Textile label and method for production therof

A label and fabric technology, applied in the field of clothing with such labels, can solve the problems of increased manufacturing costs, damage to the configuration of the transponder, and inconspicuousness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

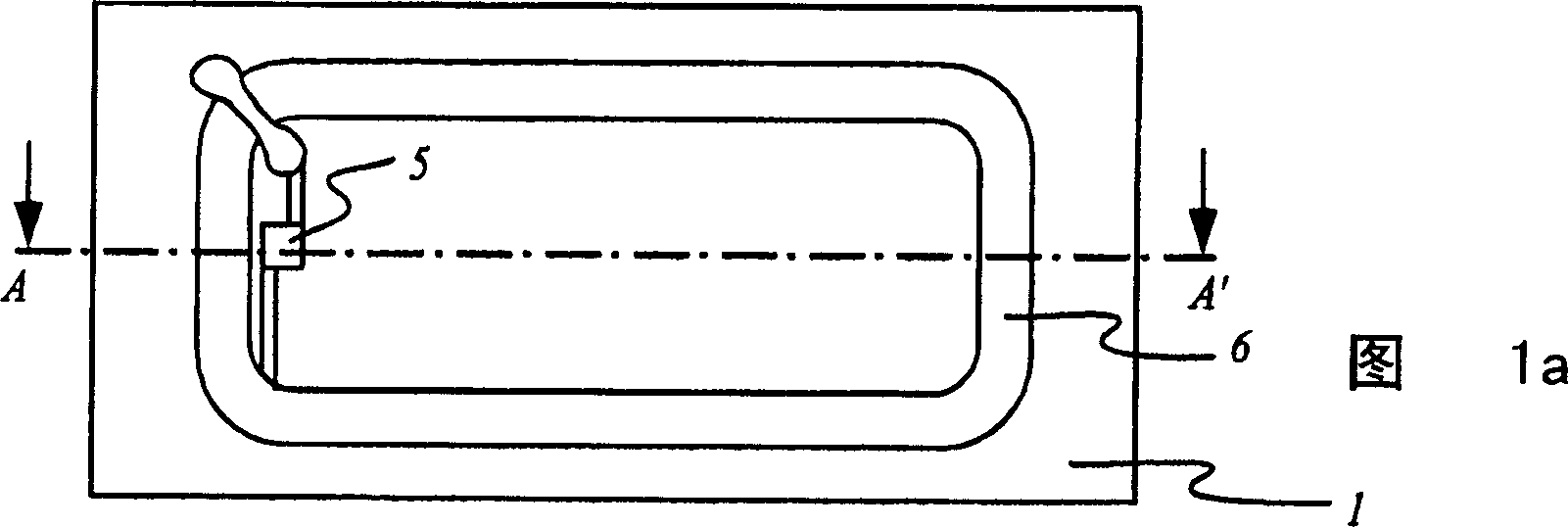

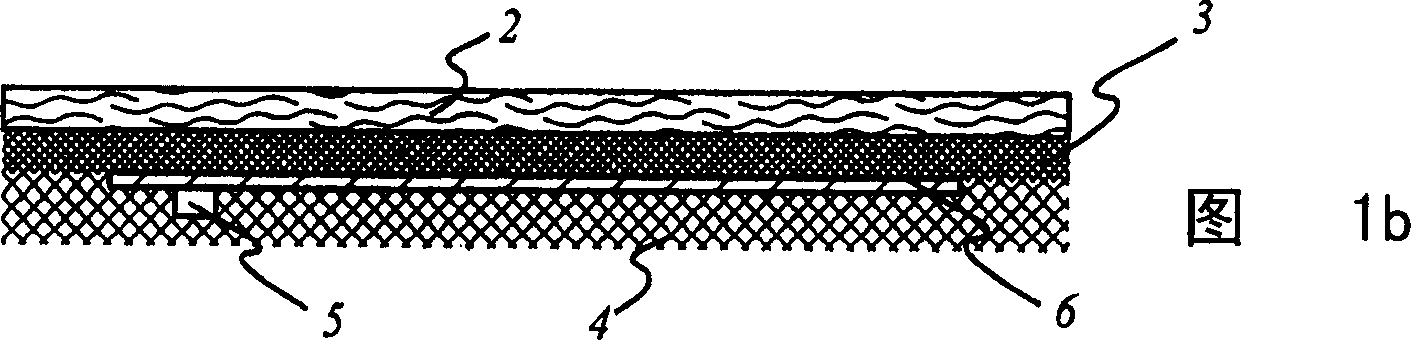

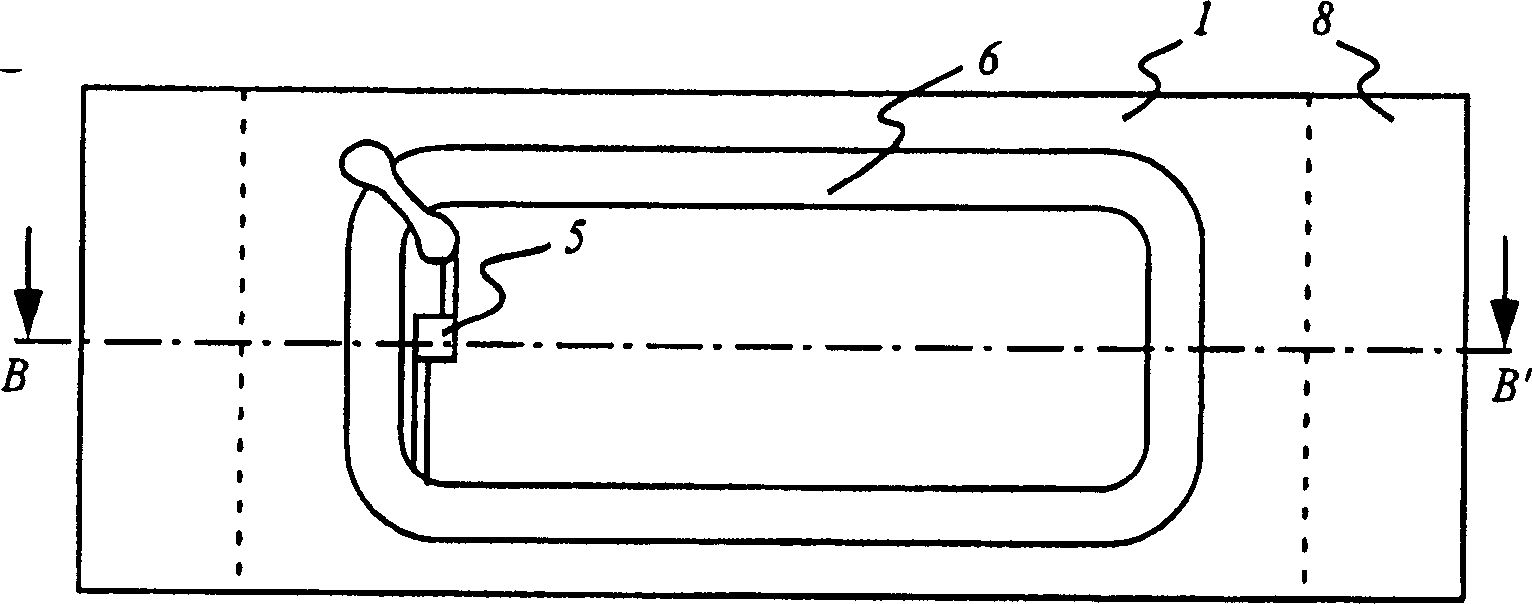

[0023] The fabric label 1 shown in Figures 1a and 1b actually consists of a printable fabric base layer 2, two adhesive layers 3, 4, and an interrogator configuration with a chip 5 and an antenna 6, the antenna 6 and The chip 5 is bonded to the fabric base layer 2 by means of a first adhesive layer 3, which preferably consists of a polyester adhesive. In addition to using the chip 5 in direct contact, it is also possible to use a chip The module is connected to the antenna 6 by metal bonding. The advantage of the polyester adhesive is that it can provide sufficient waterproofness, and sufficient resistance to soapy water and chemical cleaning agents. It is very difficult to break and has high resistance Thermal and excellent sealing properties, even under adverse environmental conditions. In addition, the material properties of the elastic polyester adhesive contribute to the elasticity of the adhesive layer 3. In view of the anti-etching properties of the polyester adhesive, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com