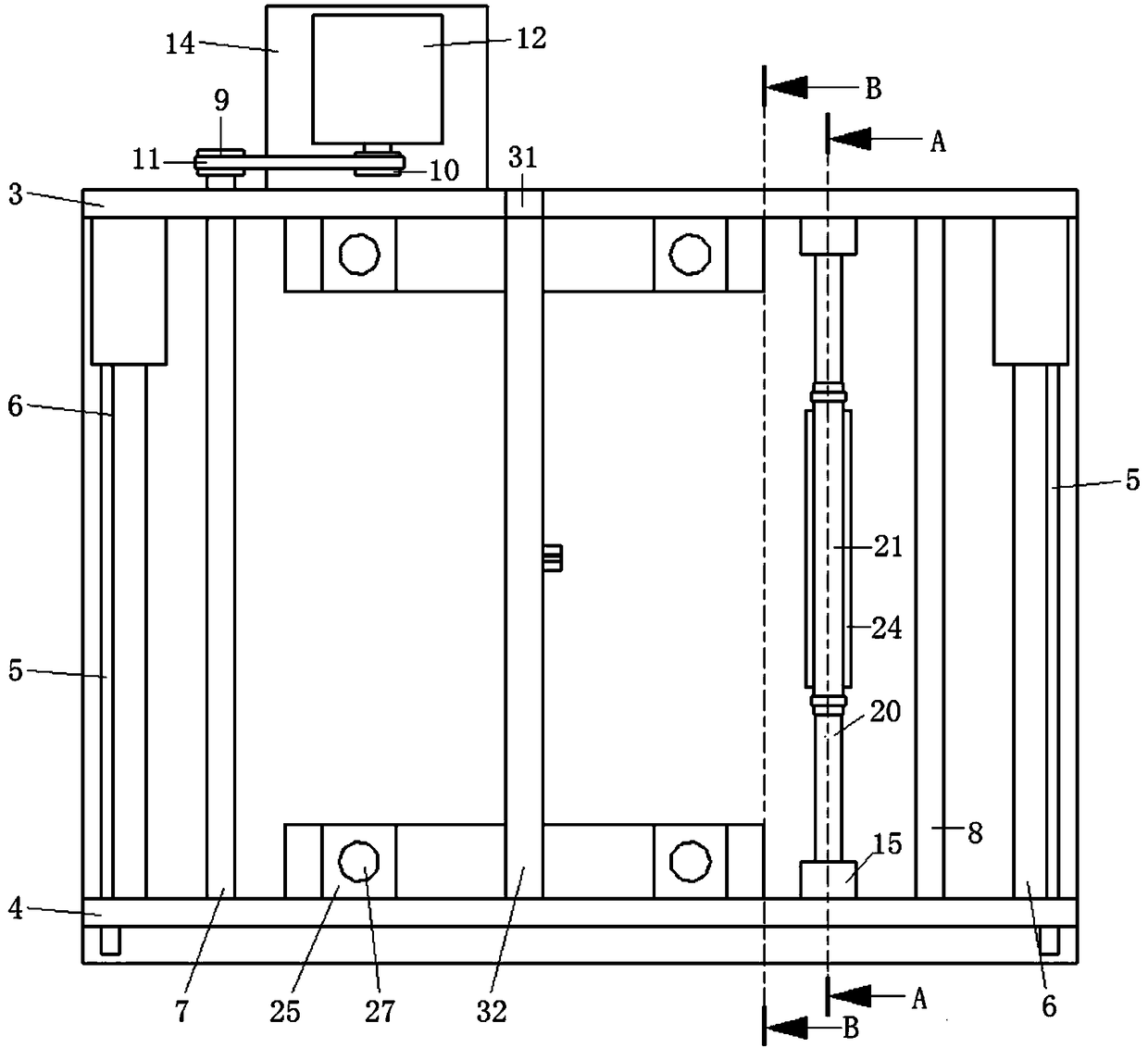

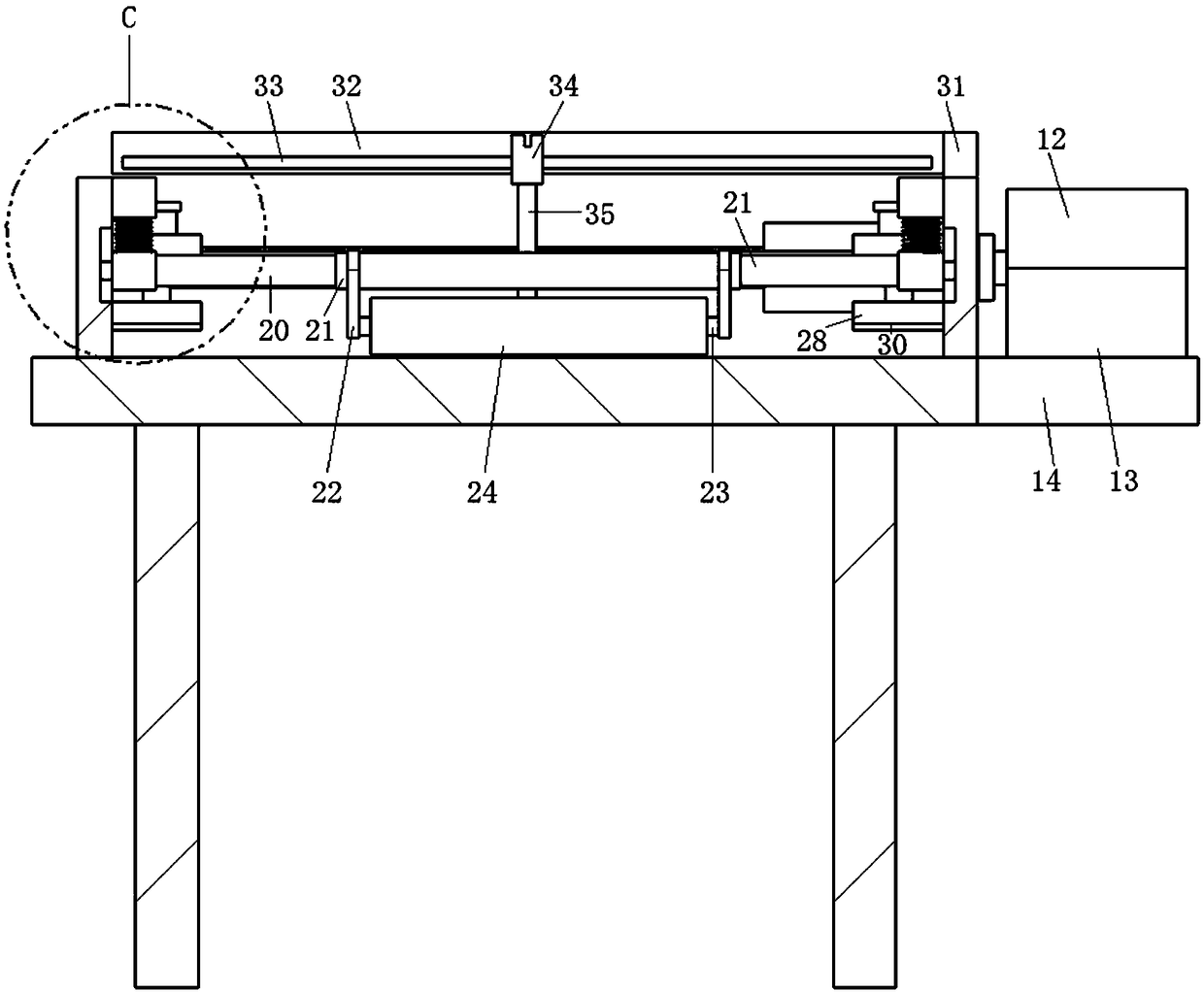

ActiveCN108842434AReduce lossesPrecise positioningMarking textilesSevering textilesDrive wheelEngineering

The invention discloses a cloth cutting device for garment processing. The device comprises a workbench, a fixing plate is arranged at one end of the workbench, a moving plate is arranged at the end,away from the fixing plate, of the workbench, the other two ends of the workbench are provided with first sliding grooves respectively, the bottoms of the two ends of the moving plate are slidably connected in the first sliding grooves through first sliding blocks respectively, the two ends of the fixing plate are connected with the moving plate through telescopic rods respectively, the sides, close to each other, of the two telescopic rods are provided with a driving roller and a driven roller respectively, one end of the driving roller penetrates through the fixing plate to the side, away from the moving plate, of the fixing plate and is fixedly provided with a driven wheel, one side of the driven wheel is provided with a driving wheel, the driving wheel is in transmission connection with the driven wheel through a transmission belt, the end, away from the fixing plate, of the driving wheel is connected with an output shaft of a motor, the side, close to the driving roller, of the driven roller is further provided with a leveling mechanism, a press mounting mechanism is further arranged between the leveling mechanism and the driving roller, and a cutting mechanism is arranged above the press mounting mechanism. The cloth cutting device for garment processing can greatly improve the precision of cutting, reduce cloth loss and reduce cost.

Owner:JIXI YUANDAO AGRI IND TECH

Textile label and method for production therof

The invention relates to a textile label in which the chip (5) of the transponder arrangement is completely embedded in adhesive, which not only provides the connection to the textile base layer (2) and to a similarly textile top label (7), or to the piece of clothing itself, but also provides a highly effective sealing. The adhesive of the adhesive layers (3, 4) is well-absorbed into the tissue structure by the textile base layer (2) and optionally into the further textile layers to give a flexible and resistant material composite which does not tend to delaminate or warp under mechanical, thermal and / or chemical stress. It is of advantage with regard to the long-life and reliability of the transponder arrangement to seal the same completely with adhesive, in other words, not just the chip (5).

Owner:SCHREINER GRP GMBH & CO KG

Metal detectable fiber and articles formed from the same

A fiber is provided with a polymer having a cross-section and a length. A particulate is distributed in the polymer in an amount to make the fiber detectable by X-ray detection or magnetic detection. The particulate is present in a core, a sheath, or both portions of polymer matrix. A process of detecting a fabric article is provided that includes the formation of a fiber in the form of a polymer having a cross-section and a length. A particulate is distributed in the polymer. A fiber is formed into a fabric. A fabric article is then manufactured from the fabric. The fabric article passes through an X-ray detector or a magnetic detector. A signal is collected from the X-ray detector or the magnetic detector indicative of the presence of the fabric article.

Owner:ILLINOIS TOOL WORKS INC

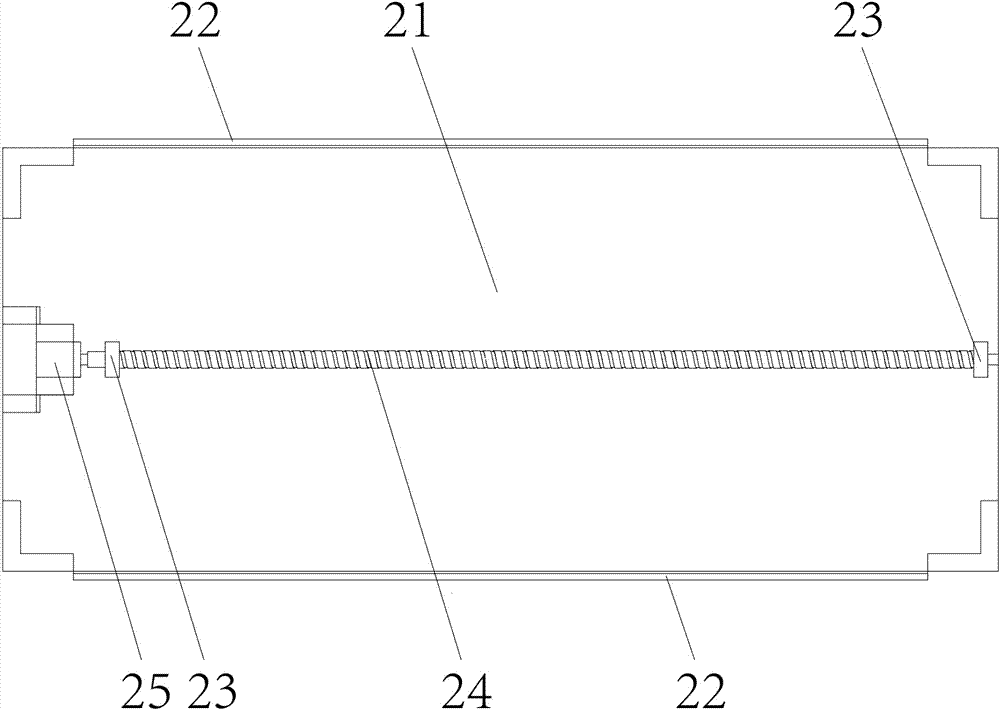

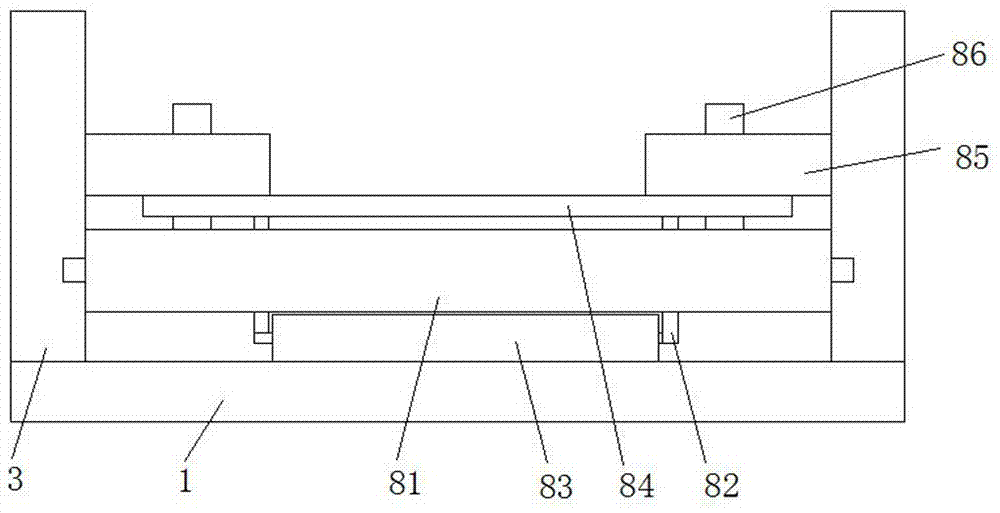

Numerical control laser cloth cutting machine

The invention relates to a numerical control laser cloth cutting machine. A machine body is a power distribution box; an actuating mechanism consists of an X-axis screw rod assembly, a Y-axis screw rod assembly and a Z-axis screw rod assembly which are arranged on the machine body; a Z sliding block nut sleeve is a screw rod nut of the Z-axis screw rod assembly; a laser generator is fixed on the Z-axis screw rod assembly; two double-shaft brackets are fixedly arranged on two lateral surfaces of one end of the machine body by bolts; two single-shaft brackets are fixedly arranged on two lateral surfaces of the other end of the machine body by bolts. The numerical control laser cloth cutting machine is characterized in that a cloth beam and a driven cloth pressing roller are sequentially connected between the two double-shaft brackets from outside to inside by a shaft; a cloth beam motor is connected with a cloth beam coupling; the cloth beam motor is fixed on the double-shaft bracket; a driving cloth pressing roller is connected between the two single-shaft bracket by a shaft; a cloth pressing roller motor is connected with a driving cloth pressing roller coupling; the cloth pressing roller motor is fixed on the single-shaft bracket. Cloth is cut by laser; a cutting number can be labeled on the cut cloth, so that follow-up operation is facilitated for a sewer; miniaturization rapid production of customizing clothes is realized.

Owner:LINAN KETAI COMM SCI & TECH

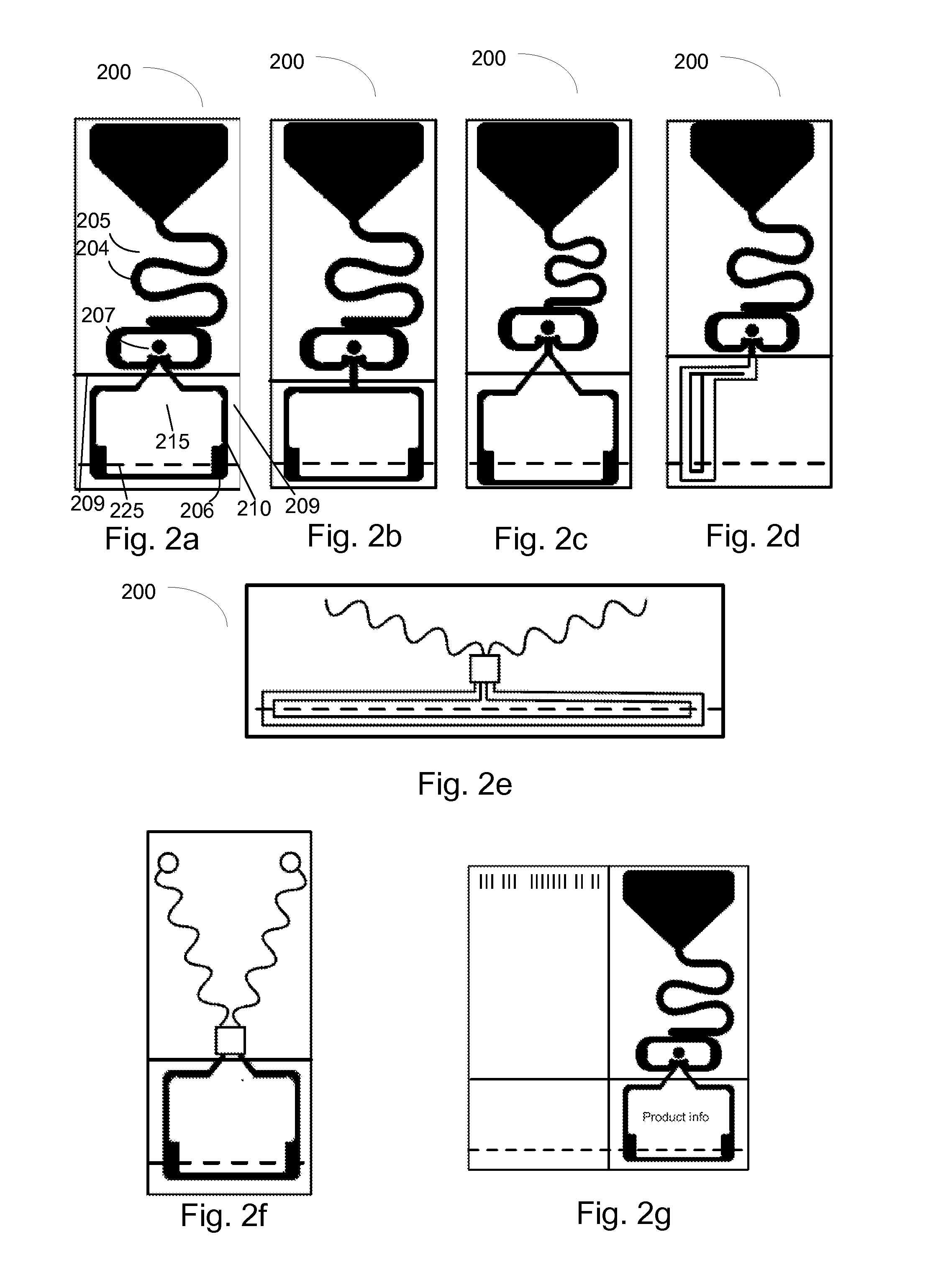

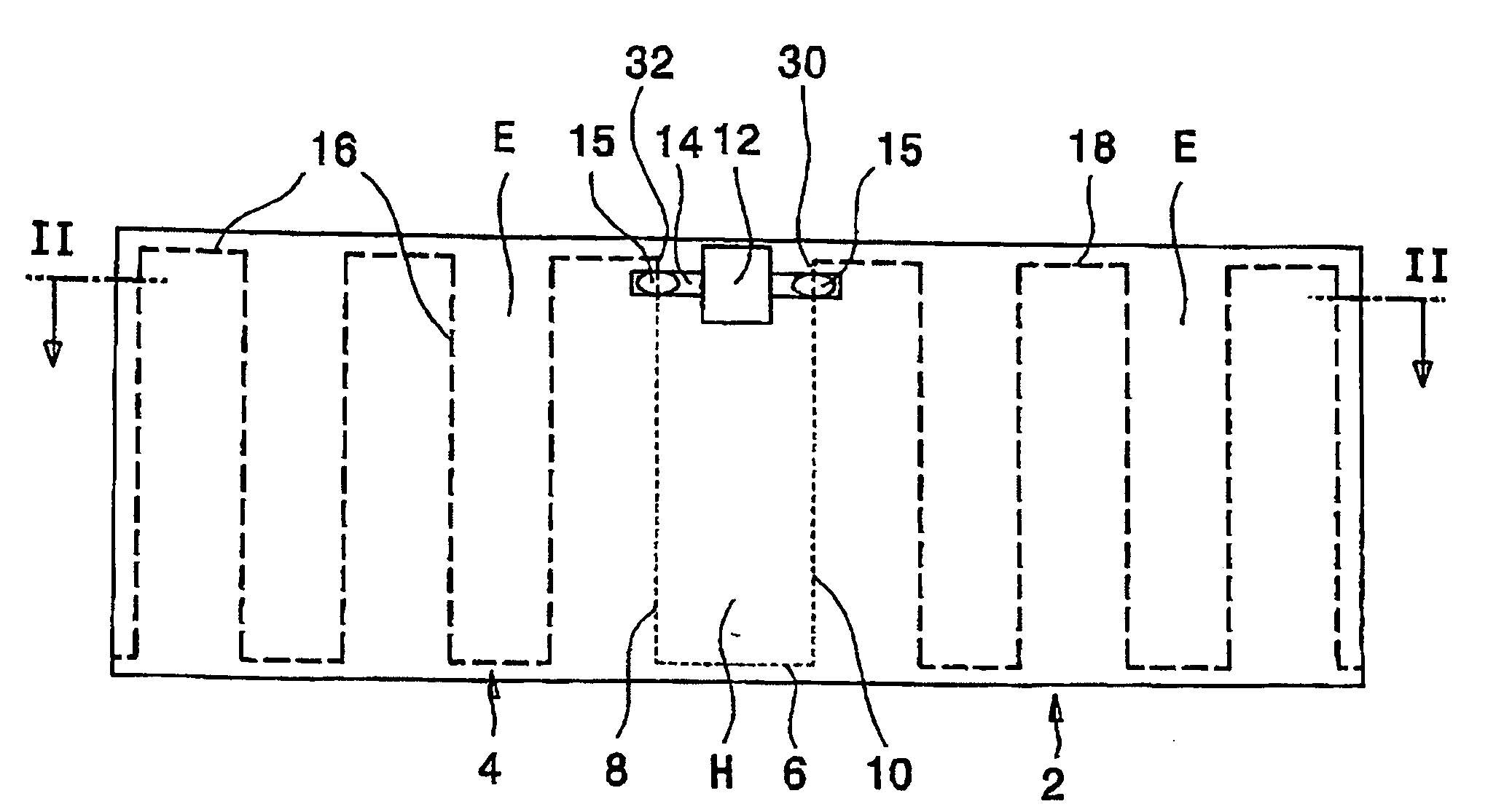

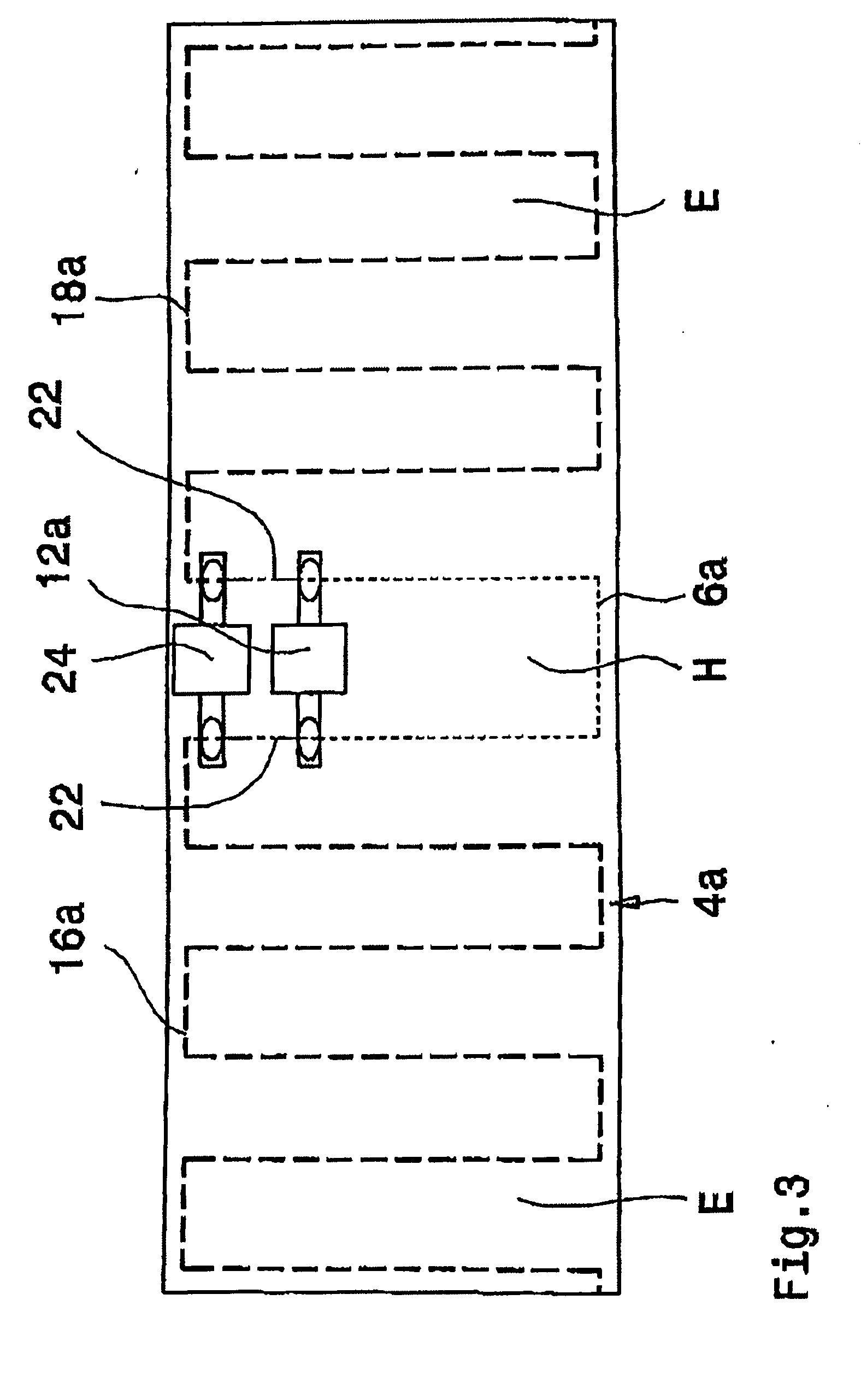

RFID textile label

InactiveUS20100051699A1Easy to solveStampsMarking textilesEngineeringElectrical and Electronics engineering

The invention relates to an RFID textile label, having an open antenna disposed on a carrier, wherein the antenna is connected to an RFID chip at the center region. In order to make the RFID textile label suitable both for long range and close range, the antenna comprises a loop in the center region, the RFID chip being connected either directly or indirectly to the shoulders of this loop, wherein the antenna loop equipped with the RFID chip serves as an H field antenna, and the antenna sections disposed outside of the antenna loop serve as an E field antenna.

Owner:TEXTILMA AG

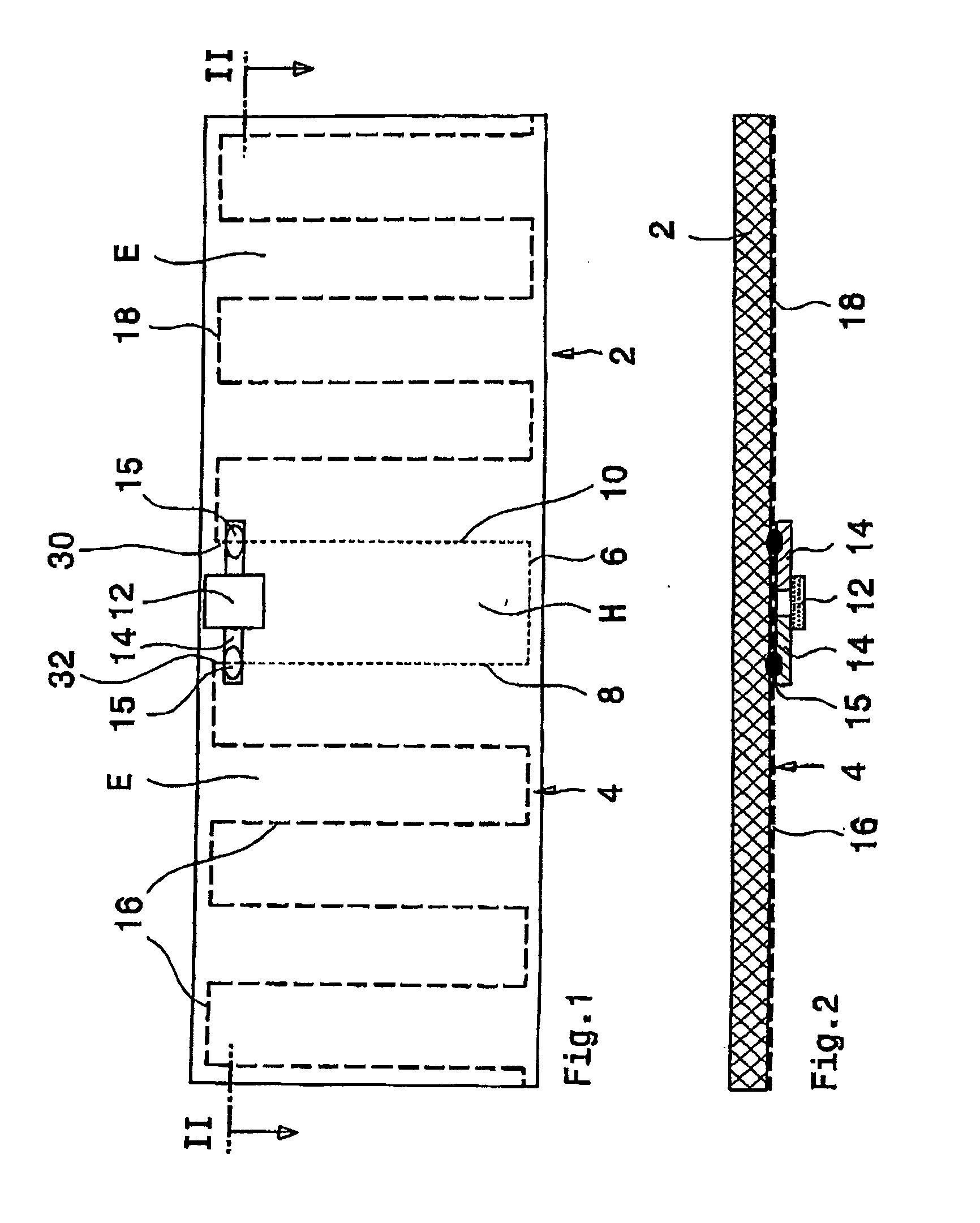

RFID tag and method and device for the production thereof

InactiveUS20090146790A1Increase flexibilityImprove handlingMarking textilesPaper/cardboard articlesEngineeringElectrical and Electronics engineering

Disclosed is an RFID tag comprising a textile design tag (4), on the rear face (6) of which a transponder is arranged that is provided with a chip (14) comprising an antenna (12). In order to create a simplified and thinner RFID tag, the antenna (12) is incorporated into or is applied to a support layer (10) and is connected to the chip (14) in the form of a transponder tag (8) which is connected directly to the design tag (4).

Owner:TEXTILMA AG

Method of manufacturing a printed textile ribbon

A method of manufacturing printed textile ribbons reliably and inexpensively, initially a web is produced which forms the later ribbon. The web is composed of two different materials, wherein a figure is applied on one side of the web. The web is subsequently subjected to a heat and pressure treatment with sublimation colors, such that the sublimation colors are absorbed by the first ribbon material and produce on one side a desired printed image. The figure is composed on this side of materials which do not absorb the sublimation colors. As a result, the color of the figure remains unchanged on this side of the ribbon, although the figure had contact with the sublimation colors.

Owner:AVERY DENNISON RINKE

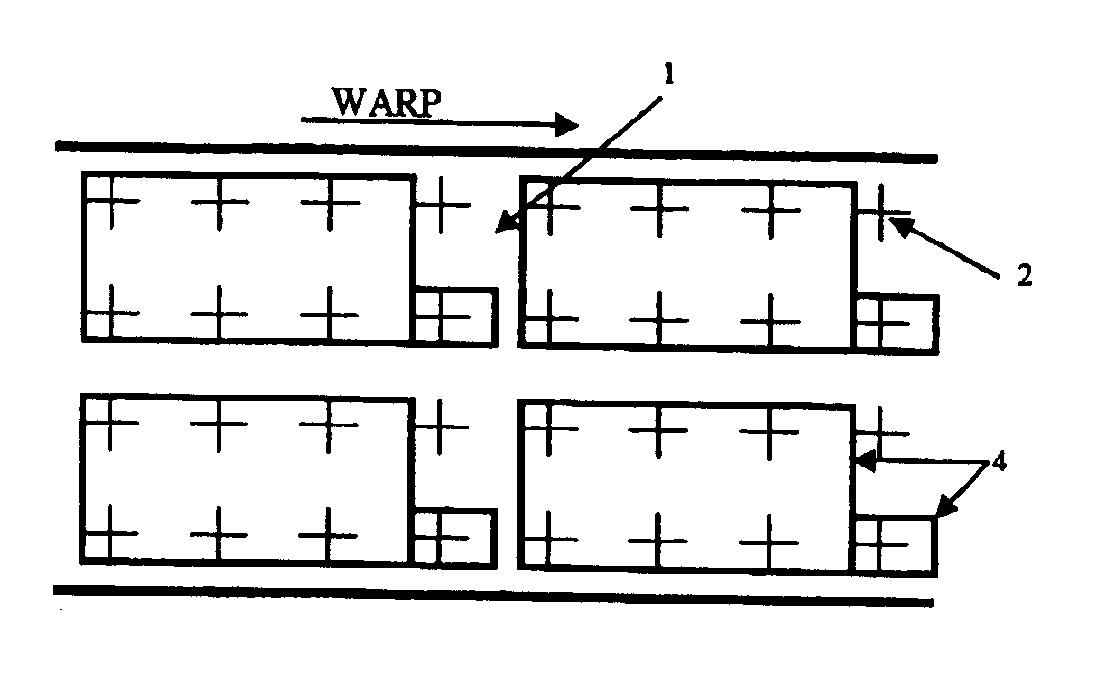

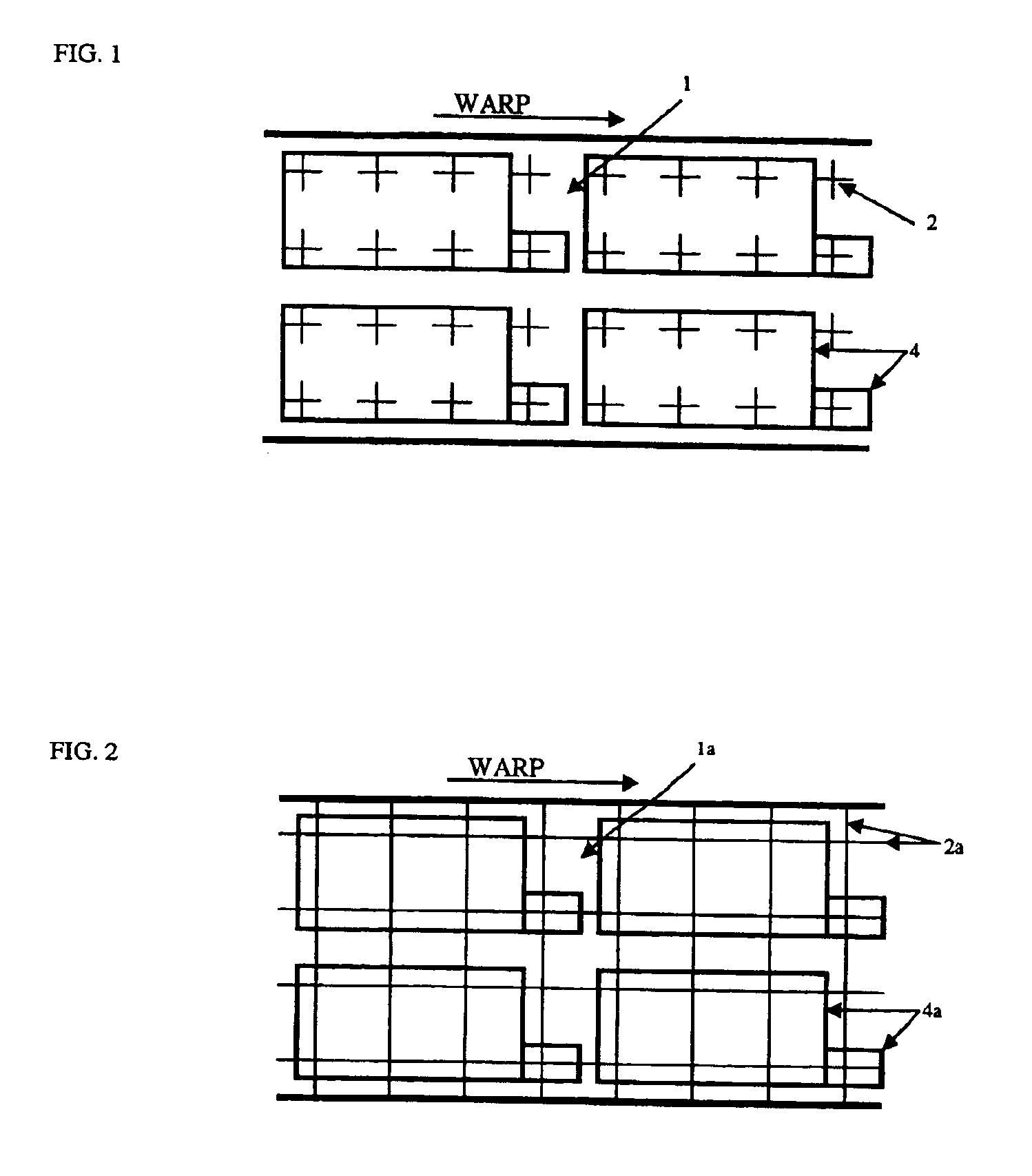

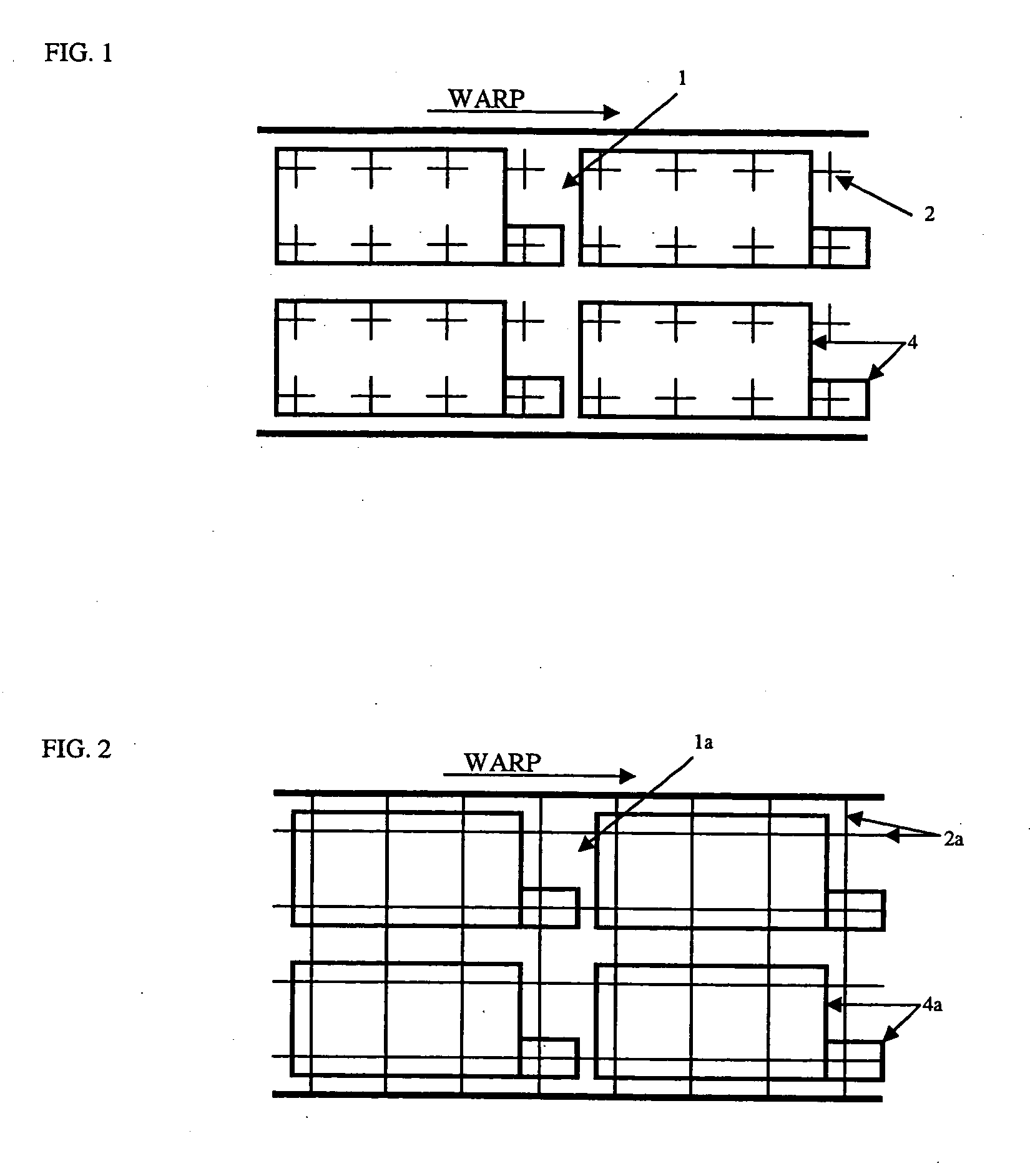

Method for producing airbags

A method for producing woven airbags, especially at least partially multi-layered airbags, includes the following steps: the warp threads are prepared in a warping room, warp threads which are suitable as marker threads for machine-readable markings being already placed in the warp; the airbag material is woven, weft threads which are suitable as marker threads for machine-readable markings being interlaced over at least part of the width of the cloth; and the airbag is cut out of the airbag material using a cutting device which is guided by the interlaced machine-readable markings.

Owner:GLOBAL SAFETY TEXTILES

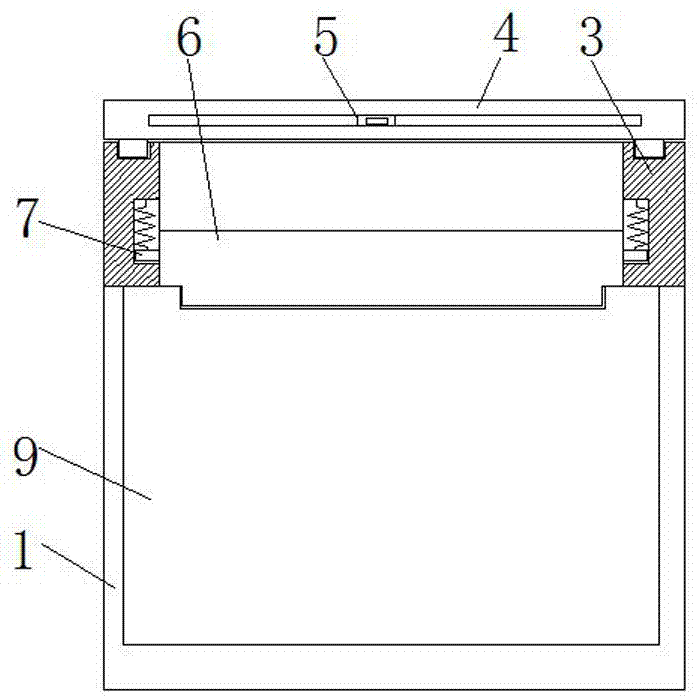

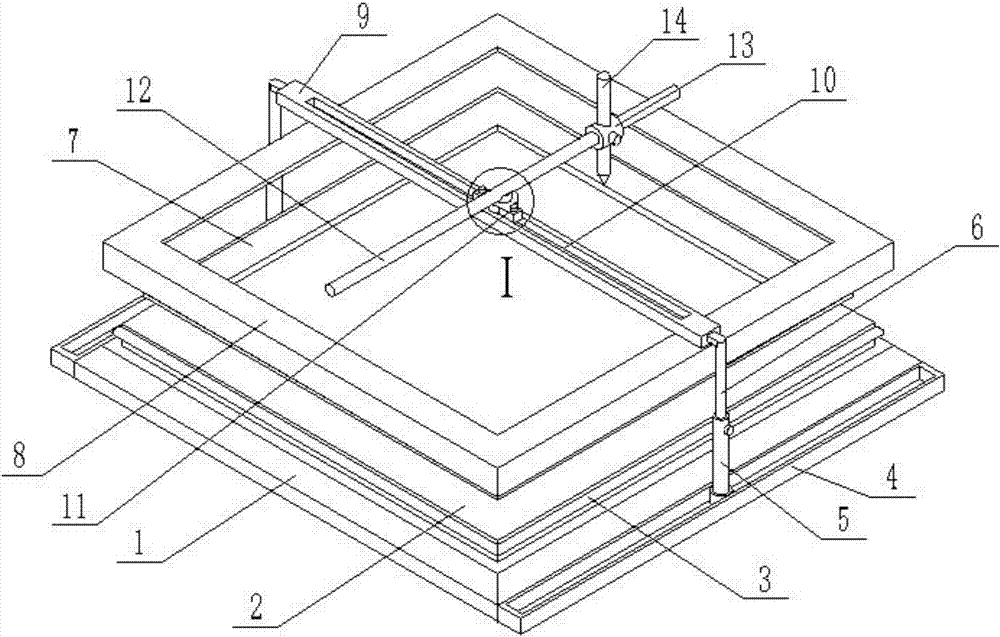

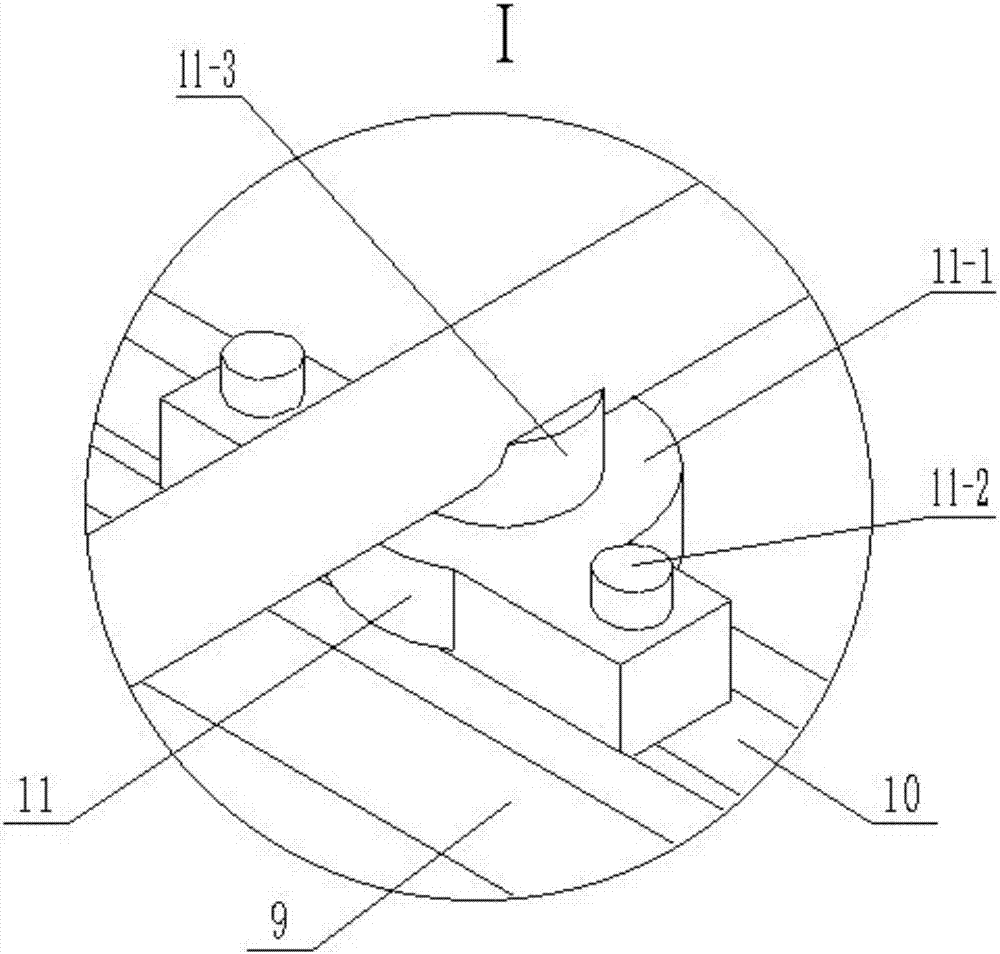

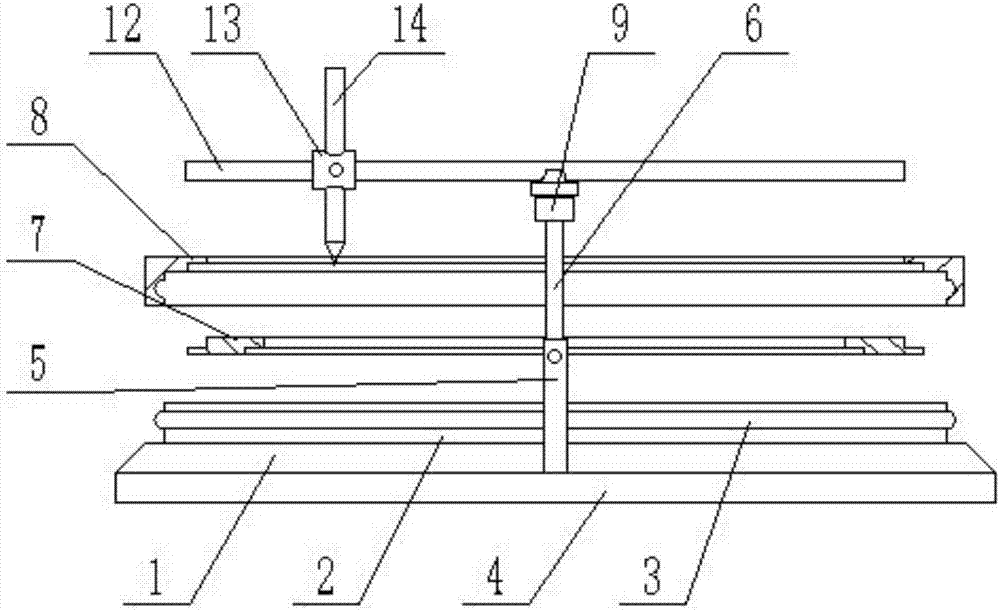

Tailoring equipment for garment processing

InactiveCN107227605AEasy to fixAccurate marking and positioningMarking textilesSevering textilesEngineering

The invention discloses tailoring equipment for garment processing. The tailoring equipment for garment processing comprises a tailoring workbench, wherein a reel insertion rod is arranged at one end of the top of the tailoring workbench; two sets of baffle plates stretching in the length direction are arranged on the tailoring workbench; a first cross plate is connected to one ends, far away from the tailoring workbench, of the two sets of baffle plates in a sliding manner; a scribing device is connected to the first cross plate in a sliding manner; a fixing plate is arranged at one ends, far away from the reel insertion rod, of the two sets of baffle plates; a guide rod is arranged at each of the two ends of the fixing plate; guide slots matched with the guide rods are formed in the two sets of baffle plates; a leveling device is arranged between the fixing plate and the reel insertion rod; the leveling device comprises a second cross plate, connecting rods, a roller, a downward pressing plate, stopping plates and insertion rods. The tailoring equipment for garment processing is simple in structure and novel in design, can guarantee that fabric is accurately scribed and positioned and does not skew or slip in the scribing and tailoring process, has good cutting quality, greatly improves the tailoring accuracy, reduces fabric loss and reduces the cost.

Owner:合肥赛格汽车服务有限公司

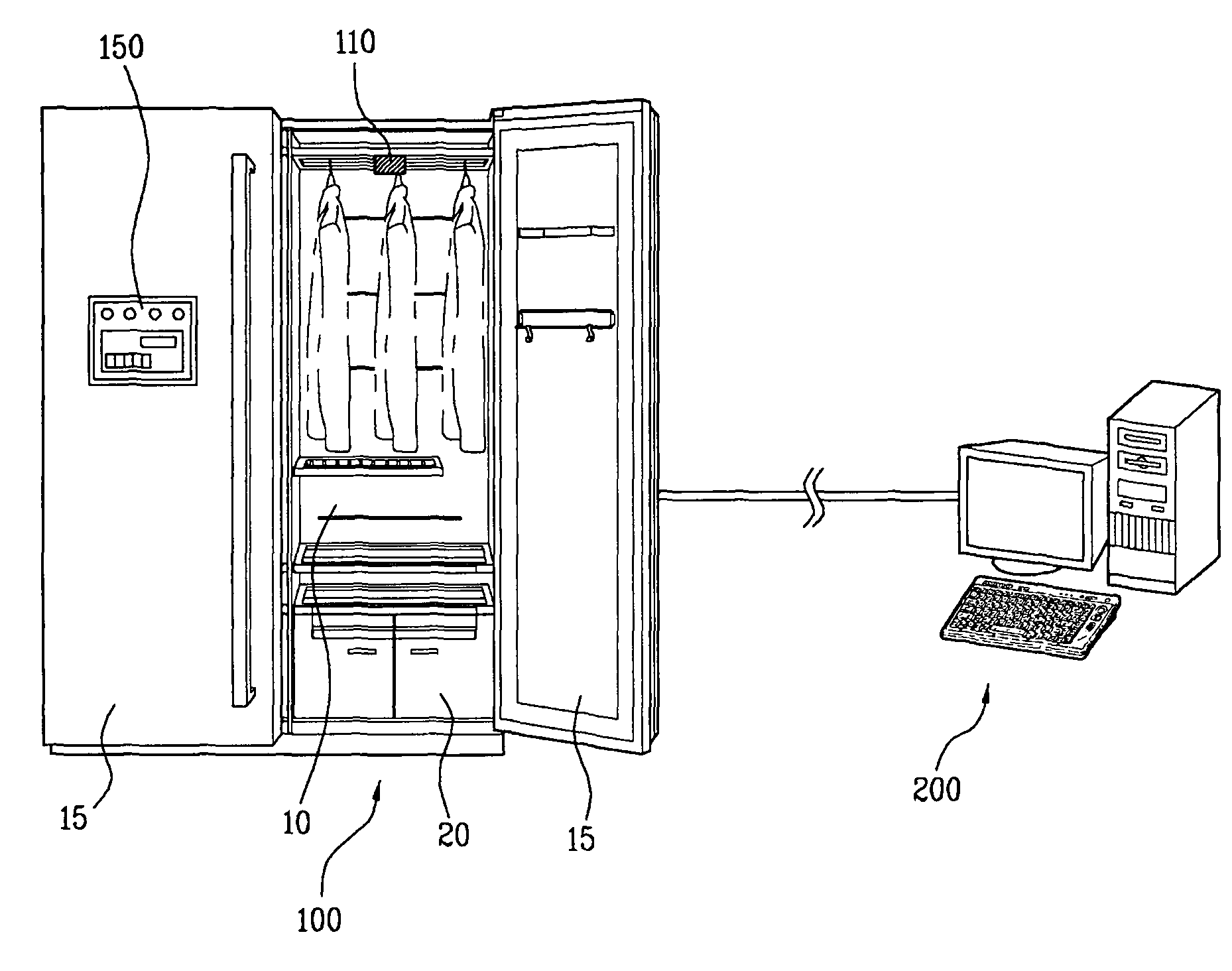

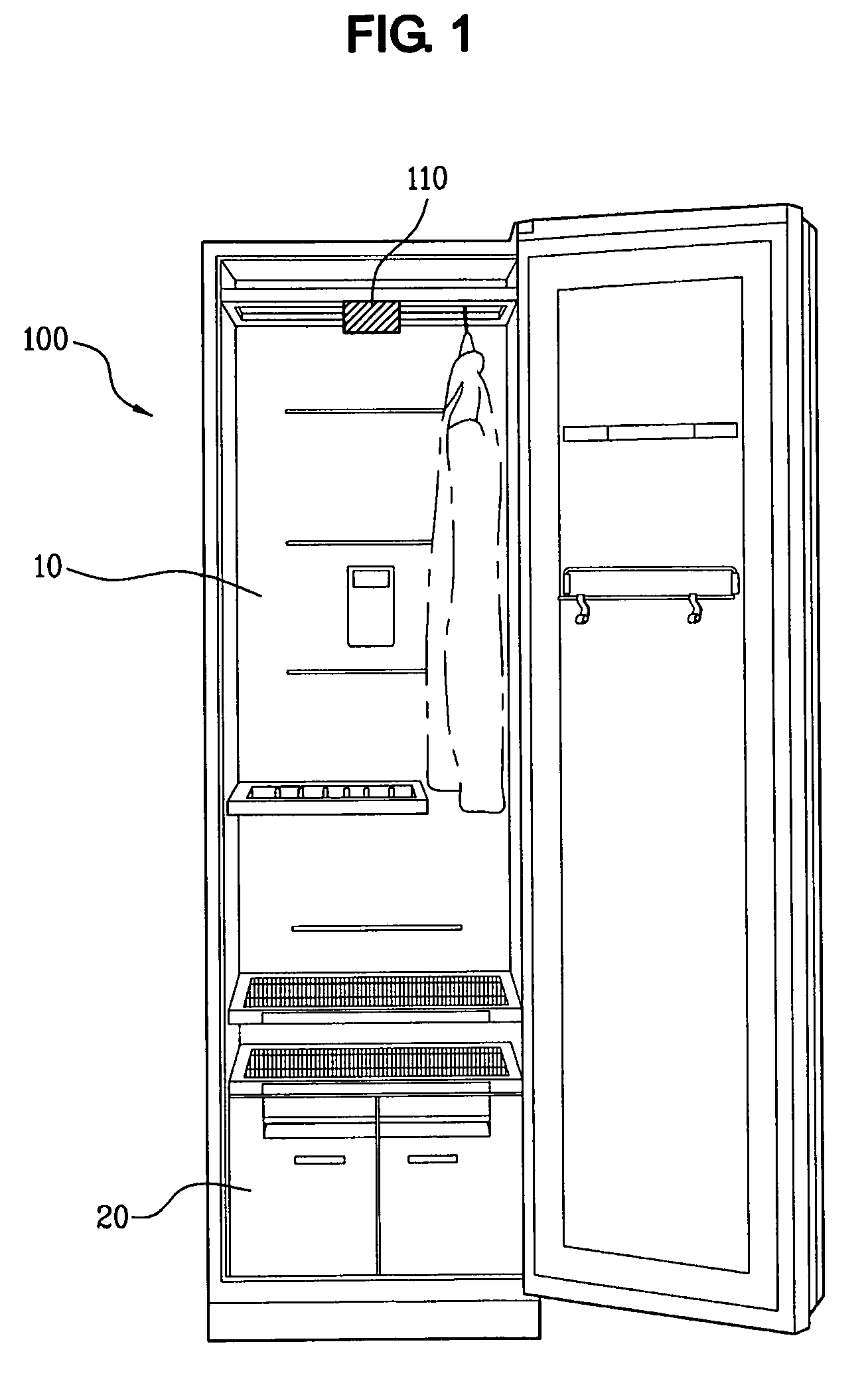

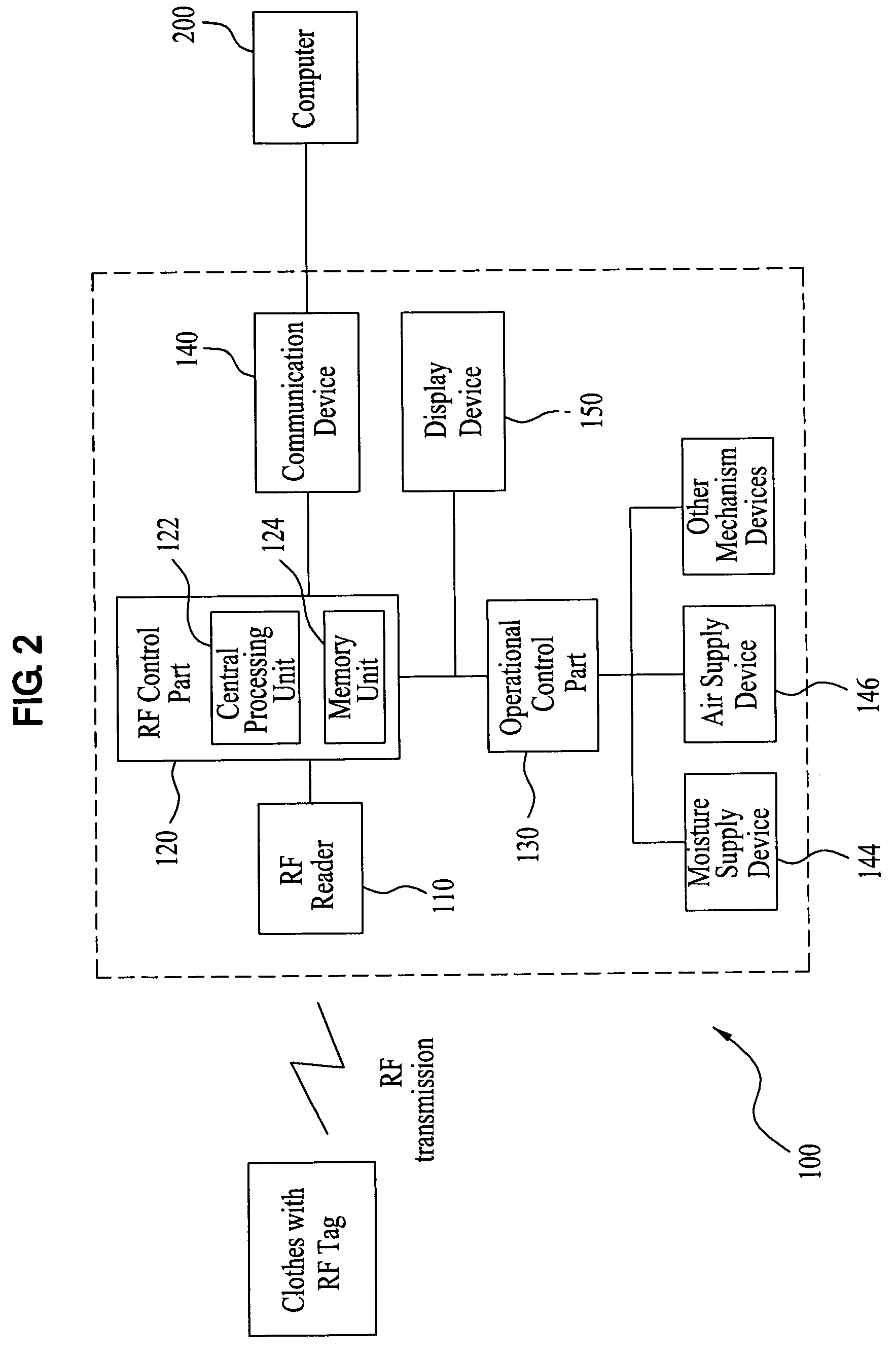

Clothes treating apparatus

ActiveUS7971777B2Simplify the management processFree from damageMarking textilesIroning apparatusDisplay deviceBiomedical engineering

A clothes treating apparatus is disclosed. More particularly, the present invention relates to a clothes treating apparatus which includes a RFID reader capable of reading information of clothes with RF tags such that the information of the clothes may be identified via an external computer. According to the clothes treating apparatus, the RFID reader is used and the information on treating states or positions of the clothes is identified via an external computer or display device. As a result, it can be simple to manage each item of clothes. Furthermore, the information on the treating states of the clothes may be identified. As a result, troubles of treating the clothes again unnecessarily as well as fabric damage may be saved.

Owner:LG ELECTRONICS INC

Automatic cutting technology for cloth

InactiveCN104963184AQuality improvementConvenience for subsequent useMarking textilesSevering textilesEngineeringMechanical engineering

The invention discloses an automatic cutting technology for cloth. The automatic cutting technology for the cloth comprises the following steps that 1 cloth rolling: test is conducted on the cloth when cloth rolling is conducted; 2 cloth loading: rolled cloth is placed on a cloth pulling machine, and cloth pulling parameters of the cloth pulling machine are set; 3 automatic cloth spreading: the cloth is spread on a cutting workbench through the cloth pulling machine; 4 cutting parameters of a cloth cutting machine are set, and cutting is conducted on the cloth on the cutting workbench; 5 cut cloth sheets on the cutting workbench are conveyed to a coding workbench; 6 coding is conducted on the cloth sheets on the coding workbench through a coding machine; 7 the cloth sheets after being coded are packed and put in storage. According to the automatic cutting technology for the cloth, when the cloth is rolled, the test is conducted on the cloth, the cloth sections with flaw are removed, the quality of the cloth sheets after being cut is improved, and coding is conducted on the cloth sheets after being cut, so that follow-up use, management and staking are convenient, the use is convenient, the effect is good, and good application prospect is achieved.

Owner:ZHANGJIAGANG SHUANGHE DYEING & TEXTILE

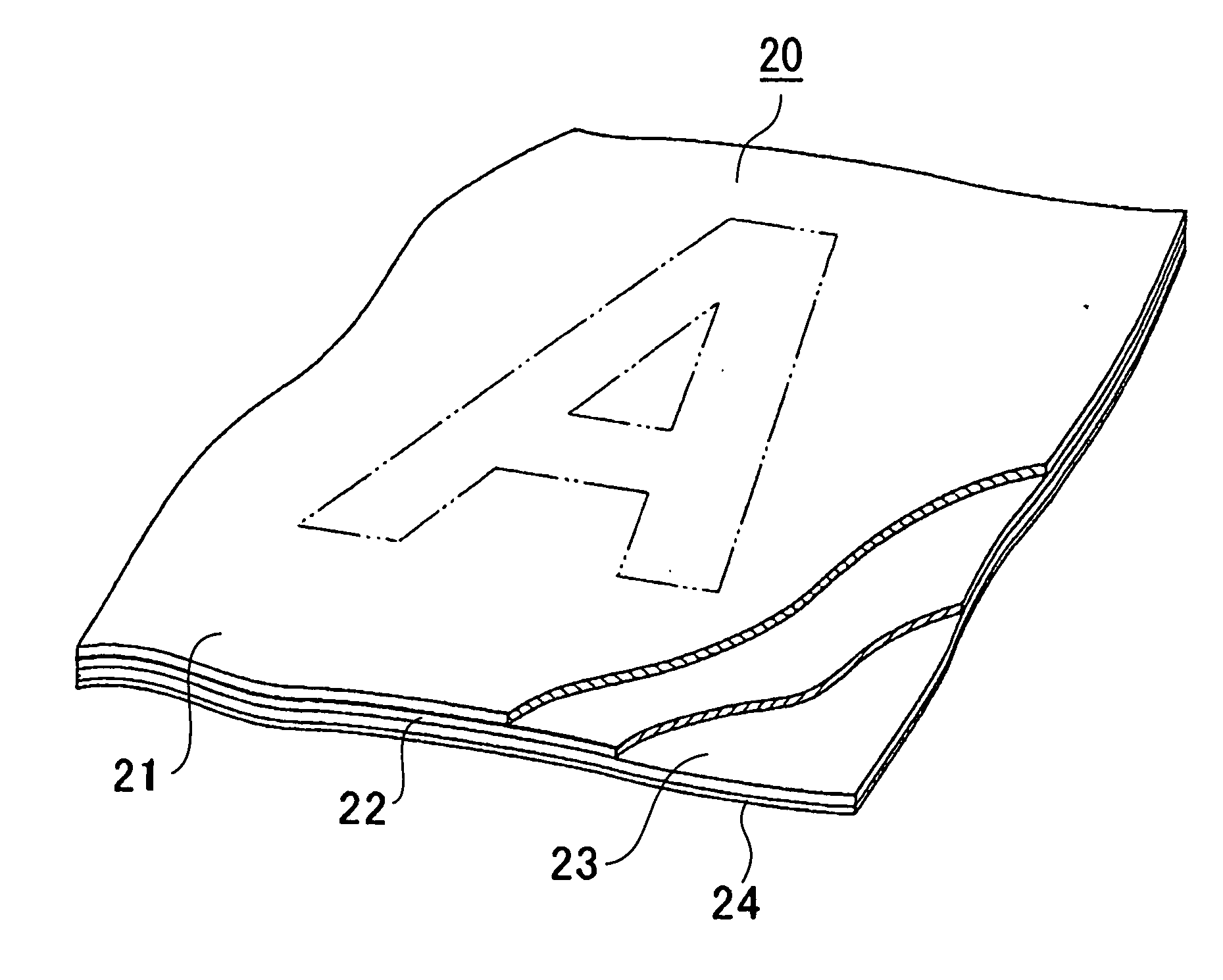

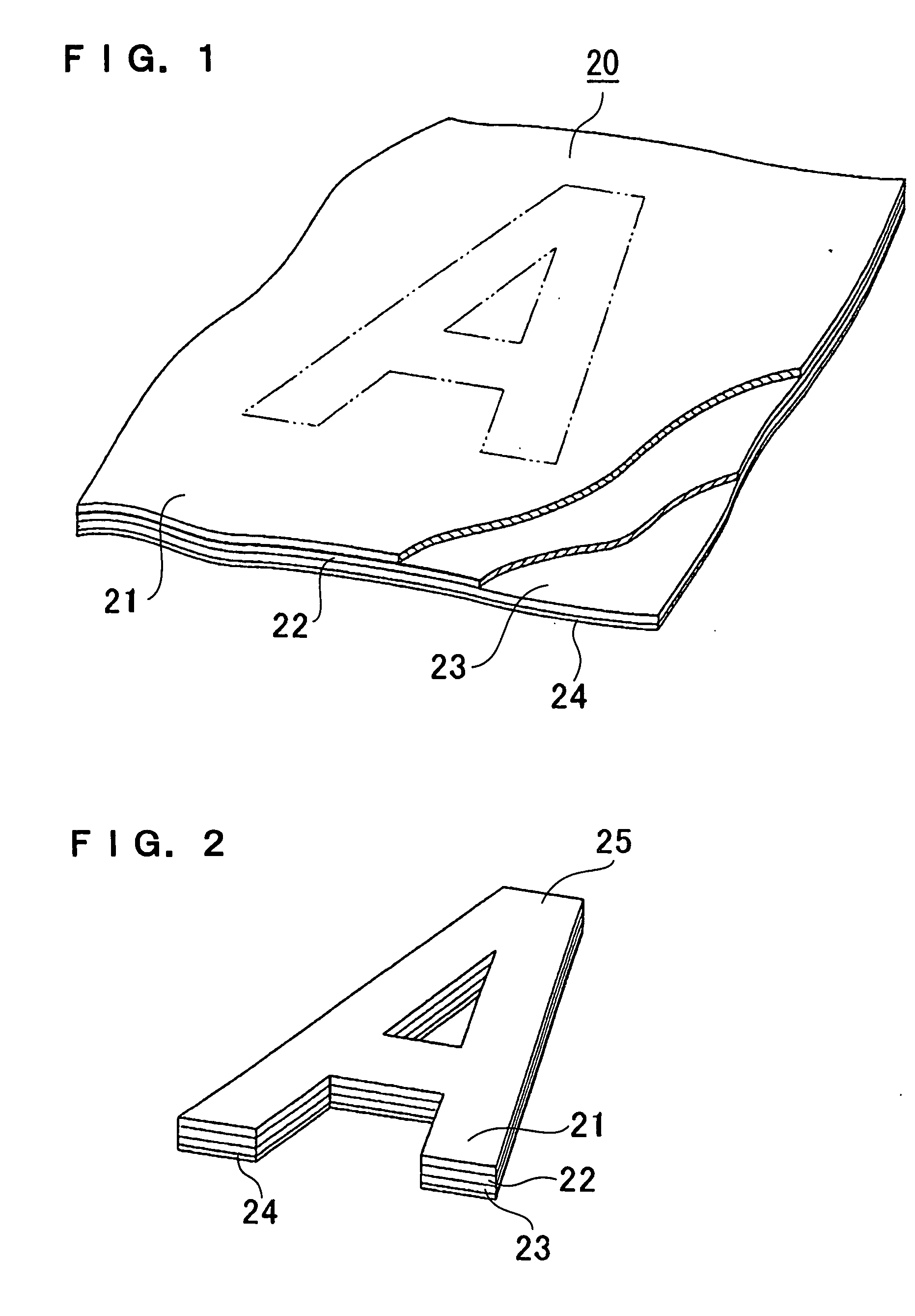

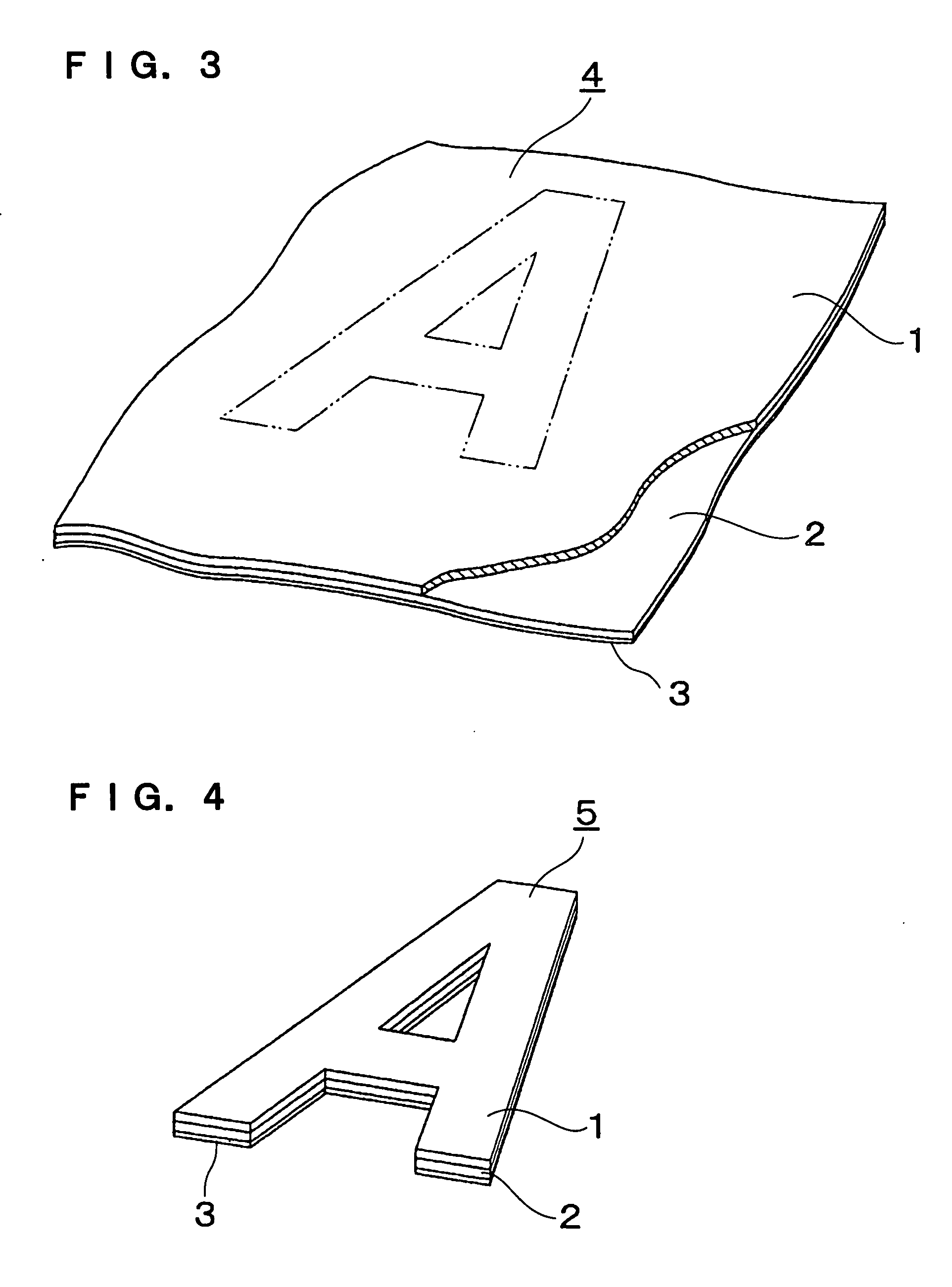

Cloth Material for Marking

ActiveUS20070289712A1Avoid layeringHigh melting pointMarking textilesTransfer printing processFiberInter layer

A cloth material for marking including: a label cloth made of a white cloth formed of a fiber containing a component having affinity for a sublimation dye; an intermediate layer disposed on a rear surface of the label cloth, the intermediate layer including a synthetic resin which has affinity for the component of the label cloth and which has a melting point higher than a sublimation temperature of the sublimation dye; a transfer adhesive layer including a hot-melt thermoplastic synthetic resin and disposed on a surface of the intermediate layer; and a sheet of release paper disposed on a surface of the transfer adhesive layer. The intermediate layer is formed and closely fixed on the rear surface of the label cloth by laminating or coating. The transfer adhesive layer is also formed by laminating or coating. Desired colors, patterns and / or figures are transferable from transfer paper printed with a sublimation dye onto a surface of the cloth material for marking that has a transfer adhesive layer on its rear surface.

Owner:HOULAISHA

Clothes tailoring scriber

The invention provides a clothes tailoring scriber. A cloth supporting plate is fixedly connected to the upper surface of a pedestal; a projected loop is formed in the outer wall of the cloth supporting plate; a guide rail groove is fixedly connected to the left and right side walls of the pedestal in respective; the bottom end of a sleeve is movably disposed in each guide rail slot; the lower end of a telescopic rod is inserted into each sleeve; a top rack is fixedly connected to the top ends of the telescopic rods; a chute is formed in the top end of the top rack; an installation seat assembly is arranged over the top rack; a T-shaped guiding sliding head is disposed in the chute; a guide rod is fixedly connected to the top of a rotary column; a scribing pen is fixedly connected to a round ring; and the round ring sleeves the guide rod. A piece of cloth is fixed on the cloth supporting plate, so wrinkles during the scribing can be avoided and the scribing work can be quickly and conveniently conducted; and straight lines and curves can be accurately drawn, so clothes scribing accuracy can be guaranteed.

Owner:苏州翼腾制衣有限公司

Process of marking a textile substrate

InactiveCN105308236AAuthentication methods are sensitiveResistance to degradationMarking textilesPattern printingMetal chelateEngineering

The invention relates to the marking of textile products that have been dyed using a supercritical dyeing process. More particularly, the invention provides a process of marking a textile substrate with a tracer, said process comprising contacting the textile substrate with a supercritical or near-critical dyeing medium containing a dye and a tracer, said tracer being selected from a metal chelate and a chemiluminescent agent. The process of the present invention uses the supercritical or near-critical dyeing medium as a vehicle for depositing a tracer onto the textile substrate that is also dyed using this medium. The presence of the deposited tracer on the dyed textile can be detected using a simple and reliable authentication method. The invention also concerns a marked textile product obtained by the aforementioned process. Also provided are a dyeing composition that can be used in the aforementioned process as well as methods for authenticating textile products that have been marked using his process.

Owner:FEYECON DEV & IMPLEMENTATION

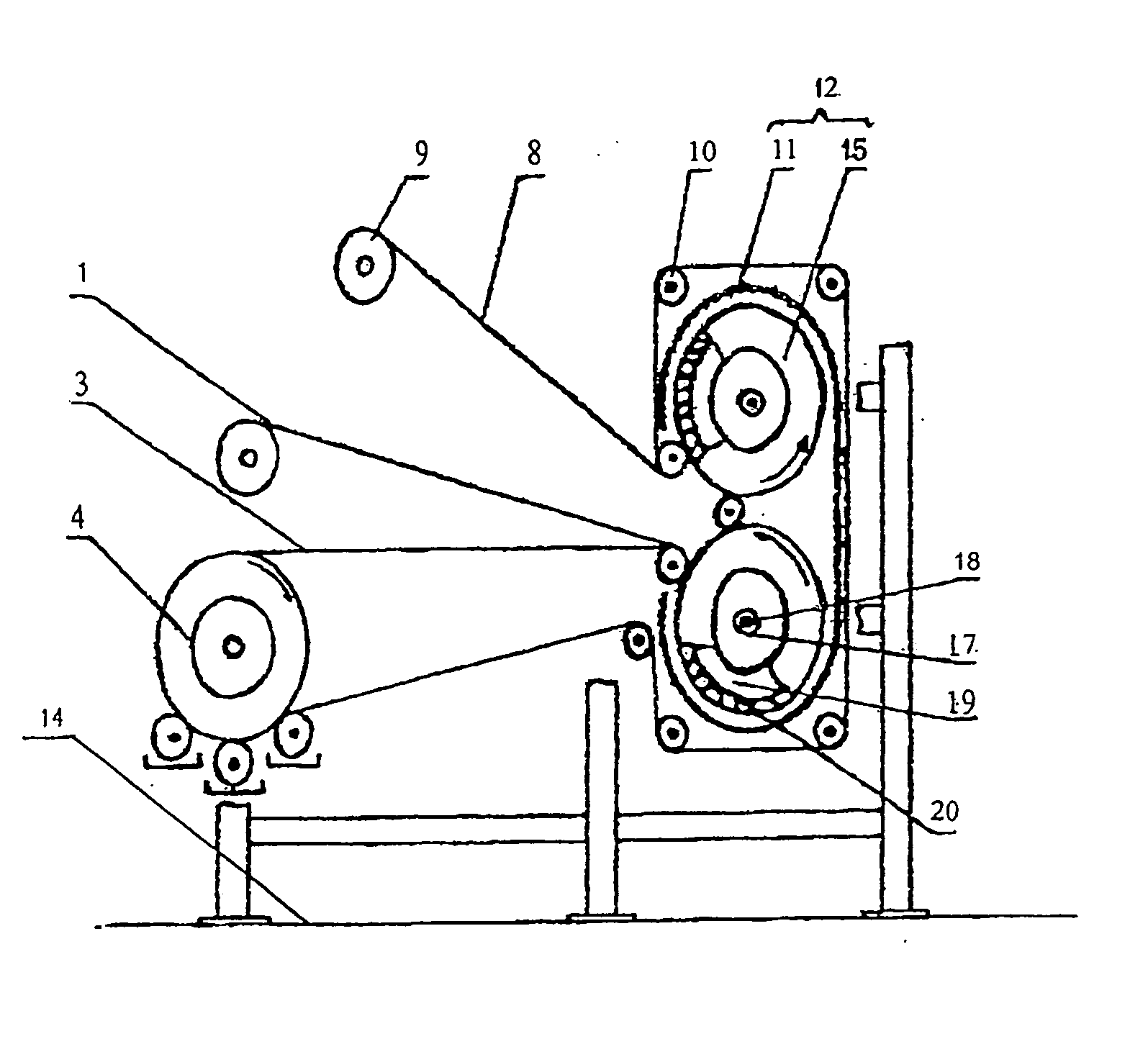

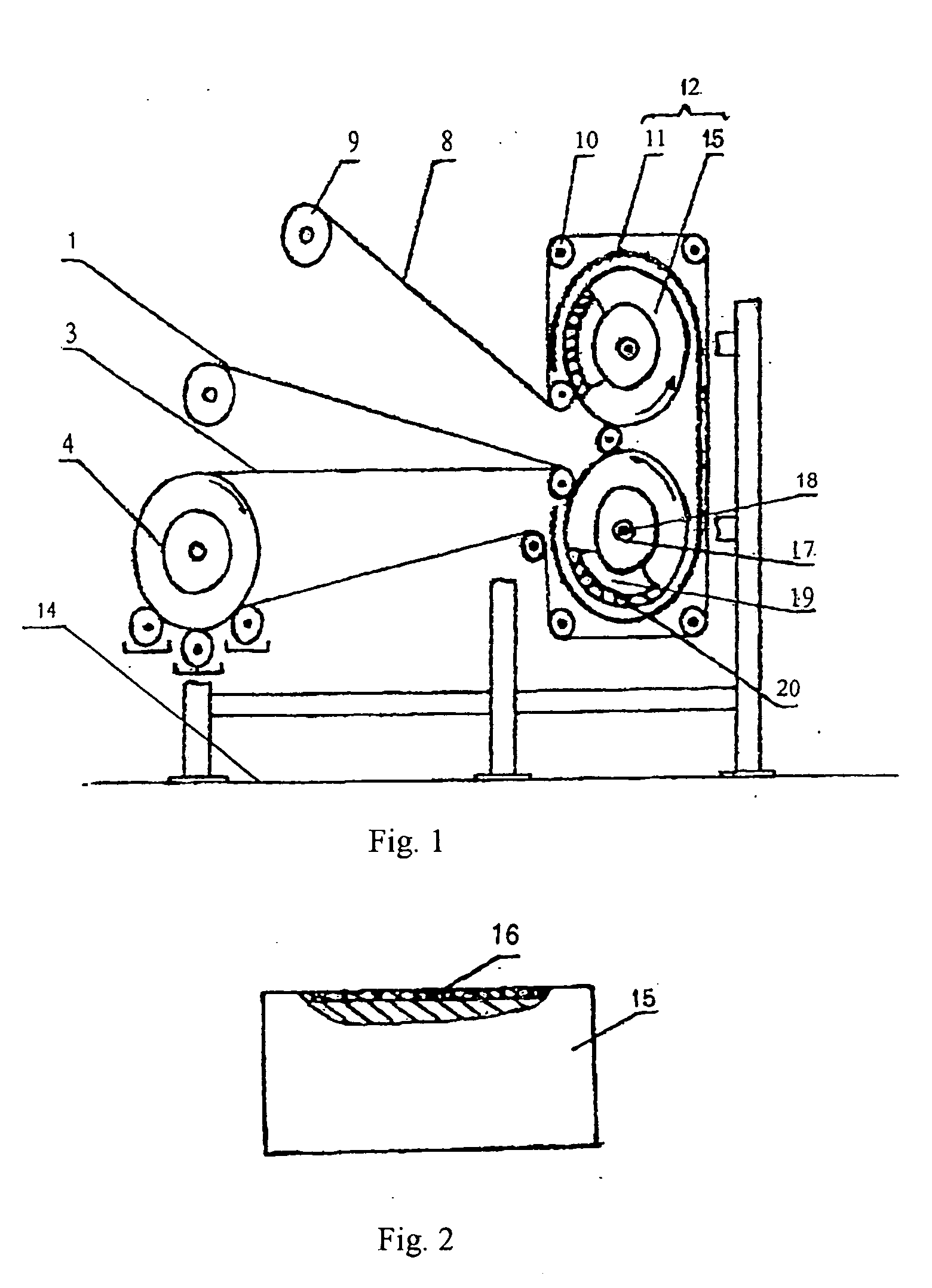

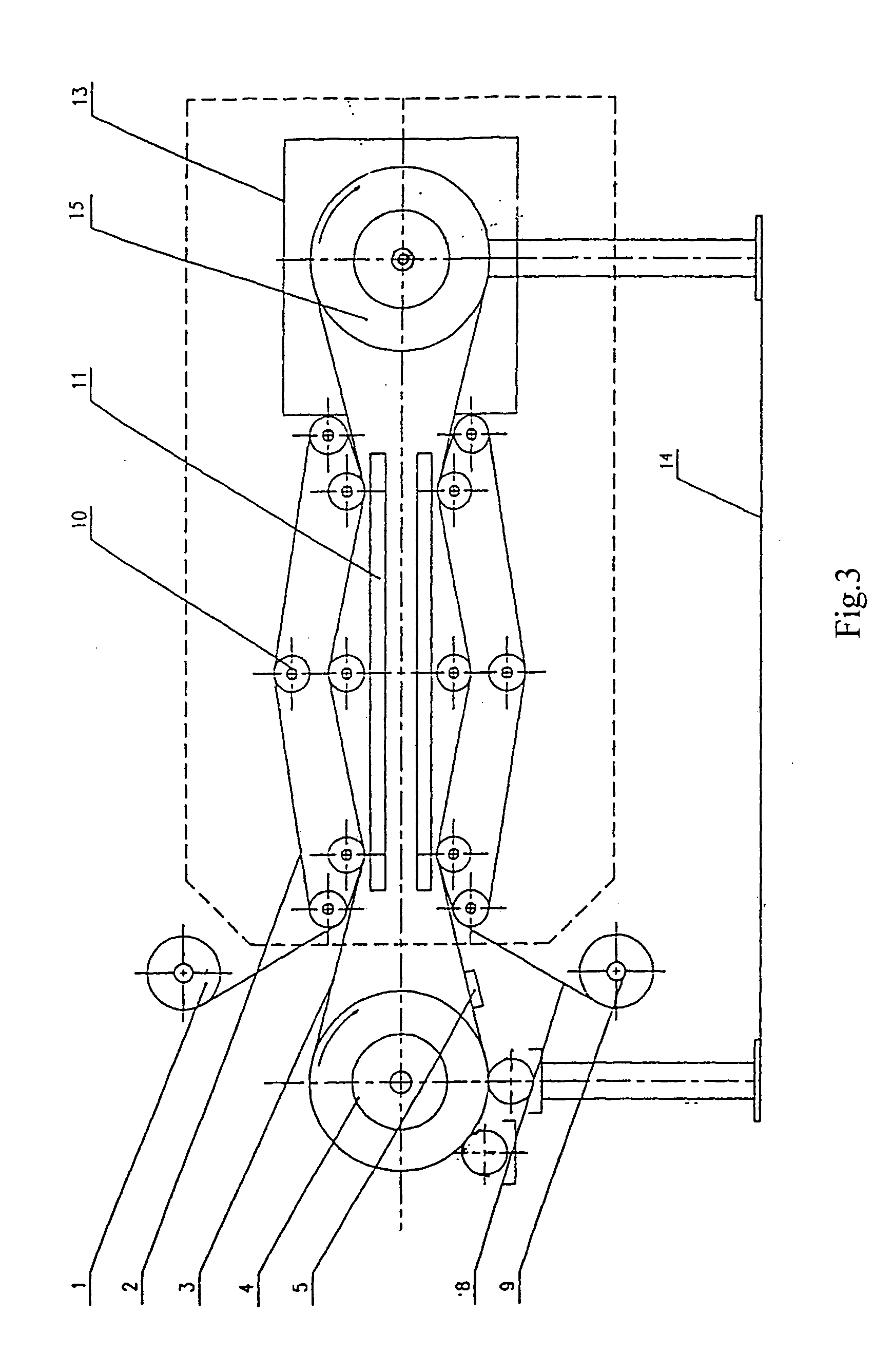

Apparatus for paperless transfer printing and the process thereof

InactiveUS20050139096A1Strong absorption capabilityReduce tensionRecording apparatusTransfer printingMetal foilClose contact

The present invention is related to an apparatus for paperless transfer printing, which includes a printer and a heat transfer printing machine, the printer is connected and assembled with the heat transfer printing machine by an endless metal foil belt, the heat transfer printing machine includes at least a heating transfer printing roller, or a weight bearing crawler belt, or a weight bearing plate the heating transfer printing roller can absorb the belt of metal foil by negative pressure of vacuum or by magnetic means, which result in the close fitting of the belt to the surface of the heating transfer printing roller. The paperless heating transfer printing apparatus also includes a heating device to heat the belt of the metal foil. A set process of printing is also proposed in this invention, which used said apparatus. By using this kind of apparatus and the process, the problem, that the metal foil easier wrinkles than paper does is overcome, and the substrate can close contact with the surface of the roller, the heat can be transferred more uniformly. The patterns the apparatus made are lucidity and less color difference or un-sharpness, the pulling force acting on the foil is also reduced.

Owner:XIANGYANG LU +1

Transponder with tamper protection

InactiveUS9058554B2Easily and reliably attached to itemAvoid easy removalStampsMarking textilesEngineeringRadio frequency

The invention relates to sewable tamper detection elements for radio frequency identification devices, and to radio frequency identification devices with such tamper detection elements. The devices can be sewn into a seam of a garment so that the tamper detection element is partially inside the garment, e.g. as part of a care label. This makes removing the device difficult without breaking the tamper detection element, and thereby shoplifting attempts can be more reliably noticed. For this purpose, the tamper detection element is formed so that sewing through it does not break the element. The radio frequency identification device may be formed asymmetric so that the tamper detection element is on a different side from the antenna elements with respect to the chip. In this manner, the disturbance from the tamper detection element to the antenna can be minimized. The tamper detection element may be formed so that it contains a transparent opening on which text can be printed.

Owner:SMARTRAC INVESTMENT BV

Method for producing airbags

InactiveUS20040200540A1Correct deviationPlace stableMarking textilesLayered productsMarking outAirbag deployment

The invention relates to a method for producing woven airbags, especially at least partially multi-layered airbags. Said method comprises the following steps: a) the warp threads are prepared in the warping room, warp threads which are suitable as marker threads for machine-readable markings being already placed in the warp; b) the airbag material is woven, weft threads which are suitable as marker threads for machine-readable markings being interlaced over at least part of the width of the cloth; and c) the airbag is cut out of the airbag material using a cutting device which is guided by the interlaced machine-readable markings.

Owner:GLOBAL SAFETY TEXTILES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com